How to determine reverse draft in a chimney?

Diagram of normal draft in a chimney

You can detect reverse draft with the naked eye.

If the stove smokes when lighting, then this effect occurs. In theory, smoke should rise upward, since it has a lower density relative to cold air. If the stove smokes into the room, it means that something in these processes has broken down and does not allow the smoke to comfortably leave the stove space. There are several reasons that, to one degree or another, affect the release of smoke into the chimney. It’s worth talking to us in more detail.

Checking the draft quality in the chimney pipe

To determine further measures to eliminate smoke from the stove, it is necessary to check the quality of draft in the smoke exhaust system. Verification is carried out in one of the following ways:

- Using an anemometer. High-precision professional device for determining smoke draft.

- Ignition of flammable material. The burning material is brought to the chimney grate - with good draft, the flame is directed upward, with poor draft or its absence, it remains motionless.

- Visual check. If, when lighting the stove, the flame acquires a dark red tint, this indicates a decrease in draft. Good draft provides a light, almost white flame.

- Presence of a strong smell of smoke. If strong odors appear when the firebox is open, this indicates a mechanical blockage of the chimney system.

The full list of reasons why a heating stove starts to smoke is quite long. In each individual situation, it is necessary to take into account: the nature (temporary or permanent) and duration of smoke, indoor temperature, weather conditions, design features and equipment service life.

Rollover traction

This process can occur after a long period of absence of heating in the stove. Simply put, it hasn’t been drowned for a long time. The chimney and stove cool down to a temperature comparable to the street temperature. As a result, warm air cannot leave the chimney, since there is no heat-conducting flow. To eliminate rollover, there are several proven folk methods. All of them are aimed at increasing the temperature in the chimney area. Here are a few of the most obvious ones:

- Every stove contains a door for cleaning the chimney. It is worth trying to heat the air here by setting fire to paper or any readily available fast-burning material;

- the previous point can be repeated for a hog in the attic. That is, open it and warm the air in this area;

- Well, the most emergency way is to throw burning materials inside the pipe. This method is worth using if others have not helped.

Main causes of smoke

If the stove smokes into the house, and not out into the street through a pipe, then this is a good reason to look for breakdowns in the heating system and to carry out timely repair work. There are a huge number of reasons, but eliminating them requires various efforts, tools, and knowledge.

Reduced traction

It happens that smoke starts inside the house the first time the system is started. And then the owners wonder why the new stove, installed in accordance with all the rules and recommendations, smokes. Usually the main reason in this case is the loss or weakening of draft, which plays an important role in the operation of the entire heating structure.

Bringing power above normal

In duct, bell-type and other brick stoves, there is a certain power level that should not be exceeded, overheating the system to excessive heat generation capacity.

When you try to boost the power of a brick system, smoke almost always begins in the room, since the structure cannot cope with the smoke escaping into the chimney.

Don't squeeze the maximum out of the stove

Insufficient air flow

For good combustion, fire needs oxygen - everyone knows this, but few people understand that for the proper functioning of the stove and its chimney, a sufficient amount of air is also required.

Even in severe frost, you should not tightly close all the doors and windows, but if you have forgotten about this and the stove is smoking into the house, then you can try to save the situation by opening the window or the entrance doors - perhaps the heating system has simply begun to “suffocate.”

Open the window

Rollover traction

A virtually uncontrollable process is the reverse draft of the heating system. It happens that even a new stove smokes if there is strong windy weather outside. Do not panic if smoke begins to occur for this reason - usually the wind subsides quickly, and operation of the stove can continue as usual.

Structural violations

The most unpleasant reason for the stove to smoke into the house may be improper installation, installation or construction. If there are violations in the design, the stove usually does not heat well, often smokes small doses of toxic air, and over time begins to emit large clouds of smoke.

If it turns out that the cause was an incorrectly installed structure, then the heating system will have to be redone, often completely.

In some cases, you can get by with partial relocation, usually with the following structural damage:

- Brick splitting in the firebox

- Small crack in chimney

- Disabling the blower,

- Collapse of solution inside the firebox.

If destruction has begun in the structure, then it is better to completely rebuild it, since partial repairs may not help, and the system will continue to collapse in the future.

Furnace wear

Incorrect operation of the heating system may result from wear and tear of the furnace, due to improper operation or frequent boosting of the furnace power. When the structure wears out, various damage occurs on it, from which smoke often pours out.

It should be understood that too large cracks or breaks can lead to a fire, so if they are detected, repair work must be carried out immediately.

Large cracks

Soot in the chimney

The most common reason for the malfunction of the chimney and the emission of toxic smoke into the room is poor draft due to a pipeline clogged with soot.

Soot

If such a problem occurs, it is very important to promptly clean the chimney from the accumulation of soot; this is done using various devices: a hammer, a brush with a weight or other tools. For preventative purposes, once a week it is necessary to heat the stove with aspen logs, which, when burned, can release soot along with smoke through the chimney to the street.

For preventive purposes, once a week it is necessary to heat the stove with aspen logs, which, when burned, can release soot along with smoke through the chimney into the street.

Preventing blockages in the chimney

Wind influence

Air currents generated by the wind penetrate the chimney at high speed, bending around its edge and causing turbulence. If the force of this flow turns out to be greater than the force of the smoke exit, the latter has no choice but to return back to the room. In other words, if the wind is very strong, the likelihood of smoke will be greater.

The effect of wind on draft can be eliminated using a special windproof cap, which should be mounted on the main chimney. It will separate the air flows so that they do not cause turbulence and do not penetrate inside the chimneys.

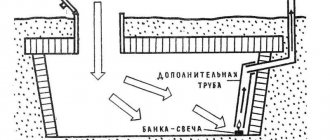

Backdraft - why it appears and how to eliminate it

It is recommended to install the boiler in such a way that the vent and smoker are located on one side. Failure to comply with the rule in a small building is infrequent, but there may be no consequences. In a high-rise building in windy weather, this can cause a pressure difference. Violation of the norm in this case leads to the appearance of reverse thrust. Often a previously unsmoked boiler lets out clouds of smoke into the room at the moment of lighting after it has completely cooled down. For normal exhaust gas removal, it is necessary that the boiler room be warmer than outside. Violation of this rule leads to a natural result - the draft will not be restored until the heating equipment warms up.

You can restore normal air circulation using a simple technique - light the paper, after placing it closer to the chimney. In this case, the ash pan is left open and the firebox door is tightly closed. Attempts are repeated until smoke appears from the chimney, indicating the restoration of normal draft. After such a signal, you can safely start the heating boiler without fear that it will start to smoke.

Subscribe to our Social networks

Violation of kiln masonry technology

Violation of stove laying technology

If a new stove smokes, most likely during its laying some technological regulations and standards were violated. Perhaps the chimney openings were too narrow or the design of the furnace wells was damaged. Unfortunately, it is not possible to get rid of this with your own hands. The oven will have to be rebuilt.

When something is wrong with the stove

If, instead of warmth and pleasant emotions, the stove for some reason begins to smoke and cause discomfort, then something is wrong. It is quite obvious that this should not happen. Even if the room still breathes comfortably, it is just kindling, acrid smoke does not get inside in large quantities, and the appearance of the structure will certainly be spoiled by soot. An open window door won't help.

It doesn’t matter whether the stove in the bathhouse is smoking, the stove is smoking in the country, or the stove is smoking in the kitchen, whether it is iron or stone - it’s time to act and act decisively. If the stove in the bathhouse smokes, for example, all the clients will run away. What kind of kindling and regular cleaning are there? This should not be allowed. Soot and sauna are also incompatible concepts. Even a small amount of smoke entering the room is an alarming signal.

To eliminate the problem, you need to know the reasons, figure out what is wrong here, why this is happening. If your business is at risk, it is certainly worth calling a specialist. When it comes to housing, the owner can handle a lot of things and it’s easy to deal with the problem on his own. Knowing the causes of smoke, it is easier to objectively evaluate all the pros and cons, either take the risk of doing the work yourself, or trust the professionals.

There are many reasons why a stove smokes. They all boil down to one thing - no traction. In some situations you need to rebuild the stove, in another you have to redo one element, and sometimes it’s enough to warm it up well and work will improve.

All stoves can be divided into new ones and those that have been in use for a long time. Service life matters, because the reasons for smoking here will be different. The new furnace probably has a defect. In the old and proven one, most likely, something has become unusable.

Wear

Over time, the materials from which the stove is constructed deteriorate. Constant temperature changes, soot accumulation, exposure to condensation and other physical processes that occur when smoke passes through all areas of the stove can affect the structure of the brick or the material from which the stove is made.

Violation of the integrity of the structure can cause the appearance of small microcracks and noticeable holes, which significantly impair overall traction. The combination of soot and condensation can cause carbon deposits to form on the inside of the chimney, thereby narrowing it. Which, in turn, also affects cravings. The chimney pipe, which can also be made of materials that deteriorate over time, is also subject to destruction.

To eliminate wear and tear, the furnace will need to be cleaned and reconstructed, the complexity of which depends on the complexity of the damage. In particular, it is necessary to eliminate the accumulation of soot, remove exfoliated masonry elements from the chimney, and get rid of depressurization by sealing cracks and holes with a solution.

If the damage is very serious and you cannot fix it yourself, there is only one option left - contact a specialist.

How to check a chimney

If there is smoke in the room from a potbelly stove, the check begins with this element:

- The presence of foreign objects is checked. Often, normal functioning is hampered by the simple presence of objects blocking the chimney.

There are special soot cleaners

We also recommend studying this topic:

Construction of a brick smokehouse: design and construction diagrams

Having decided to set up a corner in your dacha where you can prepare aromatic food, you do not have to purchase small smokehouses presented in specialized stores. You can build a smokehouse with your own hands from brick - a reliable structure that can also become a garden decoration. Drawings and simple step-by-step instructions for performing the work will help you create a model yourself.

- The presence of soot on the chimney walls is determined. The formation of this substance has an extremely negative effect on traction force. The reason may be improper chimney construction or irregular cleaning.

The appearance of soot after long-term operation without cleaning or the use of low-quality fuel may be the answer to the question of why a potbelly stove smokes at the door.

If, while searching for the reason why a potbelly stove smokes when the door is opened, it was found that the problem is not contamination, then the problem is a faulty design.

You can make and install a chimney yourself. For a potbelly stove, a metal option is more suitable than a brick one. For these purposes, the most suitable would be alloy steel with a special coating that protects the surface from the effects of oxides. Just don't use aluminum pipe - it will melt.

We also recommend studying this topic:

Construction of a furnace with high efficiency: saving on heating

What types of stoves are best for space heating? How to build a furnace with the highest coefficient of performance (efficiency)? Is it possible to increase the efficiency of an existing furnace? The answers to all these questions can be found in this article.

During production you will need the following elements:

- Metal pipes for the base of the chimney. A diameter of 16 cm is suitable.

- Elbows for joining. Their number will depend on how many times the direction of the pipe will be turned.

- Protective cap for the upper part of the chimney.

- Pocket for condensation.

- Sealant for fastening seams.

- Clamp for fastening the pipe.

- Thermal insulation.

Drawing for making a chimney for a potbelly stove through the wall

Once all the materials are ready, you can begin installation:

- First of all, a through hole is made in the wall. Moreover, if the wall is wooden, a special metal box is installed with a hole in the center, which is 5 mm larger than the diameter of the pipe. For a brick wall, a pass-through glass is used.

The box is filled with basalt glass wool, and the hole is filled with asbestos strips.

- Next, the first section of pipe is placed on the nozzle of the potbelly stove. In this case, the design is complemented by a heat-resistant seal and a special clamp that will prevent gas breakthrough.

- An elbow is installed that takes the pipe towards the wall.

- After the pipe is brought out, a pipe and elbow are installed.

Example of an external chimney pipe

- The outer chimney pipe is insulated. To provide stability, you can secure the structure with brackets.

- A protective cap is placed on the top of the pipe.

Having figured out how to install a chimney through a wall, you can also pay attention to the options for a chimney through a window for a potbelly stove and through the roof.

We also recommend studying this topic:

Water heating from a stove: device features

City dwellers are accustomed to central heating, but there is another type - water heating from a stove, and you can do it yourself with a little technical experience. Not to mention remote areas, in houses without a central system, even in winter it is necessary not to freeze. A conventional stove is not able to heat all living and other rooms in houses. And installing several ovens at the same time is quite expensive.

Thus, having studied all the necessary instructions, you can take a number of actions to clean the finished pipe or create a new one. Such measures will help get rid of the smoke from the potbelly stove.

Errors in laying a well

This reason can perhaps be attributed to violations of the furnace laying technology. It differs from ordinary smoke in that it is characterized by the appearance of smoke precisely when the door is open. This can be explained by the incorrect design of wells, in which traction flows disrupt their natural course. That is, when the door is closed, the draft is enough to bring smoke out, but when it is opened, its force decreases, allowing the stove to smoke into the house.

This problem should be resolved by a specialist. Because, most likely, you will have to rearrange the wells so that the level of the first is higher than the opening of the fire door.

Smoke when lighting

The stove smokes when lit in the cold season. This problem often occurs with ovens that are not used regularly. For example, the unit is located in a bathhouse or country house. A column of cold air forms a plug in the chimney that blocks the draft. Stove makers advise getting rid of it in the following ways:

- bring a burning torch to the smoke collector,

- burn a piece of paper directly next to the smoke collector.

These techniques allow the plug to warm up, rise and come out. The problem of cold plug occurs not only with brick, but also with metal stoves that are installed in bathhouses and saunas (heaters). If the house is 2-story, you should know that the plug often collects in the horizontal part of the chimney, if it is on the 2nd floor. According to masonry technology, the length of this section (box) should not be more than 2 m.

How to increase draft in a chimney?

Anemometer

To improve draft in the chimney and prevent smoke, you need to somehow monitor its improvement or deterioration. That is, measure the level of traction. For this there is a special device called an anemometer. But it’s unlikely that anyone will bother and purchase this device specifically for these needs. In addition, there are traditional methods for determining traction force. The simplest way that suggests itself is to set fire to a piece of paper, a cigarette or a lighter, and bring it to the oven door. If the flame deviates towards the opening, then there is draft. Focusing on the force of deflection, you can determine how strong the thrust is. Now, with this simple method in hand, you can begin to optimize traction.

Reasons for lack of draft in the furnace

As mentioned above, there may be no draft in a Russian stove for various reasons. It is very important to understand correctly when the phenomenon of insufficient draft arose: during the first tests of the heating structure, or during its operation, despite the fact that previously the stove was heated quite normally..

No draft when testing a new stove

Before testing a newly built stove, it must be dried. In a damp structure, not only may there be no traction, but the mortar can also crack, and sometimes even the brickwork itself can become deformed and crack.

Newly built classic Russian stove. After a good drying, you can proceed to testing.

The clay mass used as a solution must be dried at natural temperatures, without sudden jumps upward or, conversely, downward.

Drying the oven under natural conditions takes 5-7 days, while all doors and valves must be open. At this first stage of drying, it is possible to speed up the process with the help of a powerful incandescent lamp, for example, 200 W, placed in the combustion chamber. It must be kept on while the oven is drying. The lamp will not produce intense heat; it will slightly heat the walls and create an upward flow of warm air.

Another acceptable option to speed up the process of moisture evaporation is to install a fan heater or infrared heater directed into the open door of the combustion chamber.

Next, begin drying with light heating. This stage lasts 7–14 days, depending on the volume of the furnace structure.

For these purposes, the stove is heated three to four times a day, with an approximate duration of one and a half hours. In this case, paper, thin wood chips or brushwood can be used, in a volume of two to three kilograms per bookmark. This fuel will not produce much heat, but will speed up the drying of the masonry.

Instead of wood chips and brushwood, you can use several (5÷6 pieces) well-dried small logs.

If, during the second stage of drying with heating, smoke enters the room, this may be caused by several reasons:

- Violation of the construction scheme of the chimney or its channels. For example, if the length of horizontal channels is greater than the permissible dimensions of 1500÷2000 mm. Another incorrect option is when the gas channels are not wide enough for throughput. The smoke does not have time to go up the chimney, it has nowhere to go, and it begins to seep into the room. The other “side of the coin” is that when the channels are too wide, too much draft is created, so the efficiency of the stove is significantly reduced (and it is not particularly high for a Russian classic stove).

In order for the process to be balanced, the laying of the furnace must be carried out exclusively according to a drawing developed and tested in practice. In it, the channel parameters are calculated depending on the volume of the main hearth, as well as on the purpose of the stove and the presence of additional combustion chambers.

- Incorrectly equipped exit to the chimney well. The dimensions of this section of the furnace must exceed the cross-section of the gas channel or, in extreme cases, they must be the same. In addition, the upper edge of the exit to the well must be located above the upper edge of the combustion chamber door. Otherwise, when this door is opened, smoke will enter the room.

When laying a stove, if for some reason it is not possible to arrange the outlet hole higher, then an additional partition is built along the back wall of the stove, forming a channel that is connected to the exit to the chimney. This space will also become an obstacle to the entry of unburnt solid particles of wood combustion products into the chimney.

- If the chimney is lined with a metal pipe, its diameter must be the same throughout. Thus, a large amount of soot deposits will not accumulate at the pipe joints, which can also interfere with the creation of normal draft.

- The blower hole, located in the lower part of the furnace under the firebox or under the hearth, must have certain parameters, which are determined by the size of the combustion chambers. Otherwise, the air flow will not be enough to create normal draft.

- There is no protective cap installed on the head of the chimney to prevent moisture from precipitation, as well as dust and other debris from entering the chimney opening. This factor can also cause reverse thrust.

- When constructing the furnace, the masonry joints between bricks or around metal elements were not sufficiently sealed. That is, air from outside penetrates into the combustion chamber, and the smoke has the opportunity to find a way out other than the chimney pipe.

The height of the chimney above the roof surface and relative to its ridge.

- The chimney pipe is not of sufficient height relative to the roof ridge. In this regard, turbulence may occur in the chimney, creating obstacles to the formation of normal draft. As you can see in the diagram above, the height of the chimney depends on the distance (in horizontal projection) between the ridge and the location of the pipe:

— when the pipe is removed from the ridge up to 1500 mm, the pipe must rise above the level of the ridge by at least 500 mm.

- if the pipe is removed from the ridge at a distance of 1500 to 3000 mm, then the height is allowed to coincide with the line of the ridge;

— if the distance between the ridge and the pipe is over 3000 mm, the head of the pipe must be located no lower than a conventional line drawn through the point of the ridge at an angle of 10° to the horizontal.

- Improper ventilation of the room or even its absence can also lead to reverse draft. If it is impossible to create a normal supply ventilation system, then it is necessary to create an air flow during the fire by opening vents or doors. But there can also be negative nuances here. Thus, a violation of normal traction may occur in the following cases:

- the windows in the room are open, which are located much higher than the fire door;

- when there are strong drafts in the room, which also disrupt the normal movement of flue gases through the chimney channels;

- if there is a strong wind outside.

- If a Russian stove has several sections, that is, its design contains several combustion chambers. The partition separating them may not be built correctly, or the cross-section of the chimney may be insufficient, so it has low throughput - these two factors also contribute to a decrease in draft.

The simplest way to check for draft is to hold a lit match or paper to the slightly open firebox door.

To prevent the room from becoming smoky when testing the stove, the draft can be checked without lighting wood in the firebox. It is enough to bring a burning sheet of paper or a match to the open door and follow the direction of the flame. If the flame is directed towards the firebox, then there is draft, but if it is towards the room, then it is necessary to look for the reason for its absence.

Lack of draft in an old furnace

If the draft has disappeared in a previously well-functioning Russian stove, then the reasons for this phenomenon may differ significantly from those listed above.

The appearance of reverse draft in a long-running Russian stove - smoke begins to pour into the room.

So, if the stove was working normally, but one day, when lighting it, it was discovered that smoke was about to enter the room, then the following problems may be the cause.

- During the period of operation, the chimney depressurized, that is, cracks formed in the masonry under the influence of atmospheric factors and temperature changes. It is precisely such damage that can weaken the draft in a furnace that was put into operation a long time ago.

A fire in the rafter system can occur due to damage to the walls of the chimney pipe.

In this case, there is another serious danger - sparks and particles of burning soot that can penetrate through the holes formed in the walls of the chimney. When scattered, sparks can land on flammable materials both on the roof of the house and on neighboring buildings, which can lead to a fire.

Mechanical chimney cleaning by a professional chimney sweep.

- Narrowing of the internal space of the chimney due to blockages caused by soot deposits. In this case, the problem can be solved only by cleaning the internal surfaces of the chimney pipe, as well as the channels and combustion chamber.

Even if preventive cleaning of the smoke exhaust system is carried out even during operation, then, as a rule, the easily accessible straight sections of the structure are affected first. However, the accumulation of soot deposits occurs at turns or bends in the ducts, where the smoke changes its direction.

Due to an insufficiently well-cleaned chimney, the draft will certainly decrease. If it is not possible to clean the chimney yourself, then you should invite an experienced specialist to do this work.

If you decide to clean it yourself, then the following methods are used for this purpose:

— Starch or dried potato peelings, which are burned in the combustion chamber. They are able to partially clean the pipe; they are also used for preventive purposes.

— The vertical sections of the smoke exhaust system are cleaned with a special brush, to which a heavy object is tied, capable of pulling a light-weight brush. It will collect soot deposits from the walls, some of which will fall into the horizontal channels or firebox.

— The crumbled soot is removed from the horizontal channels through cleaning windows or holes blocked with bricks, which are temporarily removed.

— You can also clean the chimney using well-dried aspen firewood, which has a low resin content, which causes soot formation. This method has long been used by stove owners. When burning aspen wood, the ashpit must be completely open so that the smoke can freely escape into the chimney, even if there is a blockage.

A special chemical for cleaning the internal surfaces of the furnace from soot deposits.

— Today you can find special powders for removing soot deposits on sale. They are designed to be burned in a firebox along with firewood. After such a filling burns out, the chimney remains clean; all that remains is to clean the firebox from ash.

When using cleaning methods using aspen firewood or starch, you must follow safety rules, since the soot will begin to burn directly in the pipe. The draft becomes more intense when the space is freed from soot, while the pipe becomes very hot and sparks begin to burst out. Therefore, most often such methods are used in cases where the thickness of the plaque on the walls is about 3 mm. If the chimney is thoroughly clogged with soot, then you should first use a mechanical cleaning method, and then burn one of the above-mentioned substances in the firebox.

- Long pause in furnace operation. If the stove is not used in the summer, moisture may accumulate inside the channels, which, evaporating, forms air pockets (dense layers of air) in the internal space of the pipe. They prevent the free exit of flue gases outside. However, this problem should resolve itself after a few “sessions” of the firebox. Therefore, it is necessary to prepare the stove for the heating season in advance, before the cold sets in, and the room can be ventilated without compromising comfort. To avoid such problems, it is best, for preventive purposes, to choose cool days in the summer and heat the stove with two to three kilograms of firewood.

- Violation of the tightness of the masonry of the furnace itself. This can happen when a poorly prepared foundation is deformed, due to too wide joints in the masonry, incorrectly selected ingredients or the consistency of the solution. All these factors can lead to cracks that reduce traction. In addition, carbon monoxide gases through the resulting gaps can penetrate into the room or under the roof, which is extremely dangerous, since there is the possibility of a fire. Carbon monoxide itself is extremely dangerous to human health and life - it causes extensive toxic damage to the body.

Ways to increase draft in a Russian stove

When preventive measures to clean the channels and chimney of soot deposits and inspections for structural integrity are carried out, you can use some methods to optimize draft. However, this should only be done if after cleaning the traction remains weak. You can increase traction without resorting to the help of specialists or complex electrical-dependent devices, and also with the use of the latter.

A weather vane deflector installed on the pipe will help normalize the draft in the furnace. He always turns the mouth of the pipe so that the wind does not interfere with the free exit of smoke.

- Deflector or weather vane. This device is a modified version of the cap, which was previously used for installation on chimneys. The deflector rationally uses the wind to create an exhaust draft for the furnace.

Turbo deflector or ventilation turbine for removing combustion products from the furnace.

- During its operation, the ventilation turbine uses the energy of wind flows, creating the necessary air pressure in the chimney shaft. Thanks to this, the draft increases, which intensively removes combustion products, eliminating the effect of reverse draft. This device also protects the pipe mouth from precipitation and various debris.

The deflector is a draft regulator in the chimney.

- The draft regulator is another version of the deflector, which not only normalizes the intensity of removal of combustion products, but also serves as protection for the chimney from water and debris. At the bottom of this umbrella-like device there is an area of free space for the passage of air flow. There are models of regulators equipped with special sensors that can not only increase traction, but also regulate its intensity. For example, if the draft of a Russian stove is poor, the escaping gases, acting on the heat sensor, will help to strengthen it and accordingly increase the efficiency of the stove. When the combustion weakens, the sensor will reduce the draft intensity.

Heat-resistant chimney fan.

- Electric smoke fan. Installing this device on a chimney, of course, will cost much more. However, it will absolutely provide normal traction, regardless of weather and atmospheric pressure. The device will draw out almost all combustion products, so clogging the chimney is unlikely. Such fans have quite high power. Therefore, some models are installed in complex structures of multi-level chimneys and ventilation systems of multi-story buildings.

Furnace elements and the need for their regular maintenance

In order for the furnace to function normally and the draft to always be optimal, you need to know how to properly carry out preventive maintenance. Therefore, this section will detail the areas of the oven that should be monitored and cleaned regularly.

Layout of oven sections that need to be cleaned regularly.

On the above diagram of a Russian stove, departments are numbered that require regular inspection and cleaning.

1 - Ash pan. This section of the stove is usually cleaned every time before the next start of adding firewood and firing the stove.

2 - Blower. This chamber is cleaned from fly ash periodically. The blower regulates the flow of air into the fuel chamber. It should be noted here that in most stove designs the ash pan is combined with the ash pan, and in this case, cleaning, of course, is done before each use of the stove.

3 - Blower door. When heating the stove, the ash door must be kept open, and while the fuel is burning, it must be left ajar. Thanks to this adjustment, a draft of the required intensity is created in the smoke exhaust system.

4 - Grate (grid). This structural element is cleaned before fuel is added to the fuel chamber.

5 - The fuel chamber must be inspected before each fuel addition. If carbon deposits appear on the walls of the firebox, it should be removed periodically.

6 — The throat of the fuel chamber (loading tunnel) must be free after loading fuel. Therefore, when the firebox is filled with firewood from the tunnel, you should remove all elements that prevent the door from closing tightly.

7 — The fuel chamber door opens only when loading fuel, as well as when carrying out maintenance work.

8 - The mouth of the firebox (higho) serves to divert combustion products into the smoke exhaust channels. This area is cleaned simultaneously with the combustion chamber.

9 - Vertical channels are also the heat-storing area of the furnace. This area can be maintained in good condition by periodically burning starch or chemical cleaning powder in the oven. However, major annual cleaning of this department, as well as the chimney pipes, is most often carried out by a chimney sweep.

10 - Front wall of the furnace (front). From the forehead, approximately 600 mm above the firebox door, it is determined by touch whether the operating mode (stroke) of the stove is sufficiently optimal.

11 - View. When the stove is heated and in operation, it opens completely. When the fuel burns out, it can be slightly covered to preserve the heat. The view closes only after the fuel has completely burned out, when the emission of carbon monoxide is guaranteed to stop.

12 - The damper is designed to adjust the draft in the chimney. This element, in combination with the blower door, ensures optimal operation of the furnace.

13 — The cleaning door is used to discharge the air in the chimney when starting a stove that has not been lit for a long time and has been standing in the cold, as well as for additional control over the draft force.

14 - The chimney shaft is the main channel that removes fuel combustion products. It is its integrity and regular cleaning that should be given special attention.

15 - The woodshed or chamber for drying firewood is not connected to any of the sections of the stove into which open fire or fuel combustion products enter. The space of the woodshed is well heated so that the firewood prepared for the next stacking gets rid of excess moisture accumulated during storage outside. In a Russian stove, this section is usually located in the lower part of the stove brow under the hearth.

The location of the wood burner (oven) in a Russian stove.

The presented design may differ slightly from the structure of a Russian stove, but the main draft control elements for all stoves are identical. A Russian stove may differ in the design of its heat-storing sections, since they represent a common space located between the arch of the main fuel chamber and the surface of the bed.

* * * * * * *

Now, knowing how the stove works and in which departments the problem of insufficient draft may arise, you can solve it using various cleaning methods. In order not to encounter a decrease in efficiency again, you should regularly inspect the furnace and take preventive measures. And spare no expense in calling an experienced specialist who will tell you what nuances of operating a particular model you should pay special attention to. Study the fireplace in the apartment using the link.

At the end of the publication, there is a video in which a specialist shares his conclusions about the causes of possible smoke in the stove:

Chimney pipe extension

Extending the chimney pipe

If the chimney pipe was initially too low, then perhaps this is what caused the poor draft. Its increase can significantly affect its growth. However, it should be remembered that a pipe that is too high will make maintenance and timely removal of soot difficult. In addition, there are more “gentle” ways to increase traction force.

Why does the stove smoke?

If the stove smokes, then this happens in general. reasons, in descending order of frequency of cases:

- Weakening or loss of draft is most often observed in bathhouse stoves due to the special conditions of their operation, see below.

- Boosting the furnace power (remelting). A brick kiln with a perfect design (channel, bell-type), if you try to force it beyond the limits specified by the kiln design, will smoke in a special way, see below.

- Insufficient air flow into the room with the stove. If a severe frost hits, a strong wind blows, the house is sealed up tightly to save heat, and the stove, which previously did not cause any complaints, begins to smoke, then the reason is most likely that it is simply suffocating without air.

- Overturning of the draft (reversal of draft, reverse draft) - for a running stove in the house occurs depending on changes in weather conditions in combination with changes in the environment.

- Defects in the design or operational wear of the stove: if it previously did not melt well, was slightly smoking, and now smokes heavily, the reason should be looked for here.

- Incorrect stove design, careless and/or unskilled execution, incorrect chimney design, untimely (too quick) commissioning of the stove are the main reasons why a new stove smokes. The same thing - suddenly the stove began to smoke after reconstruction, see below.

You can get general information about the possible reasons for the stove smoking from the video:

Video: basic reasons for stove smoking

- Is the stove installed correctly? Has anything changed in the environment? Is there enough air flow to the oven?

- If the stove is running, how long has it been left unheated? Is it not stagnant, i.e.? Didn't you survive the winter in an unheated room?

- What material is the stove made of - brick or metal?

- How often is the stove fired, with what fuel - coal, seasoned wood or random wood?

- What is the nature of the smoke: strong, weak, during kindling, systematic or random from a stove that is running (flamed up)?

- Was the furnace already in operation or is it new/renovated?

Rules and regulations

In most cases, the immediate cause of a smoking stove lies in the chimney. If it is not designed correctly, it will not be possible to get rid of smoke once and for all. And with a good chimney, even a poor stove can be adjusted so that it never smokes.

For the chimney, in turn, the most important thing is the elevation of the chimney above the surrounding objects. Furnace SNiPs give the minimum acceptable values for it. In areas of private development, taking into account growing trees, the construction of outbuildings, superstructures on neighboring houses, etc., it is advisable to slightly increase the elevation of the pipe mouth, see Fig. Quite a bit, but this will both greatly reduce the likelihood of the stove smoking and make it easier to find its cause if the stove does smoke.

Correct location of the chimney in a private residential building and heated outbuildings

Of course, you shouldn’t rush to build up the pipe right away. While the stove is in operation, it is only necessary to clean the pipe regularly (before the start of the heating season and at its end). Suddenly the stove starts smoking - we’ll try to cope with this without leaving the warm room and without climbing on the icy roof. And in the spring, when it’s warm, we’re really thinking about how to extend the pipe. It is possible to put a deflector on it, see below.

Application of technical means

To increase the traction force, you can resort to methods that do not involve changing the design of the chimneys. There are several types of different technical solutions that can be installed directly on the finished pipe.

One of them is the rotary turbine. Essentially, this is a fan that, due to the force of the wind, draws smoke from the chimney. True, it has a slight limitation on the temperature of the outlet stream. It should not exceed 200 degrees. Therefore, such solutions are used mainly to increase thrust in gas structures. A special tip that is able to turn the area where the smoke exits away from the wind can also help increase draft. Its operation is based on the operation of a conventional weather vane. In addition, its design is made in such a way as to avoid moisture getting inside the pipe.

The use of special electric smoke exhausters with an increase in draft force will be a good solution for private houses in windy areas. These devices are a fan that operates using electrical energy and physically “pulls” smoke out of the chimney.

Causes of smoke in new heating stoves

What to do if a newly installed stove smokes? Often the cause of smoke is structural inconsistencies, non-compliance with the technology of the masonry process, insufficient ventilation, and the absence of a distribution box.

Incorrect chimney height

The main reason for smoke in new stoves is a miscalculation of the height of the chimney pipe. Heating equipment for a Russian bathhouse and a private house must meet the following parameters:

- The size of the stove pipe opening depending on the type of fuel: 140×140 mm (coal) and 140×270 mm (peat briquettes, firewood).

- The height of the chimney above the roof is 75 cm, the elevation above the ridge is 50 cm. If the ridge is more than 1.5 meters away from the chimney, then the chimney can be of a similar height.

If the height of the chimney is not sufficient to prevent smoke, then you can increase it yourself.

Why does the stove smoke when the door is opened during the lighting process? A similar problem arises when there are serious design miscalculations: incorrect cross-section of the exhaust pipe, low location of the inlet channel, unswept chimney. To eliminate the shortcomings, a major overhaul of the heating equipment will be required.

Violation of stove and well construction technology

The required clearance of the chimney pipe ensures quick and safe removal of fuel combustion products. The minimum pipe diameter for a house is 15 cm, for a bathhouse – 10 cm. The height of the pipe and its installation location on the roof must correspond to the chosen design of the heating stove.

In addition, the inlet to the first well (in the combustion chamber) must be located no lower than the top of the door, otherwise this may lead to smoke every time the stove is lit. The shortcomings can only be corrected by rebuilding the furnace structure.

When assembling the chimney, you should avoid using elements of different sections, which can be the main cause of smoke in the stove. The best option is a round pipe. Rectangular smoke exhaust channels can create unnecessary air vortices and increase soot deposition.

Poor ventilation

Another reason why a new furnace starts to smoke is poor ventilation. As a rule, when installing a forced-type ventilation system, building owners provide exhaust hood only in functional rooms - a sanitary unit, a kitchen or a dressing room. However, a separate smoke channel must also be equipped in rooms where normal movement of air masses is required: in the steam room and washing room.

No distribution box

If there are two heating stoves installed in a building, for which a common smoke exhaust system is provided, then smoke occurs as a result of the absence of a distribution box.

To eliminate this problem, it is enough to make a distribution box with two separate channels or operate the furnaces alternately.

The distribution box is a special brick partition located inside the common chimney.

Possible reasons

Many people don’t understand why the stove smokes if it was working perfectly just a couple of days ago. It is worth remembering that smoke is in any case a deterioration or change in draft in the design of the furnace.

Note! Draft is a physical force that forces smoke gases to rise up the chimney.

With good draft, the fuel produced by the wood will burn completely, releasing maximum heat. If it’s bad, the stove will smoke, creating smoke in the room.

Therefore, at first it is important not to try to go on the Internet with queries: “the stove in the house is smoking, what should I do?”, but to find out the reason for the incorrect movement of flue gases in order to correct the problem correctly.

Weak traction

Over time, the stove, especially its chimney, becomes clogged with soot (a product of burning wood), which weakens the draft. As a result, the smoke that should go outside spreads throughout the room.

Important! The frequency of blockages is affected by the design of the chimney. The more turns, the more opportunities for soot from combustion products to settle.

Remelting

Those who heat the stove for 6 or even 10 hours without breaks are acting completely recklessly. Bricks and joints are destroyed under the influence of high temperatures. As a result, the structure is deformed and the thrust weakens.

Backdraft

Normally, when burning wood, the air moves “bottom-up” - from the room to the street. But then why does smoke from the stove come into the house? The fact is that if all the windows are closed or the ventilation is not working properly, then the air begins to move in the opposite direction, a phenomenon called “reverse draft” occurs.

This happens as follows:

- The combustion heating device draws in air from the room.

- A lack of oxygen gradually develops.

- Air begins to flow through the chimney.

- The stove goes out, filling the room with smoke.

Incorrect design

Mistakes by the stove maker during the construction of the structure lead to a weakening or change in draft. More often, masters make 3 types of miscalculations:

- Use of elements of different sections. As a result, air turbulence occurs in the oven.

- Underestimation of the location of the inlet to the well - smoke enters the room as soon as the door opens.

- Narrow chimney section. The diameter of the minimum chimney clearance for a house is 150 cm, for a bathhouse – 100 cm.

Do-it-yourself stove and chimney cleaning

Over time, a thick layer of soot settles on the inner walls of the furnace, and the masonry begins to crack under the influence of thermal loads. Taken together, all this can also cause smoke. To remove soot, you can try using aspen firewood. Their combustion is accompanied by a very high temperature, at which deposits in the chimney duct are loosened and carried out along with the smoke.

However, this method is more effective as a preventive measure: if ash and soot have settled for many years, then aspen firewood is unlikely to help. Various chemicals in the form of special tablets, briquettes or pellets are also not a panacea. The best way is mechanical cleaning. To do this, you will have to purchase tools - a core, a scraper and a brush on a flexible cable.

We suggest you familiarize yourself with Insulating a steam room in a bathhouse from the inside

Before starting work, be sure to open all dampers and close all doors. Having secured yourself on the roof, remove the head from the pipe and remove the soot at a distance where your hand can reach. Then place the brush in the chimney and, turning, gradually move it lower and lower. If you come across an obstacle that you cannot break through, use the cannonball.