From time immemorial, the stove-heater was the only source of heating and steam generation in the Russian bathhouse.

Previously, in order to obtain finely dispersed light steam, it was necessary to spend a lot of time and effort on lighting the stove and bringing the stones to maximum heat. With the advent of new improved units equipped with steam generators, the processes of obtaining and distributing heat in the bathhouse have become easier and faster. Within 15 minutes from the start of firing a modern stove with a heat exchanger, the room is filled with pleasant, weightless steam.

There are some differences in the designs of a heating device equipped with a steam generator and a conventional electric heater. In the first case, there is always an additional reservoir in which hot moist air is formed when water evaporates. The sides of the oven are equipped with special chambers that facilitate rapid heating of the unit and maintain the temperature at 650 degrees. This is the heat that is considered optimal for the formation of fine steam.

The operation of a furnace equipped with a heat exchanger is characterized by maintaining two modes: dry and wet. With the help of such a unit, people suffering from high blood pressure or cardiovascular diseases can create for themselves a fairly comfortable atmosphere that does not have a negative impact on their health.

Having decided to install a combined type stove, you should first of all take thermal insulation measures and arrange an air exchange system. Such actions will create the basis for the formation of sufficient humidity in the bath and uniform dispersion of steam throughout the room.

Zhara-Extra — 9,590 ₽

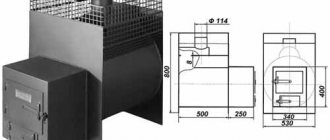

The Heat-extra 400 oven has compact dimensions and fits even in small steam rooms.

Made from 6 mm thick structural steel. The service life, subject to operation during the “dacha period”, is 8 years. In winter, the power of this model is enough to warm up a steam room with a volume of 4 m³ within an hour, and a 12 cubic meter room will warm up in 2-2.5 hours. Firewood of standard length – 370 mm – is used as fuel.

The cylindrical shape ensures efficient use of the firebox volume. Available with steel and cast iron doors. The differences are more decorative: the more expensive cast iron door has an ornament. Technical characteristics Heat - extra 400

| Characteristics | Meaning |

| Furnace power, kW | 6,8 |

| Steam room volume, m³ | 4-12 |

| Product weight, kg | 40 |

| Dimensions (WxDxH), mm | 415x660x605 |

| Weight of laid stones, kg | 60 |

| Maximum length of firewood, mm | 370 |

| Material of manufacture | Stove body - Structural steel, combustion door - cast iron |

Heat-extra 400 is not designed for use by avid lovers of bath procedures. This is evidenced by the 1-year warranty, while most other models from the Dobrostal Plant are covered by a 20-year warranty. If necessary, this model can be covered with bricks or “Zhara” convective screens can be installed. As an option, you can install a remote water tank with a volume of 20-100 liters or attach it to the back wall or pipe.

Check out the overall dimensions and find out the capabilities of this oven from a short video.

Mobile sauna

This type of bath is not traditional. Usually baths are stationary structures. However, today steam lovers have the opportunity to perform a bath ritual somewhere in nature. An example of a mobile bathhouse is the Alati model. Its kit includes a small stove with a steam generator, a removable chimney, a thermally insulated tent with an area of 2x2, and a collapsible shelf with dimensions of 0.6x1.8 m.

The Altai mobile sauna stove generates steam without using stones. The entire set, along with the tent and shelf, fits into the trunk of a car.

Mobile saunas are especially popular among lovers of winter outdoor activities, as well as among hunters and fishermen. No matter how severe the frost is, the temperature in the mobile sauna can be raised to 100°C. The bathhouse is assembled within twenty minutes. After the bath procedure, the scarf dries quickly and can be used as a room for cooking and feasting, where the shelf actually turns into a table. In general, the model is practical in all respects and finds various applications. A mobile bathhouse can also be used in a country house if there is no stationary bathhouse there yet.

Designing a homemade steam generator

The main challenge when designing a steam generator is to ensure that as much surface area as possible of the metal water drains comes into contact with the stones in the furnace. In this case, the pipes must be placed as close as possible to the stones that are heated to the greatest extent, that is, in the places of their contact with the surface of the metal of the firebox.

The use of a steam gun in stoves where there is only an open heater is especially important. The fact is that it is almost impossible to obtain high-quality steam, optimally suitable for steaming in the Russian bath mode, from a stove with an open heater. When water is supplied to the stones located in the outer layers, which are closer to a person and further from the heater, the liquid turns into fairly damp, coarsely dispersed steam, as when a kettle boils on the stove.

And maximum comfort is provided only by dry, finely dispersed steam obtained from the contact of water with the hottest elements of the stove - the firebox or stones in direct contact with it. It is impossible to supply water directly to the firebox, since it is separated from the steamer by a layer of stones, and in order to deliver water there, steam guns were invented.

Their designs can be completely different, depending on the level of ingenuity of the master and his desire to obtain maximum effect and convenience in the process of using the steam generator. The simplest solution is a metal pipe with a diameter of 5-7 cm, which is inserted into the space of the heater, after which the stones are laid.

This solution can only be used as a minimal experiment, since pouring water into it will be difficult. At a minimum, the structure must be equipped with a funnel for convenient liquid supply. Having eliminated this drawback, there still remains a problem arising from the small size of the pipe. You can only pour a little water into it, and repeating the procedure is only permissible at significant intervals of 5-7 minutes, so that the pipe and heater near the point where the water is poured have time to warm up well again.

Let's look at more complex devices designed for ease of use and the most efficient steam production process.

Black sauna from hearth to stove

The first baths were heated by an ordinary fireplace; steam was obtained from a stone bed, heated by the direct action of fire. The smoke came out of such a bathhouse through windows and doors, and such a bathhouse was called black because it was heated in black. But the black sauna is considered a classic to this day, and this is precisely because the steam in the sauna was finely dispersed. Fine steam was created by stones heated in a hearth over direct fire until they glowed crimson. The steam was of the same quality throughout the entire soaring period. Because the laying of stones was very large, sometimes even more than a ton. But steam is not the only bath factor - the temperature in the bathhouse was such that people could stay in the bathhouse for several hours, i.e. did not exceed 60*C. And all this time the heating of the room came from the heated stone. The preparation of the black bath itself was very labor-intensive. Not everyone could heat such a bathhouse. To heat it, you had to approach the fireplace, bending low, since at the top the entire room was filled with smoke. Firewood had to be added every hour, and such a bathhouse was heated for at least 8 hours. The bathhouse itself was partially warming up at this time, since it was heated with the doors open. The main task was to heat the stone filling. After the stones were heated to a crimson glow, the firebox was stopped, the heat was scooped out and taken out, the doors were closed and the bathhouse was cleaned of soot. Then they let the bathhouse sit for 2 hours. During this time, the heat from the stones warmed up the bathhouse well and you could safely go take a steam bath. Only the steaming was not always clean, since the walls were still covered in soot and they tried not to touch them.

The main negative of the black bathhouse was the open hearth - this is a great danger in the fire sense, plus the preparation of the bathhouse (cleaning off soot, ventilating fumes) were not good factors for the development of the black bathhouse. With the installation of a stove in the bathhouse, the bathhouse became white; of course, the first brick stoves were also heat-accumulating, periodic, and the stones in them were heated with an open flame. But the bathhouse itself was already becoming safe and clean, and of course the cooking time was almost 2 times faster.

Ermak 12 — 10,800 ₽

The Ermak 12 stove is interesting because it can be purchased in several versions. As a construction set, it is complemented by accessories that increase the comfort of use:

- mesh for stones that reduce hard IR radiation;

- hanging tank, heated from the back wall of the stove;

- heat exchanger for heating the remote tank.

For the economy class stove, the manufacturer used good stainless steel with a chromium content of 17%. Power 12 kW - optimal heating of a steam room with a volume of 6 m³. And again we get a result close to the lower volume range.

The weight of the laid stones is 40 kg.

Warming up such a mass of stones will require a longer firing of the stove, but when we reach the operating mode, we get good inertia - the stones will not allow the temperature in the steam room to drop too quickly. Technical characteristics of Ermak 12

| Characteristics | Meaning |

| Furnace power, kW | 12 |

| Steam room volume, m³ | 6-14 |

| Product weight, kg | 52 |

| Dimensions (WxDxH), mm | 425x520x690 |

| Weight of laid stones, kg | 40 |

| Maximum length of firewood, mm | 450 |

| Material of manufacture | Stainless steel, chrome 17% |

For the convenience of users, the length of the firebox has been increased, which ensures a more voluminous stack of firewood and, therefore, longer burning.

For additional ease of use of the Ermak 12 sauna stove, additional options are installed on the model: a heat exchanger and a remote tank. This way you can avoid boiling water directly in the steam room and ensure a sufficient volume of hot water.

How to make an electric steam generator

Despite the simplicity of the device, a factory-made steam generator is quite expensive: the average cost is about 1000 USD, and for some models it can reach 10 thousand. This state of affairs encourages you to start making the device yourself. Here's what you'll need for this:

- Ball valves designed for high temperatures.

- Heating element (several possible).

- Heat-resistant gaskets - 4 pcs. for each heating element.

- Steam hose.

- Pressure gauge.

- Safety valve.

- Squeegees, the diameters of which correspond to the connecting diameters of devices and fittings.

- Container designed for high pressure. For a medium-sized steam room, a gas cylinder is suitable, for a small one - a pressure cooker. In general, the volume of the steam generator should be selected at the rate of 10 liters for every 3 kW of power consumption. It should be taken into account that the maximum permissible power for a homemade device is 5 kW.

We invite you to familiarize yourself with: Do-it-yourself chandelier from scrap materials: how to make a lampshade, sconce, lamp, shades, step-by-step master classes

. If a cylinder is used, it needs to be prepared:

- the valve is carefully unscrewed;

- the container is filled with water (this action allows you to completely remove the remaining explosive gas);

- then the bottle is thoroughly washed from the inside with water and detergent.

You will also need a set of plumbing tools.

Here's how to make an electric steam generator:

- You need to insert a heating element into the lower part of the cylinder or pressure cooker so that it is approximately 1 cm from the bottom. If you decide to embed several heaters, then the hole for each subsequent one must be drilled only after installing the previous one - then the error (location of the holes too close) will be eliminated. If to install a heating element into the wall you have to weld a threaded bushing or some other element, then this unit should be designed in such a way that it can withstand a pressure of 6 atm. Advice. The number of parts to be welded can be reduced to one if a tee is used in this capacity: a steam tap is connected to one of its branches, and a safety group is connected to the other.

Using a gas cylinder to make a steam generator

Advice. It is advisable to equip a small steam generator made from a pressure cooker with a filling pipe cut into the very bottom. A faucet is connected to it from the outside, and a coil is connected from the inside, which will ensure heating of the incoming cold water.

Making a steam generator from a pressure cooker

In this case, you won’t have to remove the lid when refueling, but how then can you determine the water level in the steam generator? This is easy to do if you use an additional container for refilling, which is connected to the filling pipe of the steam generator using a hose cut into its lower part.

When the tap on the filling pipe is open, both tanks will be communicating vessels, so that the level of liquid in the additional container can be used to judge the degree of filling of the steam generator. For ease of use, marks can be placed inside the second container that correspond to the maximum and minimum permissible water levels.

At this point, the steam generator manufacturing process can be considered complete. Now you need to check its body for leaks, and the safety valve for operation under excess pressure.

If desired, the homemade model can be improved:

- instead of a conventional pressure gauge, you should use one equipped with an electrical outlet;

- A magnetic starter must be embedded into the power circuit.

The pressure gauge is connected to the starter in such a way that when there is excess pressure, the power circuit (power supply to the heating elements) opens.

Today there are devices for professional steam baths on sale. Outwardly, they resemble an inhaler and act on the same principle. You need to pour hot water inside, add other ingredients if desired, and turn it on.

How to make a steam gun with your own hands?

To begin with, we offer a simple design made from a metal corrugated pipe with a diameter of 4 cm.

The first stage is the manufacture of the lower sections of the pipe with holes for steam to escape. The diameter of each hole is approximately 8-10 mm. These tubes with ends bent upward are placed at the very bottom of the open heater of the stove (in this case, the Shilka model).

A vertical water supply pipe is inserted into the curved ends.

A funnel is installed on the top of the supply pipe for easy filling of liquid.

In this example, porcelain balls are used as a stone for the heater.

And this is what the entire assembled structure looks like.

In the photo you can see that both steam guns are placed on opposite edges of the firebox parallel to each other and each has its own funnel. During the vaping process, this steam generator showed the following efficiency. For 2 and a half hours of soaring at temperatures from 65 ° C to 95 ° C, three and a half liters of water were consumed.

The next model is also quite simple, but has a pipe outlet from the heater.

Since the pipe is placed in the Lamel stove from Feringer, it is possible to vent steam into the upper part of the heater - directly under the lining. There are no holes in the bottom of the pipe, so steam is formed inside the stainless steel pipe during the movement of water in the area of heated stones and comes out from the other end, connected to the top of the heater.

Additionally, small sections of pipes were placed to ensure free passage of air from the convection grille to the top of the heater.

This is what the assembled steam gun looks like with the heater filled and the lining installed.

When testing the unit, 2 liters of water were immediately poured into the pipe. The heating of the firebox began with a temperature of 20 ° C and within an hour and a half it rose to 43 ° C under the ceiling with a humidity of 57%. At the same time, only half of the firewood originally placed there burned out in the combustion chamber. Subsequently, the steam room maintained an average temperature of 50 °C with humidity from 50% to 60%. The minimum steam temperature at the outlet of the pipe was also measured, which was 340 °C.

Next we lay out more complex welded and prefabricated steam generators that require certain special skills for assembly.

In the photo above you can see the base for the steam generator, which is installed in the heater. To supply water, you just need to insert a pipe of a suitable diameter with a funnel at the other end into the upper hole.

The next gun is made on the basis of the same corrugated pipes with holes, only a splitter made of steel pipes connected by fittings has been added.

Photo for comparison with the dimensions of the polyurethane foam cylinder and the method of making holes.

Below, based on the same splitter, is a more complex design with a long metal hose with periodic slots along its length.

The water completely evaporates from the tank in 5 minutes and gives very light steam.

As can be seen from the presented examples of homemade steam guns, you can independently make a steam generator that is much more complex and efficient than commercially available factory models. All that remains is to choose a suitable model and either make a complete analogue, or take it as a basis for creating your own design, taking into account the characteristics of your stove.

Are there any fundamental differences between steam generators for baths, saunas and hammam?

Many people are interested in the question, what is the difference between steam generators for a bath, sauna or hammam? Since all three types of structures are intended not only for washing, but also for healing the body, their action is based on the formation of steam. The difference between a bathhouse, a sauna and a hammam is the amount of steam produced, its temperature and humidity level.

Temperature conditions of different types of steam rooms:

- A Finnish sauna must have dry heat - the temperature ranges from 80 to 140°C, the humidity level is from 1 to 15%.

- There must be wet steam in a Turkish hammam - the temperature is maintained at 45°C - the humidity level is 100%.

- In a Russian bath, steam should have an optimal humidity level from 50 to 80%, and the temperature should be maintained from 60 to 80°C.

A “store” steam generator, which has many operating modes for generating steam, is suitable for all types of steam rooms. Using the remote control, you can independently set the temperature of the steam and its volume. Typically, such devices allow you to select temperatures up to 95°C. Also, steam generators for industrial use are equipped with special built-in programs that can independently create a certain temperature and volume of steam output, simulating a real Russian bathhouse, Finnish sauna or Turkish hammam.

The steam that a steam gun creates is softer and more gentle than that from pouring water onto hot stones. Thus, we can say that there are no significant differences in such devices, so they are suitable for all types of steam rooms.

Bath stove with steam gun

It should be noted that the raw steam, which is necessary for the hammam, is not too heavy for the human body, does not give the feeling of a suffocating atmosphere, since the room is heated only to a maximum high temperature of 45°C. And it is with the help of a steam generator that this result can be achieved.

I would like to note that a modern Russian bathhouse is not too different from a Finnish sauna in its design. Therefore, the amount of steam and its temperature in such steam rooms can be coordinated by the visitors themselves. Using a steam generator, you can create conditions in any steam room that are intended for a bathhouse, sauna or hammam.

TMF Tunguska — 18,900 ₽

The TMF Tunguska sauna stove uses thermal uniform strength technology.

Those. the manufacturer has reduced the cost of the model by using thinner metal in “non-critical” parts of the structure and increased the wall thickness in areas with high thermal load. Technical characteristics of TMF Tunguska

| Characteristics | Meaning |

| Furnace power, kW | 24 |

| Steam room volume, m³ | 12-24 |

| Product weight, kg | 70 |

| Dimensions (WxDxH), mm | 415x990x810 |

| Weight of laid stones, kg | 92 |

| Maximum length of firewood, mm | 660 |

| Material of manufacture | Stainless steel, chrome 13% |

The TMF Tunguska stove is more massive, which involves heating not only the steam room, but also adjacent rooms. Using our calculations, we find out that the manufacturer indicates the maximum volume of the steam room at 24 cubic meters, which implies heating the bathhouse lined from the inside in the summer. If you use the bathhouse in winter, you will have to install an additional heater in the relaxation room and reaching the operating mode will take about two hours.

The action of the stove is to ensure air convection - this directly indicates that you will not be able to achieve the Russian bath mode, only a sauna, with its dry air and harsh temperatures.

Types of steam generators

If we want to get faster access to the steam generation mode, more flexible methods of process control, then we should pay attention to steam sources of a slightly different nature. Almost all of them use electric current as a source of thermal energy.

Based on heating elements

A heating element - a tubular electric heater - is widely known in everyday life. Electric kettles, washing machines, boilers carry it as a source of thermal processes. The main disadvantage of such devices is the tendency to form lime deposits on the metal contact surface, which in turn reduces the efficiency of its heat transfer. The use of heaters with a ceramic body promises some reduction in the severity of the problem, but they are significantly more expensive than metal ones.

The second thing you should pay attention to is constant monitoring to prevent the water in the generation chamber from falling below the minimum level. As soon as a heating element of this type is exposed, it immediately overheats and fails, due to the physical destruction of the conductive circuit. Otherwise, steam generators using heating elements are very popular and find the widest application: from compact saunas to artisanal workshops for producing counterfeit alcohol - live steam is very convenient for boiling and saccharifying starch-containing raw materials.

Electrode systems

In this case, heating of water occurs due to the active movement of elementary particles between the cathode and anode. The danger of overheating and failure of the current-carrying circuit does not exist here in principle. The water itself acts as a conductor of current. There it is in the chamber - the circuit is closed, the process has begun. Evaporated - the steam generation process automatically ended and energy consumption stopped. Manufacturers of such equipment promise a higher efficiency of such units and increased operating safety.

Induction heaters

One of the most high-tech examples of superheated steam production. In everyday life, an analogy can be drawn with a microwave oven. Cheburek or pizza is heated in a kitchen unit without visual processes - quickly and efficiently. In industry the effect is even more significant.

Using induction installations, heat treatment of metal parts is carried out in a short period of time, heating a product weighing several tens of kilograms to red heat. The operation of induction systems is based on the ability to heat a substance in a field generated by high-frequency currents. Simply put, the operating principle of such a device is to transfer magnetic field energy to the coolant.

By the way! The design elements of a vortex-type induction heater are mounted externally, which to some extent eliminates the occurrence of leaks and simplifies installation and maintenance of the system.

A do-it-yourself steam gun for a bath, the diagrams of which we have given, is most easily implemented through the use of heating elements, since both the induction and electrode heating principles require a responsible approach to implementation, supported by fundamental knowledge in the field of electrical engineering. Examples of the implementation of simple assemblies of steam generators for a bath can be seen in the video materials attached to this article.

Teplodar – Rus – 23,000 ₽

Stove for baths and saunas Rus 18 LNZP PROFI

Sauna stove Teplodar Rus 18 LNZP pro with a serious margin of safety - steel up to 4 mm in thermally loaded areas and chromium content up to 17%. If you want to get quality and reliability at low cost, then there is practically no other alternative. There are several shortcomings of the manufacturer, but we cannot say that they are absolutely critical.

Firstly, the main heating of the stones comes from the smoke collector (they are laid out around), so you will have to try to position them correctly with minimal gaps. Secondly, the collector slot is very narrow, which prevents the emission of soot and its accumulation. As a result, traction deteriorates and the collector needs to be cleaned 2-3 times a season, depending on the intensity of use.

When kindling and further entering the mode, it is necessary to add firewood to 2/3 of the volume of the firebox.

Good draft ensures almost complete combustion of fuel, which is visually noticeable by the transparent emanating smoke. Technical characteristics of Teplodar Rus 18 LNZP pro

| Characteristics | Meaning |

| Furnace power, kW | 21 |

| Steam room volume, m³ | 6-22 |

| Product weight, kg | 64 |

| Dimensions (WxDxH), mm | 335x790x810 |

| Weight of laid stones, kg | 90 |

| Maximum length of firewood, mm | 500 |

| Material of manufacture | Stainless steel, chrome 17% |

The stated load of stones of 90 kg does not correspond to reality - at most you will be able to load 60-65 kg of the middle fraction. The manufacturer apparently used stones with a very high density or crushed stone during testing.

Water should be poured onto the heater very carefully and the optimal amount should be selected experimentally. Insufficient heating of the stones along the edge will produce heavy steam.

Review of Teplodar Furnaces with a detailed description of the characteristics.

Features of baths

A Russian bathhouse is a well-heated room with a stove-stove, where hot cobblestones are poured with water from a ladle, and then they whip each other with birch brooms. This is the ideal, which is rarely achieved precisely because of the quality of the steam. In public baths, low qualifications of the staff affect them; in private baths, they are affected by the lack of experience of the owners or their lack of understanding of the principles of steam formation and the effects of heat and steam on the human body for the purposes of physiotherapy.

The stove in a Russian bath is large; its size can occupy up to a third of the area of the entire steam room.

Types of steam

Depending on the temperature and size of the water particles, the steam can be wet or dry. In the first case it is called coarse-dispersion, in the second - fine-dispersion.

It is dry, but not overheated, finely dispersed steam that is most useful to steam room lovers. You can get it in different ways. The traditional one with splashing on stones looks impressive, but it has low efficiency. What's really going on? After the first ladle, the surface of the stones cools down, the amount of steam produced remains insignificant.

The next watering results in the release of wet steam, which quickly condenses into droplets. The atmosphere in the steam room becomes like a tropical one: hot and humid, it’s hard to breathe, the benefits are questionable, the harm is obvious. You have to continuously maintain the heat in the stove, be distracted, add firewood, and monitor the combustion. What is common in the countryside is not always suitable for urban conditions.

The ever-busy modern person requires maximum output with minimal time investment. Special devices that produce steam come to the rescue. Their advantage is that the same steam room, by adjusting the given mode, can be turned into a Russian bathhouse, a Finnish sauna, or a Turkish hammam.

Types of doubles

Humanity has known baths since ancient times. There are different types of steam rooms. They can be reduced to three main types.

Types of doubles

Varvara Mini — 17,900 ₽

Most garden and country baths are small in size and focused on quick preparation for washing after a hard day. Accordingly, steam rooms are very small and require compact placement of stoves. Varvara Mini is designed taking into account such needs and, despite its small dimensions, has sufficient power of 8 kW.

The volume of the steam room is 12 m³, stated in the characteristics of the model is clearly overestimated. According to calculations, the steam room should be about 8 cubic meters - this is approximately a room 2 by 2 meters with a ceiling height of 1.8-2 meters. If the sauna operates only in summer, then 12 cubes will be warmed up to sauna mode in about an hour.

The manufacturer claims double convection, which quickly warms up the air, but “forgets” that heating a room is not only about the volume, but also about the walls, ceiling and floor.

Therefore, this stove is suitable only for a country bathhouse, which is launched in the summer and in the off-season. Technical characteristics of Varvara Mini

| Characteristics | Meaning |

| Furnace power, kW | 8 |

| Steam room volume, m³ | Up to 12 |

| Product weight, kg | 85 |

| Dimensions (WxDxH), mm | 655x780x740 |

| Weight of laid stones, kg | 40 |

| Maximum length of firewood, mm | 300 |

| Material of manufacture | Structural steel |

The steam in the open heater is harsh. To heat the open stones to the required temperature, you will need to run the stove, and with strong infrared radiation and small sizes, not every bath attendant can withstand a good portion of steam.

The benefits of a steam bath

Steam bath is one of the oldest ways to cleanse your face. It helps soften the outer layer of dead skin cells, helps remove it without damaging the more delicate layers, makes the skin smooth, gives a fresh look, increases blood circulation, dilates blood vessels, and removes not only dirt, but also toxins.

After using the steam bath, the face is cleansed of dirt and dead cells, natural regeneration processes are launched, the skin epithelium is saturated with moisture and nutrients.

Dobrostal Augusta — 25,850 ₽

Bath stove Dobrostal - Augusta STONE strong with panoramic glass

Currently, there is a tendency on the market to modify stoves in almost the same direction. What does the buyer require? Internal heater, heat accumulator, fast heating and long service life. This is exactly the path that the Dobrostal manufacturers took.

The Empress Augusta STONE strong stove is designed for a steam room with a volume of 10-22 m³. Not a bad run? Almost from a small nook to a quite decent room. Why is that? Let's start to figure it out. Firstly, 22 cubic meters of steam room is at an initial room temperature of 20°C in the summer. Secondly, it is indicated that the room must be properly insulated. Those.

So, although the manufacturer does not indicate the power, we will take it within the range of 14-16 kW, as indicated by the volume of the firebox and the declared efficiency. With such power and efficiency, warming up the steam room in winter without covering the walls will be about 3 hours. During this time, we will get high-quality heating of the internal heater, external stones and the opportunity to “play” with the modes.

The model uses structural steel with a thickness of up to 8 mm in areas of high thermal load.

The declared service life of 20 years is accepted with a number of reservations: do not overheat, do not pour water, moderate operation. But even 10 years is already very good and the money spent will be fully repaid by the pleasure received. Technical characteristics of Dobrostal Empress Augusta STONE strong

| Characteristics | Meaning |

| Furnace power, kW | 14-16 |

| Steam room volume, m³ | 10-22 |

| Product weight, kg | 55 |

| Dimensions (WxDxH), mm | 470x654x840 |

| Weight of laid stones, kg | 70 |

| Maximum length of firewood, mm | 300 |

| Material of manufacture | Structural steel |

Here we are again faced with the “short ones”. The firewood is only 30 mm long, but the manufacturer guarantees good heat removal from each log. The slogan “Stop drowning with sleepers” is even being promoted.

The sauna stove is very well designed, the basic needs of consumers are fulfilled, and critical comments are always taken into account and corrected in the following modifications.

Feringer Classic — 25,000 ₽

One of the best Russian manufacturers presents the Feringer Classic model, which already comes quite close to the concept of a “sauna stove”.

Internal heater, steam gun and the ability to use various bath modes, from Russian light steam to the sweltering heat of a sauna. The stove is very demanding when it comes to dry wood, as it is designed for “top burning” - the wood burns from top to bottom, and there is no grate in the stove (which reduces the cost of the design). Technical characteristics of Feringer Classic

| Characteristics | Meaning |

| Furnace power, kW | 25 |

| Steam room volume, m³ | Before 18 |

| Product weight, kg | 55 |

| Dimensions (WxDxH), mm | 480x810x800 |

| Weight of laid stones, kg | 60 |

| Maximum length of firewood, mm | 660 |

| Material of manufacture | Stainless steel, chrome 17% |

Here the manufacturer did not deceive us and with a power of 25 kW the stove will easily heat a 12 cubic meter steam room and a relaxation room of 12 square meters. But only in the summer. In winter, the stove will only be enough to heat the above-mentioned steam room, and you will have to install a heater in the rest room.

Differences between a steam generator and a steam gun

Industry and trade offer dozens of models of steam generators, but for personal needs you can make the device yourself. The principle of operation is simple, the materials are freely available.

A steam generator is a container of water from which hot steam comes out when heated. Just look at the kettle to understand how the generator works.

The steam generator is located outside the steam room

A steam gun has a different operating principle. This is a system of tubes through which water is dosed deep into the hot stones. There it instantly turns into steam, which, rising to the surface, dries.

The steam gun is located inside the steam room

Any of these devices can be of varying functional complexity. For a personal steam room in an apartment, country house or country house, you can make a model that meets your needs and desires.

We invite you to familiarize yourself with: Construction of a bathhouse from timber with your own hands

Vesuvius Skif — 25,600 ₽

The manufacturer Vesuvius is ready to meet consumers halfway and offers customers an improved oven design.

The model has a built-in heater, where the stones are heated to a temperature of about 400°C, which is enough to produce fine “light” steam. To “muffle” part of the convection, the developers equipped the sauna stove with a grate that holds the stones around the body of the model. Technical characteristics of Vesuvius Skif with closed heater

| Characteristics | Meaning |

| Furnace power, kW | 15 |

| Steam room volume, m³ | 12-24 |

| Product weight, kg | 91 |

| Dimensions (WxDxH), mm | 540x750x900 |

| Weight of laid stones, kg | 170 |

| Maximum length of firewood, mm | 400 |

| Material of manufacture | Structural steel |

To keep the price of the model in a comfortable range, structural steel was used. Yes, of course, steel forms scale, and accordingly begins to burn out already at 400°C (see the heating of the heater above), so I increased the wall thickness to 12 mm at the bottom of the heater. The fact is that the bottom of the heater is exposed not only to high temperature, but also to pressure from stones.

Punching and thinning of the steel occurs. However, the thickness of 12 mm with proper use of the model will last for 10-12 years. But on one condition. Intense destruction of the metal begins to occur at 550°C. You should not heat the firebox “red hot”, no matter how much you want to quickly heat the steam room.

Overall, the stove creates a pleasant impression, both in price and design. The main operating mode is sauna. To obtain the parameters of a Russian bath, gentle preparation (about 3 hours) is required to distribute the heat and warm up the walls of the bath.

Advantages

An excellent solution when arranging a sauna is to purchase an electric stove equipped with a heat exchanger. This unit has many advantages, among which the following qualities are worth noting:

- modern appearance;

- compactness;

- a light weight;

- multifunctionality;

- setting up automatic control;

- quiet operation;

- ease of installation;

- efficiency of heating and steam creation;

- safety;

- reasonable relationship between price and quality;

- wide variety of models.

TMF Geyser 2014 — 25,000 ₽

The TMF Geyser 2014 stove is in the same price range as previous models, but is a more advanced design option for creating Russian bath modes.

A closed heater allows you to get wonderful steam at an air temperature in the steam room of about 65-75°C. But again we are “stepping on the old rake” - convection currents. Technical characteristics of TMF Geyser 2014

| Characteristics | Meaning |

| Furnace power, kW | 18 |

| Steam room volume, m³ | 8-18 |

| Product weight, kg | 56 |

| Dimensions (WxDxH), mm | 415x800x785 |

| Weight of laid stones, kg | 55 |

| Maximum length of firewood, mm | 400 |

| Material of manufacture | Stainless steel, chrome 13% |

Look at the variation in the volume of the steam room. It is not for nothing that the manufacturer indicated such different parameters, and correctly calculating the load on the sauna stove remains the job of the buyer himself. So, 8 m³ of steam room is in conditions of winter operation, a “bare” log house and the need to heat adjacent rooms. 18 cubic meters - summer operation, heating a steam room combined with a washing room.

By the way, the increase in the cost of the stove due to the internal heater is “compensated” by thinner iron and a chromium content of 13% in steel. When “overclocking” the furnace 2-3 times a week, burnout of the walls will occur in 4-5 years.

Vulcan – Elbrus – 28,000 ₽

Manufacturers of the Vulcan stove. Elbrus 26 focus on protecting users from hard infrared radiation. What can be achieved with a conventional brick screen is implemented here in the form of “triple protection” with a steel casing. And if a brick screen allows you to cut off convection flows by closing specially installed doors, then in this model the air flows are constant, which does not have the best effect on the microclimate of the steam room.

The manufacturer is trying to mislead the user by saying that “the double casing makes the steam in the steam room soft.” This is a fundamentally incorrect statement. Good steam is generated due to the flow of water onto overheated stones (400-500°C), and this can cause problems in the oven. The stones are placed in a “bath”; the heating of the lower layer can still be considered sufficient, but the upper layer is not heated enough (about 200°C).

Technical characteristics: Vulcan. Elbrus 26 with Panorama heat exchanger

| Characteristics | Meaning |

| Furnace power, kW | 12 |

| Steam room volume, m³ | 12-26 |

| Product weight, kg | 110 |

| Dimensions (WxDxH), mm | 500x720x800 |

| Weight of laid stones, kg | 115 |

| Maximum length of firewood, mm | 400 |

| Material of manufacture | Structural steel |

A good solution for this model of sauna stove was to equip the structure with a heat exchanger for a remote tank. Thus, several problems are solved at once: there is no boiling of water directly in the steam room, you can increase the volume of accumulated hot water. In general, the stove deserves a satisfactory rating and is suitable for saunas with a short-term Russian bath regime.

Tips for use

The benefits of the bath have been proven many times, but it should be remembered that the steam room produces a physiotherapeutic effect on the body. Therapy involves consultations with doctors and dosing. What is good for a young and healthy person may be harmful for a person weakened by illness or age. Physiotherapeutic procedures can lead to exacerbation of chronic diseases. When visiting a steam room, you should pay attention to your well-being.

If you feel discomfort or pain symptoms, it is better to exercise reasonable caution and reduce the time you spend in the steam room or change the steam parameters towards softening

Despite the simplicity of steam generators or steam cannons made by yourself, do not forget about maintenance, checks, and regular cleaning. The salts contained in the water will settle in the form of scale and impair the operation of the devices.

Open fire stoves require increased fire safety measures. The use of electricity for heating elements is a direct indication of compliance with safety regulations when operating electrical appliances. Incomplete combustion of fuel and smoldering lead to an increased concentration of carbon dioxide, and even to the release of carbon monoxide. Therefore, the removal of combustion products must pass through a cleaned chimney.

The steam room door should open outward and not have locking devices. Switches should be installed inside the steam room to stop the steam generator. It would also be useful to have a signaling device to attract attention in case a person becomes ill and cannot leave the steam room on their own.

A small portable steam generator or mini-gun, assembled with your own hands from scrap materials, will allow you to create an atmosphere in a small room with parameters close to standard, classic baths. When operating steam devices, you should remember the limitations, safety precautions and the powerful impact of physical procedures on human health.

Since the steam generator is a powerful electrical device, it cannot be installed directly in a steam room where there is high humidity. The device is installed in the next room, but right next to the partition, so that the hose through which the steam will be supplied to the steam room is as short as possible (then the steam will not have time to cool down).

The hose must be laid with a slight slope in one direction or another, which will ensure the flow of condensate formed. When laying, it is important to avoid kinks in which accumulated condensate could form a plug.

The steam generator should be connected to the power supply network via a circuit breaker and an RCD. When installing the device outside a steam room, the RCD must be designed for a leakage current of 30 mA, otherwise - 10 mA (due to high humidity in the steam room).

The device body must be grounded.

It is necessary to avoid starting the steam generator without water - as a result of such an oversight, the heating element will burn out.

Limescale can also shorten the service life of the device. If you have to use water with a high hardness level, take one of the following measures:

- Before pouring into the steam generator, pass the water through a special softening cartridge (contains ion exchange resin).

- Water can be passed through a hydromagnetic system consisting of a permanent magnet (causes crystallization of hardness salts) and a fine filter (collects the resulting suspension).

Boil a solution of citric or acetic acid in a steam generator at regular intervals (helps remove scale that has already deposited).

So, today it’s easier than ever to get high-quality steam in a bathhouse, if only the user has special devices - a steam gun or a steam generator. Following our recommendations, you can make any of these devices yourself, and then the bath procedures will give the maximum healing effect.

Karelia-5 — 29,900 ₽

The cast iron stove Karelia-5 "Onezhskaya" is of the middle class with a large margin of safety, but somewhat inconvenient to use. In the classic version, heating is only possible from the steam room, which is an inconvenience for users and an additional source of infrared radiation. It does not have a tank for heating water or a heat exchanger, so hot water supply to the bathhouse is required, and this is at least constant heating of the premises.

Due to the high heat transfer of cast iron, the steam room quickly heats up, but the stones in the heater reach the desired temperature only in the lower layer, and this requires effort to supply water there.

The stove is recommended for saunas and, accordingly, there is no question of a Russian bath. Technical characteristics of Karelia-5 "Onezhskaya"

| Characteristics | Meaning |

| Furnace power, kW | 20 |

| Steam room volume, m³ | 20 |

| Product weight, kg | 150 |

| Dimensions (WxDxH), mm | 500x500x980 |

| Weight of laid stones, kg | 50 |

| Maximum length of firewood, mm | 30 |

| Material of manufacture | Cast iron |

There is no control over convection currents; we warm up and steam in only one mode without the ability to change. The stove is durable, but it seems to us that after a while you will want to change it to a more advanced model.

TMF Kalina – 30,000 ₽

It seems that TMF Kalina Carbon focuses on quickly warming up the room, although advanced bath attendants advocate uniform heat without “ears wrapping” modes.

This model has almost everything for inexperienced users. Panoramic glass for relaxation, a labyrinth of the chimney to increase the efficiency of the stove, an internal loading of stones of 95 kg, ensuring heat preservation. Technical characteristics of TMF Kalina Carbon

| Characteristics | Meaning |

| Furnace power, kW | 15 |

| Steam room volume, m³ | 18-30 |

| Product weight, kg | 96 |

| Dimensions (WxDxH), mm | 605x785x935 |

| Weight of laid stones, kg | 95 |

| Maximum length of firewood, mm | 440 |

| Material of manufacture | Structural steel |

The proud statement of the manufacturers about heating a steam room with a volume of 30 cubic meters is not entirely clear. Apparently they are focusing on the size of the stove and stones, which will give the desired effect, but only after a three-hour fire. If we take the minimum value of 18 cubic meters, then there is still hope of reaching the Russian bathhouse mode, but with the maximum numbers you will only accelerate the bathhouse to a sauna when the room quickly cools down. In general, the stove is not bad, but again the savings come out - structural steel is used.

Troika - No. 06M2 - 36,600 ₽

Troika – No. 06M2

Troika stove for a classic Russian bath. Of course, you will have to carry out the required modifications to the steam room, since the stove is designed for use in a brick lining. But in this case we get:

- soft heat that radiates from heated brick;

- high inertia, the steam room, and the bathhouse will be warm for another couple of days, and this means drying and the absence of rotting of the logs;

- uniform microclimate, no air movement from convection currents;

- Burns from hot metal are excluded.

Further, the stove has a function of supplying water to the lower part of the heater. Provided that this is where the heating is maximum and there is no significant cooling, you get light, finely dispersed steam.

The stove firebox from the dressing room is comfortable and functional.

Firstly, aesthetics, and secondly, an additional opportunity to warm up the entire volume of the bathhouse, and not just the steam room. Brick will require a longer time to reach the mode, but by placing convection doors in a brick screen, you can heat the steam room and relaxation room very quickly to “defrost” the volume of the bath, and only then prepare a Russian steam room. To regulate combustion, the sauna stove is equipped with a valve. Technical characteristics Troika. Stove for Russian bath No. 06M2

| Characteristics | Meaning |

| Furnace power, kW | 20 |

| Steam room volume, m³ | 8-16 |

| Product weight, kg | 210 |

| Dimensions (WxDxH), mm | 700x310x1350 |

| Weight of laid stones, kg | 90 |

| Maximum length of firewood, mm | 650 |

| Material of manufacture | The firebox is low-alloy steel 10 mm, the rest of the product is structural steel |

A very good stove for a Russian bath and for creating a gentle steaming regime.

The stove is the heart of the sauna

Despite some statements, most people understand that they don’t just wash in a bathhouse, they cleanse themselves. For many, the bathhouse is a place that allows us to make a kind of reboot, after which we receive: clarity of thought, clarity of mind, freshness, health and vigor. Bath traditions have been around for many centuries. There were baths in Ancient Rome and Ancient Greece. Today, in addition to Russian ones, Japanese, Finnish, and Turkish baths are known, but the difference between them is quite large. The bathhouse appeared in Rus' a very long time ago; information about it is found in the most ancient sources. It was popular among both the nobility and the poor. For Russians, the bathhouse was a ritual of purification and preparation for a new life, a new day: they gave birth in the bathhouses, they were treated, they had funeral services, the bride took a steam bath before the wedding. Ancient treatises claimed the healing properties of the bath. Today, doctors confirm that the bathhouse has a positive effect on the respiratory, endocrine, and cardiovascular systems, and they claim that the bathhouse has a positive effect on mental abilities. And the heart of the sauna is the stove. Initially, the stoves were brick or adobe with a mandatory chimney and were heated as they say in white. It was these stoves that determined the transition from black baths to white baths. With the stove, many procedures have been simplified, the bathhouse has become clean and safe. Brick kilns were divided into batch kilns and continuous kilns. Stone and brick stoves retain heat for a very long time, but require prolonged heating. Building a stove also requires craftsmen and colossal funds, which is why bathhouses with white stoves slowly entered the everyday life of common people. It spread most quickly among wealthy people, commercial and public baths. As soon as the stove entered the bathhouse, it became the center of it, as it was commonly said that - The stove is the heart of the bathhouse. The stoves became more controllable and safe, and therefore more reliable, and the sauna processes more enjoyable. A sauna with a white stove becomes a full-fledged organism, with full function. With the transition to continuous operation, the stove becomes more compact, controllable, truly the heart of the sauna stove.

Let's dance from the stove

In Soviet times, public baths slowly began to die out due to the fact that the state, in the age of technological progress, did not see any benefit in this and offered people to replace it with a bath and shower. The maximum that people were offered were commercial projects that were more aimed at entertainment and which, ironically, began to be called saunas. Many even began to confuse sauna modes from bath modes. The unique conditions of the Russian bath require appropriate temperature and humidity conditions. According to established requirements, the temperature in the bath should be in the region of 40 - 60 * C with humidity in the range of 30 - 60%. It is in these conditions of steam conditions in the bath that real steaming with a broom, herbal infusions, inhalation and massage takes place. And here the difference between the stoves is very noticeable, since sauna stoves are not capable of maintaining bath conditions. The steel stove revolutionized the bathing business by creating a separate line of high-temperature regimes. “Sauna” stoves have found their way into many bathhouses and are loved for their versatility, functionality, efficiency, and low price. Everything would be fine, but, however, organizing bath steam regimes with it has become more difficult than with a brick oven. Why initially there was a sharp division into steel - sauna and brick - sauna stoves. The steel stove quickly overheated the room before heating the heater. The steel stove was declared incapable of creating the required modes and not for steam bath modes.

The main disadvantages of steel furnaces were stated:

- Insufficient heat accumulation.

- Thermal radiation of steel structures is characterized by increased rigidity.

- Active oxygen burnout.

- Large convection

- Small amount of stone backfill.

- Short service life.

- Increased fire danger.

- Short service life of the chimney.

- Large emission of soot and unburnt gases.

And, despite the fact that many of the claims were simply far-fetched, and some arose from violations of fire safety, nevertheless, at first, the steel kiln was significantly inferior in terms of conditions and conditions to brick kilns.

One step forward two steps back

Engineering thought does not stand still and new developments in the design of the furnace have begun to be proposed, experiments are being conducted on various types of steam generation, and various finishing solutions have been created. They began to intensively customize and adapt the steel stove for bath regimes for the Russian bath and began to create something similar to a brick stove. Moreover, all resources began to spread the opinion that:

- It is impossible to create sauna regimes without a brick oven;

- convection is the enemy of bath steam regimes;

- infrared radiation from steel furnaces is dangerous for humans;

- an open heater cannot have a well-heated stone;

- an open heater overheats the steam room;

- a steel stove is not able to dry the bathhouse, etc.

All these illusions led to the fact that manufacturers of sauna stoves began to create steel stoves devoid of convection with a closed heater and a large mass, which returned all the shortcomings of a brick stove and even the high price. There were also simple solutions when they took an ordinary steel stove and lined it with bricks, reducing thermal radiation to a minimum and eliminating convection, and in order to get steam faster, they began to come up with various devices for delivering water to the bottom of the heater or to the bottom of the heater, such devices were called “steam guns." Such stoves themselves turned out to be expensive both in cost and in operation, since they required firewood a little less than a brick stove, but they produced no more steam than any steel stove, since you cannot insert a huge heater into a stove intended for a family bath. Heat storage stoves have become in demand for commercial baths and are not at all interesting for private small steam rooms. And again we reached a dead end. Some manufacturers remembered cast iron stoves and began making cast iron stoves, declaring that. That a replacement brick oven has been found. Other manufacturers have taken up this initiative.

Cast iron stoves as a replacement for brick stoves

When steel stoves “deceived the expectations” of manufacturers, they turned their attention to cast iron, declaring it the most practical, high-quality and functional option for a sauna stove. A cast iron stove combines some of the qualities of a brick heater, but at the same time does not have its disadvantages. The physical properties of cast iron are still closer to steel furnaces. Therefore, many consider the main advantages of cast iron construction to be: high thermal conductivity; heat accumulation; long-lasting heat transfer; oxidation resistance; resistance to critically high temperatures. In other words, cast iron stoves are credited with such opposite properties as: slow cooling and high thermal conductivity; maintaining a microclimate and quickly heating the room; a beneficial atmosphere in the steam room and not rapid heating of the room; resistance to deformation when heated (due to thickness) and good heating of the stone. And this conclusion - “cast iron models gain heat faster than brick ones, and retain it longer than steel ones” does not raise any surprises or questions? Of all the arguments, we can only agree with the fact that a positive feature of cast iron units is the variability of construction and design, due to the injection molding method for producing composite and decorative elements. In fairness, it should be noted that, with good quality of cast iron, this is its durability. And you don’t need to put all the cast iron products here. Most cast iron used in household stoves is not heat resistant. There is heat-resistant cast iron that is quite suitable for such use, but its cost is such that it is suitable only for commercial projects. One of the domestic suppliers of cast iron stoves for household baths and saunas is PetrozavodskMash-TNP LLC, which produces products under the ATB brand. But what should the owners of family baths do? After all, they were promised happiness with a cast-iron stove for the price of a steel stove? Here we can only advise you to carefully calculate the costs of the fact that your chimney on such stoves will last much less than on steel stoves, the consumption of firewood will be much more, and steam will be much less. People have again turned to and are pulling out a new savior - stone-filled stoves.

And again the open heater

Heat storage stoves with a closed heater turned out to be a dead end, and although this direction exists, it is not developing - a dead end. Because all the disadvantages of brick ovens remained with them. There was an understanding that something needed to be changed and heat storage stoves with an open heater were created. Their main direction is mesh ovens. The mesh oven had more capabilities, but its controllability turned out to be low. A mesh stove turned out to be a better option than a brick stove or a steel heat storage stove with a closed heater.

But the manufacturers’ joy was short-lived; mesh ovens revealed serious shortcomings

- Such a stove, filled with stones, took a very long time to warm up the steam room.

- Firewood consumption has increased.

- The chimney began to overheat greatly.

- The oven itself has significantly reduced its service life.

- There was no more steam from such a stove.

- Often such ovens begin to take up more space.

- The price of such ovens is always higher than that of convection ovens.

And again the vicious circle. The new direction did not become a breakthrough and life-saving, although many began to note that such stoves began to overheat the steam room less. As a result of a long search of directions, manufacturers are constantly darting from one direction to another, each time announcing that this time they have found the best. But then it's a valid question. Why, creating the “best” stove each time, manufacturers continued to produce “worst” ones? Why are stoves that do not meet steam bath conditions in all respects discontinued? The answer is simple. Manufacturers are simply trying to fill any market niches and are not going to engage in developments that consumers need. What should the consumer do? Search, among the general collapse, for something worthy of taking a place in their bathhouse. We, Team Belykh (KB), did not wait for a miracle from manufacturers and began to offer them first technical solutions to improve their developments, and then ready-made new developments. But manufacturers saw this as an undermining of their monopoly and a abandonment of the strategy of endlessly profiting from unsatisfied demand by creating deceptions. It was necessary to develop a concept for the development of production and production of modern products. However, then the work of the designers did not stand up to criticism, and they rejected any progress in favor of maintaining the previous stagnant movement in a circle. Factory designers talked about the impossibility of creating full-fledged new equipment and, at the most, improving the existing one with various devices. They did not see a solution to the problems, or did not want to see them.

Steel steam generator according to Bely

The decision on bath steam regimes was on the surface and we, as bath technologists, saw it clearly. The truth was in the middle of most ideas between a brick oven and a steel one, between a stone steam generator and a steel one. Since 2008, we have been offering a harmonious concept of sauna steam procedures and our image of a sauna stove, which at that time was a metal copy of a brick stove. In the new furnace according to Bely (design bureau concept), the furnace must be easily controllable and have afterburning of gases, for which we equipped it with a hood with a supply of secondary air into it.

This not only improved the combustion conditions of the fuel, but also increased the heating of the stone filling, but the stone filling was not large enough to ensure long-term steam generation. With the creation of a high-speed, highly efficient steam generator, the steel stove found a new life and began to fully meet the requirements of advanced stoves for Russian baths. The presence of a steam generator in the furnace made it possible to obtain finely dispersed steam throughout the entire period without reducing quality, the furnace does not overheat the room and creates soft conditions.

What is the connection between the steam generator and the stove's control over overheating the room? The most direct one. Placing the steam generator on the walls of the firebox significantly reduced the infrared radiation from the furnace. The stove has become truly adapted to steam bath conditions and fully complies with the concept of the stove according to Bely. The first stoves were created for family baths and made of metal, which is used for most stoves with a 13% Chrome content. Traditionally, external elements were made of ordinary carbon steel; as a result, the external convector did not survive the firebox and spoiled the appearance of the stove while maintaining its performance. We were given suggestions from people who had invested in their saunas and commercial saunas to create a stove of exceptional durability, which was a challenge to brick and cast iron stoves. As a result, after modification, the Kazachka stove not only improved its appearance, but also received record durability. The Cossack oven PRO+ is made of AISI430 steel 4 mm thick and all its parts are made of stainless steel. Carbon steel was completely excluded from the assembly material. Of course, the price of the stove has more than doubled, but the durability has increased 3 times and still the price of the stove is significantly lower than a brick stove and lower than a cast iron stove. And what is not unimportant is that the stove has a record low temperature of the exhaust gases, as a result of which the service life of the chimney increases by 3 times. “Kazachka Pro+” is a real stainless steel stove that incorporates the best features of a brick and steel stove:

- The first stove, which is all made of stainless steel, and the firebox is made of AISI 430 steel, 4 mm thick.

- An all-welded, high-strength structure, the firebox of which is made of a vaulted type - in the image of the Kuban brick stove Kabytsa.

- The presence of a gas afterburning chamber is similar to the bell of a brick kiln, which is why the kiln is called a bell-type kiln.

- Capacious firebox, with convenient loading and a large glass door.

- Active regulation of three-level combustion.

- A patented steel convection steam generator that has no analogues.

- The outer walls of the oven, like those of a brick oven, do not heat up much.

- A steam oven produces a lot and high quality.

- The chimney near the stove has a lower temperature among steel stoves.

The “Kazachka Pro+” stove received such advantages due to the introduction of new developments from the design bureau:

- Convection type steel steam generator (patent)

- Hood with active afterburning of pyrolysis gases.

- A separate channel for supplying secondary air for afterburning gases.

- Three-level combustion.

- Dosed supply of water to the steam generator.

- Additional shielding of the furnace firebox.

- Removable convector.

Before the Cossack PRO+ had time to fill the market, a new demand from gourmets of the Russian bath came with a request to increase the heater, and we did not beg ourselves for long and launched a new project called Tverdynya (Fortress), fortunately we had the main structures drawn, it was necessary just calculate the economics and launch the project. Less than a month has passed since the new Cossack Stronghold PRO+ stove saw the light of day. The stone-lined stove with thick stainless steel walls compares favorably with other manufacturers.

With the release of stoves in Bely, the market was replenished with truly sauna developments, which stand out significantly from the category of sauna stoves produced before and which became a real replacement for brick sauna stoves. By the way, the list of sauna stoves does not end there. The white team is working to meet the demand of various groups of bath specialists and designers. There are developments, it just takes time.

Steam generator

They came together - metal and stone. New songs in a bathhouse style High-speed Steam Generator - Invention Patent 142846.

Pages: ← previous

1

next

→

Hephaestus PB-03 M — 43,500 ₽

Hephaestus PB-03 M

Cast iron stove for the Russian bath Hephaestus PB-03 M, designed for brick lining. The model has a lot of advantages, but the main ones are the high inertia of the product, the internal heater made of 60 mm thick cast iron and the special design of the combustion system.

The design of the furnace walls allows heat to be quickly transferred to the heated room. The efficiency of the model is very high and wood combustion does not occur in idle mode. It is additionally provided that the heating temperature of the furnace is 750°C, but the turbulent fins reduce the temperature (i.e. heat transfer) to 300 degrees in the chimney. In fact, we do not heat the street, but remove heat from the bathhouse itself.

The forecast for the longevity of the furnace is 30 years of operation, although this period is an estimate and has not been confirmed experimentally, but 15-20 years is quite enough to “work off” the invested funds.

Technical characteristics of Hephaestus PB-03 M

| Characteristics | Meaning |

| Furnace power, kW | 18 |

| Steam room volume, m³ | Up to 25 |

| Product weight, kg | 190 |

| Dimensions (WxDxH), mm | 418x755x590 |

| Weight of laid stones, kg | 70 |

| Maximum length of firewood, mm | 420 |

| Material of manufacture | Cast iron. In the firebox with the addition of chrome |

Although the manufacturer claims that even without the combustion process the heater is able to maintain the required temperature to produce good steam, this is not entirely true. The weight of the heater itself is about 50 kg and the maximum time for which the inertia will last will be approximately 40-50 minutes or the supply of about 3 liters of water. It is not recommended to heat the stove for more than 5 hours a day.

Steam generators in wood-burning heaters

Even not very avid steamers know that it is impossible to apply water to weakly heated stones - in this case the steam will be “hard” and scalding. The higher the temperature of the stones, the “softer” the steam becomes. However, no matter how long you heat a wood-burning stove, the stones will not heat up above 300°C, and therefore the “softness” of steam in traditional stoves is limited.

They did not want to put up with this fact and came up with a revolutionary method of vaporization. Its essence lies in the formation of steam not only on the surface of the stones, but also on the metal surface of the firebox.

The walls of the firebox heat up to 650°C, and when water enters them through special channels, a large release of finely dispersed steam occurs, which is extremely “soft.” Such steam can be obtained within 15-20 minutes after the furnace enters operating mode. This method of steam generation is patented by the developer and is not used by anyone else in the world.