Despite the Internet controversy that has flared up for a long time about the use of foil to retain heat in a bathhouse, the convictions of its supporters and opponents have not been shaken.

However, the subject of dispute was initially the physical properties of the material, and in our time there are enough means to make “selection” - to strengthen the necessary properties of the material and weaken the unnecessary ones.

Look at the bathhouse and the mode of its use as a set of factors, each of which can be “for” or “against” insulation with this material. With this approach, harm and benefit cease to be absolute categories, as they are usually presented in disputes.

We will tell you how to place the foil correctly to achieve optimal results, but this will be discussed in other articles.

This article is devoted to the consideration of materials available on the market; both foil and foil bath insulation will be considered here.

Bath foil: pros and cons of use

- A bathhouse, and even more so a steam room, are places with a very specific temperature regime and high humidity. Bath foil is ideal for this environment because it can easily withstand large temperature changes .

- Most insulation materials lose their properties when wet, so they are usually protected with a layer of waterproofing. Thin aluminum easily takes on this function, since the metal does not absorb moisture .

- Its high ability to reflect infrared rays ensures the preservation of heat inside the bathhouse and steam room.

- The ease of installation makes the installation of foil insulation feasible even for a non-professional. There is also no need for special equipment.

- The downside is that moisture that has not been absorbed by water accumulates on it in the form of condensation, which can cause rotting of the finishing coating or the growth of fungi on it , but this can be treated with a ventilation gap between the aluminum and the same lining.

- The high thermal conductivity of the aluminum from which it is made would also be a big disadvantage if it were not compensated for by a layer of insulation with low thermal conductivity that follows the metal.

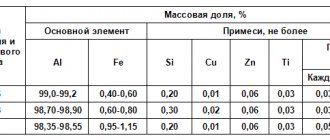

- Another disadvantage is foil corrosion , that is, the formation of an oxide film on its surface. Of course, such a film worsens reflectivity. But the purity of the metal (the absence of impurities) significantly slows down the oxidation of aluminum.

- Well, temperature + water hammer , but more on that below

Material selection

Work begins after installation and testing of the functionality of all engineering systems. Before covering it is necessary:

- Determine the type and volume of materials;

- Make a list of necessary tools;

- Perform heat and vapor barrier;

- Install the sheathing.

Previously, edged boards from various types of wood were used for interior cladding. The lack of necessary equipment and technology sharply reduced the range and quality of manufactured products. New production technologies have made it possible to increase the range and quality of modern lumber.

The main material for covering modern bathhouses is lining. The lining is a thin edged board with a special profile.

This is interesting. The name of the paneling comes from the thin wooden strips that were used to cover railroad cars.

The difference between lining and edged boards is the presence of recesses (grooves) and protrusions (tenks) along the long side. These elements ensure a tight connection of the panels during installation.

The widespread introduction of lining as a finishing material is facilitated by:

- Increased thermal insulation;

- Durability of the material;

- High installation speed;

- Ease of maintenance and repair;

- Beautiful exterior design.

When is it needed and when is it not?

It is not needed by those bathhouse owners for whom neither fuel economy nor long-term heating are a problem.

It is also not needed by those who completely deny its ability to reflect infrared radiation through a layer of lining, but believe that the thermal conductivity of aluminum is a guarantee of rapid cooling of the bath precisely with the help of foil.

There is no need for it either if the bathhouse is sufficiently insulated using traditional methods, and its heating and cooling completely suits the owner.

It is wrong to assume that it will not find application in bathhouses made of logs or timber, since in wooden buildings only proper insulation of the crowns and high-quality sealing of all cracks is required. If desired, you can insulate any bathhouse. Let this be a repetition, but foil is needed where time and effort are valued.

It heats up faster and cools down slower.

Useful video

However, despite the above, there is an opinion that the absence of foil makes vaping softer, eliminating the sharp water hammer during paired procedures:

Personal protective equipment when melting

Melting aluminum at home is an unsafe process. Therefore, you need to use personal protective equipment (PPE). Even if such melting is needed once with minimal equipment, then at least you need to protect your hands, for example, with special welding gloves, which perfectly protect against burns, because the temperature of liquid aluminum is more than 600 ° C.

It is also advisable to protect your eyes, especially if melting occurs quite often, with goggles or a mask. And ideally, you need to work in a special metallurgist suit with increased resistance to fire and high temperatures.

If you need very pure aluminum using a refining flux, you should work in a chemical respirator.

Foil and insulation for baths with foil: types

| View | Release form | Peculiarities | Advantages | Flaws |

| Rolled foil | rolls: thickness 0.007-0.2 mm, width 1-1.5 m, length – 5-20 m | a roll can have from 3 to 5 breaks inside, so take it with a margin of 5-7%; any wall, but place foil on fireproof insulation | does not burn; does not release toxins; holds up to +650 degrees; reflects up to 97% of infrared radiation. | easily torn and wrinkled |

| Kraft foil | rolls reinforced with paper or paper and polyethylene. thickness – 0.03-1 mm | any surfaces, but you also need insulation | does not release toxins; holds up to +100 degrees; stronger than baseless; reflects up to 95% of heat. | flammable |

| Foil fabric | fabric rolls with one-sided foil reinforcement, width – 1 m, length 25 m | similar to the previous one | temperature range -50 +200; thermal reflection 97%; non-flammable; environmentally friendly material. | |

| Folar | rolls in three types of release: “A” - two layers of foil, between them - fiberglass in the form of a mesh with 4x4 cells; “B” – one layer of foil and the same fiberglass; “C” – foil, fiberglass, adhesive base. Roll width 1 m, length 50 m. | “A” temperature range -40 +300 "B" -40 +150 "C" -40 +80 very durable material; environmentally friendly - does not emit toxic substances when heated. | ||

| Folgoizolon | foamed polyethylene, foil-coated on one side. release form: sheets and rolls. sheet: length 120 cm, width 60 cm, thickness 2-11 cm. roll: length up to 30 m, width 1-1.2 m, thickness 0.2-1 cm. | for insulation of wooden walls and walls covered with clapboard | holds 100-150 degrees; self-extinguishes when burning; thick sheets can be independent insulation; light weight; high strength; low thermal conductivity. | flammable |

| Foil mineral wool | mats or rolls of mineral wool with one-sided foil; thickness varies from 0.5 to 10 cm, length and width depend on the manufacturer (there is no single one). | for insulation of walls made of concrete, brick, wood | temperature range -60 +300; reflectivity up to 97%; non-flammable; high thermal insulation properties (thanks to mineral wool). | |

| Foil basalt wool | insulation for baths with foil, a type of mineral wool, the same release forms. | similar to the previous one | properties - similar to the previous one, but basalt wool retains heat better; temperature range -200 +700 degrees. | |

| Foiled polystyrene foam | extruded polystyrene foam boards with one-sided foil coating. | operating temperatures -50 +75 degrees; with the addition of fire retardants - self-extinguishing in case of fire. | flammable; releases harmful substances; | |

| Bath insulation "Rockwool" with foil | stone wool slabs with foil on one side, dimensions 0.6x1 m, thickness 5 or 10 cm. Pack of 8 slabs. | holds up to +200 degrees; biostable; non-flammable; durable; eco-friendly. |

It is worth noting that all of the listed types, which is best for everyone to decide on their own, are excellent vapor barriers. They are not afraid of mold and mildew. But this is for them, and the tree needs an antiseptic.

Melting with a blowtorch

Melting aluminum at home with a blowtorch should not take place indoors. In addition to raw materials, a blowtorch, crucibles and bricks, you need to prepare firewood, pliers and a steel rod.

So, a small well was made from bricks so that a ladle with aluminum and a small steel sheet could be installed on top. A fire is lit in the well, which must burn out a little to form coals.

Next comes the actual melting of aluminum at home. Step-by-step process instructions:

– A container with raw materials is placed on the bricks. It needs to be heated for about 15 minutes.

– After this, the burner of the blowtorch is turned on at full power and the aluminum is heated from above.

– The process begins within a few seconds, but in order for the heating to be uniform, the metal in the container must be carefully mixed with a steel rod, holding it with pliers (remembering to wear gloves). You can do without a rod by periodically shaking the bucket using the same pliers, but very carefully.

– When the liquid becomes homogeneous, you need to take the container with pliers and pour the contents onto the calcined steel sheet so that all the resulting scale remains in the ladle, and only clean metal gets on the sheet to harden.

This is how pure aluminum is usually obtained from recycled materials if aluminum parts need to be soldered with it.

"Stickiness"

The most common use of foil is to use it as a backing or envelope when baking meat or fish in the oven. When baked in an envelope, the products are more likely to stew in their own juices, so they almost never stick. But when using foil as a substrate, this happens quite often.

First of all, we decided to bake chicken wings on foil (see recipe here). The wings are baked in two batches: first without everything, at a temperature of 180 ° C for 30 minutes, and then brushed with sauce and sent to the oven preheated to 150 ° C for another 15 minutes. The only thing the chicken didn’t stick to at all was the Sayanskaya Universal foil.

We also decided to bake salted lemon on foil - it was interesting to see how foil would behave in an aggressive environment. There were no noticeable changes to the foil. The juice released from the lemons has become caked. The lemon only seriously stuck to the Paclan foil, “Every Day” and “My House”.

Fire resistance

Many manufacturers claim that their foil is suitable for grilling. We gave the samples a brutal test: we burned them with a torch for 30 seconds (about the same as throwing foil onto hot coals).

The metal heated up, but held on. Later, having examined the foil, we saw that all the sheets had burned through: a transparent mesh was visible in the light.

Conclusion: you should not throw vegetables wrapped in foil into the fire; it is better to cook them over smoldering coals.

Melting with wood or gas

Aluminum smelting at home using wood occurs in lightweight collapsible furnaces. The disadvantage of this method is the uncontrollability of the process. It is not possible to increase or decrease the heating temperature. It is possible to intervene in the process only by removing the container with aluminum from the heat.

Melting aluminum at home using gas is the only possible option for an apartment. The container needs to be heated for a long time, periodically draining the molten metal. In this case, casting is performed in layers. To work, you will need two metal containers of such diameters that one fits over the other. The smaller one serves as a crucible. It is placed with a crowbar, for example, cut aluminum wire, on the burner from which you need to remove the flame divider of a household gas stove. A larger capacity will have to be worked on first. About a dozen small holes are made in its bottom. Bolts are screwed into two or three of them, which act as handles, by which the hot container can be lifted with pliers.

This container is placed upside down on the crucible. This design allows aluminum to be heated. Periodically, the upper container must be removed and the scrap mixed with a metal rod or knife. Before draining the molten metal, the slag must be removed from its surface.

Instead of a resume.

By the end of testing, we remembered the saying about “British scientists”: it became clear that we had proven only one thing - all tested samples behave approximately the same. The leader could not be identified. But they identified a clear outsider: the “My Home” foil did not pass the strength tests, the salted lemon completely stuck to it, and the chicken wings also stuck to it. But the “Food Foil”, which tore during unwinding, passed one of the strength tests, and the wings and lemon almost did not stick to it. The most convenient to use was the Sayanskaya grill foil; it holds its shape better than others, but chicken wings, unfortunately, stick to it. Paclan foil was distinguished by an unreasonably high price - in our testing it did not show results worthy of its purchase.

Cook with pleasure!