Price overview

In addition to the world name, the cost of the heater can be influenced by:

- build quality;

- absorber and housing material;

- thickness and installation option of insulation;

- glass thickness, etc.;

Since there are many design differences that can affect the cost of equipment, prices fluctuate over a wide range. For example, a Russian-made manifold will cost around 21 thousand rubles. (Sokol-Effect), vacuum manifold 30HP – $795 (China), water heater VFK 150V – 690 euros (Vaillant, Germany), Solar 7000TF – 875 euros (Bosch, Germany).

German manufacturers include original fasteners in the kit, which are often made of stainless steel or aluminum, and this also affects the price. The final cost will include payment for installation work, purchase of necessary consumables and auxiliary materials.

Payback period for a solar system

A simple calculation will help you understand how quickly expensive solar collectors pay for themselves. For example, it will be a flat device with an area of 2 “squares” with a daily output of 6.4 kWh of heat.

When the main source of thermal energy is an electric boiler, the kilowatt-hour it produces will cost 5 rubles (according to 2021 prices), which means that the daily savings on power supply when operating a flat device will be 6.4x5 = 32 rubles, and the payback period at the price of the device is 20 thousand – 625 days (20000:32=625).

When the main heat source is a gas unit, a kilowatt-hour of energy will cost 0.7 rubles, and the daily savings will be 6.4 x 0.7 = 4.48 rubles. The payback period will increase to 4464 days or 12 years. If we take into account that the average life of a collector is no more than 15 years, we can conclude that in this case the solar system will never pay off.

Types of vacuum solar collectors

The most popular and in demand types are divided according to the type of collector design.

They are:

- Vacuum flask with heat pipe. They are difficult to operate and manufacture, because... In this type of design, vacuum-type thermal insulation is provided throughout the entire flask. These devices provide the highest efficiency. The absorber here is a plate that is covered with a selective all-absorbing coating. The heat pipe is securely attached to the plate and supplies energy to the capacitor (top of the tube). In turn, the condenser is connected to the collector heat exchanger. This is where the coolant heats up.

- “Falk in a flask” with a heat pipe. This design is slightly simpler than the previous one and has lower performance at lower temperatures. The absorbent surface is located on the inner tube. Heat is transferred to the heat pipe, made of copper, through metal fins. A heat pipe is the most efficient device designed to transfer heat.

- "A flask in a flask." This type of vacuum collector device makes it possible to achieve the highest degree of thermal insulation of the coating (absorbing), without interfering with the penetration of sunlight. As with the previous type, the energy absorption coating is located on the inner bulb. The coolant that is in contact with the absorbing surface can be heated without intermediate transformations.

Design and principle of operation

A solar collector is a thermal converter of solar energy that collects radiation (solar) regardless of air temperature. Installation is carried out at an angle of 5-90°, which makes it possible to install it so that the working surface is maximally aimed at generating energy.

The main component of the design of vacuum solar collectors is a glass tube, which is mounted in the frame (panel) of the collector. Several similar tubes are installed in one panel; depending on the design, their number may vary.

The tube consists of several components, these are:

- Glass tube with a solar-absorbing layer;

- A smaller diameter copper tube placed in a glass tube.

There is a vacuum space between the tubes.

The operating principle of such devices is as follows

- The sun's rays fall on glass tubes treated with a special layer and their energy is absorbed by this structural element.

- Tubes of smaller diameter contain a special liquid, which, under the influence of energy absorbed by the absorber (glass tubes with an absorbing layer), heats up and, when certain parameters are reached, evaporates. In the vapor state, the substance rises to the top of the tubes.

- Sets of tubes are placed in a common block in which they are in contact with the circulating coolant.

- In the vapor state, energy is transferred to the coolant, after which the substance condenses and flows down in the liquid state.

- The process repeats again.

Step-by-step instructions for assembling the unit

Coolant circulation diagram

The first stage is the installation of the drive and front camera.

The mentioned units are located in the attic of the house. Make sure the ceiling at the installation location can support the weight of the water containers. Install the front camera next to the drive. Do this so that the liquid level in the fore-chamber is approximately 100 cm higher than the water level in the storage tank.

The second stage is choosing a place to install the solar heater. The unit is fixed on the south wall of the building

It is important to maintain the correct slope of the heater to the horizon. The optimal value is 45 degrees. The collector must be attached to the house so that the solar panels look like an extension of the roof

The collector must be attached to the house so that the solar panels look like an extension of the roof.

The third stage is the connection of individual elements.

To complete this task, you need to buy inch and half-inch steel pipes. You will use half-inch ones to connect high-pressure elements of the system - from the water inlet to the anterior chamber. Inch pipes are used in the low-pressure part.

The pipes must first be painted white or another light color. A layer of thermal insulation material is fixed on top of the paint. In this case, foam rubber is optimal. A layer of polyethylene is wound over the insulation, and then a woven tape. Finally, the pipes are painted white again.

solar collector

The fourth stage is filling the system with liquid.

Water must be supplied through special drainage valves installed at the bottom of the radiators. This will avoid the formation of air locks. When water begins to flow from the drainage, the operation can be considered complete.

The fifth stage is connecting the front camera.

This unit must be connected to a water supply inlet. After connection, open the flow valve. You will see that the amount of water in the forechamber will begin to decrease.

At night, the air temperature becomes lower than the temperature of the heated water. Under such conditions, the collector will begin to heat the environment and generally operate in the reverse mode. To avoid this, the system is equipped with a valve that prevents the possibility of reverse circulation. It will be enough to simply turn off this valve in the evening, and the energy will be stored in the system.

If the thermal conductivity of the collector is not high enough, it can be increased by adding sections. The design will allow you to do this without any difficulty.

You can, of course, artificially adjust the direction of solar panels in relation to the Sun by placing additional structures under the collector

Thus, there is nothing difficult in assembling a solar heater yourself. Such work also does not require large financial investments, but it is strongly recommended to buy only high-quality materials from well-known manufacturers. Approach your work with maximum responsibility, do not violate the recommendations given, and you will receive an excellent source of heat and hot water, powered by free energy. Happy work!

Operating principle of a vacuum solar collector

The coolant in a vacuum solar collector is a non-freezing liquid, which, flowing through the upper zone of the device, absorbs thermal energy from special tips made of copper alloys. When pumping, it heats the water mass in the storage tank using a serpentine mechanism. The heat transfer cycle depends on the length of the day and occurs until the temperature of the liquid leaving the device exceeds the temperature of the water flows in the storage tank.

The receiver is made of copper with polyurethane type insulation, protected by an anodized aluminum coating. Thermal energy is supplied through the receiver sleeve. The process of changing components is not complicated. It does not require draining the antifreeze liquid mass from the heat exchanger.

At the outlet of the vacuum collector, to obtain solar energy, in the storage tank, as well as on the reverse side of the heating device circuit, temperature sensors are located. Based on the readings of temperature instruments, the solar controller turns the circulation pump on or off. If the coolant overheats, excess pressure may arise in the system; an expansion tank is provided for this.

This collector serves as an excellent alternative to electricity and gas heating, as it is an environmentally friendly device thanks to the use of solar energy. In addition, such devices are very profitable from an economic point of view.

Modification features of devices

In the manufacture of solar units, thermal channels and vacuum glass tubes for solar collectors are combined in a variety of combinations.

The most popular among consumers are coaxial models with a heat pipe. Buyers are attracted by the loyal price of the devices and very simple, affordable maintenance throughout the entire service life.

Vacuum devices with heat pipe channels demonstrate high reliability and have no restrictions on use even in high-pressure solar thermal complexes.

Devices with a coaxial flask containing direct-flow U-shaped channels are also included in the list of popular ones. They are characterized by such parameters as low heat loss and efficiency of 70% and above.

The situation is somewhat spoiled by the complex repair process, specific maintenance during operation and the inability to replace an individual damaged unit. If something happens to the device, it is dismantled and a completely new collector is put in place.

Feather tubes are structurally a single cylinder made of glass with thickened, strong walls (depending on the manufacturer, from 2.5 mm and above). The feather absorbent insert contained inside tightly fits the working channel, made of heat-conducting metal.

Almost perfect insulation is created by the vacuum space inside the glass container. The absorbent transfers absorbed heat without loss and provides the system with an efficiency of up to 77%.

Models with a feather element are somewhat more expensive than coaxial ones, but due to their high efficiency they provide complete comfort in the room and quickly pay for themselves.

The most efficient and productive are feather flasks with internal direct-flow channels. Their actual efficiency sometimes reaches record levels of 80%.

The price of the products is quite high, and when carrying out repairs, it is necessary to drain all the coolant from the system and only then begin troubleshooting.

Types of vacuum solar collectors

The classification of vacuum-type solar collectors is based on two of their characteristics. This is the type of glass cylinder and the type of heat channel used.

In the design of vacuum manifolds, there are two types of glass cylinders (tubes):

- Coaxial tubes. Their design involves the presence of two glass flasks placed one inside the other. The space between the outer and inner flask is filled with vacuum. The surface of the inner flask is coated with a special substance with a high heat absorption coefficient. In fact, the inner tube is a heat sink. The inner tube contains a hollow copper circuit filled with an ethereal composition. When heated, this composition evaporates and releases the resulting energy to the coolant, after which it condenses back.

- Feather tubes. Their design includes one glass bulb in which a special copper element is placed - a heat absorber. To increase its area, it is made corrugated. As a result, it vaguely resembles a feather, hence the name. The copper thermal absorber is coated with a special compound that increases the efficiency of solar absorption and heat production. Feather tube manifolds are more efficient and longer lasting than units that use coaxial tubes.

Among the thermal channels used in vacuum-type collectors, there are also two types:

- Heat Pipe type channels. This design assumes the presence of a special heat collector inside the cavity of the tube. The evaporated ethereal composition transfers thermal energy to it, and the heat collector, in turn, transfers it to the coolant for further distribution throughout the system.

- Direct-flow U-shaped channels. A special feature of this design is the circulation of coolant through a thin U-shaped channel directly inside the glass cylinder of the heat sink. On one side enters water or another coolant used. Passing through the tube, it picks up thermal energy from the heat sink and comes out of the second end already heated.

Polycarbonate manifold

They are made from honeycomb panels with good thermal insulation properties. Sheet thickness from 4 to 30 mm. The choice of polycarbonate thickness depends on the required heat transfer. The thicker the sheet and the cells in it, the more water the installation can heat.

To make a solar system yourself, in particular a homemade solar water heater made of polycarbonate, you will need the following materials:

- two threaded rods;

- propylene corners, the fittings must have an external threaded connection;

- PVC plastic pipes: 2 pcs, length 1.5 m, diameter 32;

- 2 plugs.

The pipes are laid parallel to the housing. Connect to the hot water supply via shut-off valves. A thin cut is made along the pipe into which a sheet of polycarbonate can be inserted. Thanks to the thermosiphon principle, water will independently flow into the grooves (cells) of the sheet, heat up and go into the storage tank located at the top of the entire heating system. To seal and fix the sheets inserted into the pipe, thermally resistant silicone is used.

To increase the thermal efficiency of a cellular polycarbonate collector, the sheet is coated with any selective paint. Heating of water after applying selective coating accelerates approximately twice.

Model overview

"Summer resident"

This model costs about 18,500 rubles. This collector is capable of heating water up to 95 degrees and is perfect for country houses. Has a 12 month manufacturer's warranty. This time is enough to ensure its reliability.

This model has the following technical characteristics:

- The 100 liter tank is made of high quality stainless steel.

- The vacuum tube is 150 cm long.

- Tube diameter (external) 4.8 cm.

- The maximum possible pressure in the tube is 0.6 MP.

- The design is resistant to hail up to 0.5 cm.

- The tubes are made of borosilicate glass, which has an absorbing effect.

- The total weight of the collector is 45 kg.

Equipment:

- set of anthers (sealing) – 1 pc.;

- vacuum tubes – 16 pieces;

- frame and set of bolts – 1 pc.;

- expansion tank – 1 pc.;

- thermos tank 100 l. - 1 PC.;

CP-II-20-175 from ANDI Group

The kit includes:

- water tank with a volume of 175 l., the internal circuit is made of stainless steel, and the external circuit is made of galvanized painted steel;

- vacuum tubes – 20 pcs.;

- TNC-2 (controller).;

The thermal insulation of the tank is made of polyurethane (50 mm). Internal diameter 36 cm, external 46 cm, steel frame 1.5 mm thick, galvanized. Net weight of the unit is 86 kg.

Device and scope of application in everyday life

Today the following types of solar power plants are used: flat-plate and vacuum

Flat plate

These are the simplest and cheapest devices. They consist of a plate that catches solar radiation (absorber), a transparent coating and thermal insulation covering the lower surface. Black paint or a special coating, such as titanium oxide or black nickel, is applied to the surface of the plate facing the sun. It's called selective. The most effective absorbers are those made of copper.

The light-transmitting coating is made of a special profile polycarbonate sheet (with corrugation) or tempered glass, almost completely free of metal impurities.

All gaps between the collector body and the transparent cover are sealed, which helps reduce heat loss due to convection.

Flat plate collector

In air collectors, the air used as a coolant flows directly through the absorber - on one or both sides. In devices focused on the use of a coolant fluid (water, oil or antifreeze), copper or aluminum tubes into which this coolant is supplied can be attached to the absorber.

If the heat accumulated by a flat plate collector is not removed, it can heat the water to a temperature of 190 - 210 degrees.

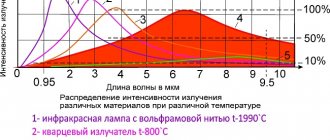

To increase the efficiency of such installations, coatings made of special materials are used that do not emit heat in the form of infrared waves.

Vacuum

The role of an absorber in such a collector is played by the surface of the tube through which the coolant flows. At the same time, it itself is enclosed in a round transparent casing, from which the air is pumped out. Thus, each coolant tube is surrounded, like a thermos flask, by vacuum.

A vacuum collector is more expensive, but it is more efficient: with its help, water can be heated to 250 - 300 degrees.

Vacuum manifolds

The performance of a vacuum collector can be significantly increased by using parabolic cylindrical reflectors. These are oblong elements with a concave mirror surface, which in cross section forms a parabola. Such reflectors are installed in the collector behind the tubes, focusing all unassimilated sunlight onto them.

An installation equipped with such elements can heat the coolant (oil is used) to a temperature of 300 - 390 degrees. To further increase the collector's performance, it is equipped with a sun tracking system.

Other system elements

In addition to the collector itself, the solar installation has a storage tank with water, to which the energy accumulated by the coolant is transferred using a built-in heat exchanger.

There are systems with both natural circulation of the coolant (the storage tank is installed above the collector) and with forced circulation - using a pump (the tank can be installed at any level).

Solar collectors in the heating system

Application

In everyday life, solar power plants are used for preparing hot water, including for baths, heating a swimming pool, or as an additional source of heat for a heating system. In industry, the scope of application of such systems is wider: they are used to build water desalination plants, steam generators (steam drives various machines) and even power plants.

Types of vacuum solar collectors

With direct heat supply

Vacuum collectors with direct heat supply have internal tubes with coolant, which are connected to a storage tank. That is, here the coolant in the tubes and the general circuit is the same. The diagram can be viewed below.

Vacuum solar collector with direct heat supply

Using a shut-off valve, the collector can be connected to the water supply system. Using a locking valve, you can control the water level in the storage tank. Typically, in such systems, the coolant is water, which means that this type of collector is seasonal.

With indirect heat supply

The operating principle here is similar, but the coolant does not come into contact with the liquid inside the vacuum tubes. The diagram can be seen in the image below.

Vacuum solar collector with indirect heat supply

This type of collector can be used without problems in winter.

Solar collector design

Solar collector design

The units in question have a fairly simple design. In general, the system includes a pair of collectors, a front chamber and a storage tank. The operation of the solar collector is carried out according to a simple principle: as the sun's rays pass through the glass, they are converted into heat. The system is organized in such a way that these rays are not able to leave the confined space.

The installation operates on the thermosiphon principle. During the heating process, the warm liquid rushes upward, displacing cold water from there and directing it to the heat source. This allows you to even avoid using a pump, because... the liquid will circulate on its own. The installation accumulates solar energy and stores it within the system for a long time.

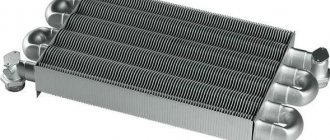

Components for assembling the installation in question are sold in specialized stores. At its core, such a collector is a tubular radiator installed in a special wood box, one of the edges of which is made of glass.

To manufacture the mentioned radiator, pipes are used. The optimal material for making pipes is steel. The inlet and outlet are made from pipes traditionally used in the installation of water supply systems. Typically ¾ inch pipes are used, 1 inch products also work well.

The grate is made from smaller pipes with thinner walls. The recommended diameter is 16 mm, the optimal wall thickness is 1.5 mm. Each radiator grille must include 5 pipes, each 160 cm long.

Solar collectors

How to choose a solar collector of the required power

If you want the heating system of your home to cope with the task of maintaining a comfortable temperature in the rooms, and hot and not lukewarm water flows from the taps, and at the same time you plan to use a solar collector as a heat generator, you need to calculate the required power of the equipment in advance.

In this case, it will be necessary to take into account a fairly large number of parameters, including the purpose of the collector (DHW, heating or a combination of both), the heat needs of the facility (the total area of heated premises or the average daily consumption of hot water), the climatic features of the region, and the features of the collector installation.

In principle, making such calculations is not so difficult. The performance of each model is known, which means you can easily estimate the number of collectors required to provide heat to your home. Companies involved in the production of solar collectors have information (and can provide it to the consumer) about changes in the power of the equipment depending on the geographic latitude of the area, the angle of inclination of the “mirrors,” the deviation of their orientation from the south direction, etc., which allows making the necessary adjustments when calculating collector performance.

When selecting the required collector power, it is very important to achieve a balance between the shortage and excess of generated heat. Experts recommend focusing on the maximum possible collector power, i.e.

e. use the indicator for the most productive summer season in the calculations. This goes against the desire of the average user to take equipment with a reserve (i.e., calculate according to the power of the coldest month) so that there is enough heat from the collector even on less sunny autumn and winter days.

However, if you follow the path of choosing a solar collector of increased power, then at the peak of its performance, i.e. in warm sunny weather, you will face a serious problem: more heat will be produced than consumed, and this threatens overheating of the circuit and other unpleasant consequences . There are two options for solving this problem: either install a low-power solar collector and connect backup heat sources in parallel in winter, or purchase a model with a large power reserve and provide ways to discharge excess heat in the spring-summer season.

Vacuum solar collector operating principle

Solar vacuum collectors are the most efficient devices for processing solar energy. In order to achieve 85% efficiency, the device uses only 15% of the solar energy received. Vacuum collectors are more efficient than solar panels, as they can not only convert solar energy into electricity, but are also used for heating. This feature allows you not only to save on electricity, but also not to spend money on heating equipment.

Due to their high efficiency, solar collectors are widely used in areas such as:

- Private houses, apartments, dachas.

- Office rooms.

- Agricultural enterprise.

- Industrial complexes of any scale.

- Health care institutions.

- Educational institutions: schools, universities.

- Children's institutions.

- Trade establishments.

- Public catering facilities.

- Railway stations, ports and many other institutions of all kinds.

Solar collectors can be effectively used almost anywhere where electricity and hot water are needed.

Features of operation of solar collectors:

- During the cold winter period, especially in January and December, solar collectors cannot produce more than 30%-50% of the heat. So during this period we will have to resort to traditional energy sources.

- The better the thermal insulation of a building, the more efficient the heating system is.

- A water-based underfloor heating system can also be heated using solar collectors. It is recommended to use this feature to improve system efficiency.

- Cloudy weather is the main obstacle for solar collectors. With increased cloudiness, you will have to use traditional heat sources more often.