MDF is a type of wood board that is a significant competitor to chipboard and laminated chipboard. The abbreviation MDF (Medium Density Fiberboard) translates as “medium density fiberboard.” This material is produced cut into slabs of various thicknesses and sizes.

The wood is pre-dried and crushed. Its particles are fastened together to form slabs of a certain thickness. It is made by pressing under enormous pressure and additional heating at high temperatures. Lignin or paraffin is used as a fastening component. Both of these substances are of natural origin.

MDF first appeared in the USA in 1966. It was here that its production on an industrial scale began. Unlike chipboard, no harmful resins that are hazardous to health are used in the production of MDF, which makes this material relatively environmentally friendly. Furniture made from MDF is suitable for children's institutions. The article talks in detail about the material and its areas of application, adds a couple of useful videos on the topic, and also offers the reader interesting material for downloading.

What is MDF.

Technical characteristics of MDF

Values of physical and mechanical parameters of MDF boards

| Options | Unit | Requirements TU 5536-003-50113531-2005 | Research according to standards | ||||

| Thickness | mm | >6 <9,0 | >9,0 <12,0 | >12,0 <19,0 | >19,0 <30,0 | >30,0 <45,00 | |

| Density | kg/m3 | For boards of brands: MDF -720÷980; HDF -840÷980; LDF -600÷800 | GOST 10634 | ||||

| Bending strength, not less | MPa | 23 | 22 | 20 | 18 | 17 | GOST 10635 |

| Tensile strength perpendicular to the plane, not less | MPa | 0,65 | 0,60 | 0,55 | 0,55 | 0,50 | GOST 10636 |

| Swelling in 24 hours (for MDF, HDF boards), no more | % | 17 | 15 | 12 | 10 | 8 | GOST 10634 |

| Swelling in 24 hours (for LDF boards), no more | % | 30 | 20 | 20 | 17 | 17 | GOST 10634 |

| Modulus of elasticity at static bending, not less | MPa | For board grades: MDF – 1700; HDF – 2300; LDF – 1700 | GOST 10635 | ||||

| Specific resistance to tearing of the outer layer, not less | MPa | For board grades: MDF – 0.8; HDF – 0.9; LDF – 0.6 | GOST 23234 | ||||

| Formaldehyde content | mg/100 g.s.m. | ≤8 | GOST 27678 | ||||

| Content of mineral impurities | % | ≤0,2 | Method of burning and wiping - infusion of a slab sample in hydrochloric acid | ||||

| Humidity | % | from 3 to 10 | GOST 10634 | ||||

| Maximum thickness deviations | mm | ±0,3 | GOST 27680 | ||||

| Maximum deviations of length and width | % | ±5 | GOST 27680 | ||||

| Deviation from right angle | Mmm | ≤2 | GOST 27680 | ||||

| Edge straightness deviation | Mmm | ≤2 | GOST 27680 | ||||

How MDF came to be

The birthplace of MDF is the USA. It was this country that invented and began producing wood panels back in 1966. In the production of MDF, wood fibers are dried, bonded and formed into a board, which is treated with high pressure and high temperature. No harmful resins or phenol are used in the production of MDF. MDF appeared in Russia only in 1997.

In 2021, the production volume of MDF and HDF boards amounted to about 2 million m3. If we take the general dynamics of wood-based panel production in Russia, we can see that since 2011 the market in this area has been continuously growing. In Russia there are 14 enterprises producing MDF boards, but only 13 are operating. The size range of produced boards is divided as follows: thin 3-4 mm, medium thickness 6-28 mm, and massive boards 30-40 mm.

The slabs are produced both untreated and coated. The production of fire-resistant and moisture-resistant boards is being mastered, but most of these boards are exported. The development of the Russian market for MDF boards is a look at the European market; what is popular in Europe comes to the Russian market in 2-3 years and lingers for a long period of time.

Interesting read: why bakelite plywood is so durable.

The consumption of slabs in European production is growing, and the demand for other materials is gradually decreasing. It should be understood that only with large production volumes and affordable prices for MDF boards will the furniture industry gain freedom of choice, and in the future, perhaps, will gradually reorient itself from chipboard to MDF.

MDF panel boards.

MDF is...

MDF is a building material for the production of which fine wood fraction . At high pressure and under the influence of temperature, it is compressed, resulting in sheets of different thicknesses, from 2 to 60 millimeters.

MDF production originated in the United States of America back in 1966. But this technology has been coming to our country for more than 30 years because of all sorts of “iron curtains”. And the first pieces of furniture appeared only in 1997.

By the way, an interesting fact - today the leader in MDF production is not the USA, and certainly not Russia, but China.

Properties and main advantages of MDF boards

MDF board has unique properties, thanks to which this material is significantly superior to fiberboard and chipboard, as its closest competitors. According to its characteristics, MDF board is close to natural wood and belongs to natural materials. The main properties that distinguish MDF from other materials include:

- Strength. Ensured through the use of synthetic resins in the production, as well as due to the dense structure of the fibers obtained during the pressing process using a natural binder - lingin. The density of the finished slab is in the range of 600 – 980 kg/m3. Thanks to this, MDF has the ability to firmly hold fastening materials and fittings. The homogeneous and dense texture eliminates such phenomena as cracking, rotting, and drying out, which are characteristic of natural wood.

- Moisture resistance. The material is resistant to warping and swelling in conditions of high humidity or when exposed to steam. Direct exposure of MDF to water during the day causes the board to swell by 8...30%, depending on its grade and type.

- Heat resistance. As a natural material, MDF is resistant to direct sunlight and temperature changes and does not change its properties under their influence.

- Insulation properties. The material absorbs sounds well and has excellent thermal insulation properties.

- Environmental and hygienic safety. MDF boards belong to class E1 in terms of free formaldehyde emissions (up to 8 mg) and do not contain harmful resins and phenol. According to hygienic parameters, the material is resistant to fungus and other biological factors.

- High quality. The quality of MDF is determined by the homogeneity of the material and the degree of processing of its front surface. This property allows the use of MDF boards in areas where the quality of the final product is a priority.

- Manufacturability. The quality and homogeneous composition of the MDF board allows it to be processed with almost any tool (mills, saws, drills, abrasives). The material is resistant to chipping during processing and does not crumble. Finished products can be glued well with any wood adhesives, painted and varnished.

MDF coating

MDF facades are very popular among furniture manufacturers and buyers. In the manufacture of furniture facades, MDF is used as a base, and the attractive appearance and performance properties depend on the MDF coating. Today, the greatest demand is for PVC-coated MDF, acrylic-coated MDF, enamel-coated MDF, and plastic-coated MDF boards.

Material on topic: All about moisture-resistant plywood.

Coating MDF with PVC film

The furniture facade is laminated with PVC film of the selected color. The advantage of MDF with PVC coating is its affordable price. The film can be of completely different colors, resemble the structure of wood, have a smooth glossy surface, or a matte finish. MDF facades coated with PVC film are popular in both classic and modern interiors. The film is not afraid of cleaning agents and mechanical stress. The only drawback is that with prolonged exposure to high temperatures, this MDF coating may peel off. Despite this, furniture made from MDF with PVC coating can delight its customers for many years.

Covering MDF with PVC film.

MDF enamel coating

Coating MDF facades with enamel is in deserved demand. After all, such a coating offers a wide range of colors not only in monochromatic glossy shades, but also in pearlescent colors, with a chameleon effect or the now popular “ombre”. For this coating, the MDF board is coated with several layers of enamel, then sanded and varnished. This surface does not fade in the sun and is not afraid of high temperatures, water or water. However, it should be borne in mind that this MDF coating has special care requirements - the enamel cannot be cleaned with abrasive agents.

MDF enamel coating.

MDF plastic coating

MDF facades coated with plastic are gaining more and more popularity among our customers. This type of coating combines the properties of film and enamel, and is much cheaper than acrylic and enamel coating. Plastic-coated MDF is resistant to high temperatures and humidity, and retains its original color for many years, even if exposed to sunlight. MDF plastic coating allows you to decorate furniture not only in solid colors, but also in wood, stone and other textures.

MDF plastic coating.

Acrylic MDF coating

MDF facades with acrylic coating are also quite in demand nowadays. Acrylic is environmentally friendly and therefore safe for humans. The acrylic coating of MDF gives a uniform, rich color that is resistant to all kinds of influences and is not afraid of sunlight, temperature changes and high humidity.

Acrylic MDF coating.

MDF wood veneer covering

There are also MDF facades coated with veneer. The MDF board is glued with a thin sheet of wood and therefore such furniture is practically indistinguishable from products made from real solid wood. MDF with this coating is safe, affordable and easy to clean.

MDF covered with wood veneer.

What types of MDF panels are there?

All types of MDF are produced using the same technology. The composition of the raw material may vary slightly depending on the type of wood and the proportionality of the parts of the massif and bark. The base of the plates has approximately the same density, the length of its constituent fibers and specific gravity. The difference lies in the amount of additional treatment against fire and dampness, thickness, shape, size and methods of surface finishing. The configuration of products determines their scope of application, installation methods, operating conditions and maintenance features.

Types of panels by production technology

According to the molding method, products are divided into the following categories:

- Whole pressed. The slabs are produced by placing them under a press simultaneously with the facing material. The finished product is characterized by an average degree of density. The strips are finished on both sides, so they can be used as office and interior partitions.

- Standard. At the first stage of production, the blank is made, at the second, the finishing is glued to its front part. Used for finishing surfaces in dry rooms.

Based on the composition of raw materials, products are classified into the following types:

- Universal. Made from fibers impregnated with lignin. They are not resistant to dampness. The cladding is applied on one side only.

- Water resistant. The mass of material is impregnated with hydrophobic agents. The outer covering is waterproof. The products can be used for finishing walls in damp rooms.

Types of panels according to the method of design of the front part

Manufacturers produce products with the following front surface finishing options:

- Plastic. A thin layer of transparent polymer is applied to the slab and fused to it under high heat and vacuum. The products are resistant to moisture and mechanical stress.

- Veneer. A thin section of natural wood is glued to the panel and then covered with varnish or film. Natural material looks beautiful and representative.

- A traffic jam. This material is expensive, but has high aesthetic and insulating characteristics.

- Adhesive film. The most common models, combining practicality of use, presentable appearance and a wide range of colors.

- Paper. The most inexpensive finishing option, which easily deteriorates under the influence of moisture, mechanical stress and ultraviolet radiation.

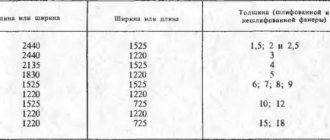

Types of panels by manufactured sizes

Sheet finishing materials are produced in the form of slabs and strips.

Rack panels have the following parameters:

- length – 240, 250, 260, 270 cm;

- width – 15, 20, 30, 45, 60, 75, 90 cm;

- thickness – 3, 6,8, 10, 12, 18, 25 mm.

Wall slabs in the shape of squares or rectangles are produced in the following range of sizes:

- length – 80, 100, 120, 140 cm;

- width – 20, 25, 30, 40, 60, 80 cm;

- thickness – 3, 6,8, 10, 12, 18, 25 mm.

Finishing parameters are selected based on their operating conditions. Thus, for finishing an apartment, it is advisable to purchase material with a thickness of 3-8 mm with a length equal to the height of the ceiling and a width of 20-30 cm. For cladding the walls of public premises, it is better to choose wide and long slabs with maximum strength indicators.

Types of panels by installation method

The following types of panels are distinguished according to the method of placement on the load-bearing surface:

- Lining. The products are strips, the connection of which is carried out using a tongue-and-groove system. Depending on the type of model, the planks are butted end to end or a narrow longitudinal depression remains between the protruding surfaces. Based on the characteristics of the room, horizontal, vertical or diagonal orientation of the planks is selected. Using connecting profiles, you can create beautiful and interesting geometric shapes and compositions.

- Tile. The retail network offers models of square and rectangular shapes. Tiles are used to lay out walls in a plain, simple style or in the form of a mosaic, when the project involves the use of products of various shapes, sizes and colors. The joints between the tiles are masked using one of the methods suitable for the interior.

By color

If you look at the photos of MDF panels, you can get an idea of the variety of product designs. The texture of the front side can be matte or glossy, smooth and voluminous.

Laminated wall panels can imitate the following materials of natural and artificial origin:

- Wood - oak, walnut, ash, birch, beech, cedar, larch. The array image is realistic and deep. Not only the texture of the wood is drawn, but also its features - knots and cracks.

- A natural stone. Imitation of masonry made from boulders, polished granite or marble blocks, and torn basalt are in demand. At the same time, the weight of the panels is incomparably less than that of natural minerals.

- Skins of animals and reptiles, plumage of birds and scales of fish.

- Brick or ceramic tiles.

- Fantastic and abstract theme.

- Various types of fabrics with characteristic patterns, ornaments and compositions.

For the decoration of office-type premises, products coated with film or varnish with a uniform color of a neutral color are used.

Types of MDF

MDF boards are selected depending on the tasks.

- MDF boards with a smooth surface on both sides are used in a wide range of applications as a building material. They can be easily processed, painted, veneered, plastered, or puttyed.

- Laminated MDF. The plate is covered with a thin polymer film on one or both sides. As a result, high-quality protection from mechanical stress, moisture and other negative factors is achieved. Film of various colors can be used.

- Moisture-resistant MDF panels. To create the panels, only high-quality wood is used, which is pressed under prolonged exposure to high temperature. Moisture-resistant MFD wall panels can be used for decorative finishing of bathrooms, balconies and loggias.

It’s worth finding out: what thermowood is.

MDF sanded

Sanded MDF is a board without a decorative coating. It is absolutely smooth, even, and has no internal or external defects. It is mainly purchased by furniture makers who need further processing and decoration.

Question to the expert

What are the most popular sizes and thickness of MDF?

Sanded MDF is produced in several thicknesses: from 3 to 40 mm and, depending on the manufacturer, it can have several sizes: 2440*1830, 2800*2070, 2750*1830, 2620*2070 and others.

MDF is painted and milled (for the production of relief facades). For these purposes, only first-grade MDF is purchased, otherwise any coating on a slab of the worst grade will lie unevenly, with flaws, forming a generally uneven surface.

MDF polished.

Wall panels are usually made from thin MDF boards and are used as the basis for laminated parquet. The use of MDF boards is very common in the production of doors, railings, platbands, staircases, commercial equipment, advertising signs and various exhibition structures.

In addition, MDF board is used as an additional material: for leveling walls, as a substrate for other floor coverings, for invisible parts in furniture production, and partitions. For these purposes, second-grade MDF is suitable, which does not require a perfectly flat surface of the board and the price per MDF sheet will be much cheaper.

MDF painted

This is grade 1 sanded MDF, painted in various decors at the production stage. It is usually used in the production of facades for cabinet furniture. Due to the use of paint, MDF becomes more resistant to high temperatures, moisture, and exposure to the sun.

MDF painted.

MDF veneered

It consists of polished MDF boards of the 1st grade, decorated with veneer - a natural material made from wood. Veneer is a very thin layer of wood glued onto an MDF board, and then covered with a special furniture varnish in several layers. Veneered MDF is a board that can replace products made from natural wood both in terms of its technological, consumer and aesthetic indicators, and in terms of pricing policy in relation to natural wood. These types of boards are also used in the production of furniture and interior decoration. Products made from veneered MDF are very similar to products made from natural wood; they have the same properties, and in addition, many others that products made from natural wood do not have.

Typically, an MDF board is covered with veneer, the thickness of which is 0.6 mm. When talking about the actual thickness of veneered MDF, we mean the thickness of the veneer and the board itself. There are more than 20 colors of veneered MDF: beech, cherry, oak, wenge, etc. The range of board thicknesses ranges from thin - 4 mm to thick - 39 mm. Depending on the quality of the veneer, there is a standard designation for veneered MDF, where A, B, D indicate the sides of the board:

- A/A – high-grade veneer is used, two sides are veneered,

- A/B – high grade veneer is used on one side, lower grade veneer is used on the other side of the board,

- A/G – on side A, high-grade veneer is used, and on the other side, cardboard or stretching made from veneer of any wood species is applied.

MDF veneered.

MDF laminated

This is grade 1 sanded MDF, made from wood fibers, which is covered with film under high pressure. Thanks to the high technology of the production process, today MDF boards have achieved low emission of formaldehyde E1, which meets the international standard. Laminated MDF is more durable, and a huge number of different colors and surface textures satisfy the tastes of a huge number of consumers and make the board a popular material in furniture production.

Single-sided and double-sided laminated white MDF is especially popular. It usually comes in thicknesses of 16mm and 19mm. Single-sided laminated MDF is produced with only one side coated and double-sided, where two sides of the board are laminated. Laminated MDF can be plain (white, gray, etc.), as well as imitating wood (beech, alder, cherry and other species, including expensive ones).

Laminated MDF is a durable material that has sufficient durability due to the laminated surface. In addition, it is quite durable in everyday life, is resistant to various chemicals, and is easy to care for and process. It is also devoid of such disadvantages of natural wood as cracking, warping, its physical and mechanical properties are several times superior to wood, and its cost is almost several times cheaper. All this allows the use of laminated MDF for interior decoration and the production of furniture facades.

MDF laminated.

Characteristics of MDF boards

In appearance, the material has a brown tint interspersed with gray. The color depends on what wood they were made from. By its structure, MDF has a fine-fiber structure, therefore, during processes associated with cutting or milling, a significant amount of dust is generated.

Most often, this material is used to construct lightweight partitions or to create smooth wall surfaces. However, the slabs can be brought into an attractive state using lamination or painting. Thanks to this, the use of MDF is possible both in the construction field and in many others. You can make furniture or kitchen doors.

Thanks to manufacturing technology, it is possible to create material of various densities and sizes. The density of MDF can vary from 760 to 1100 kg/m3. The lower the density, the less load on the material should be, this could be the furniture industry or finishing the ceiling and walls.

High-density products can be used for floor finishing. Due to its properties, the material has increased abrasion resistance, which explains its popularity among builders and furniture makers.

The thickness of the material can vary from 3 to 40 mm, the width is 2800 mm, and the length can be 1250 or 2170 mm. Thus, you can easily select the MDF that is the right size for you and reduce costs. Also, the weight of the panels can be completely different, it depends on the shape and thickness of the material.

According to GOST, deviations for MDF boards should be insignificant, for example:

- thickness deviation is no more than 0.2 mm;

- deviation in length is no more than 5 mm;

- The difference in width is no more than 2 mm.

By following GOST for the manufacture of MDF, it is possible to produce high-quality products that should not create problems during installation or manufacture of furniture. Therefore, when joining the plates, the difference will be either completely noticeable or absent altogether. This allows for quick installation work.

GOST 32274-2013 Monostructural wood boards. Specifications

1 file 157.50 KB

Solid or MDF – which is better?

To figure out what is better than MDF or solid wood, you need to look at each of these materials from the outside and draw the appropriate conclusions. First, let's evaluate all the advantages and disadvantages. The main feature of MDF board is its homogeneous composition. Thanks to it, manufacturers can create various products of any shape with proper processing of the material. It is considered the most diverse material used for facades. Many people choose MDF to furnish their kitchens, but what is the reason for this?

What is solid wood?

Let's take a closer look at the advantages:

- similarity to natural materials;

- safety and environmental friendliness. MDF products do not emit toxic substances and fumes harmful to humans;

- has impressive advantages and external data at a low price. Many consumers are limited by a certain budget and cannot afford expensive furniture, and MDF in this case is the best option.

- quite long service life. OVER a long period of use, the material does not undergo any serious changes that would significantly worsen its external condition.

- possibility of fine processing. This fact is useful in the production of modern kitchen models, which is why consumers in most cases choose such furniture for the kitchen.

Solid wood is also popular in furniture production. Of course, this is sometimes a capricious material that requires special care, but this will not overshadow all the advantages and advantages. This is the highest class of quality. But some, due to tenderness, do not want to take such furniture for themselves. All this is due to the fact that, for example, you can’t put a hot mug of tea on oak furniture, and it’s even worse with smokers. Wood absorbs everything you breathe, including smoke. Subsequently, you can see on the surface what is possibly happening inside the smoker.

Solid or MDF.

If you are not a neat person and do not want to take care of your furniture, although any item requires care, then it is better not to look at solid wood furniture. And those who have chosen this excellent option and take care of it from time to time, wipe the surface, treat it with oils, and subsequently enjoy beautiful products that fit perfectly into the interior of the room and give unforgettable emotions to everyone who sees this beauty.

Let us highlight the advantages that allow solid wood furniture to lead over its competitors:

- environmental friendliness. Furniture made from this material is 100% guaranteed not to harm your health, because it is essentially natural wood with a beautiful finish. There are no toxic impurities or other nasty things in it!

- practicality. Although we touched on the topic of constant care, by its nature solid wood, unlike the familiar chipboard and MDF, tolerates moisture much better and is resistant to rotting. And the use of protective coatings and care products will improve the effect several times more. For example, by covering a table with polyurethane varnish, you can even allow yourself to place a hot object on it.

- aesthetics and combination with the interior. When talking about the similarity of MDF to natural wood, we were talking about similarity or imitation, but nothing more. Natural wood has always been the standard of beauty and fits perfectly into a variety of room designs, adding special charm and luxury to it.

- indescribable energy. In addition to the fact that real wood furniture gives coziness and comfort, it also creates an extremely positive atmosphere and fills it with special energy. Every owner of solid wood furniture will confirm this fact and sign every word.

When it comes to purchasing, the question arises: what is better solid wood or MDF for the kitchen. There cannot be a definite answer here, since everyone has their own needs, tastes and preferences. Unusual and interesting options are made from MDF, which most people like better than from solid wood. The choice should be made taking into account the many facts that we described above, and you also need to approach the issue taking into account your financial situation. MDF is a great alternative to real wood, but investing in real wood furniture is not just a practical and eco-friendly choice for people who appreciate nature's graceful simplicity. It is also an investment in the health and harmony of your family.

Types of MDF finishing.

Types of MDF panels

There is no generally accepted unified classification of MDF panels: they differ in the processing method and purpose. But depending on the finish, several large categories of material can be distinguished.

Laminated MDF

A thin PVC film is applied to the front side of the slab, as a result of which it resembles a classic laminate. Contrary to popular belief, the surface of the film is not necessarily glossy: it can be matte or satin. Textured film easily imitates the texture of wood or even natural stone.

To ensure that the PVC layer does not move away from the base, it is also glued under pressure. This gives the slab additional strength, moisture resistance, resistance to ultraviolet radiation, detergents and other chemicals.

Painted MDF

To paint MDF boards, special protective paints and enamels are used, which simultaneously improve aesthetic and performance characteristics. Plastic fluid compositions are applied manually or automatically. Although finished boards are less durable than laminated boards, coloring is still widely used in interior design and furniture making.

Milled MDF

Processing the pressed fabric on milling machines allows you to give the necessary texture and relief. This is especially valuable if you need an imitation of natural materials from MDF. Modern technologies make it possible to achieve such precision that it is impossible to distinguish a slab from a valuable rock at first glance.

Veneered MDF

Thin veneer is glued to the base of the board, like PVC film during lamination. But unlike polymer film, it is a thin fragment of natural valuable wood. This is a rather expensive type of MDF board, but it is the most presentable and noble, so it will fit even into luxurious classic interiors.

Glossy MDF

Glossy MDF furniture is very popular, and there are several technologies for its manufacture. In addition to lamination, polyester coating or special acrylic primers are used. Acrylic is the most expensive, but the most effective, and its surface is perfectly smooth, almost mirror-like and scratch-resistant.

Flexible MDF

MDF is a fairly flexible material, unlike other chipboard and wood-fiber analogues. The manufacturer takes care of this at the manufacturing stage, so the slabs do not require additional processing. Flexible panels can be single-layer and immediately glued to the frame, or double-layer and connected to each other.

MDF panels

MDF (Medium Density Fiberboard) is a popular finishing material, medium-hard chipboard. An analogue of fiberboard, with the only difference that MDF has a higher density (600-1200 kg/m3). Manufactured by hot pressing. The essence of the technology is that lignin fibers present in wood shavings become plastic under the influence of high temperatures and adhere tightly to each other. This ensures the strength of the material. In the production of panels, urea resins modified by melanin are used.

The first MDF panels appeared in 1966 in the USA. In Russia they became known only in 1997. At the moment, China is the leader in sales volume among manufacturers by a large margin.

A little theory about the material

- The abbreviation MDF stands for Medium Density Fiberboard and in translation means “medium density fiberboard.” In short, MDF is a material made from compressed sawdust, “bound” with resins.

- It is more correct to call MDF kitchens “kitchens with MDF facades”, because its frame, shelves and walls are most often made of laminated chipboard and less often - of plywood and MDF;

Why is MDF better than chipboard and wood?

- Variability of finishing and design (compared to chipboard). The MDF base can be: painted, enameled (matte/glossy enamel), covered with plastic film, veneer, patina (pictured below) and can even have a concave/convex shape and milling;

- Higher wear, heat and moisture resistance, tolerance to external influences. Wooden facades can be scratched, dry out, or crack over time, and fasteners in chipboard doors “loose” faster;

- Cheaper than wood.

Why are MDF facades worse than wooden and “chipboard” facades?

- MDF is more expensive than chipboard and weighs more, so cabinets are rarely made from it;

- MDF is less noble and durable. Wood is environmentally friendly, holds fasteners longer and is subject to restoration.

The service life of an MDF kitchen is on average 10 years or more if used carefully.