Refueling options

Statistics say that any climate-class product during operation loses 8% of the initial charge per year, so once every 2 years it is necessary to fill the split system with freon.

Whether you will do this yourself or invite a specialist is a separate issue. The air conditioner needs to be recharged, and if it produces a temperature slightly lower than what you set on the display, the pressure must be constant inside the system and the amount of refrigerant plays a major role. There are two main methods for refilling an air conditioner with freon.

- According to the degree of pressure

. To determine the amount of volatile gas for refilling, you need to know the optimal pressure indicated in the operating instructions, compare it with the pressure in the air conditioning system, which is indicated by the connected manifold. As a rule, this method of refilling the air conditioner by pressure is carried out when freon leaks due to long-term operation. - By weight

. The method is used when completely replacing the refrigerant - first it is pumped out of the system, and then, using electronic scales, knowing the weight of the gas pumped into the cylinder, the split system is filled with freon.

There is a method using a measuring glass, but it is used to fill the air conditioner with refrigerant very rarely, only after repairs have been carried out. If the presence of air bubbles is detected in a special viewing window, freon is not pumped in until they disappear from the system.

Methods for controlling the amount of freon

When figuring out how to charge a split system with freon yourself, you should remember that the amount of refrigerant should be sufficient, but not excessive. If there is too much gas in the circuit, the operation of the device will be seriously impaired, since the refrigerant simply will not have time to evaporate. This can seriously damage the compressor.

This situation is worse for the device than if the system is missing a few grams of refrigerant. Therefore, during refueling, it is necessary to organize control of the amount of freon entering the system.

They do this in the following ways:

- by measuring the change in mass of the refrigerant cylinder;

- taking into account the pressure in the system, which must reach a certain level;

- assessing the condition of the circuit through the sight glass;

- taking into account the temperature change at the indoor unit fan.

The easiest way to control the amount of freon is to record changes in the weight of the cylinder. To do this, before refilling, place the container with the refrigerant on the scale, reset the result and observe the change in indicators when the cylinder tap is open.

As soon as its weight decreases by the required amount, refueling is stopped immediately. Of course, this method is only used to completely charge the circuit. If you just need to top up the system, you first need to find out the weight of the refrigerant that is already inside, but this is difficult to do at home.

How to find out how much freon should be in a split system?

Currently, there are several types of freon or refrigerant. In the system, this gaseous substance is not only a working element of air conditioning, but also a kind of lubricant for the compressor, which is found in any installation.

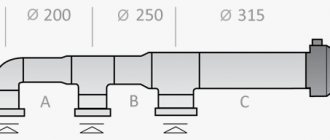

Any split installation consists of two blocks. One is always installed outside the room, and the other inside it. A cold line runs from one compartment to another, through which freon directly circulates, as well as an electrical cable and a drainage system. To lay the route for freon, only tubes with a small cross-section in diameter, made of copper, are used.

The amount of freon in the split system directly depends on the length of the route for a given gaseous substance, as well as on the power consumption of the compressor. For example, the standard route for an air conditioner is up to 5 meters long. Even if you purchase a new system, by increasing the length of the freon pipeline, you will have to refill it into the system itself. That is why there is no single value for all systems that could be used to guide their refueling or full refueling.

Directly at the manufacturer's factory, the installation itself is usually charged taking into account the available length of the route. It is worth noting that in air conditioning systems the length of copper pipelines is not less than 3 meters.

Thus, it turns out that for every meter of copper route at the factory, 0.15 kg of refrigerant is charged into the system. Plus, the power indicator of the built-in compressor is added to this mass. If we take the parameters in general terms, it turns out that a powerful installation contains about 0.5 kg of freon.

Naturally, over time, freon gradually evaporates in each installation. This process is accelerated if errors were made during the installation of the system and the joints of the pipelines, or rather their connection, were performed poorly, and the gas gradually evaporated through the gaps left. Of course, in these cases, before starting a new refueling or refueling, it is necessary to eliminate all existing flaws in the system.

Freon quantity for refilling

About how much refrigerant needs to be charged into the installation and how much freon is there - these data are usually indicated by the manufacturer. They are indicated on a metal plate, and the plate itself, or in other words the nameplate, is always located on the internal housing of the split system. Refueling of the air conditioner is carried out taking into account the indicators indicated there.

The amount of gas that needs to be added to the air conditioner is usually calculated using a device such as a pressure gauge. Using it, the pressure value in the cooling circuit is determined.

How to find out if the amount of freon is insufficient

Every owner should know how to find out that there is not enough refrigerant in the system, this will help to refill it in time. The following factors usually indicate this:

- The air conditioner has become much weaker in cooling the air in the room, even if it operates at maximum mode.

- The installation completely stopped cooling the air in the room.

- Frost has appeared at the junctions of the cold pipes and valves, which is visible to the naked eye.

These are the most basic facts that directly indicate that there is not enough refrigerant in the installation. Before you begin to determine the amount of refrigerant in the air conditioner for refilling or completely refilling it yourself, you need to find out what kind of gaseous substance was charged into it. Currently, several types of freon of different brands are used for split systems.

The very first air conditioners and indoor air conditioning systems were charged with R-22 freon. At the same time, the freon pressure in the air conditioner at an outside temperature of up to 30 degrees is 4.5 bar. Subsequently, scientists found that this gas has a very negative effect on the earth’s ozone layer. In addition, with a sharp drop in temperature, the system with such a refrigerant became very inefficient in operation.

Subsequently, new models of air conditioners and units began to be filled with more modern refrigerants, which were also completely safe to operate and did not in any way aggravate the state of the ozone layer of the atmosphere. So, today you are unlikely to find at least one installation operating on this gaseous substance.

Of course, service companies know many nuances and various factors that should be taken into account when filling the system with freon. But if you plan to do this work on your own, then you will certainly benefit from their experience and knowledge.

Main advantages and disadvantages

Modern refrigerant R-410A belongs to the group of specific hydrofluorocarbons. Its composition is considered by world organizations as ozone-safe. Regarding the minimum temperature glide, this parameter is equal to 0.15 K, due to which it is included in the category of single-component refrigerants. The wide range of applications of R-410A freon is due to the fact that it has multiple advantages:

- If gas has escaped from the vessel due to a breakdown, it can be easily replenished without losing the quality of the refrigerant itself.

- Wider horizons are opening up for manufacturers in the field of reducing energy consumption of equipment.

- There is no need to install a powerful, expensive compressor, since the heat exchanger has a high level of specific cooling capacity.

- The efficiency of the systems has increased significantly, since R-410A freon has low viscosity and good thermal conductivity.

There are not so many negative aspects, but all of them must be taken into account not only by experienced craftsmen, but also by ordinary users who use household appliances with freon. The main disadvantages include the following:

- Due to the pressure difference in relation to the discharge and suction of freon, the efficiency level of the compressor may be reduced.

- Professionals note rapid wear of bearings, which is caused by high operating pressure in the system.

- The use of freon affects the fact that the housing of household appliances must have increased tightness. The final wall thickness of the copper pipes of the working line should be greater than for the usual R22 refrigerant. The minimum value should be within 0.9 mm. It is worth noting that a large percentage of copper content leads to a significant increase in the cost of the operating system.

- Air conditioners use high-quality polyester oil, which is much more expensive than mineral oil.

- This type of refrigerant is incompatible with elements of climate control equipment. The rule applies to those parts that are made of elastomers and materials sensitive to pentafluoroethane and difluoromethane.

How to check freon in an air conditioner

First, let's look at how to measure pressure in an air conditioning system. For this purpose, a certain device is used, available to every refrigeration technician, called a manometric manifold.

It consists of 2 pressure gauges with separate tubes of different colors (as a rule), mounted on a common manifold with valves.

To carry out measurements, it is necessary to connect the tube from each pressure gauge to the service fittings located on the side panel of the outdoor unit of the air conditioner. They are not difficult to find: fittings are valves to which the main freon pipes are connected. After this, you need to start the split system in cooling mode and open the valves. One sensor connected to the low pressure pipe will show its value before entering the compressor. The second is at the output of the capacitor, and these numbers may differ.

Moreover, this parameter fluctuates depending on the ambient temperature and indoor air. On the Internet you can find advice that you need to focus on the data printed on a metal plate, as in the photo:

The air conditioner plates indicate not the operating pressure, but the maximum (discharge) and minimum (suction) pressure, so you cannot rely on it when taking measurements. The readings on your pressure gauges will still not match these data.

Now a little theory about the operation of the air conditioning system. Freon R410 or R22, which is used to fill modern split systems, is located in a closed volume. If the ambient temperature increases, more refrigerant evaporates, and accordingly, the pressure in the air conditioner line begins to increase. And vice versa, when it decreases, more freon is in a liquid aggregate state and the pressure drops. What conclusion can be drawn from the above?

The dependence on external temperature and the properties of the refrigerant itself does not allow setting fixed pressure values indicating its sufficient amount in the system.

Practical observations of some split system service specialists indicate the following approximate figures. A pressure gauge connected to the air conditioner line with R410 refrigerant at an outside temperature of 25 to 30 ° C will show about 6.5 Bar, and at +15 – 5 Bar. If the unit is charged with R22 freon, then at the same ambient temperature values the sensor will show 4.5 and 3.5 Bar, respectively.

We repeat, these pressure indicators are very approximate and cannot serve as a basis for determining whether there is enough freon in the air conditioner. But what can it do? From the point of view of an ordinary user - only observing some signs. An insufficient amount of refrigerant is indicated by:

- a continuously running compressor is one of the sure signs of a shortage;

- deterioration in cooling efficiency or complete failure of this mode;

- the appearance of frost on the external heat exchanger;

- icing of valves on the external block where the main pipes are connected.

What to consider when designing a freon route

Discharge lines

In precision air conditioners (cabinet type), it often happens that the condenser is mounted above the level of the compressor. In this case, there is a risk that oil from the discharge line will flow back into the valve group. To avoid this, an oil lifting loop is installed between the condenser and the compressor (if the height difference is no more than 3 meters). If the distance is large, then it is provided every 3 m. At the same time, an oil separator is installed at the outlet of the compressor.

If we are talking about installations with controlled capacity, then two lines are provided.

Oil lifting loops

During operation of the refrigeration unit, oil accumulates in the oil lifting loop and is carried along with the refrigerant. If there are several such loops, then the oil consumption can be quite significant, due to which it becomes insufficient to lubricate the compressor. Therefore, the size of the oil lifting loops should be small, and after the first start-up of the installation, you should not forget to add the missing amount of oil to the compressor.

Thermostatic valves (TRV)

Basic requirements for a thermostatic valve:

- the distance between the expansion valve housing and the evaporator should be small;

- The thermal bulb is mounted on the suction pipeline, which allows it to be adjusted to the temperature of the gas leaving the evaporator. Its placement depends on the diameter of the pipeline;

- The thermal cylinder should not be installed on the oil lifting loop. Because the oil in it distorts real temperature readings.

The thermal cylinder is secured using special clamps supplied with the expansion valve. Other devices must not be used due to the high probability of deformation and weakening of the contact between the thermal cylinder and the pipeline. The thermal cylinder must be securely secured with a clamp.

It is best to install the thermal cylinder on a horizontal area, closer to the entrance to the evaporator. When it is installed in a vertical section, the water that is in the oil lifting loop and the lower part of the pipe begins to evaporate, thus helping to cool the suction line. Because of this, pulsations of the expansion valve often occur.

If installation on a horizontal section is not possible for technical reasons, then it must be installed so that the refrigerant flow is directed from top to bottom.

It is important to remember that under no circumstances should the thermal cylinder be located in the area where the pipeline is soldered. You also need to pay attention to ensuring that it is thoroughly thermally insulated and that the outside air does not affect the operation of the expansion valve.

The equalizing pipe of the expansion valve is mounted at a ten-centimeter distance from the thermal cylinder and the oil lifting loop.

Drainage pipeline

To install the drainage pipeline, use a plastic pipe with a diameter of 16-25 mm. It is also necessary to maintain a slope so that the condensate drains by gravity. If this slope cannot be ensured, then condensate pumps are installed. The drainage pipeline is secured to the wall using clamps. They are taken in quantities that will prevent sagging. The drainage pipe must be sealed. The use of pipes of different diameters to create it is prohibited.

Install the drainage pipeline along with the freon line and power cable. Bends are made using a flexible hose with a radius equal to at least 8 diameters. The outer end of the drainage pipe is mounted at a slope of 5 degrees, preventing its end from reaching the ground.

When discharging condensate into the sewer, a drainage system with a water seal must be installed. The use of standard siphons or sewer tees is allowed.

When the drainage pipeline is removed from the premises in winter, the outer part of the drainage pipe must be heated. For this purpose, a self-regulating heating cable is used.

To evaluate the quality of the installed pipeline, it is first purged with air, and then a certain amount of water is poured into the pan of the indoor unit or onto the evaporator. Then all the water coming from the drainage pipeline is collected and compared with the amount poured.

Freon pressure table

Freon R410a pressure parameters on the suction side

Freon R22 pressure parameters on the suction side

Indoor temperature readings are for dry/wet bulb

But remember that high-quality diagnostics can only be carried out by a specialist who can not only connect a pressure gauge station to the required valve, but also has a good understanding of the structure and specifics of the refrigeration cycle. Many people, without possessing these skills and knowledge, as well as additional tools, such as a clamp tester, draw conclusions about the lack of freon only by the pressure in the system. Very often (especially in cold weather) this leads to the appearance of excess pressure and, subsequently, the death of the compressor.

All household split systems are supplied with refrigerant already pumped into them. If it suddenly turns out that there is a leak, then before refueling, you must find the cause of the leak, eliminate it, and only then refuel. Otherwise, the work will be done in vain and everything will happen again.

Freon R22 - consists of one component, therefore it is easier to use for refilling air conditioners in case of leakage. It can be pumped into the system without the use of electronic scales, using only a pressure gauge station and an electronic thermometer. Since freon R22 is recognized as harmful to the environment and the ozone layer, its use is gradually being phased out. In the European Union countries, this type of refrigerant has been banned since 2010. At the moment, household air conditioners are supplied to the Russian Federation only using the safer and more modern R410A freon, and in the near future equipment will begin to be supplied using the new R32 freon.

Attention: systems operating on R410 freon can be refueled only in very rare cases, and only a competent specialist can determine this. Mostly, refilling with R410a freon occurs when the length of the freon line is increased during installation, and is done by adding refrigerant strictly by weight for each meter of line that exceeds the standard, the weight is indicated in the installation instructions for the system

In cases of R410a freon leakage, air conditioners should be refilled by weight, having first removed all old freon from the system. This is due to the fact that R410a consists of two components, and in the event of a leak, one component, having a higher density, squeezes out the other, disturbing the proportion of the components, as a result of which the refrigerant loses its thermodynamic properties.

Refilling process with freon R410a.

If the “air conditioner” simply “threw” a pressure gauge unit onto the service valve and started filling the air conditioner with R410a freon without electronic scales, you should know that the result will be a call to another technician, and possibly a failure of the system.

Refilling the air conditioner is a very responsible procedure that can only be entrusted to a qualified specialist!

If you want to carry out professional diagnostics and refueling of your air conditioner, I recommend contacting our partner, who kindly provides a 15% discount on all work and materials to any buyer of our store*

*Affiliate discount is provided based on the purchase invoice

freon pressure table r22; freon pressure table r410; freon pressure table R407; freon pressure table R32

Source

How to charge an air conditioner with freon?

Before refilling the air conditioner, you need to prepare the necessary devices and tools, such as a freon cylinder, scales, manifold, thermometer, vacuum pump, etc.

In general, the procedure for refueling a split system on a scale is as follows:

- First, the radiator blocks must be cleaned of dust to ensure proper operation of the fans.

- Remove the cap from the large tube on the outdoor unit.

- Connect this outlet to the manifold hose.

- Place a container with freon on the scale.

- Set the scale to zero and turn on the tare weight measurement mode.

- Attach a vacuum pump to the circuit to pump out the remaining old freon, moisture, dirt, air, etc. from the system.

- Connect a container with freon to the circuit.

- Open the valve and observe the scale readings.

- Close the valve and disconnect the container from the air conditioner.

- Disconnect the hose and close the hole with the cap.

- Check the system operation.

When refueling with temperature measurement, you need to set the average mode for the indoor unit fan and run the device in cooling mode to a temperature of 18°C. Record the temperature readings and data from the pressure gauge.

You can use a manifold with two or four positions, the latter is preferable since after evacuation you will not have to reconnect the hose intended for additional equipment

If the outside temperature is 25°C, then the normal pressure level in the circuit should be 4.2-5 bar.

When the pressure reaches its maximum, the air temperature is measured again.

After the cylinder is installed on the scale and its valve is open, you should immediately and just for a second open the liquid valve of the manifold to bleed the air lock

It should drop noticeably. At this point, open the pressure gauge for about 10 seconds and then continue to pump refrigerant into the system to the maximum pressure level.

After the initial air temperature drops by 12-14°C, refueling can be considered complete and testing of the system can begin.

A vacuum pump intended for this type of work must have a pressure gauge as well as a check valve to prevent oil particles from entering the circuit

To check how well the device works after refueling, it is recommended to turn it on and switch it to the minimum cooling mode. If after about a quarter of an hour the pipes begin to freeze, it means that there is too little refrigerant in the system, you should add a little freon. If the pipes are in order, the procedure can be considered successfully completed.

Preparing to refill the air conditioner with freon

You can’t just take a bottle of refrigerant, attach it to a pipe and let a certain amount into the system; first you need to prepare the air conditioner for charging with freon. If freon flows out unnaturally quickly, the housing is most likely depressurized.

Leakage may occur at the junction of the copper tube with the outdoor unit due to improper installation and damage to the flared edge

You need to find out the cause, eliminate it, and only then let a new portion of gas into the system. The tightness of the circuit is also checked when it is necessary to replenish the refrigerant lost during operation. Very often, a leak occurs after inept installation.

Refueling rules

In order to perform refueling yourself and without damaging the device, you must adhere to certain rules.

- One of the easiest and safest methods of refueling is the weight method. All necessary information is indicated on a plate attached to the device body. New external units do not require refueling if the length of the pipelines is not greater than that specified by the manufacturer.

- Split systems that have been in operation for a long time and have been dismantled need to be refilled with only 10% of the total mass of refrigerant. This information is again indicated on the nameplate.

- Sometimes, if the piping is not installed or connected correctly, the amount of refrigerant in the appliance may be low. And to correct the situation, you need to release all the freon present in the device outside, trying to keep the oil inside the compressor. To do this, the valve through which the filling occurs is slightly opened. Within a few hours, all the freon will leave the system. If the oil begins to flow out along with the gas, then you need to open the valve even less. When all the refrigerant has been released, you can refill with new freon.

Refueling instructions

If you want everything to be done correctly, you must strictly adhere to certain nuances. First, let's look at the points that need to be taken into account.

Basic moments

- First of all, it is necessary to understand why the refrigerant leaks. We have already described this in detail earlier in the article. You need to get rid of leaks so that they don’t bother you in the future.

- Next, you should immediately decide whether you need to carry out the procedure of vacuuming the entire air conditioning system or whether this can be avoided. In the event that you plan to replace the consumable completely, in any case it is necessary to evacuate the system. Thanks to this process, you can rid the air conditioning system of condensation, which often collects in pipes and hoses. Thanks to evacuation, it is possible to increase the operating efficiency of the device and increase the service life of the compressor.

- In addition, you need to decide directly on the brand of refrigerant. The choice of brand is carried out in accordance with the model of air conditioners and the manufacturer’s instructions. If there are no instructions, check this point with the dealer or in the service book. The same applies to oil - it must correspond and be suitable for a specific brand of air conditioner. It is advisable not to miss these points, otherwise you may encounter other problems, for example, lack of pressure in the system.

- Another point - if you plan to completely replace the refrigerant, then first of all you need to make sure that the hoses inside are clean. If the pipes are dirty, replacing the working fluid will not solve old and new problems that may be associated with ineffective operation of the device. In particular, we are talking about a lack of pressure, as a result of which the cold flow will be too weak (video author - RealStuntDriver).

Algorithm of actions

What is the algorithm for refueling the device:

First of all, it is necessary to remove the cap from the main line, which is responsible for the low pressure level in the system. This way you can relieve the pressure. In addition, it is advisable to clean this place, since its cleanliness is very important. If dirt or dust gets into it, this can cause the compressor to fail. After these steps, you can put the pipe on a special fitting for refilling. Next, start the vehicle engine and let it run for a while. During operation, the engine speed should remain around 1500, but not less. Then you need to turn on the air conditioner itself, it must operate in recirculation mode, you must activate the highest power. After these steps, it is necessary to open the valve with a low pressure level, at the same time the tap on the refrigerant bottle opens, this tap must be turned down. When you have been able to release the pressure, refueling is carried out. In this case, the engine cannot be turned off, since according to the standard, refueling is carried out with the internal combustion engine running. During refueling, you must carefully monitor what indicators the pressure gauge gives; pressure is a very important parameter.

It is important that the pressure level is no more than 285 kPa. After some time, you may notice that the vehicle interior begins to fill with cold air flow. It is important not to turn off the tap too early

The tap is closed at the moment when the temperature of the air flow leaving the air ducts is about 5-8 degrees. Now it is important to evaluate the correctness of the entire refueling procedure. This process can be considered correctly completed if there is a clear liquid on the filter element that is free of bubbles. If the liquid is not clear or has bubbles, it means the system has not been cleaned properly or you have made some mistakes in the process. To do everything correctly, you can repeat the procedure again.

If, after refueling, you notice any problems in the operation of the car air conditioner, then this indicates that something was done incorrectly. In this case, to solve the problem, it is advisable to seek help from specialists.

How to check the freon balance in a split system

You can determine the lack or excess of refrigerant in the split system circuit by the amount of overheating of the gas coming from the evaporator to the compressor. Let's explain this concept:

- the refrigerant evaporated in the internal heat exchanger moves through the low pressure pipe into the compressor;

- on the way, the steam has time to additionally heat up by 5-8 ° C (if the amount of freon corresponds to the norm);

- The difference between the boiling point of the liquid and the actual gas temperature at the compressor suction pipe is called superheat.

Location of the split system service ports and connection of the pressure gauge station

To work, you will need a pressure gauge station with connecting hoses and a contact thermometer (an electronic pyrometer will also work). We diagnose freon residue according to the following instructions:

- Find out the type of refrigerant used in the air conditioner by looking at the nameplate attached to the external module.

- Connect the blue hose leading to the low pressure gauge (abbreviated as LP), located on the left of the manifold, to the service port of the gas line, as done above in the photo. It has a large diameter.

- Turn on the split system for cooling with the fan operating at maximum speed. Open the left tap of the pressure gauge station.

- Take readings only after the compressor has started. The sound of the operating unit can be clearly heard from the external unit.

- Find out the boiling point of your brand of freon at the measured pressure, using the table as a guide.

- Using a thermometer, measure the actual heating of the gas tube on the suction side. Calculate the difference between this temperature and the boiling point table.

- Proceed to analyze the result.

Using a thermometer, the heating of the large diameter gas pipe coming from the indoor unit to the compressor is determined

Let's look at the example shown in the photo. The arrow shows 5.4 Bar, which corresponds to the boiling point of freon R22 +8 °C. We measure the temperature of the suction pipe and get, for example, +14 degrees, the amount of overheating will be 14 - 8 = 6 degrees. The permissible range for all types of air conditioners, including automobiles, is 5-8 ° C, which means that the amount of freon is normal.

Signs of freon shortage in a split system

If, as a result of the measurements, you get steam overheating of more than 8 degrees, there is a lack of freon in the split system circuit. What happens in the air conditioner:

- The liquid boils in the first section of the evaporator and turns into a gaseous state. The steam, having passed through the heat exchanger tubes and the section of the line to the compressor, manages to heat up very much.

- Constantly sucking in hot gas, the compressor unit is poorly cooled and begins to overheat, reducing the service life of the mechanism.

- Cold performance is noticeably reduced. On average, 1 kg of refrigerant is capable of absorbing and transferring 50 W of heat - the lower the freon consumption in the circuit elements, the weaker the air is cooled.

When a refrigerant leaks, traces of oil appear at the joints, not noticeable at first glance.

A lack of refrigerant is accompanied by other side symptoms:

- at the command of the sensors, the split system often turns off and displays an error;

- the compressor operates for a long time at maximum mode;

- the tubes and service ports become covered with frost; in advanced cases, a snow “coat” grows on the evaporator fins.

Identical symptoms appear on car air conditioners, since they operate on a similar principle.

Oversupply and other problems in the split system

Was the overheating value less than 5 degrees? This means that there is too much fluid circulating in the system. Some of the substance does not have time to evaporate in the heat exchanger of the indoor unit; individual drops may fall into the compressor, and this can lead to major damage.

If you are confident in your abilities, try to remove some of the freon yourself. Using the pressure gauge on the manifold or the table, determine what pressure should be in the air conditioner at normal superheat of +7 °C and carefully bleed off a small portion of the gas.

Abnormally high or low superheat occurs not only due to the refrigerant, but also to various faults:

- the capillary tube of the throttle valve is clogged;

- Compressor or dryer problems;

- The four-way solenoid valve that reverses the cycle (cooling/heating modes) is faulty.

It is better to entrust the diagnosis and troubleshooting of car air conditioning to a service station technician.

These problems can be solved in one way - by calling a technician; an ignorant user simply will not be able to diagnose them. If manipulations with the freon do not produce results, call customer service.

Methods for refilling air conditioners

First of all, the master will need freon, equipment and tools. He must have:

If a difficult path to the goal is chosen, the presence of electronic scales, a refrigerant evacuation station, and a vacuum pump will be required. There are several ways to charge the climate control system with freon. A simple option does not make it possible to answer the question of how to determine the amount of freon in the air conditioner absolutely accurately, but it will help to understand what problem has arisen - a lack or excess of freon in the system. Or it is absent, since everything is normal.

Filling by temperature and pressure

As already noted, the method of determination by pressure alone cannot be considered reliable. As a rule, it is used by specialists who are already able to determine the quantity by eye; for them the only guideline is the pressure.

The first step is to make sure that there are no leaks. Otherwise, time and effort will be wasted. The refrigerant refilling procedure itself consists of several successive steps.

- The pressure gauge hose of the LP valve (on the left on the manifold) is connected to the service port, the middle tube, which is yellow, is connected to the gas cylinder.

- Then open the reservoir valve, blow out the hoses, briefly opening the high-pressure tap; it is located on the right side of the manifold.

- The freon cylinder is placed on the scale, then the readings are reset to zero. If R-410a is to be poured, then the container is placed upside down before starting the operation.

- The air conditioner is turned on for cooling, the cap is unscrewed from the service valve, then it is opened. Then turn off the LP tap so that freon comes out in small portions (about 30 g). The filling is controlled using electronic scales.

- After each portion, turn off the tap, then measure the temperature of the gas pipe for one to two minutes. If necessary, serve the next portion. The task in this case is to reduce the temperature to the ideal - to 5-8°.

After refueling is completed, close the taps in turn: first the manifold, then the service port and the cylinder.

Filling with refrigerant by weight

Experienced technicians can quickly determine the remaining refrigerant and then charge it into the system with amazing accuracy. This method is not available for beginners. For them, the best way is to get rid of the old gas and refill with a new, fresh portion of freon. However, before refilling, it is necessary to find out the cause of the loss of refrigerant and then eliminate it. The ideal method is pressure testing with nitrogen, which is pumped under the maximum pressure possible for a particular air conditioner (25-30 bar).

- First, drain the old refrigerant: either unscrew the tube, or get rid of the gas through the service port by opening both taps. To avoid depriving the circuit of oil, the operation is done slowly.

- After completing the first stage, the taps are closed. Then connect the blue (left) LP hose of the pressure gauge station to the service port, make sure that its valves are also closed.

- The yellow hose is connected to the vacuum pump, then the unit is turned on, the LP valve and service port valves are opened. Monitor the vacuum gauge: its needle should drop to -5 bar.

- Vacuuming is continued for about 20 minutes. After completing this segment, the pump is turned off, but the pressure gauge readings are monitored for another half hour. A leak is confirmed when the needle begins to move towards zero.

- The hose from the pump is connected to the cylinder, and the left valve of the station is closed. Then open the tank tap a few times, blowing out the hose. To do this, open the right manifold valve (high pressure) for a second.

- Place the cylinder on the scale (bottom up, if R-410a), and reset the readings. After this, the left valve of the station is opened again, starting to track the decrease in the weight of the cylinder on the display.

When the display confirms that the container has lost the required amount of freon, the tap is closed. The taps at the service ports are closed, the pipe is disconnected and they begin to check the functionality of the split system.

How to determine the amount of freon in an air conditioner? It cannot be said that these procedures are elementary, but the operation with a manometric manifold and thermometer cannot be called super complex either. If you don’t have confidence in your abilities, then it’s better to first try to “find” it. Maybe your search will end after watching the following video:

Was this article helpful? We want to improve. Thanks for your opinion!

Freon-free air conditioner

In Ukraine, a group of engineers from the Air Technology Center created a climate system that has no analogues on the world market. An air conditioner in which air is the refrigerant is much cheaper in terms of energy costs, while air is the most accessible substance. Compared to conventional household systems that circulate air from the room through themselves, the VCS - air climate system - is capable of constantly ventilating rooms. This makes it possible to install such a system in large centers - sports, entertainment, for which there are special standards for the amount of fresh air per hour per person.

The temperatures at which the device is capable of operating range from minus 50 degrees to plus 50. In winter, in heating mode, the system removes cold air into the atmosphere. In summer, warm masses are used to simultaneously heat water in the pool and showers for free. This reduces costs by 3–4 times.

Advantages of VKS:

- quick installation;

- cheap repairs;

- small dimensions and weight of the structure;

- the required temperature is achieved in the shortest possible time;

- the quality of the system does not depend on the ambient temperature.

The air conditioning unit allows you to take into account all standards of indoor air quality and its ozone safety.

Air conditioner specifications

Before starting work, you need to study the technical characteristics of the air conditioner passport and the instructions that come with it. If these documents are lost, you should definitely pay attention to the metal nameplate attached to the outdoor unit.

The main technical characteristics of any split system are duplicated on a metal nameplate attached to the side wall of the outdoor unit of the device

This metal plate usually contains all the basic information about that particular model. Here you can find out what brand of freon is used to fill the circuit, what the pressure in it should be, how many grams of refrigerant need to be pumped into the system, etc.

It should be remembered that the nominal pressure in the circuit depends on the brand of refrigerant, as well as on the ambient temperature. If it is too cold or hot outside, and measurements are taken using a pressure gauge, an adjustment must be made. Data on pressure changes can be found in reference books.

When testing the air conditioner after refueling, you need to turn on only the cooling mode. If you accidentally start the heating, you can flood the compressor and completely break the split system.

R-422d

Freon R422d was developed as a drop-in replacement for R22. This gas is a complete replacement for the prohibited refrigerant. Has 50% higher GWP. The ozone layer depletion potential is 0. The refrigerant contains:

- R-125 – 65.1%;

- R-134a – 31.5%;

- R-600a – 3.4%.

R422d gas mixture is compatible with mineral, alkylbenzene and polyolester oils. To replace R22, no equipment modifications are required (except for replacing the filter-drier). The refrigerant is rarely used to charge new air conditioners; it is used to replace HCFC-22 in old equipment.

Now the use of R422d is not limited, since it has zero ORP. But in the future, this mixture may be banned due to its high impact on global warming.

Car air conditioner malfunctions

The causes of breakdowns can be divided into three groups:

- technological (poor quality materials, assembly, engineering errors);

- operational (violation of operating and maintenance rules, natural wear and tear);

- external (aggressive environment and external influences).

The first reason is relatively clear, and the motorist simply cannot influence it. Marriage is marriage, no matter what the reasons are. This is the manufacturer's fault. Modern production policy must also be taken into account.

Now “disposable” materials and components are used, and the declared service life of devices rarely exceeds 5-7 years. Cause? Money! It is profitable for manufacturers that if something breaks, the consumer will buy a new one. This boosts production and generates profits. You can no longer find refrigerators or vacuum cleaners that work without repair for 30-40 years - nothing has been done “forever” for a long time.

Well, we are not able to influence production, but we will talk about the last two causes of breakdowns in detail. In order to better understand the causes of the malfunction, you need to know how the air conditioner works. Read the article: “The principle of operation of a car air conditioner.”

How to find out how much freon should be in a split system?

Currently, there are several types of freon or refrigerant. In the system, this gaseous substance is not only a working element of air conditioning, but also a kind of lubricant for the compressor, which is found in any installation.

Any split installation consists of two blocks. One is always installed outside the room, and the other inside it. A cold line runs from one compartment to another, through which freon directly circulates, as well as an electrical cable and a drainage system. To lay the route for freon, only tubes with a small cross-section in diameter, made of copper, are used.

The amount of freon in the split system directly depends on the length of the route for a given gaseous substance, as well as on the power consumption of the compressor. For example, the standard route for an air conditioner is up to 5 meters long. Even if you purchase a new system, by increasing the length of the freon pipeline, you will have to refill it into the system itself. That is why there is no single value for all systems that could be used to guide their refueling or full refueling.

Directly at the manufacturer's factory, the installation itself is usually charged taking into account the available length of the route. It is worth noting that in air conditioning systems the length of copper pipelines is not less than 3 meters.

Thus, it turns out that for every meter of copper route at the factory, 0.15 kg of refrigerant is charged into the system. Plus, the power indicator of the built-in compressor is added to this mass. If we take the parameters in general terms, it turns out that a powerful installation contains about 0.5 kg of freon.

Naturally, over time, freon gradually evaporates in each installation. This process is accelerated if errors were made during the installation of the system and the joints of the pipelines, or rather their connection, were performed poorly, and the gas gradually evaporated through the gaps left. Of course, in these cases, before starting a new refueling or refueling, it is necessary to eliminate all existing flaws in the system.

Other methods of gas injection

Since a complete replacement of gas involves certain costs, refrigeration technicians use the following methods for refilling freon into a split system:

To top up the refrigerant, it is very important to understand how much gas is left in the circuit, compressor and both heat exchangers. Only the first method gives an accurate answer: using a contact thermometer or a remote pyrometer, the real freon temperature is measured when the compressor is running and compared with the value of the desired scale (boiling point of the corresponding refrigerant) marked on the station pressure gauge.

The meter contains boiling point scales for various types of refrigerants. The current pressure indicator is 5.4 Bar, R22 freon should boil at +8 °C

If the difference between the actual temperature and the value indicated by the arrow on the scale exceeds 8 degrees, there is not enough freon in the circuit. The technician adds refrigerant in small portions and measures the temperature again. When the difference is less than 5 °C, refilling occurs - you need to bleed off excess gas.

Since the freon pressure and current in the compressor circuit depend on many factors and are constantly changing, it is impossible to accurately determine the freon balance. We do not recommend that beginners use these methods, so as not to damage the most expensive unit - the compressor.

Determining the amount of freon to refill the air conditioner

The most common way to determine the required amount of freon for refilling an air conditioner is to monitor the pressure in the cooling circuit using a pressure gauge station, which is a pair of pressure gauges for determining the refrigerant pressure at the inlet and outlet of the compressor.

With this method, the specialist performing the refueling has all the necessary information before his eyes.

In addition to pressure, the electronic pressure gauge also shows the temperature of the refrigerant at two most important points in the circuit. The amount of freon required can be determined by weighing or by measuring the temperature of the refrigerant at the same points, but a pressure gauge is still used to monitor the correct filling.

In any case, the answer to the question of how much freon is in the air conditioner can only be given by a service specialist equipped with the necessary equipment.

Application of freon

Freon is used as a refrigerant due to its physical properties - it absorbs heat during evaporation and then releases it during condensation. The operating principle is as follows: in refrigeration equipment, freon in a gaseous state is extracted (sucked out) from the evaporator using a compressor, compressed into a mechanically reduced volume (in a piston compressor in a cylinder - by a piston), with simultaneous heating and transported to the condenser. There the freon cools down to the temperature of the air around it and turns into a liquid state. Liquid freon flows through a throttling device (capillary tube or Thermostatic Valve - TEV) into the evaporator, expands due to the low pressure after the throttling device, and again turns into a gaseous state. The expansion process is accompanied by the absorption of a large amount of heat, as a result of which the walls of the evaporator (the container in which freon boils and evaporates) are cooled, lowering the air temperature inside the cooled volume.

We recommend: Do-it-yourself grouting of brickwork joints

The cycle is repeated until the temperature of the evaporator walls drops to the value set by the thermostat, after which the thermostat opens the electrical circuit of the compressor and it stops working. After some time, under the influence of various factors, the air in the refrigeration chamber heats up, and the thermostat turns on the compressor again. Freon has been used as a coolant in any refrigeration equipment and air conditioners since 1931 (before that, ammonia, which is harmful to health, was used). Also, due to its thermodynamic properties, the refrigerant is used in perfumery and medicine to create aerosols. Freon is widely used when extinguishing fires at hazardous facilities.

Refueling instructions

We bring the equipment into working condition

We install a valve on the refrigerant canister, which with a special puncture will punch a hole in the canister (when unscrewing it), opening access to the freon. We connect a hose to the valve through an adapter, which is screwed with the opposite end to the test connector. We attach another hose to the other output of the metrological station.

This is what a ready-to-use air conditioning charging system looks like

The equipment is ready for use, you can proceed directly to refueling.

Refueling steps

We find a low pressure line in the engine compartment (a larger diameter pipe in the air conditioning system), it should have a small outlet with a protective cap; Without removing the cap, carefully wipe with a rag all parts located in the immediate vicinity of the refueling point (such actions are necessary to prevent dirt from entering the system, which can damage the compressor); We remove the protective cap and in its place put on the fitting located at the end of the filling hose; We start the engine; Set the engine speed at 1500; Set the air recirculation level to maximum; Open the low pressure valve and the tap of the refrigerant cylinder, turn the cylinder over (pay attention to the pressure, it should not exceed 285 kPa); After 10–15 minutes, the temperature in the cabin will drop; when the air coming out of the blowers reaches t = 5-8°C, charging the air conditioner should be stopped (look at the filter drier - if no air bubbles are visible in it, this indicates that the operation refueling of the system was successful).

Video guide “How to refuel the air conditioner in a car with your own hands”

When performing work to refill the air conditioner with refrigerant, it is necessary to adhere to certain safety measures. Wear protective glasses and gloves when working; if freon leaks, do not inhale it, as it is harmful to the human respiratory tract.

It is not difficult to refill a car air conditioner with your own hands; the main thing is to correctly determine whether freon has evaporated normally (about 15–18% per year) or whether a section of the structure has been damaged. Be sure to undergo diagnostics before refueling.

Conclusions and useful video on the topic

This shows the process of fixing the leak and pumping freon into the refrigerator using a scale:

The general procedure for performing this type of work can be seen in the video:

Filling a refrigerator with freon is relatively easy if you have the necessary equipment and the appropriate skills. However, it is necessary to take into account a number of nuances: comply with safety requirements, identify and eliminate all faults that caused a refrigerant leak, perform final soldering efficiently, etc.

It is better for inexperienced craftsmen to first observe the work of specialists in order to learn how to perform this operation on their own.

Sources

- https://FB.ru/article/211209/freon—eto-temperatura-freona-freon-v-holodilnike

- https://oventilyacii.ru/ventilyaciya/osnovnye-harakteristiki-i-temperatura-kipeniya-freona-r-410a.html

- https://www.profholod63.ru/poleznaya_informaciya/opisanie_i_sostav_freonov/

- https://homeasking.com/chto-takoe-freon/

- https://VentingInfo.ru/konditsionery/freon

- https://otivent.com/davlenie-freona-v-kondicionere

- https://sovet-ingenera.com/tech/xolodilniki/zapravka-xolodilnika-freonom.html

How do you like the article?

Sergey Vladimirovich

Ask a Question