When installing a heating system, homeowners sometimes install radiators with bottom pipe connections that are located under the screed. For ease of replacement, maintenance and uniform heating, a bypass is installed in the wiring. The lower battery connection unit with bypass makes it possible to connect heating elements to pipelines made of different materials.

What is a bottom line knot?

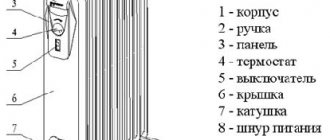

The radiator connection unit with bottom connections (“binoculars”) is an N-shaped plumbing fitting with two parallel fittings at the battery connection points, and a strong jumper between them. On one side of this element there is a fitting with a pressed-in union nut and a gasket with an internal cross-section of ¾ inch, and on the other side the fitting has a ¾ inch external thread.

A screw valve or ball valve is installed inside each input, which are designed to regulate or shut off the flow of incoming coolant; when removing radiators for their subsequent repair or replacement, shut-off properties are used.

The heating equipment for the lower connection of the radiator makes it possible to connect aluminum or steel radiators with pipe outlets at the bottom, which have an external thread. Radiators are connected to these pipes in the floor or wall using an angled or straight American N-shaped adapter.

The efficiency of connecting to heating systems from below in the case when the supply pipes pass under the floor, in rare cases, to preserve the aesthetics of the interior, and also for convenience, they are inserted into the walls at a low height - thanks to the corner fittings, the pipes can be connected to the body of the heating radiators.

In addition to control and shut-off valves, in order to increase operating efficiency, external and internal bypasses are often introduced into valve connecting units, and thermostats are used to stabilize the temperature regime.

What is a bypass in a water supply and heating system? This part is an ordinary jumper, thanks to which the coolant can move freely along the line, bypassing any equipment.

Aluminum heating radiators Rifar with bottom connection

| Rifar Alum 350 Ventil VR 4 sections RUR 4,957 | Rifar Alum 350 Ventil VR 5 sections RUR 5,766 | Rifar Alum 350 Ventil VR 6 sections 6575 rub. | Rifar Alum 350 Ventil VR 7 sections RUR 7,384 |

| Rifar Alum 350 Ventil VR 8 sections RUB 8,193 | Rifar Alum 350 Ventil VR 9 sections 9002 rub. | Rifar Alum 350 Ventil VR 10 sections RUR 9,811 | Rifar Alum 350 Ventil VR 11 sections RUR 10,621 |

| Rifar Alum 350 Ventil VR 12 sections RUR 11,430 | Rifar Alum 350 Ventil VR 13 sections RUB 12,239 | Rifar Alum 350 Ventil VR 14 sections RUR 13,048 | Rifar Alum 500 Ventil VR 4 sections RUR 5,031 |

| Rifar Alum 500 Ventil VR 5 sections RUR 5,859 | Rifar Alum 500 Ventil VR 6 sections RUR 6,687 | Rifar Alum 500 Ventil VR 7 sections RUR 7,514 | Rifar Alum 500 Ventil VR 8 sections RUB 8,342 |

| Rifar Alum 500 Ventil VR 9 sections 9170 rub. | Rifar Alum 500 Ventil VR 10 sections 9997 rub. | Rifar Alum 500 Ventil VR 11 sections RUB 10,825 | Rifar Alum 500 Ventil VR 12 sections RUR 11,653 |

| Rifar Alum 500 Ventil VR 13 sections RUR 12,481 | Rifar Alum 500 Ventil VR 14 sections RUR 13,308 |

Today, when designing a heating system in a country house, much attention is paid to the rationality and compactness of the systems. Therefore, the bottom connection of radiators is the most versatile and aesthetic option, due to the fact that all return and supply pipelines are carried out under the floor, and the connection to the radiator is made in the lower part, which is very convenient. It was believed that the bottom connection reduces the efficiency of heating systems by 5%, but today, thanks to modern developments, this opinion has changed. For such heating devices, underground piping is optimal. In such devices, distribution tubes are used to better distribute the coolant. The best choice is the Rifair radiator, which, in the case of a bottom connection, is equipped with a special thermostatic device located in the body of the heater. Rifair radiators use seamless technology without the use of welding, which allows the use of oil as a coolant, as well as various antifreeze liquids. Thanks to a special lightweight aluminum alloy, a high heat transfer rate is ensured, and the special design of the internal channels and housing allows it to withstand high pressure. In terms of overall dimensions and the best heat transfer performance, domestic radiators with a bottom connection, Rifar, stand out, where, being particularly compact, they can heat fairly large areas of premises. All models are able to withstand pressures of up to 20 bar and coolant temperatures of up to 110 C. In private homes and multi-storey buildings, it is recommended to use Rifar steel panel radiators, consisting of several panels. A distinctive feature is a two-layer environmentally friendly varnish coating that does not emit harmful substances into the environment, and special methods for performing the painting process and applying protective layers reliably protect the heating device. In case of bottom connection, a ¾-inch external thread is provided. Among the offered options there is a large selection of sizes, where you can choose the right model for any ceilings and window sills. Universal Russian radiators Rifar with bottom connection can be installed in heating systems with copper, steel, metal-plastic and polypropylene pipes. All models are made using injection molding.

| Also articles on this topic: Installation, repair and connection of aluminum radiators Technical characteristics of aluminum radiators Diagram of an aluminum radiator Which aluminum radiators are better to choose? Cheap buy aluminum radiator |

Advantages of bottom connection

The radiator fittings with which the bottom connection is made are directly suitable only for steel panel heat exchangers, and cannot be used for aluminum heating radiators - which is why steel radiators have more advantages in this case. The lower connection, in comparison with other types, has the following advantages of using fittings:

- Saving of outlets and pipes - there are only two short outlets on the wall or in the floor structure for connecting heating batteries; there is no need for pipes to lead to the upper inlet.

- The bottom connection is more aesthetically pleasing, and in the case when the pipeline is removed from the wall, it is almost invisible under the housing and thus does not create an unnecessary obstacle when cleaning and washing the floors.

- Shut-off and control valves (valves and ball valves) in the “binoculars” make it possible to regulate the intensity of the liquid entering the heat exchanger, and in case of complete shutdown, it makes it possible to dismantle the radiators for their subsequent repair or replacement.

The lower connection unit equipped with a vertical bypass allows you to evenly distribute the coolant across the heating radiators in order to heat its colder upper corners, this phenomenon is not uncommon with the lower connection. Even in the case of a single-pipe distribution, the bypass allows you to equalize the supply and return temperatures, which naturally evenly heats the devices built into the line.

Types of connection nodes from below

Individual dwellings are equipped with a two-pipe or one-pipe heating system. To connect a free-standing heat exchanger, a combined method is used, in which, in the case of a two-pipe distribution, it is connected only to the supply line in the node according to the Leningradka scheme.

Thus, units with bottom connections in heating or plumbing should be used with fittings in single-pipe, double-pipe and combined circuits, and have the following features:

- In a single-pipe line, as the coolant flows sequentially through all heating devices, its temperature decreases, which is why the first radiators in the chain heat up very much, and the last ones remain cold. To equalize the temperature of the coolant, a thermal compensation method is used, which is carried out using bypass wiring. It divides the incoming flow into two - one of which goes to the heating battery and heats it, and the other goes to the next one without interference, mixing with the cooled flow that comes out of the first battery.

- The heating temperature in two-pipe systems is the same for all devices and in this case there is no need to use the temperature compensation method. This type of wiring uses a “binoculars” type design, which is a fitting with shut-off or control valves, one of which is connected to the supply, and the other to the return.

- A combined unit with a bypass channel is used in both one-pipe and two-pipe heating systems; in the first case, the bypass channel is slightly open, in the second it is completely closed.

The design of the body has two main types of bottom connection fittings:

- Direct. They are used to connect radiators to pipes that come vertically out of the floor, since the outlet pipe of the unit has an external thread; the pipes must have outlet fittings with a union nut (American) or be equipped with a compression coupling with a transition to an American one.

- Angular. Corner fixation systems - represent the most successful design from an aesthetic point of view; with this configuration, the pipes come out of the wall at a small height above the floor level, and the threaded pipes of the corner fitting are connected to them using union nuts that are installed at the ends of the pipes.

In order to connect the node to the main line, which is made of steel pipes, an American connector is used; in the case of cross-linked polyethylene (plastic metal), a special compression connector is used, which is called a Eurocone. Its fitting must be inserted into the pipe and pressed against it with an outer ring with a slot using a union nut, which rotates around its axis; this, in turn, together with a cone seal, connects the parts being joined to each other.

In addition to the standard design equipped with built-in shut-off and control valves, the construction market offers a fairly wide selection of products that differ from the standard design unit. The main modifications of units that are found on sale:

- With control or shut-off valves. This fitting is intended for connection to a two-pipe system; screw or ball valves built into the body make it possible, if balancing is necessary, to separately regulate the supply and return flows, and in addition to completely disconnect the radiator from the main line.

- With built-in bypass. Hummel radiators have a similar scheme - it has a bypass channel in the lower part, the diameter of which is adjusted using a screw valve. This design is especially effective for single-pipe systems, where the same coolant temperature at the inlet of all radiator heat exchangers must be maintained.

- With remote bypass. This scheme for connecting radiators makes it possible to increase the temperature of the passing flow in order to heat up the following batteries more strongly, thereby equalizing their heat transfer throughout the entire circuit. The bypass line is connected to the heating battery from the side, the bypass pipe is connected to its top point using a fitting that is equipped with a thermostatic head. Since water moves through the bypass to the upper part of the radiator, after which it flows down, thus returning to the circuit through the return, the efficiency of this heating is much higher compared to modifications with a purely bottom connection in which heat loss is about 20%.

- Injection. Another type of device with connections from below can be considered injection devices that are connected to the side of the radiator from the side; this circuit includes a tube that is inserted into the outlet housing pipe. The coolant from the supply flows into the heating battery through the inlet located around the tube, and then through the tube it enters the return. A valve regulator is equipped on the side of the injector.

In addition to the previously listed devices, there are also a number of other fittings of the H-shaped modification, which have various design features of the fittings - devices with cross flow direction, parts with outlets to the sides for coolant drainage, with transition eccentrics, offset alignment of inlet and outlet.

Features of the use of bottom connection units

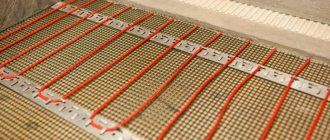

Connecting to heating systems below is effective if the supply pipes pass under the floor; sometimes, for convenience and aesthetics, they are inserted into the walls at a small height - corner fittings allow you to connect the pipes to the radiator housing.

In addition to shut-off and control valves, to improve operating efficiency, internal and external bypasses are often built into valve connecting units, and thermostats are used to set the temperature regime.

The main material for making devices is brass; when purchasing, you should pay attention to the wall thickness and thread length - manufacturers who produce budget products make them thin-walled with a short thread.

Fig.3 Bottom line - installation examples

Types of bottom connection nodes

In individual residential buildings, one-pipe and two-pipe heating systems are used; to connect a separate heat exchanger, a combined method is used, in which, in a distribution with two pipes, it is included only in the supply line according to the Leningradka scheme.

Accordingly, the units with bottom connections produced by the manufacturer are designed for the use of fittings in one-pipe, two-pipe or combined circuits, their features:

Rice. 4 Fittings from leading foreign manufacturers

Based on the design of the housing, there are two main types of bottom connection fittings:

To connect the unit to the main line of steel pipes, an American connector is used; for cross-linked polyethylene (plastic metal), a special Eurocone compression connector is used. Its fitting is inserted into the pipe and pressed against it with an outer ring with a slot using a union nut rotating around its axis, which, together with a cone seal, connects the joined parts to each other.

Rice. 5 Units with built-in bypass

In addition to the standard design with built-in shut-off or control valves, which resembles binoculars in appearance, the construction market offers a fairly wide range of products that have a design different from the standard unit. The main modifications of units presented in the trading network:

Rice. 6 Vertical bypass design

Rice. 7 Injection liner - operating principle and design

In addition to the devices listed above, a number of other modifications of N-shaped fittings are produced that have various design features of the fittings - devices with cross flow direction, elements with a side outlet for draining water (drainage), with transition eccentrics, offset alignment of the inlet and outlet holes.

Rice. 8 Connection and types of model range of lower inlet units

Node connection diagram

The main types of radiators for heating, which are connected with low connections, are steel panel and bimetallic (withstand high pressure); terminals located at the bottom are much less common in the design of an aluminum radiator and tubular modifications.

Since the liquid supply from below can be used in a single-pipe and two-pipe system, its diagram is no different from other methods of connecting and connecting radiators (side, diagonal, top). With a single-pipe wiring, the standard heating circuit requires manual or automatic adjustment; the Tichelman wiring (passing), in which the total length of the supply and return heating circuit is the same for all heaters, helps to significantly simplify balancing.