Heat transfer property

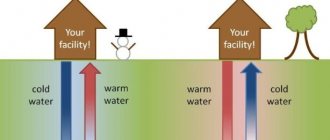

The power of steel heating radiators, as well as all other types of heaters, is based on the principle of their operation:

- The coolant, entering the battery, circulates through the reservoir (for steel panel models these are channels), while when it is hot it is directed upward, while when it cools it goes downward. In an autonomous or centralized heating system, the boiler heats the medium.

- During the time that hot water comes into contact with the radiator, it gives off its heat to it, heating its walls. This point is very important, since the length of its path depends on the size of the heater, and the longer it is, the hotter the radiator.

- The heated walls of the structure give up their temperature to the air, which spreads throughout the room under the influence of heat flows.

- To increase the level of heat transfer, the heating device is equipped with heat exchangers, as can be seen from steel radiators of types 11, 22 and 33.

The presence of heat exchangers significantly increases the power of steel radiators, working on two heating principles: radiator, which uses the heat of the walls of the device, and convector, which creates the movement of heated air.

As a rule, the manufacturer indicates power indicators in the data sheet, so you can use it as a guide, but it’s even better to make your own calculations taking into account the area of the room, air temperature and the amount of heat loss.

The consequences of an incorrectly selected heater are:

- The so-called overheating, when the room is so hot that you have to keep the window open. This creates a microclimate harmful to the body, forcing you to pay more for energy costs or install thermostats to reduce the load on the system.

- If the power of panel steel heating radiators is below the required level, then the room is cold even at their maximum load.

- Strong pressure drops in a heating system equipped with weak batteries will lead to an accident, since they will not withstand such “stress”.

All of these problems can be avoided if you know what exactly affects the heat transfer of heating batteries and how to increase their efficiency.

Main types of steel heating radiators

Steel radiators can have different designs and shapes, vary in design, including even color scheme. Based on their basic design, they are divided into panel and tubular. The first of them consist of one or more panels, and the second of round, rectangular or narrow panels of pipes.

To determine the optimal choice of such heating devices, you need to familiarize yourself with their designs and characteristics in more detail.

Panel radiators

These heat exchangers began to be actively produced in our country in the 70s of the last century. For some time they tried to replace traditional MS-140 radiators made of cast iron, which were the only effective device for central heating of multi-story buildings. At that time, panel batteries did not take root, since in terms of heat transfer, and in terms of the quality of their workmanship and durability, they were significantly inferior to the cast iron version. Those apartment owners who were “lucky” to get steel heating panels tried by all means to replace them with the usual cast iron as soon as possible.

Panel type steel radiator

Many years passed until engineers “reanimated” the previously developed design and improved it. The updated version of panel batteries began to be made from higher quality materials and using the latest technologies.

Modern models of these heating devices are becoming more and more popular, as their performance characteristics have increased significantly, and the price has remained quite “democratic”.

Manufacturing of panel radiators

The production of panel radiators is carried out on special machines, where steel sheets are given the desired shape using stamping. This process includes several stages:

- The first step is stamping steel sheets, usually about 1.25 mm thick.

- Next, two workpieces of the same size, “mirror” in configuration, are connected to each other at the edges by welding

Automated line for the production of steel panel radiators

When stamping metal sheets, vertical channels are extruded onto them, which, when two plates are welded, form a sealed space in the form of peculiar pipes through which the coolant will circulate. To connect the sheets, roller welding is used, which securely fastens the sheets between the formed channels.

Sectional view of a panel steel radiator

- Convectors with U-shaped ribs are also made from steel sheets with a thickness of 0.3÷0.5 mm by stamping.

- After this, convectors are fixed to the finished panels using spot welding, if they are provided for this type of radiator.

- The next step is to weld pipes onto the resulting panels for insertion into the heating circuit pipes.

- Upon completion of welding work, all seams are ground.

- The final stage is painting of the products.

The duration of their operation directly depends on the high-quality painting of heating devices, so this process can be called one of the most important in their manufacture.

Steel is susceptible to corrosion, especially when it comes into contact with water or other chemically aggressive coolant for a long time, so high-quality painting, carried out using a special technology, is necessary.

Painting panels

The process of painting panels is carried out in different ways, and the quality of the products largely depends on which of them was used:

- Immersion of the product in the coloring composition (OP).

- Method using anodic electrophoresis (AEF).

- The third staining method is cathodic electrophoresis (CEP). By the way, it is also used for applying paint to car bodies, and is rightly considered the most advanced for coating steel radiators.

This coating technology is highly reliable and resistant to various influences. The dyeing process is carried out in three stages:

Multilayer coating of steel radiator

— The first stage is the treatment of the steel radiator with a zinc-manganese anti-corrosion compound, which significantly increases the service life of the batteries.

— The second stage is painting the radiator using cathodic electrophoresis. The products are immersed in a dye composition, which is given a positive charge, while the panel is connected to a negative electrode. The process is completed when the paint evenly covers all surfaces of the panel. This layer of paint is a reliable insulator for steel from various aggressive influences.

— The third stage - epoxy powder is applied to the paint, and the products are sent to a chamber with high temperatures to melt this protective layer. After heating and melting the powder, a high-quality glossy coating of the required color is formed on the panel - it is not exposed to ultraviolet rays, and does not turn yellow or fade over time.

When painting metal products that are subject to periodic heating, compositions containing substances such as heavy metals and formaldehyde are not used. The paint used in the dyeing method (CEF) contains only 2% solvent, while when using AEF it contains 9-10%.

Due to the fact that the paint contains a small amount of solvent, the battery, even when heated to extremely high temperatures, will not emit harmful substances.

All finished radiators must be tested under a pressure of 1.3 MPa, and if the products are successful, the manufacturer can safely give a guarantee for their operation for a period of 10–15 years.

When purchasing steel panel batteries, you need to carefully study the accompanying passport with characteristics, where the painting method should be indicated.

In addition, it is recommended to carefully inspect the radiator coating. It must be of high quality on both the front and back surfaces, without cracks, chips and scratches, without paint sagging.

A coating is considered to be of poor quality if the front and back surfaces differ from each other in color or texture smoothness. It is better to discard such products immediately.

Existing types of steel panel radiators

Panel radiators are divided into several types, which are usually divided according to the number of panels and convector heat exchangers in the design. So, a radiator can have one, two or three panels, and one, two or three convectors are installed between them.

Panel radiators can vary significantly in size

If the radiator consists of more than one panel, then walls are usually mounted on its sides, and a grille is installed on top.

The table shows some parameters of standard types of panel radiators.

| Appearance | Brief description of the design | Radiator dimensions | ||

| Height, mm | Length, mm | Width, mm | ||

| Type 10 panel radiator consists of one heating panel without convector fins. The device does not have side walls or an air outlet grille. The numbers characterizing the heating device mean: “1” - one row of panels; “0”—no convectors. Despite the fact that there is only one row of panels, and there are no additional heat exchange elements, this type has its own important advantage, which in other cases is considered a disadvantage - the absence of a convector. If there is no convector, then there is no directional movement of heated air masses that contain a large amount of dust. Thanks to this, type 10 radiators can be installed not only in residential premises, but also in children's or medical institutions. One panel, which does not have complex configurations, a top grille and side walls, is much easier to care for. It is enough to wipe its surface with a damp, clean cloth. | 305÷905 | 405÷3005 | 63 | |

| Type 11 consists of one panel and one row of convector fins welded to its rear side. This option lacks the top grill and side walls. Convection occurs through one row of ribs, but it also promotes the circulation of dust masses along with the air. Therefore, having such radiators, they will have to be cleaned more thoroughly, since dust settles on the walls of the convector. | 305÷905 | 405÷3005 | 63 | |

| 20 type . This type of radiator consists of two panels without convectors. There is an air outlet grille on top, and walls are fixed on the sides. The heat transfer from this type of radiator is twice as high as from a single-panel one. Cleaning this model is quite simple due to the absence of convector fins. | 305÷905 | 405÷3005 | 66 | |

| 21 types . This design consists of two panels and one convector installed between them and welded to the outer panel. The entire complex is covered with a lattice on top and walls on the sides. | 305÷905 | 405÷3005 | 102 | |

| 22 type. This type of radiator consists of two panels, two convectors, side walls and a top grille. In this case, the fins are welded to both panels. | 305÷905 | 405÷3005 | 102 | |

| 30 type This design includes three panels connected to each other at a certain distance, side walls and an upper grille. | 305÷905 | 405÷3005 | 102 | |

| Type 33 has the largest depth, up to 170 mm, and consists of three panels and three rows of convector fins installed between them. The ribs are welded to the inner surfaces of the panels. The radiator has side walls and an upper grille. | 305÷905 | 405÷3005 | 157 | |

Now - about the main technical and operational characteristics of the products:

- Panel radiators are designed for a maximum coolant temperature of up to 95÷100 degrees, so at a standard heating system temperature of 70 degrees they will last a long time.

- The operating pressure for these batteries should not exceed 10 bar (1.0 MPa). If the calculated baric loads are exceeded, the welds on the panels may fail, which will lead to an emergency. The standard pressure for a central heating system is 9 bar, but when it is checked before the heating season, water hammer may occur, short-term pressure surges at which can reach 11÷15 bar, which is unacceptable for panel batteries.

- The test pressure of this steel battery is 13 bar (1.3 MPa) - this is the maximum it can withstand. However, you need to take into account that you need to purchase products that have a certain reserve for this parameter.

If you nevertheless decide to install these particular radiators in a house with a central heating system, then in order to guarantee avoiding accidents due to pressure drops and protect heat exchange devices from dangerous loads, it is necessary to use gearboxes that will take the “blow” upon themselves, and in The system itself will maintain a stable coolant pressure.

Possible sizes and power of radiators

Obviously, the functionality of the device, and therefore the heating efficiency, will directly depend on the number of panels in the radiator. Thus, types 10 and 20 batteries, without convectors, radiate heat only from the panel itself, and those radiators on which these functional elements are installed create thermal curtains for the cold coming from the window, as they direct the heated air upward.

Naturally, the power of the battery will depend on its size, which is selected for the heated area and for the specific installation location.

Panel radiators are produced in different dimensional parameters, both in length (usually from 400 to 3000 mm) and in height (from 300 to 900 mm). Therefore, you can choose them for any installation location, both near a panoramic glazed wall and near a high window.

Judging by demand statistics, the most popular panel devices today are types 11, 21 and 22. They can also have different heights and lengths, so if you decide to choose one of these options, then their power, for example, can be previously “estimated” using the data from the table below:

| VKO 11 - one heating panel + one convector element | VKO 21s - two heating panels + one convector element | VKO 22 - two heating panels + two convector elements | ||||||||||

| Height in mm | 300 | 450 | 500 | 600 | 300 | 450 | 500 | 600 | 300 | 450 | 500 | 600 |

| Length in mm | Radiators power W | |||||||||||

| 400 | 265 | 382 | 420 | 495 | 370 | 513 | 559 | 650 | 476 | 656 | 715 | 832 |

| 600 | 398 | 574 | 630 | 742 | 555 | 770 | 839 | 976 | 714 | 984 | 1072 | 1247 |

| 800 | 531 | 765 | 840 | 989 | 740 | 1026 | 1119 | 1301 | 952 | 1312 | 1430 | 1663 |

| 1000 | 663 | 956 | 1051 | 1236 | 925 | 1283 | 1398 | 1626 | 1190 | 1641 | 1787 | 2079 |

| 1200 | 796 | 1147 | 1261 | 1484 | 1110 | 1539 | 1678 | 1951 | 1428 | 1969 | 2145 | 2495 |

| 1400 | 929 | 1338 | 1471 | 1731 | 1295 | 1796 | 1958 | 2277 | 1666 | 2297 | 2502 | 2910 |

| 1600 | 1061 | 1529 | 1681 | 1978 | 1480 | 2052 | 2237 | 2602 | 1904 | 2625 | 2860 | 3326 |

| 1800 | 1194 | 1721 | 1891 | 2225 | 1665 | 2309 | 2517 | 2927 | 2142 | 2953 | 3217 | 3742 |

| 2000 | 1327 | 1912 | 2101 | 2473 | 1850 | 2566 | 2797 | 3252 | 2380 | 3281 | 3575 | 4158 |

| 3000 | 1990 | 2868 | 3152 | 3709 | 2774 | 3848 | 4195 | 4878 | 3570 | 4922 | 5362 | 6236 |

Connection method

For convenient installation of heating radiators in the circuit, manufacturers produce batteries with bottom or side connections. When choosing the right model, this factor must be foreseen in advance, since both options are sometimes required in one heating circuit, depending on the location of the battery installation and the method of laying the pipes.

When using radiators with bottom connections, it becomes possible to completely hide the circuit pipes in floors or walls, or to run them as close to the floor as possible. A battery with a bottom connection is more expensive than radiators connected to the side. In product labeling, they have a special designation - the letter “V”.

Bottom connection of panel radiator

The lateral connection is mainly made from a circuit running along the floor or on vertical risers. Radiators are produced with a right or left connection, and this also needs to be taken into account when drawing up a diagram of the heating system and purchasing batteries.

It should be noted that the side connection is easier than the bottom connection, since it will be much more convenient to carry out installation work. In addition, correct side connection always results in higher heat transfer. With a bottom connection, no matter how beautiful it may look, losses in the efficiency of the heat exchange device (up to 15÷20%) are simply inevitable.

This diagram shows the option of lateral connection of the radiator to the pipes of the vertical riser:

Example of lateral connection on a vertical riser

1 – coolant supply pipe;

2 – return pipe;

3 – steel panel radiator with left side connection;

4 – thermostatic head, which allows you to set the required heating level.

5 – balancing valve for precise adjustment of the system.

Advantages and disadvantages of panel steel heating radiators

Having familiarized yourself with all the characteristics of panel radiators, as a result, you can highlight all their “pros” and “cons”.

The advantages of such devices include the following qualities:

- Thanks to the integral design of the radiator, installation is quite quick. The device only needs to be hung on brackets mounted in the walls and embedded into the heating circuit. However, such inseparability can be considered not only a “plus”, but in some cases also a “minus”, since if an emergency occurs, the radiator will have to be completely replaced. In a sectional battery, it is possible to replace only failed sections.

- High heat transfer, which occurs due to a fairly large metal surface that is heated and gives off heat, as well as convectors that create directional movement of heated air.

Characteristic picture of the distribution of heat released from a panel radiator

- Economical. Panel radiators require a small volume of coolant, which means less energy is required to heat it. Therefore, according to calculations, when using them, energy savings reach 35% compared to cast iron batteries.

- It is difficult to get injured on the surface of the panels, since there is no pronounced ribbing with traumatic angles - this factor is especially important if there is a small child in the house. Even if he hits a smooth steel surface, he will not receive serious injuries.

- For this type of device you do not have to purchase protective or decorative screens, since their surfaces already have a neat appearance.

The disadvantages of panel batteries are the following:

- Low resistance to sudden changes in coolant pressure, since the highest quality weld can crack if a water hammer occurs. Therefore, in a central heating system, a gearbox must be built into the circuit, which will “dampen” the water hammer.

- Panel radiators quickly fail when using low-quality coolant. Unfortunately, the central heating system usually cannot “boast” of its high quality, and a large amount of dirt and scale is deposited on the inner walls of the radiators, which contributes to clogging of the channels and the appearance of pockets of corrosion.

- Radiator panels are not resistant to mechanical stress and therefore require careful transportation. Also, when using them, it is necessary to avoid impacts and scratches, for example, when rearranging furniture.

Tubular radiators

Features of manufacturing tubular radiators

Another option for steel heating devices are tubular radiators, which are also produced by stamping. This type of battery has several variations with the same operating principle, so their production is somewhat different.

Representatives of the “family” of tubular radiators

For some, even tubes of different diameters are used, installed vertically, and then connected by upper and lower horizontal collectors.

Read about vertical heating radiators, as well as how to choose the best option, in a new article on our portal.

Others are made in sections, somewhat reminiscent of cast iron, which are joined together by welding. But be that as it may, all tubular radiators are always a non-separable welded structure.

Despite this “sectionality”, steel radiators are always a non-separable, complete structure

Tubular batteries are assembled from stamped steel blanks made of steel 1.5÷2 mm thick.

The process of their manufacture takes place in the following sequence:

- Halves of tubular radiator sections are stamped from steel sheets.

- Next, the individual halves are connected by contact welding using special equipment.

- The next step is to grind the finished sections to remove burrs and protrusions left after welding.

- After this, the polished elements of the section are connected to each other to form a radiator, also by welding.

- The welds are then ground again.

- The next stage is testing the products for leaks - this process is carried out in a special test bath.

- Finished and tested radiators are sent to the painting line. It occurs in the same way as when coating panel batteries, using the same coloring compounds.

Painting line for tubular radiators

- After painting, the radiators enter high-temperature chambers to melt the epoxy coating.

Blanks for other tubular radiator designs are made slightly differently.

- For them, pipes of the required height are cut, which will serve as convectors. They are completely brewed on the bottom side, and left open on the top side.

- The pipes are fixed by spot welding on horizontal collectors through which the coolant will flow, giving off heat to the convector pipes.

- Upon completion of assembly, the welding seams of the radiators are polished, and the products are sent to the line for applying decorative and protective coating.

- On some of the radiators, the upper openings of the convector pipes are decorated with nickel-plated rings.

Various types of convector tubes for radiators

There are several more quite elegant designs of tubular radiators that can be matched to any design project. Moreover, they are not always made in the form of pipes - sometimes they can be hollow panels mounted on collector pipes through which the coolant circulates.

Such radiators also belong to the category of tubular

Main technical characteristics of tubular heating radiators

Despite the fact that tubular radiators differ in their design, their characteristics are almost identical. It is characteristic that such devices usually surpass panel options in heat transfer. But, it should be noted that their cost can be much higher.

- Almost all models of tubular radiators are equipped with outlets for bottom and side connections.

- When choosing these radiators, you must also take into account what pressure they are designed for, since in a central heating system, as mentioned above, pressure surges can reach 10÷15 bar

- The maximum coolant temperature is from 100 to 120 degrees.

Tubular radiators can be quite large in size

- Such radiators are produced in a very wide range of sizes and shapes:

— Height varies from 20 to 1500 mm.

— Length can be up to 1400 mm.

— The depth of radiators ranges from 40 to 292 mm.

Advantages and disadvantages of tubular steel heating radiators

Tubular radiators are quite popular, especially for installation in private houses with constant moderate operating pressure without drops and water hammer. Their popularity is explained by a number of positive qualities :

- Uniform heating of the surfaces of tubular radiators quickly ensures a comfortable temperature in the rooms.

- High heat transfer of devices.

- Easy to install and operate.

- Thanks to the smooth surfaces of tubular radiators, layers of dust do not accumulate on them, so they are easy to care for. Due to the fact that batteries do not collect dust and dirt, they are recognized as complying with existing sanitary and hygienic standards.

To care for tubular radiators, it is recommended to purchase a special brush

- The ability to adjust the temperature in the room, since this type of battery may well be equipped with a thermostatic regulator.

Tubular radiator equipped with thermostatic regulator

- A very wide range of varieties of design solutions. Some of the tubular battery models are equipped with shelves or wooden panels for sitting, which can also be used for drying clothes or shoes.

Tubular radiator with shelf-seat

The kit with other options for heating devices may include special brackets used for drying towels. Such radiators are perfect for installation in bathrooms, washrooms, and also in the kitchen.

Radiator with bracket for drying towels

There are also completely unusual models, height from floor to ceiling, capable of dividing rooms into different zones.

- Tubular radiators are quite safe from the point of view of accidental injuries, since they have “soft” rounded shapes, so they can be installed in children’s rooms.

The disadvantages of these batteries include their following qualities:

- The instability of the manufacturing material to corrosive processes, especially if radiators are installed in a central heating system where the coolant is not of high quality.

- High prices for such devices.

- Instability to accentuated mechanical stress.

What affects heat transfer?

When choosing a heater model, you need a table of the power of steel radiators, which should be provided to consumers by the manufacturer or sales consultant.

You should also take into account several nuances that are inherent in them:

- Before purchasing new heating batteries, you should ask what the temperature of the coolant in the system is. The hotter it is, the higher the radiator will be heated, which means the heat transfer will be greater. Having found out the exact temperature, you need to compare it with the indicators of the selected model, which are indicated in the data sheet. They must match for safe and efficient operation.

- The size of the radiator matters. The larger it is, the longer the carrier stays in it, and this makes its walls hotter.

- The thermal conductivity of the material is also important. In this case, we are talking about sheet steel no more than 1.5 mm thick, which indicates the ability to heat up quickly.

Such nuances determine the power of panel radiators, so when calculating it, all their parameters should be taken into account.

Construction of steel panel radiators

- Structurally, panel radiators consist of several steel panels (from 1 to 3) in which there are vertical and horizontal channels for coolant.

- To increase the heat exchange area and convective heat transfer from the inside, U-shaped steel ribs are welded to the panel. The increase in heat transfer is more than 50%.

- The radiator panel is made by welding two stamped sheets of cold-rolled carbon steel sheet with a thickness of 1.2 mm - 1.25 mm. Some manufacturers make radiators from galvanized steel on special order. For convective heating fin plates, steel with a thickness of 0.4mm - 0.5mm is used.

- The outside of the radiators are primed using the cataphoretic immersion method and painted using the powder method. The standard color is white, but some manufacturers produce colored panel radiators on special order.

- Panel radiators with two or three panels usually have decorative grilles on top and solid panels on the sides.

- The standard radiator is equipped with four lateral connecting pipes 4x1/2″ BP, two on each side. To connect the radiator, two pipes are used, and the remaining two are closed with plugs.