7465 0 0

Mullvatt July 28, 2016Specialization: Capital construction work (laying a foundation, erecting walls, constructing a roof, etc.). Internal construction work (laying internal communications, rough and fine finishing). Hobbies: mobile communications, high technology, computer equipment, programming.

Plastic pipes (pictured) are one of the main elements of the heating system.

The debate about the benefits of certain building materials with which I work will probably never end. So recently I had to explain to a client which plastic pipes are better for heating.

The fact is that I am taking part in the construction of a country house in one of the cottage villages. We have now begun the stage of constructing utilities. Usually I choose one or another option myself, but this time I came across a very meticulous owner who decided to stick his nose into all processes without exception.

In general, he wanted to install metal pipes first, because, you see, that’s what his mother advised him to do. Therefore, he asked me to prepare a short presentation in which he explained why plastic heating pipes are better than metal ones, so that he could present this “document” to his mother for approval.

Everyone has their own oddities, but I complied with his request, because I thought that such information would be useful to other people who are going to make heating from plastic pipes with their own hands. That's why I'm posting the presentation here. Now instructions on how to select the necessary parts are for your full and free use.

Positive qualities of plastic pipes

Plastic pipes for heating have a list of positive qualities that set them apart from similar metal products.

It is worth highlighting the main advantages of plastic pipes:

- Plastic heating pipes are not afraid of a humid environment. Plastic is a polymer, and such a material is known to not interact with chemicals and other aggressive substances.

- Due to their corrosion resistance and resistance to rotting, such pipes can easily last up to fifty years.

- Plastic heating pipes are considered environmentally friendly because they do not emit toxic compounds.

- When transporting water through such pipes, they do not make noise. This is because plastic transmits sound worse. In addition, plastic pipes do not accumulate plaque, which has a positive effect on their throughput.

- Plastic has low thermal conductivity, which is very important for designing a heating system. This can be considered its main advantage over steel pipes, in which the water quickly becomes cold.

- The characteristics of plastic heating pipes are such that they cope more successfully with temperature changes. This also makes them indispensable when organizing a heating system in the house.

- Due to their lightness, they are very easy to transport and install. It is worth noting the fact that the pipes are connected to each other using fittings using the soldering method. The process takes a minimum of time, and the pipes themselves do not need painting, maintaining their aesthetics for a very long time.

- In addition, they have a low cost. Steel pipes will cost much more.

Installation features

Please note that products made from chlorinated polyvinyl chloride cannot be installed by soldering.

High molecular weight glue is used to join these structures. The use of this material is similar to the cold welding procedure. Since the adhesive composition is liquid chlorinated polyvinyl chloride.

After applying it to the surface of structures, it polymerizes within five minutes.

The installation procedure includes several steps.

Each of them is important to perform at a high professional level. So, the circuit assembly looks like this:

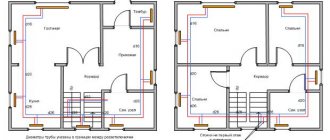

- designing a diagram and marking the location of structural components;

- cutting products to obtain pieces of the required length;

- selection of fittings for arranging the system;

- gluing components in the correct order;

- testing the heating circuit for resistance to operating pressure.

To solve the problem, it is also permissible to use threaded connections or fix them with flanges.

Arranging a heating circuit made of chlorinated polyvinyl chloride is beneficial. Its cost is relatively low. At the same time, the functionality indicators are impressive. The service life of pipelines made from this material is fifty years. This figure is significantly higher than that of metal (especially cast iron) analogues.

Metal-plastic heating pipes

Metal-plastic is one of the types of material for the manufacture of plastic pipes for heating. The walls of such pipes consist of five layers: plastic on top and bottom, and inside there is a layer of aluminum foil separated by two layers of special glue.

Metal-plastic heating pipes consist of high-strength PEX polyethylene, which is produced using a special technology that allows them to withstand a burst pressure of 70 bar. This polyethylene has a high resistance to chemicals, it does not oxidize, and biological growths do not appear on the walls over time.

PEX polyethylene is characterized by a very low roughness of the internal walls, which is equal to 0.004 mm. In addition, polyethylene is not afraid of high temperatures, up to 90 °C. The high strength of polyethylene allows pipes to function for up to 50 years.

The layer of aluminum foil located between the polyethylene has a thickness of 0.2-0.3 mm. It prevents the plastic pipe from lengthening over time, and the plastic, in turn, protects the aluminum from environmental influences.

A plastic pipe has a linear expansion rate less than that of polypropylene, but slightly greater than that of copper. The manufacturing technology of the aluminum layer gives it high elasticity and great strength. This allows metal-plastic pipes to bend quite easily without losing their structure throughout their entire service life. In addition, aluminum protects the pipes from oxygen penetrating inside.

The layers of glue, in turn, give the pipe joints strength. The glue used is of high quality, so it perfectly glues all layers together, giving the product flexibility and resistance to high temperatures.

However, the metal-plastic pipe is currently losing its popularity. This happens because you can often find low-quality products on the market; moreover, leaks often form at the joints 2-3 years after their installation.

Heating installation

The heating system is installed in the following sequence:

Radiator installation

First of all, you should determine and prepare a place for their placement . Typically, heat exchangers are mounted under window openings, this is due to high-quality air flow circulation. It is important to accurately calculate the distance from the support base where the battery will be located.

Upon completion of the preparatory work, for hanging the batteries, markings are made for the consoles. To do this, the heat exchanger is centered along the window opening at a distance of 11-12 cm from the floor covering and window sill.

Then, at the marks, using a hammer drill, holes are drilled for fasteners, which are subsequently screwed in so that there is a gap of 3-3.5 cm between the wall and the back side of the heat exchanger. For 1 radiator mounting, you will need 4 brackets, for installing a cast iron battery - 6.

Installing plugs for piping the mounted heat exchanger

Almost all heating batteries have 2 open inlet holes on both sides, some of them are closed with plugs during the installation process, and others are closed with threaded passage plugs.

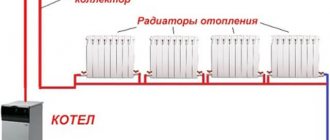

Most often, in the process of installing a heating system, they use the connection of batteries on one side, which provides for the supply of thermal mass from above the heat exchanger, and the return is carried out from below the same side of the battery. On the other hand, in the upper part of the battery, a Mayevsky valve is mounted to remove air, and the lower hole is closed with a plug.

Installation of taps on a heat exchanger

Upon completion of the installation of the plugs, a regulatory element is installed in them, which can serve as valves with a spherical lock . To carry out manual regulation of the movement of thermal mass, you can use conventional radiator taps; for automatic regulation, taps with thermostatic heads can be used.

Typically, American ball valves are used, which ensure quick shut-off of water. To install such a faucet into the battery plug, you will need a special key that is placed in the faucet connecting adapter.

The joint between the passage plug and the tap should be sealed with elastic sealing paste or flax fiber. To do this, check the tap threads in advance by connecting them without a sealing agent. After densely filling the entire depth of the thread with fiber, paste must be applied to the winding and the element must be screwed in.

In the case of using metal shut-off valves, in order to switch to plastic, it is necessary to screw in threaded couplings. As in the previous case, winding is also used here.

Installation of the Mayevsky tap (due to the presence of a rubber gasket) does not require tightness.

Upon completion of work, the heat exchanger can be installed in the designated location.

Pipeline laying and assembly

In the process of installing a heating system, the primary thing is to groove grooves in the floor and walls. When using a two-pipe system, the best solution is to lay it in the floor, and connect the heat exchangers from the walls. The layout can be carried out in a cement base, by cutting a groove, or laid before the screed is poured. It is advisable to place the supply and return pipes in isolated channels, at a distance of at least 10 cm from each other.

When laying plastic products, they should be separated with polyethylene foam to ensure thermal expansion. The space around the connecting elements is also filled.

It is not recommended to use rigid fasteners for fastening, which will prevent linear expansion. For these purposes, elastic clamps or plastic brackets are used. In this case, the pipes must be firmly fixed at the point where they exit the wall.

Laying should be carried out vertically or horizontally on the walls, bends should only be made at right angles.

Installation should be carried out in the direction from the risers to the installed heat exchangers. The place of the last welding is preliminarily determined; it should be convenient for working with a soldering iron (as a rule, this is the area between the radiator and the wall).

The material is prepared based on the number of straight zones determined by the diagram. Their sizes are determined by measurements using a centimeter tape. Please note that about 1.5 cm of the pipe length extends into the connecting element.

Technical characteristics of metal-plastic pipes

Metal-plastic pipes can be used for transportation for both hot and cold water.

This type of plastic heating pipes has the following performance characteristics:

- maximum operating temperatures should not exceed 95 °C;

- at this temperature, the maximum pressure in the system should be 10 bar;

- at water temperatures from 0 to 25 °C, the pressure can reach 25 bar;

- permitted peak temporary temperature – 130 °C;

- The service life of such pipes is 50 years - this is provided that the material has the above parameters.

Foampropylene

Propylene products are a practical, affordable budget option. Their advantages make this type of product very popular:

- affordable price compared to other materials;

- light weight, which does not place excessive load on the structure, and also facilitates pipeline installation;

- there are no unreliable connections. All of them are connected using the hot soldering method, and this completely eliminates or minimizes the use of detachable connections using paronite or rubber for sealing;

- attractive appearance;

- not subject to corrosion, formation of deposits, blockages;

- manufacturer's warranty up to 40 years.

Disadvantages - sagging of the pipeline, which can lead to breakdowns. When installing them, you need to use special equipment for soldering connections, but this is easy to do even for a person without the necessary training.

Results

Plastic pipes installed in heating systems do an excellent job. However, for different conditions it is necessary to select pipes individually, taking into account the specifics, since it is impossible to name one option for all cases.

Under some circumstances, metal-plastic ones will be preferable, under others, polypropylene ones. When choosing, it is important to take into account all the nuances, and subsequently carry out their installation efficiently.

Continuing the topic: it is also quite interesting to use old metal pipes. Used pipe is a great way to save money without losing the technical properties of the material. Good luck to you!

Technical characteristics of PE pipes

Polyethylene pipes can also be used in systems with circulating hot water.

They have the following performance characteristics:

- ability to operate in media temperatures up to 90 ℃;

- the maximum operating pressure can reach 10 bar;

- the maximum pressure at temperatures of 0-25 ℃ can reach up to 25 bar;

- a short-term peak temperature may be 100 ℃, but no more;

- when using pipes made from a material with the above characteristics, their service life can also easily reach 50 years.

Let us note the technical characteristics of PP pipes

Polypropylene pipes can also be used for heating systems and hot water transportation. However, pipes made from this material are not used so often, because their performance properties are slightly inferior to the previously mentioned materials.

Polypropylene has the following performance characteristics:

- allowed for use in systems with coolant up to 70 °C;

- maximum operating pressure at maximum temperature is 10 bar;

- the maximum operating pressure at temperatures from 0 to 25 °C is 25 bar;

- peak temporary temperature can increase to 90 °C;

- when using polypropylene pipes with the above characteristics, their service life may well be 50 years.