Infrared carbon film, the operating principle of which is based on the emission of long-wave infrared rays, is an emitter in the form of a non-woven fabric, covered on both sides with plastic film. It has 100% heat transfer thanks to a technological layer of carbon fiber and two copper busbars. Carbon film can be used as a main and additional heating system in almost all types of premises. It is used in heating offices and schools, industrial buildings, department stores and hospitals, parking lots and garages, open areas, stairs, and sports fields. Thanks to the flexibility of the film, it is possible to heat not only the floor, ceiling, walls and other flat areas, but also uneven surfaces of the interior, roofs of columns and others. For installation, the film does not require a cement screed or an adhesive base, which makes it easy to install the film and also dismantle it if necessary to use it in another place. The scope of application of the film is very wide. Drying trees, food, food, soil in greenhouses - this is an incomplete list of its uses, except for heating systems in homes.

- 2 Types of infrared films

- 3 How to choose the right option

- 4 Restrictions on the use of IR films

- 5 Useful properties of heating film

How does infrared film heating work?

Infrared radiation is part of a wave change in the electromagnetic background; its second name is thermal, because the human body perceives it as heat. The sun is also a source of heat and the principle of its operation is as follows: it brings heat to our planet, its rays, falling on the earth, heat water, soil, trees, buildings, and those, with their radiation, warm the surrounding airspace.

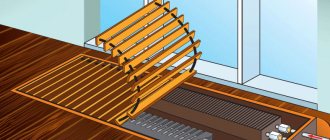

A low-temperature film heater works in the same way , the maximum heating temperature of which is no more than 50˚C. Regardless of the manufacturer, any IP (infrared film) consists of three components:

- a heating element that converts electricity into heat;

- foil, thanks to which heat is distributed with equal force over the entire surface;

- double-sided lamination with PET film, which performs the functions of insulation and protection from mechanical influences.

Heating begins after current is applied to the heater. Passing through the heating components, the current is converted into thermal energy, which is transferred from the emitter to the double-sided PET film by contact method, and both sides of it begin to emit thermal waves. Thus, the source of radiation is the IP, and not the foil or heating elements.

What happens when film is used as ceiling heating when it is covered with plasterboard, for example? The primary radiation of the film will heat the drywall, and it will begin to emit infrared waves into the surrounding space, heating the objects located there, and then the air.

The same thing will happen in a heated floor system, only there the radiation flow will go from bottom to top. Again, the primary radiation is IP, and the secondary radiation is the floor covering.

What is infrared heating and how does it work?

By film infrared heated floor we mean a heating element consisting of two layers of dense polymer. Between them, the heating element is located. The heating element is a carbon nanostructure, which has unique properties. Formed carbon atoms into a hexagonal lattice (several nanometers in size) have a unique ability to emit in the far infrared spectrum.

It is worth noting that the radiation of infrared waves cannot be seen by the eye. The wave spectrum is about 20 microns in length. More importantly, this type of radiation is absolutely safe for the human body. By the way, it is this radiation that is used in such fields as sports medicine, dentistry and surgery.

Types of infrared films

Infrared films from different manufacturers may differ in their appearance, technical parameters, however, high-temperature and low-temperature IP films can be distinguished from them. Films also differ in technical parameters - power, maximum heating temperature, width and thickness, type of application of emitting material (solid and striped), and, accordingly, areas of application. An important parameter for IP is the heating temperature of the film.

A film that heats up to a temperature above 27˚C is absolutely not suitable for a heated floor under a laminated coating, because it is deformed from high temperatures. But it will be just right for ceramic tiles.

The 13.5 cm wide Ondolla high temperature film can be used as baseboard heating. It has many advantages: located around the entire perimeter of the room, it heats it from all sides, is easy to install, invisible in the interior, and has a low power of 10 to 35 watts per 1 linear meter.

Answers to your questions about film heated floors (IR films, infrared heated floors)

Hello again Ladies and Gentlemen.

Today I would like to talk about the differences between film heated floors (infrared)

The article will be in the form of questions that buyers most often ask before purchasing heated floors. And so, here we go:

- Is it infrared?

Every 2nd buyer asks this question.

We answer:

Yes, infrared, and also infrared. Your heating radiator and even a person are also infrared. How can this be, you ask, since the infrared spectrum is a spectrum similar to the sun... etc. and so on

Quote from Wikipedia:

Infrared radiation is also called “thermal” radiation because infrared radiation from heated objects is perceived by the human skin as a sensation of heat.

We conclude: everything that emits heat also has an infrared spectrum.

— What is the power of infrared film heated floors?

We answer:

The most common power of film heated floors = 220W/sq.m. And this is no coincidence. After numerous tests and many years of sales experience, our South Korean manufacturers came to the conclusion that this is the power of infrared film that is sufficient to compensate for heat loss in our homes/apartments.

— Why is the power of a film heated floor 1 meter wide = 220 W/linear meter, and 50 cm wide = 110 W/ linear meter. Does it heat up 2 times less?

We answer: infrared film

1 meter wide and 1 meter long is 1 sq.m., respectively, the power will be 220 W both per linear meter and per square meter. But a film heated floor 50 cm wide and 1 meter long is only 0.5 sq.m. (0.5 m. * 1 m.), respectively, power per 1 sq.m. will be the same. The same story applies to infrared film 80 cm wide. In simple words: Film of any size heats up with the same power.

— You say the film power is 220 W, does that mean it will constantly consume 220 W/h?

We answer:

No. The power of infrared film and its energy consumption (energy consumption) are completely different things. The principle of operation of heated floors is as follows: You turned on the heated floor system and set a comfortable temperature to 23 degrees. After 5-10 minutes, the infrared film will warm up to a temperature of 23 degrees, and will also warm up the laminate and the thermostat will turn off the system, because reached the set temperature. Next, the film heated floor under the laminate will release the accumulated heat for several minutes. Having cooled down by 2-3 degrees, the thermostat again supplies power (220 W/sq.m.) to the infrared heated floor, heating it again to the set 23 degrees. So it turns out that infrared film does not always work in heating mode, but only 50-60% per hour.

— How much underfloor heating can be connected to one thermostat?

We answer:

As a rule, standard thermostats are designed for current = 16A, if in Watts, then 3.5 kW. The power of infrared film is usually = 220 W/sq.m. , accordingly, no more than 16 sq.m. can be connected to one tremoregulator. film heated floor. However, there are exceptions: for example, the programmable thermostat Grand Mayer PST 3 can supply 6 kW of load or 27 sq.m. infrared film.

— Is it possible to connect infrared heating films of different widths to each other?

We answer:

It is possible and necessary. This is why there are different sizes of infrared floors, so that you can optimally assemble a warm floor system specifically for your room.

— But there is a film heated floor for laminate with a power of 150 W/sq.m. - Is it more economical?

We answer:

No. Such a film heated floor consumes less when heating, however, it does not heat up as quickly as infrared film with a power of 220 W/sq.m. Accordingly, infrared film with a power of 150 W/sq.m. It will take longer to warm up using more energy. In fact, film heated floors with reduced power were created mainly for large industrial premises, so that a larger amount of infrared film could be connected to one thermostat for uniform heat distribution.

— Do I need to cover the infrared film with anything else for additional protection before laying the laminate?

We answer:

The IR film itself has a hermetically sealed structure. Another thing is the end connections of the copper busbars to which the wires and terminals are connected. These places need to be well sealed. For this purpose, special kits are sold for connecting infrared heated floors, which contain special bitumen waterproofing. Its main property is that when it sticks to the surface, it will not allow moisture to get under the joint. If everything is done “wisely”, then nothing threatens your infrared heated floor and no additional materials are required.

— Is a heat-reflecting underlay required for heated floors?

We answer:

In principle, if you install a heated floor system from infrared film without using a heat-reflecting substrate, and let’s say, on a cork substrate, nothing bad will happen. A warm floor will also pleasantly warm your laminate and yourself (CHECKED), however, some of the heat will still go to heating the cork substrate, and accordingly, the energy consumption will be slightly higher (CHECKED). This is more a question of saving electricity.

— Which thermostat is better - a simple mechanical one or a programmable one?

We answer:

It all depends on the area underfloor heating and its purpose. If you plan to heat the corridor and the area of the heated floor is only 1 sq.m. (for drying shoes, for example), then in this case it’s definitely worth taking the simplest mechanical thermostat for a heated floor. It will more than fulfill its function of maintaining the set temperature. The power of such a system will be 220 W/h, and the energy consumption with constant heat maintenance (not the power of the film, but energy consumption) will be about 120 W/h. However, if you decide to heat a room of 20 sq.m. of which the heated floor area will be 10 sq.m. - then the power of this system will be 2.2 kW/h, and the energy consumption with constant heat maintenance will be about 1.3 kW/h - not a little, would you agree? Here you can save on electricity by installing a programmable thermostat that will work according to your schedule and save electricity.

— Is it difficult to install an infrared heated floor yourself?

We answer:

No. Infrared film heated floors can be installed by any adult, both men and women (VERIFIED). However, it is always better to contact qualified specialists with many years of experience.

These are the most popular questions before clients want to buy film infrared heated floors. I hope some myths have been dispelled, and you have clarified some questions that interest you.

If you have any questions, be sure to call us and we will tell you everything in detail and show you.

Well, let me remind you: buy high-quality infrared film heated floors in Murmansk at the address: Murmansk, st. Domostroitelnaya 7

KITMiX store on the territory of the MEGAstroy shopping center or by phone 78-51-52

How to choose the right option

The variety of choice of heating film itself can puzzle everyone. You should always start from the initial conditions. So, you have your own heating, and the back room, intended for the nursery, does not warm up well and has the lowest temperature. What to do? There is an exit. Under the existing laminate flooring, you need to install a heated floor system. This is where low-temperature films like Caleo, Heat-Plus, Power Plus, RexVa XiCa and many others will come to your aid. Installation is not that difficult. You can, of course, get by with a warming mat, but this is an electrical appliance, and you cannot leave a child unattended on it.

If you don’t want to redo the floor in the room, you can simply attach heating baseboards, which will make the task of insulating the room much easier. If you want to insulate the loggia, but do not want to change the floors in it, a good option would be to insulate the walls with infrared film. You can also apply panels on both sides of the loggia under the window and opposite the street windows. It would be best to hang infrared panels from the ceiling. It will be quick; you don’t need to remove furniture from the loggia to open access to the walls.

What is the reality

Having discussed all the pros and cons, it is worth turning to reality, namely to practice. Here we mention some interesting facts:

- The installation work cannot be said to be that easy. Everything looks like this: a substrate is laid out, an infrared heated floor film is laid, it is connected to electricity and everything is covered with finishing material. But here one nuance arises, which lies in the correct connection of the silver contacts to the film itself. Not everyone does this work correctly. If the contact is not properly clamped, this affects the quality of heating. Moreover, such a contact can only be pressed once. Otherwise you will have to cut off part of the infrared film and use a new clip. As a rule, there are a limited number of them, so everything must be done accurately and without errors. So, if a specialist has about seven years of experience, then a floor area of 18 m2 will be covered in approximately 6 hours. And this is provided that the technological process provided by the manufacturer for the installation of infrared heated floor film is fully followed.

- Of course, to lay an infrared heated floor there is no need to fill in a new screed. however, a level surface is essential. If the floor surface is curved, this may lead to damage to the heating film.

- Now it’s worth mentioning the height savings. According to the technology, the manufacturer recommends laying plywood up to 10 mm thick or chipboard up to 20 mm thick on the base. A special 3 mm substrate is also provided, the film itself is 3 mm, polyethylene film up to 1.5 mm and a finishing coating, which can range from 2 to 5 mm. So, you can really see how thick the heating cake will be.

- Among the advantages is high reliability. And this is true, but only under one condition - if the installation technology was followed 100%. Otherwise, problems may occur during operation.

- As for saving up to 20%, this is a reality, but only if the operating conditions are met at a temperature of no more than 21.5°C.

- As for eliminating unpleasant odors, this is also a reality. In ionized air, certain odors do not last long.

- If film infrared heated floors are combined with conventional local heating, the effect of air drying is eliminated. The air will not dry if only film infrared heated floors are used.

- If we talk about anti-allergic properties, then this is a little exaggerated. However, if you install an air purifier, humidifier and ionized air in the room, then perhaps this effect will be possible to achieve.

After all this, you can draw your own conclusion whether it is worth installing an infrared floor heating system based on infrared film. If yes, then you will be interested in the continuation of this topic. Next, we will learn about the principle by which film infrared heated floors work and how to implement it yourself.

Restrictions on the use of IR films

Limitations in choosing an infrared type of heating may include:

- maximum temperature of the film, laminated flooring, parquet boards, carpet can be laid on a heated floor using a low-temperature film that heats up to 27˚C. tiles, expanded clay coating require a higher temperature of the order of 45−50˚С;

- large rooms require high power and, therefore, amperage, which is not always possible in residential premises;

- high ceilings prevent the cost-effective use of infrared radiation;

- used as the main source of heating in areas with a mild climate, in other cases it can be used as local heating, additional to the main one.

Existing restrictions

Infrared films, depending on the type of heating system, may have restrictions on the maximum temperature of the material itself:

- laminated coating;

- parquet board;

- carpet

Usage example

All of them can be laid on the surface of a heated floor, which is set at a low temperature, not exceeding 27°C. But expanded clay and tiles require stronger heating. The floor film used should already be heated to a temperature of 50°C. A larger square footage of premises requires the use of more power.

Additional properties

One of the undeniable advantages is the environmental friendliness of the material used, which is considered completely harmless to human health. If you use film materials in combination with gas heating systems, you can find many advantages. It is worth noting that only interior items and their surfaces are heated, and not the air in the room. The generated heat rays easily pass through dense matter and are absorbed by them. But secondary waves already warm up the air directly. Thanks to this, the air in the room is slightly lower than the surrounding furniture, which allows you to create optimal areas for comfortable spending time.

Advantages

In this case, the chemical composition of the air does not change. We are talking about organic matter and various oxygen compounds. It has long been proven that cool temperatures help improve brain and physical activity. If all infrared floor elements are installed correctly, the system will not emit harmful waves. This can be achieved by correct arrangement of conductive components. Unlike other heating systems, it does not create noise. They do not contribute to raising dust in the room, which is extremely important for allergy sufferers.

Comparison

The use of this system allows you to control and regulate the temperature. You can also use automatic settings that will allow you to warm up faster. Such an adjustment has maximum accuracy, so there is no need to worry about its operation in the absence of all family members. The available temperature sensors not only monitor the temperature of the air and floor of the room, but also maintain it at the optimal level. Their operation does not affect the level of humidity, so the air will not be overdried, unlike the actions of other systems.

Distribution

AdminAuthor of the article

Did you like the article?

Share with your friends:

Video

https://gold-cottage.ru/poly/infrakrasnyj_plenochnyj_teplyj_pol_svoimi_rukami.html

https://samelectrik.ru/kak-pravilno-stelit-teplyj-pol-pod-linoleum.html

https://sdelai-pol.ru/montazh-infrakrasnogo-teplogo-pola

https://leroymerlin.ru/advice/elektrotovary/montazh-plenochnogo-teplogo-pola/

https://babyremont.ru/o-remonte-poverhnostej/o-remonte-polov/chto-takoe-tyoplyj-pol-iz-plyonki-kak-ulozhit-elektricheskij-plyonochnyj-tyoplyj-pol-svoimi-rukami.html

Laying underfloor heating

Depending on the selected additional heating system, the floor is laid in different ways:

Warm electric floors are most often laid under tiles; this material is affordable and does an excellent job of transferring heat. Heating mats are predominantly used as a heating element; they are very easy to install and repair, which makes such a system an ideal option for installation in a city apartment. Another advantage of such a system is that there is no need for a cement screed, which allows you to maintain the height of the room. Heating elements are laid in the last stages of repair work before laying the tiles. They are placed on a concrete base, prepared in advance for work. The heating elements should be placed in a layer of tile adhesive.

All heating mats are calculated according to their area; these elements cannot be shortened.

When laying such a floor, the use of reflective materials is not required. The heating area for installing the main heating system via underfloor heating should be approximately 80% of the area of the entire living space.

An electric heated floor under a laminate is in most cases a film infrared emitter. Special mats of reduced thickness are placed under the laminate. This is due to the proximity of the heat source to the surface of the floor covering; thin heating mats avoid deformation of the floor covering. Heating mats are a thin cable attached to aluminum foil. It is covered with foam plastic on the front and outside. This measure is necessary to provide additional sound insulation and more uniform heating of the floor surface.

Warm floors are installed under carpet very rarely, because home owners believe that this material conducts heat poorly and does not allow it to heat the room. But contrary to this opinion, carpet behaves perfectly when laying heated floors. The material will reflect some of the heat energy and divert it to the room opposite the apartment, but at the same time a significant part of the heat will spread throughout the living quarters. An infrared system is best suited for use with carpets; it heats the surface evenly and ensures fire safety, which cannot be said about cable floor heating.

All installation options have one common requirement: the heating elements must not touch or even be near flammable elements.

The correct operation of the additional heating system is checked before laying the cement-sand screed. In case of incorrect operation of the heated floor, at this stage it is possible to carry out repair work and correct errors.

After filling the floor with cement screed, it can be used no earlier than 28 days after completion of the work. By this point, the concrete mixture will gain maximum strength and will not interfere with the operation of the elements. When pouring concrete, it must be remembered that the material must gain strength in a humid environment. Work should be carried out at air humidity of at least 80%.

After laying a heated floor without using a screed, it can be turned on immediately after the solution has dried. This usually takes several days.

After laying the cement screed, the coating must be left undisturbed for at least 72 hours, after which time you can already walk on the floor and carry out further work.

In a room with a heated floor, in addition to installing thermal insulation of the floor covering, the possibility of wasting heat energy on heating the street should be eliminated. To do this, owners are recommended to take care of installing additional thermal insulation of all enclosing structures. In a room with heated floors there should be no constant drafts or other factors that waste heat energy.