Hi all! I don’t think it’s worth saying that a number of synthetic materials are harmful and dangerous. Even when it comes to construction. That’s why people are increasingly paying attention to natural and environmentally friendly analogues. As you understand, we will talk about flax and hemp insulation.

I confess honestly. Once upon a time I myself was surprised to know what linen insulation was. And hemp insulation raised no less questions. It is clear that this is insulation made from flax, as well as insulation from hemp, respectively.

But how they are made, how effective they are in terms of insulation and how they are used has been a mystery. Then he began to gradually unravel it. Now I share my thoughts with you.

History of appearance

In general, insulation made from hemp fiber, as well as from flax, is not uncommon in our market. And the history of the appearance of the material takes us many centuries ago.

Even in Rus', plants were grown long before industrial hemp fiber appeared, as well as full-fledged automated production.

In the USSR, a couple of plants were among the leaders in the light industry segment. The material had reliability, durability, and good antiseptic properties. As a result, they began to create threads, ropes, sails and tarpaulins.

If we talk about construction, then even then the material was actively used as natural insulation from flax and hemp. Along with moss, which made the house much warmer.

Thanks to modern technologies, hemp thread, like linen mats, have significantly improved their properties and capabilities.

Pseudo-friendly insulation materials

Photo: mineral glass wool insulation is very dangerous for the respiratory tract of humans and animals.

Approximately the same situation applies to pseudo-environmentally friendly mineral fiber insulation! Few people know what is used in their manufacture! What mineral fiber? What rocks? From rocks or, after all, from slag waste from Magnitogorsk blast furnaces?

Photo: harmful fiberglass has flooded the Russian construction insulation market!

Have you ever wondered how waste from mineral and glass production is turned into super environmentally friendly insulation? We think that they were transformed not by the wave of a “magic wand,” but most likely by the wave of paid mass advertising companies that pushed false information into people’s heads about the environmental friendliness of insulation materials based on industrial waste.

What are the features of thermal insulators

When thinking about how to cover a frame house, as well as buildings made of other materials, you should not forget about the importance of high-quality and effective thermal insulation.

Speaking about flax and hemp insulation, it is important to focus on the properties and features of these products.

The raw materials are approximately the same, which makes it possible to create insulators with almost identical characteristics and properties. More than one manufacturer whose specialization is thermal insulation combines two plants, mixing components in different proportions, and obtaining a finished product for use in construction and renovation.

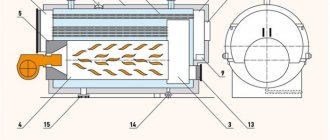

Production looks something like this:

- the collected plants are processed and processed;

- the output is coarse fibers, which serve as the basis for insulators;

- after purification, plant fibers are mixed with additives;

- the main one is bi-component staple fiber;

- the mixture is baked in an oven where the temperature reaches 180 degrees Celsius;

- the process is called thermal bonding.

There are also completely natural insulating panels. Here starch is used as a binder. But due to their low durability, they are only suitable for insulating horizontal planes.

The insulation, made using thermal bonding technology, includes about 15% of binders. They are somewhat reminiscent of padding polyester, since the material used is similar. Binders make flax and hemp insulation stronger and add elasticity.

What can be considered environmentally friendly insulation?

In fact, environmentally friendly insulation is something completely different. This group of insulation materials, according to reviews from environmentalists of the organization Greenpeace Russia, can only include in our country only natural, environmentally friendly insulation materials, for example, swamp moss - sphagnum, cuckoo flax moss, insulation materials based on natural flax and natural jute. An excellent environmentally friendly insulation material, of course, is wood made from loose layers.

The photo shows one of the most environmentally friendly insulation materials - cuckoo moss. Most often, this natural insulation is used in the construction and insulation of environmentally friendly wooden log houses of country houses and log baths.

The photograph shows a cut of one of the most healing - environmentally friendly insulation - a cut of Siberian fir wood. A wooden house made of timber or rounded logs made from Siberian fir wood, with block house finishing, can be considered one of the most environmentally friendly wooden houses. In addition, such a wooden house will not only be environmentally friendly, but also a healing, rejuvenating residential building.

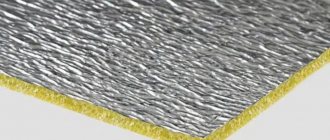

And, in this picture - photo - an environmentally friendly thermal insulation (thermolen) based on the natural flax plant. This environmentally friendly insulation appeared on the domestic market quite recently. It is 85 percent flax - flax fiber and 15 percent chemically neutral thermal bonding fiber. We will talk about this insulation in a separate construction article posted on the page of our website. But, if we briefly list, according to the manufacturer’s reviews, the advantages of this environmentally friendly insulation, then these are:

- natural, breathable insulation composition;

- useful antiseptic and bactericidal properties of insulation;

- durability and inability to self-destruct;

- absence of harmful electrostatic properties.

Photo: environmentally friendly insulation of the Lighttek brand is very well suited for environmentally friendly insulation of the floors and ceilings of a wooden house.

Photo: Lighttek insulation is supplied in bags and does not require special protection from external influences.

Photo: thermal insulation based on polyethylene foam is used in environmentally friendly construction products.

Is there a difference

Many people are interested in whether flax-based insulation differs from hemp fiber insulation.

If we talk about thermal conductivity, then there is virtually no difference. It can be ignored.

It is believed that for insulators it is better to take materials with thinner fibers. But when studying the test results, it is safe to say that there will be no real difference between hemp and flax.

I think the main difference is something else. These are opportunities for production. Given the specific nature of the properties of hemp, industrialists were not allowed to grow and use this plant for a long time. But there were no such problems with flax. That’s why most heat insulators were made from it. Now the situation has changed. But the ratio of the number of produced flax and hemp slabs is still in favor of the former.

Experts recommend

All construction experts in the field of wooden country house construction strongly recommend this environmentally friendly insulation for use in construction. It is especially recommended to use this insulation in the construction of environmentally friendly wooden houses made of timber and rounded logs. To insulate, for example, the ceiling of a wooden log bathhouse today there is no better insulation than environmentally friendly flax - it is warm in combination with isospan.

In general, according to reviews from experienced builders, today on the modern construction market there are practically no environmentally friendly - natural, natural insulation materials. Up to 90% of the market for modern thermal insulation materials is filled with pseudo-environmentally friendly insulation materials. The environmental friendliness of modern industrial insulation, based on fiberglass brands Ursa and Knauf, is a big advertising bluff. How can fiberglass made from dirty glass waste be called clean?

Advantages and disadvantages

See also:

What does grinding plaster mean: how to do it yourself

Both materials used in the construction and repair industry are characterized by:

- environmental friendliness;

- security;

- thermal insulation properties;

- ease of use;

- resistance to combustion (due to special treatment);

- durability.

But there are also disadvantages. The main disadvantage is the high price.

Previously, flax and hemp insulation materials were produced only abroad. Then production started within the Customs Union.

But still, even domestically produced mats and panels are still much more expensive than mineral wool, as well as its analogues, including the well-known insulation material basalt wool.

Disadvantages of linen insulation

Linen insulation has a lot of advantages. However, this fact does not detract from its shortcomings. In order not to regret your choice later, you also need to get acquainted with them.

The disadvantages of linen insulation are not so significant, however, it is precisely because of them that this wonderful material is still not very popular.

People do not always have the opportunity to insulate their homes with linen material. It's all about his shortcomings. Let's get acquainted with them.

Disadvantages of linen insulation:

- Linen insulation has a high price. It is more expensive than most other insulation materials.

- Also, many complain about the narrow range of use of such material. For example, they cannot be used to insulate roofs or be used for outdoor work.

- In combination with wooden walls, such insulation will quickly absorb moisture. Because of this, the material may begin to rot.

- When stretched, this type of insulation can tear.

- If linen insulation is used in rooms with high humidity, it will have to be treated with a special moisture-proof impregnation.

- Despite appropriate processing, flax insulation can become the main component of a fire in the event of a fire.

Linen is a good material for insulation. Despite its shortcomings, it is considered one of the best options. Indeed, in most cases you will not have to deal with the disadvantages of flax.

Application area

See also

Insulation of a brick wall from the outside: how to insulate the facade and how

Considering each property that materials have, it would be logical to ask where they can be used.

Such a solution will become relevant in the following cases:

- Frame houses

. The characteristics allow you to effectively withstand extreme cold, as well as prevent the house from overheating during the hot summer; - Wooden houses

. By insulating your house with such materials, you protect it from moisture, wind and noise. An important nuance is that it is not necessary to use vapor barrier films. After all, it is films that usually lead to the appearance of condensation, mold and mildew; - Saunas and baths

. Eco-insulation materials help purify the air, are also resistant to dampness and retain heat well. Therefore, hot and humid rooms are excellent; - Apartments

. For an apartment, natural insulation will be more useful as a sound insulator. And there will be less synthetics.

Working with flax and hemp insulation does not require the use of protective equipment. Absolute safety. You can even lie down on them and rest.

Features of thermol

There are several flax products used for home insulation. The most famous of them is flax wool, which serves as an excellent heat insulator, laid between the tiers of a log house (during the construction of houses and baths). The difference between Thermoln and it is that the former is produced using a different technology - its constituent components form a single structure under the influence of high temperatures (about 150 degrees). With such heating, flax sinteres, taking on “lush” shapes as it remains in normal conditions. This is how the material in question is obtained.

For more reliable bonding of insulation fibers during manufacturing, polyester binders are added to the mixture. With their help, the previously mentioned splendor is achieved, as well as elasticity and durability.

The capillary structure of the S-shaped fibers allows the insulation to regulate indoor air humidity, and the low thermal conductivity coefficient ensures a comfortable temperature for living all year round.

It is almost impossible to distinguish thermolene from flax wool by color or composition, but other parameters are obvious. To ensure the same microclimate indicators, the former will require much less, since the thermal conductivity coefficient is lower than that of the latter. Consequently, it is much more profitable to purchase thermolene and insulate the room with a thin layer of material than to take a thicker flax analogue.

Selecting insulation sizes

See also

Brick-like facade panels for exterior decoration of the house

When planning to use linen mats for insulation, or a hemp analogue, from which the slab is also formed, you need to think about the issue of their dimensional characteristics.

Experts advise that the width of the mat be approximately 3-5% greater than the distance between elements such as the ceiling, post, beam, and rafters.

For example, if the partition has a distance between elements of 570-580 mm, then mats with a thickness of 600 mm should be taken. If the distance is 600 mm, then it is better to take a mat for 620-625 mm. This will ensure a tight fit without heat leakage. Plus, take into account possible differences in distances.

It is not recommended to push mats that are too wide into narrow gaps. Otherwise, waves will form, which will not benefit the thermal insulation performance of the house. And insulators that use starch as a binding component are better off compressed only minimally.

Types of thermal insulation from flax

This is flax wool, quilted with nylon thread.

Flax fiber has been used as insulation for a very long time, ever since huts were chopped down by hand with axes, and there were no alternatives. This is a natural material that is grown as a raw material on an industrial scale. Fortunately, in our latitudes there are all the necessary conditions for this plant to flourish. This probably explains the widespread use of this material from ancient times to the present day.

Flax fiber insulation is available in the following versions:

- ribbons;

- mats;

- rolls;

- tow.

Flax in strips is used for sealing crown joints during construction from logs or timber, as well as for caulking cracks. It is produced both in pure form and as part of other materials, such as jute insulation. In terms of characteristics, these materials are approximately equal, but jute, unlike flax, practically does not absorb moisture. In its pure form, flax in ribbons can also differ in the manufacturing method, including:

- felt;

- flax wool

Felt, also known as eurolinen, is produced without any additional materials by weaving fibers together. Linen batting is stitched with threads, which maintain the structure of the material. Felt is denser than flax wool. Also in architecture, tow - combed felt - is used for similar purposes.

Linen for insulating crowns.

Linen in mats is very similar to mineral wool. This material is produced in Russia, for example, linen insulation ecoteplin is made from raw materials grown in the Novosibirsk region. The business has been put on the conveyor belt, the quality of the product is high thanks to new German equipment. It is positioned as an eco-material and has recently been actively lobbied for. Thermal insulation made from flax has the following characteristics:

- resistance to heat conduction – 0.038 W/mK;

- degree of noise absorption – 0.98;

- material density – 32-32 kg/m. cubic;

- degree of steam conductivity – 0.4 mg/m*h*Pa;

- flammability group - G1 (does not support combustion);

- maximum temperature – 160 degrees;

- service life – 75 years.

As you can see, flax slab insulation does not have any special advantages over mineral wool, and it is more expensive.

Linen has shape memory - this means that even after it gets wet and deformed, after drying the material returns to its original shape.

There was a case when the slabs were stored stacked on top of each other directly on the floor, and a water leak occurred, which was noticed only in the spring. It turns out that the material lay in a puddle for about 5 months. The bottom plate became five times thinner (out of 50 mm, about 10 mm remained) and changed in color. After it was dried, it again became 50 mm thick, but the color remained unchanged.

Tow made of flax - used for inter-crown insulation and caulking of cracks.

Based on this, we can conclude that although flax absorbs moisture, it easily releases it and does not lose its qualities. By the way, even when wet to 30%, it does not lose its ability to retain heat. A similar property is also inherent in sheep wool insulation. In addition to mats, the production of linen insulation in rolls has also been established.

Linen insulation is produced by both domestic and foreign companies. Moreover, foreign analogues are no better than ours, but they are more expensive. The difference in price is explained only by transportation costs, payments of customs duties and other government taxes when transporting goods across the border. Therefore, you should not think that they are more expensive because they are better, no - this is not so. The most popular in Russia and the fraternal republics:

- Ecoteplin – Russian Federation;

- Termolen - Russian Federation;

- Ecotherm – Republic of Belarus.

According to reviews from real users, autonomous home heating is much more convenient and economical than centralized heating. And with proper insulation, heating costs are significantly reduced.

To draw up a project for autonomous heating of an apartment, you need to contact specialists. More details here.

Density indicators

When choosing the optimal linen material, also take into account the density.

Now many insulators are produced without distribution depending on the density class. Basically, they are universal, which allows you to use mats to protect different areas of the house.

The universal density for flax and hemp products is 35 kg/m3. It is allowed to choose an indicator of 30 kg/m3.

But it’s not worth saving by buying products with a density of 15-20 kg/m3. They are blown, have low heat capacity, and also weak sound absorption.