How to disassemble a flat tank water heater

Action plan:

- the boiler is disconnected from the power supply, the water is drained and the check valve is unscrewed;

- unscrew the plug nut;

- plastic shields are dismantled;

- in the center of the plastic cover, a screw is unscrewed, which is most often sealed with a sticker;

- the bottom cover is removed and access to the complex circuit of electrical components is opened (before disassembling it, it is advisable to photograph the structure, sketch and label each component, this will then help to assemble everything correctly and quickly);

- The next step in disassembling a water heater with a flat tank will be to disconnect the control board and thermal protection, for which you unscrew all the screws and nuts of the grounding bracket (you should remember that the thermal protection and electronic board are afraid of water, so it is very important to protect them from its influence);

- disconnect the connector that comes from the outer board from the electronic control board;

- to dismantle the heating element, which is attached to the flange, you should unscrew the nuts (the work can be complicated if the heating element is covered with scale; remove it slowly, with extreme caution).

Sometimes it is necessary to dismantle both the internal and external control board, which is located on the outside of the water heater body. Before removing it, remove the plastic sticker from the front panel and unscrew the bar.

It's simple. Anyone can do this kind of work with their own hands, without the help of specialists.

The best posts

- How to make a plasterboard ceiling in the kitchen with your own hands

- Painting drywall - step-by-step instructions

- How to join drywall in corners and the process of building a decorative niche

- Sealing drywall joints - recommendations from professionals

- Epoxy resin, application

- How to seal a doorway with plasterboard - installation diagram

- DIY plasterboard ceiling installation - video tutorials and installation instructions

- How and how to glue a foam plastic ceiling plinth

How to disassemble a water heater with a heating element

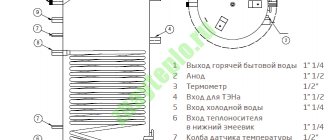

This is a relatively inexpensive type of boiler that has a heating element attached to nuts. This device, as a rule, does not have external adjustment. Its distinctive feature is the presence of a hexagonal flange, which can be unscrewed with a 55 wrench or a regular gas wrench.

Algorithm for disassembling a water heater with a heating element:

- the device is disconnected from the network, the water is drained and the check valve is dismantled, which will only complicate the work;

- the boiler cover is removed, which is screwed closer to the pipes;

- The thermostat is being dismantled;

- place a container under the water heater into which the remaining dirt, water and scale will be drained;

- unscrew the flange counterclockwise (existing dirt and scale can complicate the work, so they are carefully cleaned off with a wooden or plastic knife; as soon as the thread ends, the flange is carefully removed);

- in order to remove the heating element, remove the scale from the bends of the heating element and, carefully swinging it left and right, pull out the lower part of the element.

How to disassemble an economy class water heater (boiler) Economy class water heaters are distinguished by their oval flange shape, therefore the principle of their disassembly has some peculiarities.

Stages of disassembling an economy class boiler:

- the device is disconnected from the power supply, the water is drained and, if necessary, the check valve is unscrewed;

- There are two screws near the drain and fill pipes that should be unscrewed and the water heater cover removed;

- with a sharp downward movement, the thermostat is removed and access to the flange is opened, which is attached with a nut to the body using a strip; After the nut is unscrewed, you can remove the flange.

READ MORE: Indicators blink in an Indesit washing machine without a display - how to find out the error code | RemBytTech

How to disassemble a medium-class water heater Medium-class water heaters have an average price category. The device comes with flanges that are attached directly to the neck using 6 bolts.

The disassembly process for this water heater is as follows:

- the power supply to the device is turned off, the water is drained and the check valve is removed;

- to remove the cover, find the screws and unscrew them (the location of the screws may vary);

- after this, it is necessary to remove or remove the thermostat (depending on whether it is connected to the heating element with a wire or inserted into it);

- all necessary screws or nuts are unscrewed.

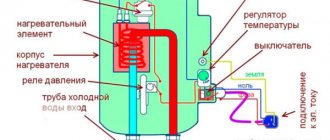

How it works

To minimize problems with the device, you should study its structure and operating principles. Typically, private households use storage models rather than flow-through ones, which allow them to use electricity more efficiently. Such a device consists of a heat exchanger tank, inside of which a heating element is installed - a heating element, connected to the power supply.

An important part of the device is the thermostat. This element allows you to maintain a constant temperature of the water inside the storage tank. Water flows through pipes into the heat exchanger. If its temperature is too low (and this is usually the case), then the thermostat sends a signal and turns on the heating element.

The water is heated until it reaches the required temperature. After this, the thermostat operates again and turns off the heating element. Hot water is taken from the tank and replaced with cold water, the heating process is repeated again and again. This is a general diagram of the design and operation of a conventional storage water heater.

Flow models are designed somewhat differently. They heat not a static volume of water, but a flow. They use more powerful heating elements that start when the water is turned on and stop when it is turned off. To study the operation and design of a particular model in more detail, you need to carefully read the technical documentation accompanying it.

The heater tank is a durable stainless steel container, one or two millimeters thick. No matter how resistant this material is to corrosion, these processes still periodically arise and develop, which leads to water leaking from the device. One of the common causes of such breakdowns is electrocorrosion.

Flow-through heaters usually break down for the same reasons as storage models. Diagnostics and repair of such devices are carried out using similar methods ( )

To prevent it, you need to regularly, i.e. annually replace the magnesium anode installed inside. This element is designed specifically to prevent electrocorrosion

Over time, it wears out, and storage tank owners neglect to replace this important part.

As a result, the tank, which has been serving well for some time, suddenly begins to leak. The incorrect condition of the magnesium anode can also affect the condition of the heating element. On the outside, the storage tank is usually enclosed in a metal or plastic housing, and it also has an insulating shell that prevents heat loss.

Damage to the outer shell and insulation occurs rarely, usually due to careless handling of the device. Cracks and chips on the body of the water heater may not disrupt its operation, but this will lead to a deterioration in the properties of the heat insulator and will negatively affect the functioning of the device as a whole.

Inlet and outlet pipes for cold water and outlet pipes for hot water usually do not cause any problems if the heater is installed correctly. Typically, a water heater is equipped with two thermostats, one of which is designed to control the water temperature, and the second monitors the condition of the first device.

READ MORE: 35 hairstyles to make you look younger than your age: tips and photos

Sometimes a third thermostat is used, which determines the working condition of the heating element. In any case, a broken thermostat will have to be completely replaced. There are capillary, rod and electronic types of thermostats. Their design is different, but the principle of their operation is similar.

The insulating gasket not only serves to seal the connection between the elements of the water heater, it is also necessary as an electrical insulator. It is recommended to replace this element regularly during each maintenance of the water heater.

The thermostat shows to what temperature the water inside the device is heated. If this element breaks, the water heater will still perform its functions, although data on the degree of heating will not be received.

In what cases is it necessary to disassemble the boiler?

Gas boiler wiring diagram.

The magnesium anode in the boiler, used as a catalyst to protect against corrosion of the tank walls and aggressive effects on the heating device, must be changed periodically.

The service life of the anode depends on the quality of the water used in the boiler (it is recommended to install a special filter on the cold water supply pipe), the operating temperature of the water, and the intensity of operation of the water heater.

The standard period of use of a magnesium anode, indicated in the boiler operating instructions, does not exceed 6 months. When using the boiler in a gentle mode, the magnesium anode can last 1-1.5 years without replacement.

We recommend: Water pump for heating - selection, installation and nuances of application for a finished system (125 photos)

Along with replacing the anode, as a preventative measure for the water heater, it is necessary to thoroughly clean the inside of the tank from scale and wash the walls.

The heating element must also be cleaned using special chemicals or a regular metal dish sponge.

An additional need to disassemble the water heater arises as a result of an accident, breakdown or reaction of the boiler to non-standard operating conditions.

As a rule, the heating element fails.

Diagram of connecting the boiler to the network.

If the water from the boiler has an unpleasant odor, yellow or brownish tint, this indicates corrosion and clogging of the tank. The same is evidenced by the fact that the water takes too long to heat up and the appearance of loud extraneous sounds during operation of the heating element.

It is necessary to immediately disassemble the boiler, determine the malfunction and eliminate it. In any case, you should thoroughly rinse the boiler and make sure that both the walls of the storage tank and the heating element are clean.

If there is a leak in the boiler, you need to make sure that the rubber waterproofing gasket is reliable. If necessary, the gasket should be changed.

If the leak occurred as a result of depressurization of the storage tank itself, it is not possible to repair such a breakdown with your own hands. This may be a manufacturing defect - then the boiler must be replaced in accordance with the warranty agreements.

Sometimes, as a result of improper operation of the boiler, the walls of the storage tank may rust. In this case, the procedure for replacing the storage tank may cost more than a new water heater.

Step-by-step instructions: remove the cover from a domestic water heater

Disassembling a boiler takes place in several stages, which can be handled successfully if you know exactly how to remove the cover from a domestic water heater.

We recommend disassembling the structure in the following sequence:

- Turn off the water supply. In most cases, the valve is located at the bottom of the housing.

Cold water valve location

- It is necessary to disconnect the equipment from electrical networks. If the device is not connected directly, but through a surge protector, it is better to completely unplug the extension cord from the outlet and take it out of the room, since devices connected to the network only increase the likelihood of a current short circuit.

- Next, you need to drain the water from the hose attached to the drain pipe. It is better to pour it into a basin or bucket, and then into the toilet. This will prevent accumulated scale from clogging your bathroom or sink drain.

- Using a straight screwdriver, unscrew the screws and remove the protective cover from the bottom of the case. The tight-fitting lid is removed very slowly - as if unscrewing the lid on a can of canned food. It is very important not to damage the enamel.

Removing the protective cover from the tank

- After removing the cover, use an indicator screwdriver to determine the voltage at the terminals. To do this, ring all the contacts one by one, touching the iron cap of the screwdriver. The light in the screwdriver should not light up or blink in any case.

- Next, you need to empty the tank of water. You must wait until the contents of the tank cool down. Some models need to be removed from the wall. In this case, it is necessary to disconnect the hot and cold fluid supply hoses.

- If the equipment is still under warranty, you cannot drain the water, otherwise it may be considered as a non-warranty case. This must be indicated in the instructions or warranty card.

To drain, you will need a gas wrench and a hose. The sequence of actions to free the water heater from water is as follows:

- Use a gas key to turn off the cold water supply - the valve for incoming water;

- open the hot tap on the mixer to avoid vacuum;

- drain the water to the mark - this will take from 1 to 10 minutes;

- do not close the mixer, open the tap and let the water drain, you can also simply tighten the nuts at the cold water inlet and the liquid will easily drain;

- connect the water outlet hose to the thread of the heater, lower its second end into a sink or some container deep enough;

- then disconnect the hot water outlet hose from the body - this way we will get rid of the liquid accumulated around them;

- when you unscrew the nuts, the remaining water will finally drain from the water heater tank.

READ MORE: Methods for connecting a CCTV camera to a TV: VGA, tulip and SCART

Emptying a small tank from residual water

This method of draining remaining water is suitable for units whose volume does not exceed 20 liters. Most often these are heaters of the Termex, Ariston, and Oasis brands. If the tank volume is large or a valve without a lever is installed, you will have to remove the water yourself. You cannot unscrew such a part, but you can press out the spring yourself.

Draining water from the storage tank

Diagram of the heating element device.

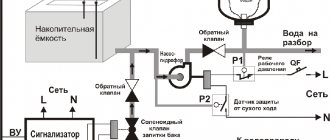

Using a shut-off valve, the cold water supply to the apartment is shut off. If a local valve is provided for the boiler, which shuts off only the necessary part of the apartment water supply, it should be used.

The hot water intake valve on the boiler and the cold water supply check valve are closed.

Using an adjustable wrench, the cold water supply hose to the water heater is disconnected, but the hot water extraction hose is not disconnected.

A rubber hose is placed on the boiler check valve. The second end of the rubber hose is directed into the sink, jacuzzi, bathtub. Water from the boiler will drain through it.

The boiler check valve and the hot water intake valve open. All hot water taps connected to the water heater are fully opened: in the bathroom, in the kitchen.

Atmospheric pressure is generated in the boiler storage tank, and water is pushed out through a check valve. Typically, water is discharged from the boiler in several portions as the pressure in the tank increases.

You can check that all the water has been drained by blowing into the rubber hose on the check valve. If water remains in the tank, a characteristic gurgling sound will be heard.

It may happen that the pressure in the water supply system is not enough to displace all the water from the boiler. In this case, the hot water extraction hose is removed and additional pressure is pumped into the tank through the hot water extraction tube using a compressor.

Attention! The cold water supply pipe to the storage tank rises above the level of the bottom wall. Therefore, a small part of the water will remain in the boiler and will drain only through the mounting hole of the heating element panel. This factor must be taken into account when further disassembling the water heater.

How to drain water from a water heater

Before disassembling the water heater, it is necessary to drain the storage tank - drain the remaining water in the water heater. Typically, two pipes are connected to the device:

- liquid withdrawal system;

- system for collecting liquid from a water supply system.

Drying can be done in several ways.

Standard method

This method is given in the operating instructions for the device. You will need to use a tee, which is located next to the valve and pipes of the system. Drying is carried out by shutting off the water supply pipe. The remainder of the already stored liquid is drained through the mixer.

The described method is relevant for models of the previous generation; modern devices are most often not equipped with a tee.

Using a lever (trigger)

A device located on the safety valve will help quickly get rid of accumulated water. All you have to do is simply bend the lever and the boiler will drain. It is worth noting that the procedure performed using a trigger can take a long time. Connecting a hose will help speed up the process significantly. By attaching it to the spout, you will greatly facilitate the outflow of water, but the water will still drain within two hours.

Alternative method

If none of the listed devices are installed on the device, you will have to resort to a more complex method. To do this, you need to unscrew the check valve counterclockwise. The pressure of the drained water will be very strong, no need to panic because of this, prepare a suitable container and clothes that you don’t mind getting wet. To protect the room from water, experts recommend using a durable hose, the length of which will be sufficient to connect it to the drain of the bathtub or toilet.

We recommend: Gas stove for home: heating in a private home, required burner power

If water does not flow after unscrewing the valve, this means that the hot water supply is cut off. At the same time, the flow of air is blocked, without which draining is impossible. Only after completing this procedure can you begin to further disassemble the boiler.

Types of instantaneous water heater control systems

Depending on the model and design of the water heater, the control system for its operation can be designed differently. For example, in the THERMEX STREAM model, temperature control is carried out by controlling the water flow. The flow itself is regulated by special shower or washbasin nozzles included in the delivery set. In this case, the protection components are a pressure switch and a thermal fuse (temperature sensor).

Flow-through heater THERMEX STREAM disassembled

Accordingly, the electrical circuit diagram of this water heater differs significantly from the electrical circuit given above - here the phase current passes sequentially through the pressure switch and the thermal fuse, which returns to the on position after the temperature drops. Before repairing the water heater yourself, you should definitely study the electrical diagram and instructions from the manufacturer.

Example diagram of instantaneous water heaters THERMEX STREAM

As can be seen from a comparison of two circuits from the same manufacturer, the principles of control and protection in these models of water heaters differ significantly. Water heaters have a completely different design, and the circuit will be different. Below, for example, is the electrical circuit of the Atmor water heater.

Scheme of instantaneous water heater ATMOR, power 7 kW

Also, some models may have an electronic interface directly connected to power relays for controlling the supply of heating elements. This means that a breakdown in this electronic board, or a failure of the algorithm, can lead to the stoppage of the water heater. Some instantaneous water heaters may have temperature control, which is achieved by switching heating elements, or using an electronic circuit.

Features of various designs

Before you start repairing a water heater with your own hands, you need to figure out what type of device it is. There are several varieties:

- electric boilers;

- flow-through;

- indirect heating systems;

- geysers.

The word "boiler" means "boiler". It follows from this that such products include not only storage devices, but also flow-through devices.

Electric heaters

This type of boiler is considered the most popular. The design consists of a tank, a thermal insulation layer (polyurethane foam is often used), and an upper casing.

The heating element is located at the bottom of the device. The water is heated to a certain temperature, which is pre-set on the thermostat, the maximum value is +75°C.

If no water is drawn, the device maintains temperature readings by turning the heating element on and off. It is equipped with overheating protection, so when the maximum performance is reached, the device turns off.

The optimal temperature value is +55°C; it is in this operating mode that the structure will last longer and save electricity.

This device is the most common

Hot water is drawn through a tube located at the top of the device. The cold liquid inlet is located at the bottom of the device. The metal tank is protected from corrosion by a special magnesium anode, which has a certain working life. The element must be replaced once or twice a year, depending on the hardness of the water.

Indirect heating systems

Such products do not independently generate thermal energy; water is heated using a coil in which the coolant is located.

Cold water comes from the bottom of the device, hot water comes out from the top. Indirect heating devices can provide large quantities of hot water, which is why they are often installed in large houses. The operating principle is to exchange heat between liquids at different temperatures. In order for the output to be +55°C, heating is carried out to +80°C.

The process takes a lot of time, this feature must be taken into account when choosing a suitable device. Like their electrical counterparts, indirect ones are equipped with a magnesium anode. The structures can be wall-mounted or floor-mounted; in addition, they can be connected to a double-circuit gas boiler. More expensive models are equipped with additional electric heating elements, which reduce heating time as needed.

Gas and flow structures

Gas-powered appliances are only wall-mounted. There is a thermal insulation layer inside the structure. There is a chimney pipe at the top, and a gas burner at the bottom. The latter is a source of heating, in addition, it is helped by the heat circulation of combustion products. An automatic electronic system monitors and extinguishes the gas as needed. The column is equipped with a protective anode.

Gas water heaters produce large amounts of hot water in a short period of time.

Flow systems do not accumulate liquid inside. The heating process occurs at the moment the tap is opened, when the devices allow water to flow through them. The structures operate on both gas and electricity. Gas products are modern modifications of popular geysers.

Electrical systems carry out heating using heating elements of increased productivity. Despite their small dimensions, the products are high-power, so their scope of use is limited. Hot water flows regularly without interruption for heating.

Gas water heaters have greater efficiency