Hot water from a wood stove

Sergey N » February 28, 2014, 11:39

Hot water from a wood stove

Bibikin Ivan » March 06, 2014, 10:10

Hot water from a wood stove

by sergiodessa » Mar 27, 2014 3:26 pm

Stove heating of a private home is still one of the most popular in all Russian regions. Previously, several stoves were used to heat a large house, which were installed in different rooms, but this is not the most economical option, as it requires a large amount of solid fuel.

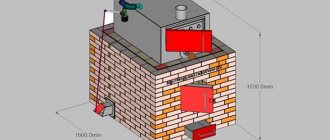

Stove heating of a private house - sketch

Today, thanks to the developed modern schemes, as well as the fact that many different modern types of stoves have appeared on sale, organizing heating has become much easier. It comes in different types and using different fuels. To choose the most suitable option for your home, which will suit all parameters, you need to take a closer look at some of the types and find out how they work.

Skirting radiators

This is a newfangled option when small radiators are installed around the perimeter of the apartment, at the level of the baseboard and disguised as worthless.

The main disadvantage will be this very plinth, it is wider and higher than ordinary plinths, and therefore there will be a small side around the perimeter of the room, which will not allow the bedside table or bed to be pushed completely against the wall. Agree, it’s very inconvenient when all the objects in the room stand 3-5 centimeters from the walls.

The advantage will be a more uniform heat distribution compared to radiator batteries. There will be no warm or cold corners in the rooms and it will be more pleasant to be in such a house.

Advantages and disadvantages of heating from a stove

Stoves with a water circuit are easy to make yourself, but you can purchase ready-made heating devices in the store. The models are characterized by the following advantages:

- Furnaces with a water circuit do not need to be connected to electrical networks. They do not use gas as fuel. The devices run on coal, peat and wood, which are renewable fuels.

- Stove water heating is completely autonomous, but it can be combined with other systems.

- Adjustment is carried out using a manual valve.

- The walls of the furnace are massive, they transfer heat, heating the air and surrounding objects. The room is heated evenly due to the use of coolant. It passes through the pipes, heating them and radiators.

- Heating a private home will not require large expenses. Coal, peat and wood are available to everyone.

- Stoves not only heat the room, they are used for cooking and heating water.

- Devices, the front of which is covered with glass, allow you to contemplate an open flame. Fireplaces create a comfortable atmosphere in homes.

- The design of the stove is massive; during the cold season it accumulates a large amount of thermal energy. The stove cools down gradually, so it heats the room for a long time after the fuel has burned out. In summer, the processes proceed in the opposite way. If the stove in a wooden house is built on a separate foundation, during the warm season it releases excess heat into the ground, working as an air conditioner.

- The natural fuel on which the stove operates moderately pollutes the environment.

- Water is used as a coolant. It has a volumetric heat capacity, which allows heat to be transferred over long distances. Water is affordable. It does not burn, is not toxic.

But furnaces with a water circuit also have disadvantages. They must be constantly monitored, firewood must be placed in time and the draft must be adjusted. The chimney should be cleaned and the ash removed.

A powerful brick oven is large in size, so it is placed on a solid foundation. It takes up the usable area of the room, which is why large structures are installed in spacious rooms. Such a furnace has low efficiency.

When installing a stove, you need to build a chimney. The draft must be strong, then the fuel burns intensely and the smoke is quickly removed outside. The pipe is isolated from the wooden elements of the roof and ceilings. Having installed a stove in the house, it is necessary to maintain a fuel supply and dispose of ash and slag in a timely manner. This adds more work to the owners of a private home.

The main disadvantage of water heating is that the water freezes quickly. Turning into ice, it expands, damaging devices. Combining with air, it promotes corrosion on the metal elements of the heating system. If the water is hard, scale will form inside radiators and pipes.

Brick oven

So, as mentioned above, for a small building it is enough to build one stove, which will be heated with wood or coal.

The stove model must be chosen in such a way that it can not only heat the premises, but also be an assistant in cooking.

To ensure that this heating structure does not cause any inconvenience and is as efficient as possible, you need to choose a suitable location for it. A well-placed stove can easily warm two rooms and a kitchen.

Such a stove will successfully heat several adjacent rooms.

For example, this model shown in the figure would be a good option for heating three rooms. You need to know that the heat transfer from the stove depends on the surface area of the structure, i.e. if one side of the stove opens into the room, it will be fully heated. In addition, the massive structure takes much longer to cool down. By heating the building in the evening, you can be sure that it will radiate heat into the room until the morning.

The stove must be laid during the construction of a house, but its foundation must be separated from the general foundation of the building. It is possible to install a brick stove in an already built house, but this will be more difficult, since you will have to raise part of the floor and make a hole in the ceiling and roof to install a chimney.

General diagram of a home stove heating system

This diagram clearly shows the structure of the building, the structure of the foundation, the chimney channels and the passage of the pipe through the floors with all the necessary parameters that must be adhered to.

Making a heat exchanger with your own hands

It is not always possible to buy a ready-made furnace project with a heat exchanger. Also, not everyone can weld themselves. But building a heat exchanger for a heating stove with your own hands is not such a difficult task. By using aluminum or copper you can avoid welding work. With good preparation and correct calculations, this is possible and not burdensome. In addition, it saves the family budget.

Consumables

Having chosen the location and size, it is worth considering what is easier to build a heat exchanger from. You can use both the materials listed above and cast iron radiators, car radiators, and the like. The main thing is to correctly take into account thermal conductivity. Think through exactly what tool you will need and prepare it in advance. All these little things will make installation easier.

Assembly algorithm

You need to start with the project - thinking through the little things and selecting options. It is worth starting from the size - if the stove is weak, then a disproportionately large heat exchanger will only do harm. If you use copper as a pipe for the coil, then the length should not exceed three meters.

The simplest manufacturing option is a coil. It will require a copper pipe from 2 m to 3 m long.

The heating rate depends on the length of the pipe and the number of turns. But it’s worth remembering that you need to take into account the size of the stove and firebox and not overuse the enlargement of the coil. Distortions in size reduce the service life of the furnace.

To twist the pipe into a spiral, you need a template. This is any cylindrical auxiliary part. The diameter of the template must fit into the combustion chamber size.

Having prepared the materials, let's start:

- Bending the pipe, we wind it onto a prepared blank to obtain a spiral;

- We observe the dimensions in which the coil must be placed;

The average design power of the heat exchanger is 1 kW per 10 meters of area.

If you are not satisfied with this type of heat exchanger, you can make another type, for example by welding steel pipes. It looks something like this:

Examples of drawings on which to carry out work:

How to install?

It is convenient to install a heat exchanger in a stove when laying a new stove. This will allow it to be completely installed, observing all the gaps and dimensions. With this installation it is easier to maintain the correct size. Having mounted the heat exchanger on the foundation of the furnace, it is easier to cover it with bricks than disassembling the finished furnace and trying to fit it into place. But this is also possible.

There are also important points and requirements that should be observed to increase service life:

- Do not fix structural pipes with metal fasteners;

- Do not fill with ice water to avoid condensation;

- maintain the proportions between the furnace and the heat exchanger, avoiding large differences;

- use sealing materials with high heat resistance;

- fully comply with all fire safety measures;

Simple rules will help you avoid dangerous situations and help extend the life of the stove. Don't forget about fire safety.

Examples of installation in the photo:

How to choose?

When choosing, the price of the heat exchanger for the furnace plays a fundamental role. The design decision depends on the choice of material. The second most important aspect is the possibility of manufacture.

And the final choice is the place where the stove will stand. You need to take into account what exactly you want to achieve. You need a heating and cooking stove or garage heating, whether it be a heater for a bathhouse or a stove for heating a country house. Each option has its own characteristics and subtleties.

The main thing is to accurately calculate what area needs to be heated, whether hot water is needed, how many units of fuel can be spent during the heating season, and much more. The result of all estimates should be the same - focusing on finances, available materials, needs, choose the most suitable design.

What is better in different options:

- For a bath - needs a complex option. The primary task is to heat water and two rooms. Dressing room and steam room, plus possibly a shower. Here it is better to use a coil for stove heating and water heating. Also, additional heating of the steam room improves the quality of steam in a Russian bath. Read also: DIY heat exchanger for a sauna stove.

- For the home - consider the necessary functions. The choice of design depends on this. Most often, in village houses they try to build universal heating and cooking stoves. It is possible to install here widely used heat exchangers, which are easy to manufacture and solve at least three problems - heating, cooking, water heating. A common option for using a heat exchanger in a brick oven for heating, with a container.

- For a garage, the choice is simpler here, because here water heating is not necessary and only heating is important. Such conditions simplify the choice. Homemade horizontal heat exchangers for a heating furnace, built from scrap materials - old cast iron batteries, car radiators and the like - are perfect.

Design features

Most often, a metal tank with a capacity of up to 5 liters with built-in pipes acts as a heat exchanger. There is no direct contact with fire. The device allows you to heat cold water, which then flows into radiators or a removable tank of larger capacity located in the same or an adjacent room.

As a result, by heating the stove in one room, it will be possible to heat another. According to its design, the heat exchanger for a furnace can be external or internal.

External

This type is very similar to a tank filled with coolant. Inside the container there is a part of the pipe used to remove combustion products. In terms of its design, the external heat exchanger is more complex than the internal one, as it places increased demands on welding work.

However, its maintenance is much easier. If necessary, the tank can be dismantled to remove scale or eliminate leaks.

Interior

Mounted above the firebox directly inside the stove. It is easy to install, but if maintenance is necessary, certain difficulties may arise. Especially if the stove is made of brick.

To avoid this, at the time of design development it is worth taking care of the maintainability of the future heat exchanger.

Principle of operation

The heat exchanger for a brick kiln is an indirect water heating device. The principle of its operation is that liquid circulates in the enclosed space of the device, as a result of natural convention. When exposed to heat, water heats up.

Hotter layers rise to the top, and cooler layers take their place. Mixing water under the influence of heat is called circulation. Heated water or any other coolant liquid, rising, gives off heat to the water. The furnace itself is not a heat exchanger because it creates heat.

Making a homemade heat exchanger

To make a heat exchanger with your own hands. many nuances must be taken into account. Only after carefully considering all stages of work, the end result will be a device that can provide the optimal temperature in the house. The main advantage of a device made by yourself is that the price of such a product is much lower, because you will only have to spend money on purchasing materials.

To ensure the maximum level of heating at home, it is necessary to choose the right material for the heat exchanger. Each metal has its own level of thermal conductivity. For copper, this figure is 7 times higher than for steel, so 2 pipes of the same diameter can provide different levels of heating. Therefore, copper is the best option for such a device. The price of this material is quite reasonable.

As for determining the power of the heat exchanger, these calculations are quite difficult. This is due to the fact that too many factors influence this indicator. However, on average, one meter of coil with a diameter of 50-60 mm is capable of producing 1 kW of thermal power. This indicator can be used as a starting point when making calculations.

Design features when making it yourself can be very different.

You can weld a pipe in the form of a coil or a regular rectangle, but there is a list of rules that you should definitely pay attention to:

- The diameter of the inner part of the pipe should not be less than 5 mm. Otherwise, the water may simply boil.

- To prevent overheating of the metal, the wall thickness must be at least 3 mm.

- There should be a gap between the walls of the firebox and the heat exchanger, the size of which is 10-15 mm. After all, metal tends to expand.

A water heat exchanger has these basic rules. Its manufacture (with proper welding skills) will not be difficult. The right approach to your home heating system will ensure comfortable living conditions.

Be sure to read these materials:

- Chimney pipe in a bathhouse

- Heat exchangers for hot water supply

What determines the efficiency of a heat exchanger?

- First of all, the efficiency of this device is affected by the difference in temperature between the two environments - the greater it is, the more energy they exchange.

- Another equally important factor is the thermal conductivity of the material.

- Finally, the heat exchange area is directly proportional to the efficiency of the device.

Important! Any pipeline through which fluid circulates at a temperature different from the air temperature is considered a heat exchanger.

Things to remember

With natural circulation of the coolant, the heat exchanger should be placed above the furnace at a distance of 1.5 - 2.5 m. Due to the constant change in geometric parameters, the pipes cannot be fastened to the wall tightly enough. It is necessary to provide a small gap.

It is important to remember that if the stove is used not only to heat the house, but also to heat water, a maximum of 10% of the total amount of heat generated should go to the heat exchanger. When using a structure with an expansion tank for heating, the volume of the latter should be selected so that the water in it can heat up to the required temperature in two hours

The return pipes should have a smaller diameter than the coolant supply pipes. The material intended for sealing threaded connections is selected with a sufficient level of heat resistance.

If the house is not intended for permanent residence, but is used only from time to time, then it is better to refuse water heating. It is advisable to fill in special antifreeze instead of water if you plan to heat a stove with a heat exchanger in the cold season. This will prevent pipes from bursting. Remember that adding coolant when the furnace is fully heated is unacceptable.

Functions

- Most often, heat exchangers are used to create a second heating circuit. Without it, the fuel burns and heats the walls of the firebox. Interacting with air, heated bricks give off heat. But it flies away through the flue.

- With the help of a heat exchanger in a brick kiln, hot air transfers excess heat to the circulating fluid. Allows you to increase efficiency by obtaining a double output coefficient per fuel unit.

- Heat exchangers are used in stoves for baths, garages, and houses. In each listed option, the heat exchanger has its own function: heating water for a shower, heating the coolant for heating, and the like. Various designs increase the range of applications.

Instructions for building a stove heating system with a water circuit

- A hole is being dug.

- A “cushion” is laid, consisting of broken bricks, crushed stone and medium-sized rubble. The width of this layer is approximately 20 cm. Natural materials are compacted and filled with cement mortar.

- Bricks are being laid. It is laid in two rows on cement, and covered on top with a waterproofing layer of roofing felt, parchment and roofing felt.

- A brick foundation is being built with clay mortar.

- The first continuous row is laid. In the second row, an ash chamber begins to form, for which a special door is installed. The third row repeats the previous one.

- The fourth row is formed. It serves as the basis for the fuel chamber made of refractory bricks; grooves are provided on it for installing the grate.

- A U-shaped boiler made of steel is installed. Two pipes are welded to it - one at the top for supply, the other at the bottom for return. It also has a rectangular hole through which heated gases will escape.

- The fifth row is laid. It is necessary to provide channels behind the side and rear walls of the boiler. Two small doors are installed on them to remove soot.

- A sixth row is formed, in which a hole is provided between the gaps made in the previous row. This is a suction channel to increase draft in a heating furnace. The door for the fuel chamber is also installed here.

- The wall is being laid out. It should be taken into account that fire-resistant bricks are laid around the door leading into the combustion chamber and above the fuel boiler.

- Cast iron stoves are being installed on which food can be cooked. A metal corner is attached to the entrance of the heating and cooking chamber.

- Chambers are formed, a channel is made on the back surface, and doors are installed.

- The facade of the cooking chamber in the 16th row is covered with a metal strip. And then it itself is covered by laying bricks on specially laid metal strips.

- A steam exhaust valve is installed to ventilate the furnace and an upper flue is formed.

- 35 rows are laid, on which the construction of the chimney begins.

Some people want to use a ready-made stove or fireplace, combining it with a water circuit. In this case, you will have to disassemble them almost to the ground in order to install the register.

Mayevsky crane

Water circuit installation process

Register for water stove heating

For efficient operation of equipment for a heating water system, it is necessary to install a so-called register, which is a boiler or heat exchanger. It is also often called serpentine. Such a register is placed in the stove firebox.

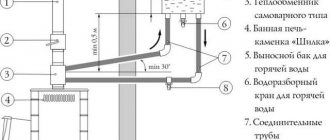

A water stove heating scheme for a private house consists of the following elements:

- combustion chamber;

- ash pan;

- sealed oven door;

- hatch for cleaning the oven;

- special surface for heating the oven;

- injector;

- gate;

- cutter;

- convection pipes;

- grate

When making a container yourself, it is important to take into account that only welding is used to connect parts. When connecting heating pipes, you need to use special connection elements in the form of fittings, couplings, etc.

Using this type of design for your home will make it possible to save money on a boiler, for which the manufacturing materials will cost much less than if you buy a ready-made one. The best option is to use a regular metal pipe for water heating, in which holes are simply made for the outlets and inlets of the pipeline.

Is it possible to install a heating register in an existing furnace?

It would be more correct, of course, to build the furnace around the manufactured register. But, if the stove is already standing, you can still build a water circuit into it. True, you will have to try hard - they are of considerable size and must somehow hold on. So the task is not an easy one. In addition, do not forget that you will have to make two more conclusions - to connect the supply and return pipelines.

The best option is to make a water jacket under the shape of the stove (this one is for a metal stove with burners)

Finding a place to locate the register is also not very easy. Its direct contact with fire is very undesirable, but it should be in an environment of hot gases. In this case, you can hope that the heat exchanger will last a long time.

Advantages and disadvantages

Designs with a built-in heat exchanger have many advantages:

- The system is energy efficient and economical. Brickwork will not require serious financial investments, the costs for pipes and radiators will be in any case, and the heat exchanger is an order of magnitude cheaper than ready-made boilers. When operating a stove, the cost of heating the house will be several thousand rubles for the purchase of firewood for the winter period.

- The design of a brick stove hides unsightly elements; if desired, a fireplace or decor can be added to the system.

- Heating of the room does not depend on the location of the structure; radiators can be installed anywhere

- A brick stove takes a long time to cool down; the water circuit will remain hot for several hours after the wood burns out.

Some publications list the advantages of the water circuit system as the possibility of installing it in a ready-made furnace, which is possible in principle, but in practice this option is associated with a large number of problems that have to be solved.

Disassembling and subsequent reassembly of the stove is the most necessary thing that will have to be done. The cost of correcting an incorrectly installed register is comparable to the cost of a new stove, so contact professionals for such work.

The disadvantage of this design is a continuation of its advantages; in order to make a stove with heat exchangers yourself, experience is required, both in laying bricks and in installing heating systems. If experience comes with age and the amount of material studied, then when building a furnace with a water circuit, its disadvantages should be taken into account:

The fireplace is a fire hazard; it is necessary to take measures to prevent fire from reaching flammable objects; The stove takes up a significant area of the house, design the rooms in advance, include a large heating system in the design of the room; The temperature near the stove will always be higher than in the rest of the room; The heating process of the oven cannot be stopped instantly. If you are using a closed loop system with a circulation pump, turning off the electricity (even briefly for a few minutes) and stopping the pump will cause the water in the heat exchanger to boil. To avoid this, provide a combined system for water movement in the circuit. If the heating system is not used regularly, the water must be drained, which leads to premature wear of the entire structure. Otherwise, the water will freeze, which will lead to the destruction of the entire complex of devices. You cannot light the stove without water in the circuit.

This will lead to the destruction of the register and the reconstruction of the stove in order to use the stove in the summer without “turning on” the battery using the original design of the installation of heat exchangers. There is a risk of carbon monoxide poisoning, as with all solid fuel heating products, special attention must be paid to the correct manufacture of the chimney.

Making a heating system in your home based on a stove with a heat exchanger and batteries is an economically viable solution, but the design and construction must be approached competently, taking into account all the nuances of the work.

Flaws

Despite many advantages, the installation of a heating element on a chimney pipe also has disadvantages. One of them, the most important, is a sharp decrease in the smoke temperature at the installation site of the heat exchanger. This can lead to deterioration of traction and the formation of condensation, increased soot deposition inside the pipe.

In addition, when connecting a heating system, for example, a garage, you need to calculate the volume of coolant to avoid boiling water and bursting pipes. Welds must be completely sealed.

Any heat exchanger design significantly increases the efficiency of the furnace. For trouble-free operation of the system, it is necessary to carry out a visual inspection of all its elements at least twice a year, and, if necessary, timely repairs, descaling, replacement of gaskets and other necessary maintenance work. In this case, water heating and heating systems will operate flawlessly for a long time.

What else can be used

If you can’t find a copper pipe for one reason or another, then you can try to find something suitable in your “home” scrap metal dump (every owner should have one). For example, the coil can be replaced with an old heated towel rail; you can also use cast iron batteries, having first checked them for leaks.

Heated towel rail

Radiators from car stoves can also be considered ready-made heat exchangers. They can be used as heating elements, having previously thought through the adapters and, if necessary, connecting several radiators to increase the total heat exchange area.

Old gas water heaters are also great for heating water. Moreover, in this case you won’t even have to redo anything.

How to make a homemade heat exchanger

Multi-pipe register

The shape of a heat exchanger for heating made by yourself can be different. The most common option is a register made of several steel or copper pipes, but plate-type examples are also used.

The temperature in the combustion zone is very high, especially when burning coal. Therefore, increased demands are placed on the metal from which the heat exchanger elements will be made, the rationality of its design and the quality of the welds.

Materials for production

An example of using cast iron radiators as a heat exchanger in a brick oven

The task of water heat exchangers for heating is to ensure optimal heat transfer, and in this process the degree of thermal conductivity of the metal is important. For example, a steel pipe conducts heat 7 times less than a copper pipe. Therefore, with the same pipe diameter, to transfer the same amount of heat, you will need 25 meters of steel pipe instead of 3.5 meters of copper.

Copper heat exchangers are the most economical to operate, but also expensive. Heat exchangers made of steel pipes with a diameter of at least 32 mm are considered more affordable for self-production.

If you plan to heat the stove with coal, it is better to install a heat exchanger made of cast iron. This metal is stronger, and the walls of the device will not burn out for a long time.

Heat exchanger power calculation

It is quite difficult to calculate in advance the power of the heat exchanger for a heating system. To do this, you need to take into account too many factors: pipe diameter, coil length, thermal conductivity of the metal, fuel combustion temperature, coolant circulation rate, etc. The real ability of the heat exchanger to cope with its functions will become clear only after the heating system starts operating.

When calculating, you can estimate that 1 meter of pipe with a diameter of 50 mm, serving as a heat exchanger, will provide 1 kW of thermal power.

You can take as an example any well-known boiler model and, in accordance with its parameters, make your own homemade heat exchanger.

Design Features

A heat exchanger for water heating of a house, welded from smooth-walled pipes, is called a register. It looks like a kind of “grid” and is the most popular form of homemade heat exchanger. In addition to this design, simpler devices are also made in the form of a rectangular or cylindrical tank. The main thing is that the surface area for heat exchange is as large as possible.

When making a heat exchanger with your own hands, several conditions must be observed:

- the width of the internal voids in the heat exchanger must be at least 5 mm, otherwise the water in it may boil;

- the thickness of the pipe walls must be at least 3 mm so that the metal does not burn through;

- a gap of 10–15 mm between the heat exchanger and the walls of the firebox should compensate for the expansion of the metal when heated.

Installation features

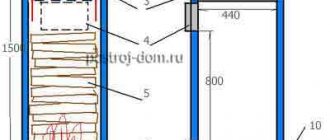

The heat exchanger is installed inside the furnace during its laying

The easiest way is to install the heat exchanger simultaneously with the construction of the furnace. If you install it in an old stove, you will have to dismantle part of its brickwork.

- A tubular heat exchanger is installed on the prepared furnace foundation directly into the furnace cavity.

- When further laying rows of bricks, space is left for the inlet and outlet pipes of the device.

- After completing the laying of the stove, connect the heat exchanger to the heating system, fill the system with water and test fire the stove.

The video material offers useful tips for making a heat exchanger yourself:

So far we have only talked about heat exchangers in a water heating system

Let's pay attention to other areas of their application.

Types of sauna stoves with a water heat exchanger

Units for heating a steam room can be made of several types, depending on the material of manufacture. The following types exist:

- Metal

. Most often made of steel or cast iron. There are many factory-made stove models on the market. Despite this, they can be made independently in various shapes (square, oval, rectangular). Depending on the design features, they may have heat exchange containers and different doors.

The main positive aspects of metal sauna stoves are: ease of installation, affordable price, quick heating of the room, no need to make a strong foundation, possible installation of a water tank on the chimney.

The negative characteristics of a wood-burning stove in a bathhouse with a water tank are poor performance under sudden temperature changes, rapid loss of thermal energy (cooling).

- Brick

. Brick stoves for baths, equipped with a water tank, powered by wood, are distinguished by the absence of negative parameters that metal options have. Thanks to the stone construction, it is possible to retain heat for a long period. Beautiful appearance also plays a big role when choosing a heater material; brick options look much more beautiful.

Despite the large number of positive characteristics of a brick kiln, some disadvantages stand out: high construction costs, high complexity of construction, and the need to create a massive foundation.

Stove with a water circuit for heating a house: advantages

As already mentioned, a conventional stove is not able to provide uniform heating of all rooms in the house. In modern stoves and fireplaces, this problem is partially solved by installing a convection chamber to which an air duct system is connected. As a result, the flow of warm air from the stove is not left to its own devices, but moves in the limited space of the pipes and is regulated by valves, dampers, grilles and other additional devices.

However, air ducts are bulky, eat up useful space, and as their length and number of turns increases, heat loss increases. They need monitoring and maintenance: periodic cleaning of dust, soot and soot. The air itself has a low specific heat capacity; in order to transfer heat to a room remote from the furnace, forced injection of heated air masses by a fan is required. Therefore, water, as a coolant, is in many respects preferable to air.

Combined cottage heating system using a fireplace stove with a water circuit and solar collectors

Fact! The specific heat capacity of water is almost 4 times higher than the specific heat capacity of air. It is enough to compare 4.187 kJ/(kg×K) and 1.055 kJ/(kg×K).

Hot water is easy to transport through small-diameter pipelines, while transferring thermal energy over considerable distances. In addition, water is a harmless, non-flammable, non-toxic, chemically neutral and always available substance.

Advantages and disadvantages of stove heating

Traditional heating through a stove has both its advantages and disadvantages. Traditional stoves can be found even in the most modern homes. Stove heating systems can be used in private houses or cottages, in country houses or in the country. Among the advantages of such a heating system are the following:

- Simple and quick installation. A traditional stove can be built from inexpensive and readily available materials.

- Easy to operate and maintain.

- This heating system has a high efficiency rate. If the heating system is designed as correctly as possible, then this figure can reach 60%. The value of this efficiency is almost similar to the efficiency of a device that runs on liquid fuel.

- Modern stove heating can be combined with an appliance such as a fireplace. Thus, we will get not just a heating structure, but also a decorative element.

- By using stove heating you can create a cozy and comfortable atmosphere in your home.

- Thanks to furnace components such as dampers, you can regulate the temperature in your home.

The stove is an important element in the interior of the house.

The wood heating system also has its disadvantages. It would be wrong to hide such shortcomings, since they need to be taken into account when organizing stove heating:

- A significant part of the usable area is lost. A more efficient stove will be larger, which means there will be less free space in the room.

- It takes some time for the oven to heat up to the required temperature. The moment the stove is ignited does not mean that it is already starting to distribute heat into the room.

- The stove quickly pollutes the room in which it is located. This means that it will need to be cleaned periodically.

- Stove heating is not able to heat the house evenly. The temperature near the furnace will always be higher than in other parts of the building.

- If such a system is operated incorrectly, there is a risk of carbon monoxide poisoning.

- The risk of fire is higher.

Lighting up the stove is a lengthy process

Choosing the design of the device

When choosing a suitable heat exchanger for a furnace, you should strive to ensure that the total surface area of the finished product is as large as possible. This will ensure the most efficient heating of the room.

The most widespread are registers (coils). Such heat exchangers are made from smooth-walled pipes with a diameter of 40 - 50 mm. Outwardly, they resemble a characteristic L-shaped grille. For their manufacture, you can use not only round, but also profile pipes with a similar cross-sectional area.

The return and hot water outlet can be located either on one side of the register or on different sides.

The output option is determined by the design features of the furnace itself and the piping layout of the heating system.

The next most popular are rectangular or cylindrical tanks, inside of which there is a pipe or coil. The length of such a heat exchanger depends on the parameters of the furnace firebox. The heat exchanger installed on the chimney usually has a cylindrical shape. There is a pipe running inside it, the diameter of which is equal to the diameter of the chimney. The pipes are welded from below. Can be used both for heating a room and for heating water.

This design requires special attention. Due to the rapid cooling of combustion products, the draft in the chimney itself is significantly reduced. This helps slow down fuel combustion.

Installing the product on a heating and cooking stove requires special attention. Care must be taken to ensure that hot gases pass over the top shelf and enter the chimney at the front of the firebox.

In this case, the cooking plate can be located directly above the heat exchanger. It is also possible to manufacture a register without a top shelf. The so-called shelf consists of lower and side parts connected to each other by pipes.

Kinds

Types of heat exchangers are divided by design, location and material of manufacture. For each specific case, you can select a combination of these types.

By combining design and material, and placing it correctly, you can significantly increase the efficiency of a brick kiln. It is worth considering how to make a heat exchanger for a furnace without extra costs. By analyzing the types of existing structures, you can select the most optimal heat exchanger for a particular layout.

- Coil. It is created from a pipe, coiled in the form of a spiral, several meters long. Such a water heat exchanger for a furnace is installed in a container with a liquid coolant. The ends of the pipe are expanded into the walls, allowing the coolant to circulate inside, simultaneously heating the water in the tank. With the correctly calculated length of the coil, the material it is made of, and the number of rings, you can speed up the heating of the water. Also, the part of the coil that remains in the air increases the rate of heating of the room.

- Heat exchanger with container. The tank and heat exchanger pipe for the furnace are installed directly next to the combustion chamber. It is necessary to strictly observe the degree of inclination of the supplied pipes in order to achieve natural circulation. In some cases, it is necessary to install an electric pump for these purposes. This solution has its advantages: the water is heated directly by passing through a pipe that goes around the firebox. This solution increases the heating rate. Typically used for heating circuits.

- Pipe board. It consists of two completely sealed containers and a large number of small pipes. The main pipe-containers are located in different parts, near the combustion space and are connected by pipes. Heat exchange occurs at the joints. This design is used for heating large spaces, up to high-rise buildings. The operation of such a heat exchanger is complicated because precautions must be taken. The chemical composition of the water is important here; due to the formation of scale, wall breakthroughs are possible.

- Water jacket. This heat exchanger is the most difficult to create with your own hands. Its design is two sealed tanks, located one inside the other. An efficient and easy-to-use heat exchanger for a pipe stove. It allows heat exchange to occur quickly, but is difficult to manufacture and requires professional skills.