A fireplace or Russian stove is a real decoration for a dacha, country house, or cottage. But it happens that the stove is folded crookedly, or low-quality brick was used during the laying, and this greatly spoils the overall appearance. Correcting such defects is quite simple; tiling the stove with ceramic tiles with your own hands will save the situation. This will not only maintain the attractive appearance of the stove, but will also simplify its external cleaning.

At least this look is attractive

Features of tiling different types of stoves

First of all, not all stoves are suitable for lining, and with some types you will have to tinker. There are three types of furnaces:

Metal furnaces

When tiling a metal surface, you need to understand that metal and tile have different coefficients of thermal expansion. Thus, the stove and the tiles on it will heat up and cool down at different rates. This will invariably lead to the decorative tiles peeling off or even cracking. But, even in this case, tiling a metal stove is possible. Professionals recommend installing a movable bond between the tiles and the stove surface using clamps; this technology will help avoid cracking;

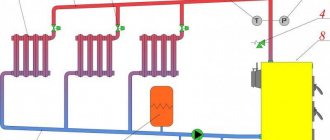

Double-circuit heating stoves made of bricks

An ideal option if you plan to tile a brick oven. This is due to the fact that the stove has two circuits: internal (firebox and vaults) and external. The outer contour, which is in contact with the cladding, heats up significantly less than the internal one, and therefore the cladding tile adheres best to such a stove. By the way, an additional advantage of this furnace design is the absence of local overheating. This allows you to clad a fireplace or stove with one material and using one type of mortar for its fastening;

Single-circuit brick kilns

They are often installed in bathhouses, which is why the stoves are called “sauna stoves.” The most problematic option. After all, there is only one circuit, which means that the surface heats up more than in a double-circuit oven. Craftsmen who perform cladding of a single-circuit stove must have certain experience in order to correctly select the tiles for cladding and the mortar that will hold it. Areas of local overheating deserve special attention.

Among other things, a stove installed in a bathhouse is exposed to changes in temperature and humidity. Tiling a sauna stove requires a more careful selection of materials. It is recommended to use porcelain stoneware for it, as it is the least porous material that can withstand the highest temperatures. It is also possible to line the stove with terracotta tiles, but its thickness must be at least 8 mm, and the distance between adjacent tiles must be at least 10 mm.

Note. Knowing what type of oven does not yet give you the opportunity to start working. You also need to consider what type of fuel the stove is heated with. Different types of fuel have different combustion temperatures. For example, when using solid fuel, the facing material must withstand temperatures up to 1600 degrees; wood (firewood) will allow you to expand the choice of facing tiles because burns at temperatures up to 800 degrees.

Installation of natural stone

Before installation, preparatory work is also carried out, however, it is somewhat different from work with decorative stone.

The wall surface is reinforced with a special metal mesh, which is secured with staples.

Next, the mesh is covered with concrete mortar or a layer of plaster. This stage must be approached very carefully and avoid the appearance of defects and irregularities, since they cannot be sanded and leveled.

All other actions will be the same as in the case of artificial stone.

Furnace measurement and tile calculation

After the dimensions of the stove have been measured, the type of material has been determined, the exact dimensions of one tile, the presence of decorative elements and their parameters have been determined, you can begin to calculate how many tiles are needed to cover the stove.

To do this, it is necessary to calculate the area of the furnace, including vertical and horizontal surfaces. It should be remembered that laying tiles on the stove requires a joint gap (the distance between the tiles), which ranges from 2 to 10 mm. This area must be subtracted.

Stove makers recommend adding 10-15% to the calculated value for undercuts and chips that appear during cutting.

Note. The more complex the tile layout pattern, the more material goes into trimming. However, the smaller the tile, the less material is wasted.

Users are advised to make a safety stock of 5% of the quantity received. After all, the tiles may fall off or burst during the operation of the stove. Moreover, if there are several types of decorative elements, then you need to have at least two pieces of each of them. This increases the cost of tiling the stove, but eliminates the need to think about how to replace the missing cladding element.

Note. Particularly accurate calculations must be made for tiles.

Methods for laying tiles on a stove

The second aspect that affects the volume of materials purchased is the method of laying tiles when facing the stove (Fig.).

Laying tiles joint to joint in straight rows (joint to joint, seam to seam)

You can lay square or rectangular tiles.

The use of this method is only possible when the tiles have the same geometric dimensions. It is suitable for laying out panels or patterns on the surface of the oven. In this case, it is desirable that the layout begins and ends with whole tiles. It is this nuance that will not allow the method to take a leading position; Laying tiles in a bandage offset (in a bandage)

is the most popular laying method, since when using it, cut pieces of tiles are not noticeable.

You can also vary the thickness of the vertical seam. The method is suitable for those who are going to do the tiling of the stove with their own hands; Laying tiles diagonally Laying tiles diagonally

allows you to create an unusual pattern.

But it is rarely used due to difficulties with surface marking and a significant amount of waste; “Chaos” styling

allows you to implement a wide variety of solutions. Most often used for laying tiles made from natural materials. Using the random layout method forces craftsmen to more carefully calculate the material.

The variety of facing tiles allows you to create your own ways of laying them, combining materials and creating unique designs.

How to cut tiles

Before the furnace is lined, the material must be cut correctly. In order not to spoil a lot of tiles and to cut them well, you need to do everything carefully. Having completed this procedure once, which, along with plastering the surface, purchasing materials and tools, can be safely classified as preparatory work, you will gain valuable skills in the future. To cut, you need a special machine - a tile cutter.

The first step is to measure the required distance on each piece and mark it using a marker and ruler. Next, the material is attached to the unit so that the marking line is under the cutting roller.

When the lever is lowered, the tile breaks into pieces. For the best performance of such manipulations, the roller and guide frame must be lubricated with machine oil. To avoid a crooked cut of the material, you need to check how correctly the roller is secured and whether it is loose. When you are dealing with a previously used tile cutter, it may be necessary to replace the roller. This is not difficult to do, since you can buy a new one in stores that sell tiles.

A simpler cutting device is a manual tile cutter in the form of nippers. It is unlikely to be suitable for very thick floor tiles, but can be used for wall material. Some craftsmen use a jigsaw available on the farm, on which they place a tungsten carbide file. But if you choose this method, cutting each piece will take at least 10 minutes (while on a tile cutting machine this procedure takes only 1 minute).

Another option for cutting yourself is to use a grinder with a special circle. Some people experienced in this matter even get by with an ordinary glass cutter. Here it is important to carefully break the tile into pieces after preliminary marking. But, due to lack of practical experience, it is better to abandon the latter method. Because otherwise there is a high probability of damaging your hand.

Of course, the most reliable way is to use a large tile cutter, which must be installed on the floor or a reliable table. If you are unable to get a perfectly straight edge of the cut material, you need to polish it using a special stone.

Selecting tiles and tools for oven cladding

A detailed explanation of how to tile a stove is only possible when there is an understanding of what material we are talking about.

For a long time, tiles remained the most accessible option for cladding. Many today consider it as a full-fledged alternative. But, despite the cheapness of the material, tiling the stove is fraught with pitfalls. After all, tiles for lining a stove must meet certain conditions (fireproof, heat-resistant, heat-resistant).

Cladding the stove with ceramic tiles is possible if the material meets the requirements:

- shape and size. Experts say that the smaller the tile, the less likely it is to peel and crack. For example, tiles with a size of 100x100 are more flexible due to the seams than tiles with larger sizes. The shape leaves an imprint on the installation method. The presence of a pattern that needs to be selected also complicates the calculation and layout;

- matching shades of tiles;

- technical properties: strength, fire resistance, fine porosity of the structure, indicative moisture absorption, coefficient of thermal expansion, resistance to mechanical damage;

- environmental safety confirmed by a certificate.

Today, among the materials that satisfy these conditions we can highlight:

- terracotta tiles (terracotta);

- majolica;

- clinker tiles;

- tiles;

- porcelain stoneware

Advice. A beautiful tile layout will be ensured by the use of friezes, borders, inserts, and panels.

In addition to tiles, for cladding you need:

- crosses or patterns. To ensure a seam thickness of 10 mm. users advise using pieces of ceiling plasterboard. Their advantage is easy dismantling;

- heat-resistant grout;

- metal mounting mesh;

- bierbach hardware or nails/screws and washers;

- rubber hammer;

- chisel or hammer drill to remove old coating from tiles;

- putty knife. They need to be prepared in three types. A regular spatula for removing the coating and applying a leveling layer of putty or glue. Toothed - for applying mortar to tiles. And also a special spatula for jointing (grouting joints).

- tile cutter Will allow you to minimize the cost of material from chips on the front surface;

- level and plumb;

- soap solution;

- adhesive solution;

- primer.

Properties of decorative stone

The advantages of decorative stone include:

- Durability and reliability. Due to its strength characteristics, artificial stone is very resistant to mechanical and physical damage.

- Easy to care for. The surface of the coating is easy to wash and clean.

- Moisture resistance. A protective layer on the surface of the decorative stone protects the coating from moisture absorption. Therefore, you can safely wash it with a damp cloth and a mild detergent.

- High temperature resistance and fire resistance. Artificial stone will withstand even prolonged exposure to open fire, since it does not burn at all.

- Wear resistance. Despite constant wet maintenance, the stone finishing of the stove retains its decorative properties for a long time without losing its appearance.

- Resistant to sudden temperature changes. Such a material retains its properties despite changes from very low to high values, and vice versa.

- And the biggest advantage is the ease of laying decorative stone with minimal expenditure of time and materials.

Tile adhesive and mortar for stoves

The quality of adhesion between the tile and the stove surface depends on the solution on which the tiles are placed on the stove. In view of its intended purpose, the adhesive solution must be heat-resistant, fire-resistant, and heat-resistant.

There are three types of mortars for laying stove tiles:

Clay mortar for oven

How to prepare: clay, sand and water are mixed in certain proportions, which depend on the type of clay:

- for oily clay the ratio will be 1 part clay, 4 parts sand, 1 part water. The fat content of clay can be determined in the laboratory or in a traditional way - you don’t feel sand in it, and a ball rolled out of it cracks badly when it dries;

- for normal – 1:3:1

- for skinny people – 1:2.5:1

Cement mortar for furnace

How to prepare: cement and sand are mixed in a ratio of 1:3 and brought to the desired consistency with water. In this case, the cement must be grade M 400 or higher. To improve the properties of the solution, it is recommended to add PVA and asbestos to it. Stove makers advise adding 1 kg of salt. onto a bucket of mixture;

Dry mixture mortar or special adhesives (cement, dispersion, epoxy)

They are ready-to-use mixtures intended for a specific type of tile. They are good because the proportions in them are carefully adjusted, and in addition, various plasticizers are added that improve the properties of the adhesive solution. Such adhesives have proven themselves well: SCANMIX Skanfixsuper (Finland), Plitonit-SuperKamin (Russia-Germany). Budget options: SILTEK T-84 (Ukraine), “Pechnik” (Belarus) and “Plitonit W” (Russia).

Ready-made adhesive solution - adhesive mastic

When choosing this type of glue, you need to pay attention to the markings. It should be intended for lining stoves and fireplaces. Good user reviews for NEOMID SUPERCONTACT (Russia), Terracotta (Russia), “Parad-77” (Belarus). But, in general, the quality of adhesion of the mastic to the surface leaves much to be desired.

In any case, the solution must meet the requirements for heat resistance and coefficient of thermal expansion. Ideally, laying tiles on the stove should be done using the same mortar that was used to level its surface.

All professionals and users agree that it is not worth saving on materials.

Metal sauna stove

This is the simplest and most traditional option for building a stove in a bathhouse.

The design has a number of advantages that make it popular:

- ease of installation;

- ease of use;

- heating in a short period of time;

- good traction;

- high efficiency;

- a budget option;

- economy in fuel consumption.

In order for the design to work properly, it is first prepared for operation and the initial characteristics are improved. We are talking about covering the frame with natural stone or brick. Considering the high cost of these materials, not everyone can afford to build a stove from them. And for cladding you will need much less of the same brick, so this option is quite acceptable for those who want to save money.

You can’t do without lining an iron stove in a bathhouse for several reasons:

- the metal quickly heats up, so being in the room becomes unbearable;

- rapid heating is replaced by rapid cooling. To maintain a certain temperature, you will have to constantly add firewood;

- the cladding will help optimize the heating process and maintain a comfortable temperature in the bathhouse, air humidity will be maintained at an optimal level;

- finishing materials will provide protection against burns that may occur if you accidentally touch the hot surface of a metal stove.

Tile layout - drawing, cutting

Laying tiles on the stove is carried out on the basis of a prepared drawing or sketch. In this case, professionals provide a specification on the basis of which the material is purchased. For beginners, a visual image and the actual layout of the desired composition will greatly facilitate the process of calculation, purchase and installation.

Note. Layout is made for all furnace walls, taking into account the size of the seams.

The drawing of the furnace with facing material looks like that shown in the figure.

Furnace tiling - drawing

3D visualization will help you evaluate the appearance of the future cladding.

Furnace tiling - 3D layout

Tile layout – simplifies the installation process, as it allows you to lay the tiles on the stove in the exact sequence. In addition, it allows you to select tiles according to pattern, shape, and shade. The size of the tiles is adjusted before laying, taking into account the seams. Products with chips and defects are used for trimming.

Note. Increasing the distance between the seams will help avoid laying tiles in small pieces.

Advice. The most massive (large) tiles are laid on the bottom rows. There are also thicker tiles on the bottom. Otherwise, it will be impossible to make a smooth surface.

The finished stove after lining will look like this

What is artificial facing stone?

Lining the stove with artificial stone has gained great popularity.

This material is easy to purchase at any construction supermarket; it weighs less than natural lump minerals. For the manufacture of this building material the following are used:

- Sand

- Natural mineral crumbs of fine fraction

- Lightweight artificial fillers

- Various adhesives

- Dyes and pigments

- The backing is made of special fiber, which makes it easier to install on the stove.

There are several types of artificial facing stone, such as gypsum artificial stone, stone made from marble or granite chips, stone from sandstone chips, wood panels for fireplaces, as well as flexible stone for the stove, made on a special substrate. They can cover even the most curved surfaces.

Preparing the stove for tiling

High-quality installation and long life of the stove cladding is only possible when laying the tiles on a prepared base.

The need for cladding can be caused by two reasons, and the scope of work for each will be different. However, the general goal is the same - to give the oven the correct geometric shapes, in which all surfaces are smooth and the corners correspond to 90°.

Note. In addition to the fact that leveling increases the speed of work, it allows you to reduce the consumption of expensive glue for laying facing tiles on the stove.

Option 1: lining a new (freshly built) furnace

Even a structure built in accordance with all building codes will need preparation. In this case, it boils down to the fact that the surface of the base is cleaned of dust, primed, equipped with a grid and markings. These types of work will be discussed in more detail below.

Note. You can start lining a new furnace only after a month of operation. During this time, it will shrink and reveal hidden defects.

Option 2: lining an old (operating) furnace

This option is much more complicated than the previous one, since it involves performing more rough work. Therefore, let's look at the sequence in more detail.

5.1 Dismantling the old coating

Stoves installed in the house, as a rule, already have some kind of lining. Often this is finishing with plaster followed by whitewashing or tiling. Therefore, before installing a new coating, you need to remove the old one.

Dismantling (removing) plaster from the surface of the furnace

Plaster does not last long on a hot stove. High temperatures cause cracks to appear on it or the surface layer moves away from the base. In any case, before you begin cladding, you need to get rid of the decorative coating (remove, clean).

How to remove old plaster from a stove

In practice, two methods are used to remove plaster from the surface:

Force method

. It is used if most of the plaster adheres well to the walls of the oven. Its use involves knocking down plaster using the impact attachment of a hammer drill. This method is quick, but it creates a lot of dust and is likely to damage the brickwork.

Using a grinder can simplify the work. Using a diamond blade, slits are made on the surface of the furnace. Their depth should be equal to the thickness of the plaster layer. There is nothing critical if the disc extends 10-15 mm into the thickness of the masonry. Next, the removal of the plaster continues with a hammer drill, hammer or chisel. If removal is still difficult, experts advise heating the area with a hair dryer and continuing work.

Note. Periodically wetting the surface with water will prevent the appearance of dust or reduce its amount.

Gradual cleaning

. The method is slower and involves soaking the plaster with water and then scraping it off with a spatula.

It is worth noting that some craftsmen recommend leaving the plaster on the stove, provided that it adheres well over the entire area.

Dismantling (removing) paint from the oven surface

Painting your stove is a simple and inexpensive way to decorate your stove. But, the painted surface will peel off under the influence of temperature and can harm human health (release of harmful substances).

How to remove old paint from a brick kiln

Removing paint from a brick surface is not so easy. A thin layer is removed using a metal brush. A good way to remove paint is to use a hair dryer. The thicker layer comes off on its own in some places, and where this does not happen and the adhesion to the surface is strong, notches should be made, for example, with a hatchet.

Note. Special solutions for paint removal have a pungent odor that takes a long time to dissipate, and are also high in cost, so users are not advised to use them.

Dismantling (removing) old tiles from the stove

When tiles peel off or you want to renew the stove lining, it becomes necessary to knock the tiles off the stove.

How to remove old tiles from the stove surface

It is recommended to carry out dismantling work from top to bottom. After removing the last row, go down to the next one. The tile is removed using a chisel that hooks onto the edge of the tile. In this way, the tiles are removed without damage. If this maneuver fails, the tile must be broken. Broken tiles are easier to remove.

Don't be surprised if some brick chips when you remove the tiles. In any case, cleaning a fireplace or stove does not end with removing the old coating.

Attention! Removing old tiles is done strictly with safety glasses, because... During operation, a large number of sharp fragments fly apart.

5.2 Cleaning the surface of the oven walls

After removing the finish coating, the entire surface of the stove must be thoroughly cleaned of any traces of solution. The ideal way to clean brick walls is to use a metal brush.

5.3 Deepening joints between bricks

To ensure that subsequent layers of mortar adhere better to the base, care must be taken to remove the mortar and increase the depth of the brickwork joints. To do this, use a chisel, grinder or spatula to remove the solution from the joint spaces. Cleaning depth 5-10 mm.

Upon completion of the work, the surface is once again cleaned of dust and solution residues with a brush.

5.4 Leveling the oven walls for tiles

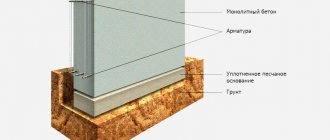

To prevent the tiles from peeling off from the base, you need to install a metal mesh on the surface of the oven.

To work, you will need a mounting mesh with cells of 50x50 mm and a wire diameter of up to 1 mm. To secure the mesh, you can use a ceiling dowel with a cap (bierbach).

Or you can simply put washers or pieces of galvanized steel on the nails. The main thing is that the hat holds the mesh securely. Hardware is installed only in seams. In this case, the nail is driven in, and a hole must be drilled for the self-tapping screw. The mesh fastening pitch is 500 mm.

The mesh is installed on the surface with tension. Next, the surface of the walls is leveled with plaster. To do this, you can use glue on which the facing tiles will be mounted or a special solution (clay, cement, sand) in a ratio of 3: 1: 0.2 parts.

Recommendation. Users advise adding PVA glue or any other glue with a low expansion coefficient to this solution.

If the surface that needs leveling has depressions up to 10 mm, then the solution must be applied in two approaches. The maximum permissible layer thickness is indicated by the manufacturer. In practice, it is better not to make a layer thicker than 5 mm, this increases the time and reduces the uniformity of its hardening. In this case, the second layer is applied only after the first has completely dried.

Advice. When starting to level the walls, the craftsmen advise heating the stove. The solution must be applied at a surface temperature of 30-35°C.

An alternative to a grid for leveling walls:

- installing hardware with caps and stretching ordinary wire between them;

- using stretched burlap, previously soaked in a clay solution. When laying burlap, it is important to avoid folds and air pockets.

Note. If the surface of the stove is flat, you can eliminate the plastering step and lay the tiles directly on top of the metal mesh.

5.5 Priming the oven walls

A heat-resistant primer applied with a brush will improve the quality of adhesion of the solution to the surface. When choosing a primer for stoves and fireplaces, it is better to give preference to deep-penetrating compounds. When the primer has completely dried, you can pre-mark the surface.

Advice. You can reduce primer consumption without changing the quality of application if you first walk over the surface of the wall with a slightly damp sponge.

5.6 Preliminary markings before laying tiles

The surface on which the markings are applied is considered fully prepared for cladding. It involves the installation of beacons that allow you to navigate when performing cladding work.

Markings are made using a plumb line and level. It is convenient to mark the horizontal using a cord. A more technologically advanced approach is to use a laser level.

You should be aware that even a perfectly prepared surface may not save the stove from cracking. The cause of cracks can be:

- excessive overheating;

- an incorrectly executed bunch of bricks during the construction of the furnace;

- different thickness of the interbrick joint.

High-quality preparation of the base of the furnace surface will avoid its deformation and will firmly hold correctly laid facing tiles.

5.7 Preparation of the adhesive composition

The mortar for laying tiles is prepared in small portions for 10-15 minutes. before starting work. Moreover, master stove makers do not use any devices for kneading; the work is done by hand.

Applying glue for laying decorative stone

For strong adhesion of the material to the surface of the oven, both must be covered with a layer of glue. To do this, first apply glue using a simple or notched trowel, after which a wavy groove is made in it. Next, you need to press the stone tightly to the surface and, to be sure, tap it with your fist or a special rubber hammer.

The next row is laid above the first in a checkerboard pattern to obtain a stronger masonry.

Do-it-yourself tiling of the stove

The technology for tiling stoves involves choosing a laying method, and the progress of the work will vary accordingly. In this case, in any case, installation is carried out from the bottom up and on a heated (at least 30°) oven.

6.1 Tiling the stove in straight rows or offset

Installation of the first row. Covering the stove with clinker, terracotta tiles or porcelain stoneware starts from the corner of the stove. First, the corner elements are installed.

It is worth noting that if tiling work is carried out before the floor is laid, a gap must be left. In this case, the support for the first row will not be the floor, but a strip nailed to the surface of the stove. The support rail should only be attached to the stove, since the floor may deviate from the horizontal. To draw a horizontal line, you need to mark the upper border of the first row and lay the tiles with trimming from the floor side. With this approach, subsequent rows will be laid out in accordance with the level.

Note. A technological gap of 5-10 mm is left between the floor and the tiles. Its presence will compensate for the expansion of the material when heated.

Please note that the lining of the stove with majolica starts from the corner and continues along the installation. If a whole strip hits the corner, great. If trimming is required, then work should begin from the second row. The tile pieces are installed last. It looks more beautiful if whole tiles are located in the corners, and cut fragments are hidden in places where they adjoin the wall.

Next, an adhesive solution is applied to the prepared tile.

How to apply adhesive to tiles

The adhesive composition is applied in two ways:

- using a notched trowel. This method is suitable for flat surfaces. Then the glue spreads evenly on the surface of the tile and air pockets are eliminated;

Note. Air pockets or bags are dangerous because the air in them heats up faster than the tile or glue and expands. As a result, tiles may peel off.

- using a trowel. The method is used when the surface has deviations along the plane. In this case, the glue is applied to the corner of the tile, which is pressed against the surface in a circular motion. The glue fills all the unevenness, and its excess extends beyond the edges of the tile. If you have difficulty installing the tiles in place, you can hit them lightly with a rubber hammer.

Some craftsmen recommend applying glue not to the tiles, but to the surface of the stove. This method is suitable for surfaces of any quality.

The thickness of the glue application is indicated by the manufacturer and is 2-7 mm. To level out unevenness, it is possible to apply glue up to 10 mm thick, however, after laying the tiles, work must be stopped so that the glue can dry evenly.

How to glue tiles to a stove - tips

- Before applying glue to porcelain tiles, it should be wetted. To do this, brush over the surface or moisten it in water. In no case should the tile be completely immersed in water.

- The heavier the tile, the thicker the adhesive layer should be and the greater the distance between adjacent tiles.

- You can level the tiles on the surface within 10-15 minutes. after installation. If you didn’t make it in time, you need to remove the tile, clean it and the surface of glue, and only then continue working.

The second row is laid after the first one is completely laid. Work also starts from the corner. Crosses, templates or pieces of other materials of the same thickness will help ensure an even gap between the tiles

Joint width between tiles (thickness)

The seams between rows of tiles need to be addressed separately. The width of the seam depends on the type of tile, its thickness and weight. And their absence leads to the fact that the tiles have nowhere to expand and they burst. In order for the grout mixture to lay down beautifully in the future, the seams should not be completely filled when laying the tiles, and the excess mixture should be removed using a spatula.

The craftsmen emphasize that it is not worth laying more than three rows in one approach. In order for the glue to set well, it is better to take a break for several hours. The drying time depends on the type of glue and the manufacturer's recommendations.

In addition, after laying each row of tiles, the horizontal position is checked. If a defect is discovered, there is time to fix it.

6.2 Tiling the stove diagonally

With this laying method, the first row is most often laid straight. This will allow the cladding to be leveled relative to the floor. Next, the layout is carried out in one of the following ways:

- triangles are laid out, wide side down. The upper corners of the tile serve as a guide when checking with a level;

- laying proceeds diagonally, then the mooring cord (marking) is pulled at an angle of 45°.

The penultimate row is similar to the second. The last one goes to the first one, which is also usually laid out in a straight row.

Note. During the tiling process, a certain area in front of the stove is often tiled. This technique allows you to protect the floor covering from sparks and deformation from the heat of the stove from below.

The cladding work ends with cleaning the seams (deepening for better grout application) and washing the lined surface of the stove. After the time required for the glue to completely harden, you can begin grouting.

Advice. It is better to stop work for 5-7 days. During this period, the risk of tiles moving is minimized.

Finishing the wall behind the stove

Many people pay attention only to what to cover the stove with, but completely forget about protecting the wall behind it. It is not right. There are several options, each of which is suitable in certain conditions:

Advice! It is better to take care of the wall behind the stove in advance, then you will not have to perform unnecessary manipulations.

- To protect this area of the house, it can be lined with red brick. This is the most common option. This material is not afraid of constant thermal exposure.

- You can use foil. A sheet of such material is attached directly to the wall. It successfully reflects most of the thermal radiation. This method cannot be used when the heat source is very close to the wall.

- Instead of a sheet of foil, use stainless steel. This is a durable material that is not subject to severe destruction.

On a note! If you decide to line the wall behind the stove with bricks, then you don’t have to do it completely. The main thing is to lay the masonry according to the dimensions of the heat source itself.

Any work in a house with a stove requires compliance with numerous rules and precautions. You cannot use materials that are not intended for such work. It should be remembered that nearby surfaces that are exposed to thermal effects need protection. It is better to cover them with bricks, which are covered with a stainless steel sheet. Then you can be sure that living in the house will be comfortable and safe.

Jointing tile joints (grouting)

Grouting the joints between the tiles is done with a special mixture or clay-sand mortar with the addition of coloring pigments. The work is done with a rubber spatula. It is suitable for tiles because... allows you to fill small seams. Or with a construction gun, if the stove was lined with porcelain stoneware, terracotta or clinker tiles.

Types of grout for tiles and their comparative analysis are presented in the table (analysis of grout for clinker tiles)

Tile grout - comparison table

After applying the grout, wipe the surface with a damp sponge. This technique will remove any remaining mixture. Be careful not to press too hard on the sponge, otherwise you may damage the seam.

Advice. Users suggest using your hand to form a concave seam. It can be done with your fingers (if the seam is wide enough) or with improvised means, for example, a flexible tube or the handle of a toothbrush.

Final cleaning of the grout on tiles or majolica is carried out after the grout has dried (after 1-2 hours). Visually, this can be seen by the fact that the tiles will become lighter. Cleaning is done with a flannel rag soaked (soaked) in a solution of a cement-grout film remover.

The process of tiling the stove is complete. Now all that remains is to wait 3-4 weeks before trying the stove in operation.