The efficient operation of stove equipment in a bathhouse or private house depends on the chimney. From there, oxygen-rich air, necessary for active combustion of the fuel, enters the firebox. Smoke, soot and exhaust gases are removed through the pipe. Gas exchange in the chimney is based on the draft force - the pressure difference in the upper and lower sections of the chimney.

At the top, the movement of air masses occurs more actively, as a result of which an area of low pressure is formed there. Due to this, the smoke from the firebox rises up the chimney by force of traction and comes out. But under normal conditions, heat will also come out of the stove along with smoke and carbon monoxide. To hold it, as well as regulate combustion and draft, a damper is used inside the chimney.

What is it and what is it for?

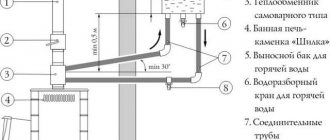

Damper (from the German Schieber - damper) is a device for completely or partially blocking the movement of gases in the chimney. It has been used since the appearance of the first Russian stoves. Made from cast iron or steel. In modern engineering it has found application both in smoke exhaust structures and in ventilation systems.

Damper functions:

- Regulating draft and maintaining heat in the room.

The chimney is closed after use to prevent warm air from being drawn from the room into the chimney. Using a damper, you can reduce or increase the working cross-section of the chimney.

- Saving fuel consumption.

The valve can be used to regulate the intensity of oxygen flow to the flame, and accordingly increase or decrease the efficiency of the heater.

This statement is true only for furnaces and boilers without blowers and forced air supply devices.

What is a gate?

The basis for good draft of your heating system is the damper.

The stove damper (damper) is an element that regulates air flow and helps maintain healthy draft of the device. Simply put, this is a metal valve that is installed in the chimney duct.

As experience shows, not a single furnace can operate without a damper. Without this device, you will lose traction and, accordingly, heat. A damper for a homemade stove is easy to buy or even make with your own hands. Its design is quite simple.

Functions, purpose and characteristics

The damper is a partition that is located inside the chimney. It follows the shape and area of its cross-section and, when closed, almost completely covers it. Changing the position of the damper allows you to increase or decrease the opening of the chimney pipe, increasing or decreasing the air flow. Using the damper, you can stop the movement of air after lighting the stove.

The gate valve is a thin metal plate that is manually adjusted using a special handle. The latter is located outside the chimney pipe so that the user can manually adjust the position of the plate.

Depending on the design and type of damper, it is installed using a special metal frame, or is inserted inside the pipe and fixed with an axial rod.

Important! Do not assume that the valve completely seals the pipe in the “closed” position. According to fire safety requirements, the damper must have a small hole through which weak gas exchange occurs.

The damper in the chimney performs the following functions:

- increases traction force in difficult weather conditions;

- increases the intensity of combustion in the furnace due to increased oxygen flow;

- reduces draft when there is a strong hum in the chimney during strong winds;

- saves fuel by reducing combustion intensity;

- prevents heat loss after the heater has warmed up.

Very important! You can close the chimney with a damper only after the wood has completely burned and the flame has gone out. If you close the damper prematurely, this can lead to a dangerous situation due to the release of large amounts of carbon monoxide into the room. If the damper is closed too late, the efficiency of the furnace will be reduced, because Most of the heat will go out through the chimney.

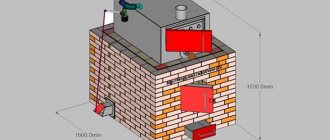

Is a valve needed in a sauna stove?

Definitely needed. Good draft in the bathhouse is the key to successful construction of the stove. According to experts, it all depends on the design of the sauna stove. If there is a chimney, then there is no doubt about the need for a damper.

The oven damper is used in all types of ovens. The principle of their operation is a little similar, so you shouldn’t bother. A gate is definitely needed. If combustion is only carried out thanks to the supply air, the valve is not installed. The gate will help you save on fuel, getting the most out of every run. The fuel will not be wasted.

Types of gate valves

There are two main types of gate valves - sliding and rotary (throttle). The design features are clear from the name: the first type works due to the perpendicular movement of the metal plate relative to the chimney pipe.

We recommend that you read: How to make a spark arrestor for a chimney with your own hands?

To increase draft, the damper is moved back and almost completely extends beyond the chimney, and to reduce the flow it is pushed back into the pipe.

Retractable gate

The most popular damper for a retractable type chimney. It compares favorably with other varieties in terms of reliability and ease of use. The retractable gate is a plate with a smooth, even surface, in which there is a special longitudinal hole. It runs along the grooves in the chimney.

This type of valve is installed strictly horizontally. To change the draft force in the chimney, it is enough to move the damper in the desired direction, increasing or, conversely, reducing the cross-section for the pipe.

This option is suitable for steel pipes, but is more suitable for stoves made of brick. Its installation does not require special knowledge or significant effort.

Some models provide a small cut-out area. This ensures the safety of the structure: even if this valve is completely closed, the movement of carbon monoxide in it will continue.

Rotary gate

Another type is a rotary gate. It is a plate made of metal, which is fixed in the central part of the guide by welding.

Dimensions and principle of operation of the rotary gate

Its main portion is located in the inside of the chimney, but the tip should always remain outside. Against the background of rotation of this plate relative to its own axis, the draft in the chimney is regulated.

The disadvantage of this type is the need for fastening by welding. It is this place that is the weak point of the design: the damper will open if the fastening becomes loose.

The rotary gate is characterized by low reliability. But this indicator may vary depending on what it is made from. Most often it is used for installation in steel chimneys. It is also installed in cases where there is not enough space to extend the classic valve.

Cast iron gate

Cast iron dampers have found quite wide application in various types of stoves and fireplaces. The disadvantage of such products is their significant mass. At the same time, cast iron itself has been used for a long time in the production of valves for furnaces. This is explained by its high reliability, durability and strength.

Model range of cast iron gates

Steel type gate

A gate unit made of stainless steel is not the cheapest option. But the design is characterized by high quality and excellent performance characteristics. Its advantages are as follows:

- maintaining furnace efficiency;

- small weight;

- long service life;

- not subject to metal corrosion;

- prevents soot accumulation.

We recommend: Deflector for the chimney of a gas boiler - installation requirements and installation rules.

The specified dampers may have a different design depending on the features of the furnace. They are relevant for chimneys made of steel or brick.

Kinds

Despite the simplicity of the design, there are different valves. The design, material and dimensions of furnace valves play a role.

By design

- Retractable. This type of plug is the most convenient. It is a chimney nozzle with a retractable plate in the middle. It is this plate that moves freely in the grooves of the chimney. This type of damper is most often used in brick stoves. But it can be installed on others. This design is easy to install and does not require installation costs.

This valve is used in brick kilns - A rotary (throttle) gate is a type of valve where a guide is welded in the center to a metal plate. The end of this guide is on the outside and makes it possible to control the damper. By rotating the same plate along the axis, you adjust the draft in the furnace. The design is not as reliable as in the case of a retractable gate, but it has the right to life. Butterfly dampers are mainly used for steel chimneys. The rotary valve is slightly inferior to the sliding valve, but is also confidently popular.

By material

The material from which the gate is made is also very important. Each has its own nuances. There are cast iron and steel plugs.

- Cast iron provides an incredibly durable and stable appliance. It is common for furnace valves. The only significant drawback is its impressive weight. Thus, installing the valve in the furnace can become a problematic part and the installation will take more time.

- Stainless steel is lightweight, but also durable. She is not afraid of corrosion. With high-quality polishing it can last for a very long time. Just clean it, under the same conditions. Steel dampers are made of absolutely any design and are used for different types of stoves. Stainless steel began to be used quite recently, like cast iron. Maybe there is some modernity and perspective in this. Which one is up to you to decide. The main thing is to understand what is best for your stove.

Safety precautions

When talking about gate valves, first of all we should focus on safety precautions. Already from the definition it becomes clear that this device is capable of completely blocking the natural flow of air from the room through the stove and chimney to the street. The oven can be in such a locked state only under one condition - there is nothing in it that is still smoldering even a little, much less burning.

As you know, burning wood in a stove leads to the release of carbon monoxide, which is poisonous to humans. The danger of poisoning with this gas is that a person may simply not feel the harmful effects of the gas until he begins to lose consciousness, and then it may be too late. This danger should not be underestimated: for example, it is known that the famous French writer Emile Zola died in Paris in his bedroom from carbon monoxide.

We recommend a video review of the features of gate valves of various designs.

An attentive reader may notice that valve manufacturers produce them with special holes that prevent complete blocking of the chimney. However, with regular use over time, soot and resin accumulate on these holes, which gradually reduce their throughput, and then can completely block them. Obviously, the chimney periodically needs to be cleaned and the damper is no exception, but in practice this procedure is carried out much less frequently than required by safety regulations.

Differences between retractable and rotary gates

So far we have been talking about the retractable type of damper on a stove chimney, although there is another type - a rotary one. Let's look at how they differ.

The purpose of both types is the same - to partially or completely block the flow of flue/heated gases. The differences relate to the design.

A retractable model is a metal plate that is fixed in a frame and moves along guides in a horizontal position. There are no strict requirements for the dimensions of the device, since they must correspond to the cross-section of the chimney and completely depend on its parameters.

Thus, the valve consists of two main parts:

- frame , which is fixed in the smoke exhaust duct and is motionless;

- plate moving inside the frame.

Typically, both parts are made from the same material to maintain performance when heated or cooled.

A properly designed and installed damper should never completely block a stove chimney. A small gap is necessary for fire safety purposes.

The design of the rotary (throttle) gate does not extend, but rotates along an axis, as the name suggests.

A round or rectangular plate (depending on the cross-section of the chimney) is fixed on a metal rod, the free end of which extends beyond the channel and serves as an adjustment tool.

The simplest model of a rotary gate with a diameter of 120 mm. Manufacturing material – stainless steel. The smoke exhaust channel is closed by turning the handle with a curved end

Gate valves are considered more reliable and wear-resistant devices. The weak point of the rotary devices is the connection between the rod and the plate, which becomes loose over time and renders the valve unusable.

Drive types

Depending on the size and purpose of the pipeline on which the gate valve is installed, different forces are required to change the position of the control element - the greater the throughput of the pipes and the higher the density of the working medium, the more difficult it is to open and close the valve.

Therefore, various options for controlling the mechanism are used for adjustment:

- The valves with a small internal diameter, installed on pipelines transporting liquid and gaseous working media of low density without hard particles, are controlled manually - using a handle, screw or lever.

- The electric drive allows you to precisely regulate the throughput of the unit without the application of physical force. Electrically driven gate valves can be used on large pipelines and to regulate the flow of viscous and granular working media. The only drawback of such a mechanism is its energy dependence.

- The pneumatic actuator drives the rod and locking mechanism using a compressed gas turbine, the operation of which is similar to that of a conventional pump. The strength of pneumatic control is that the entire control mechanism from the rod to the pneumatic turbine is located outside the valve body and does not come into contact with the working environment, which increases the service life of the device.

Pneumatically driven valves are the most complex and expensive. It is installed on pipelines that require remote adjustment, but the design of the control mechanism is such that, if necessary, manual adjustment is possible, which, thanks to the pneumatic turbine, does not require much physical force.

Which material is stronger

In addition to structural differences, types of gate valves may differ in the material of manufacture. The only possible option is metal, since it is the only one that does not burn or deform at high temperatures, and over time, even in an aggressive environment, does not change its characteristics.

For production, either cast iron or stainless steel is used. It is not possible to build a damper from cast iron yourself, since this requires, at a minimum, a forge. However, you can find both nondescript and beautifully designed cast iron dampers on sale.

Cast iron rotary gate with a comfortable handle. This design is suitable for a brick chimney with a rectangular cross-section, capable of supporting the fairly heavy weight of the device

Steel products look simpler, but their characteristics are similar to their cast iron counterparts. The advantage of steel fixtures is their light weight.

If a cast iron damper for a stove chimney is installed only on a durable, permanent structure, then a steel damper is suitable for any smoke exhaust ducts - brick and steel, rectangular and round, solid and light.

Samples of a galvanized steel damper, chimney cross-sectional diameter – 150 mm. Galvanization, unlike ordinary steel, does not react to moisture (condensation) and does not corrode

When choosing a material, you need to focus on the characteristics of the chimney pipe and the features of the interior.

For a country heating stove, a modest steel valve is sufficient, while for upgrading a Russian stove in a cottage, a custom-made cast iron valve is better suited.

Selecting a location option

There are three main options for placing the damper in the chimney:

- pipe-to-pipe fastening;

- placement in a fireplace insert;

- installation in a ventilation pipe.

Brick chimney with damper

If you place a gate valve in the outlet pipe or in the furnace firebox, that is, build this element into its design, the damper is placed on a section of pipe as close as possible to the heating boiler. This guarantees ease of control and ease of turning the valve. This is explained by the fact that the handle will not touch either the portal or the cladding area. If it is located according to the “pipe to pipe” option, no additional fastenings are required for connection with other elements of the furnace.

If you place the damper assembly in a pipe intended for ventilation, overheating of the fan motor during its operation is prevented.

Typically, ready-to-install chimneys are offered, which are equipped with everything necessary, including a slide valve. In this case, it is placed in the system in accordance with the manufacturer's instructions. If it is not provided for one reason or another, it is quite possible to manufacture and install this element yourself.

Principle of use

In order to reduce the draft, you need to close the damper a little. If, on the contrary, you want to increase traction, you need to open the gate. The principle of use is extremely simple.

The main thing is to choose the right device for your stove and learn how to use it (even though it is very simple). An important nuance is that when the furnace is idle for a long time, you must keep the damper closed to avoid foreign elements getting in there.

The damper also separates the insulated part of the chimney from the non-insulated part. The gate is usually installed at the beginning of the pipe. At the end where the pipes are well insulated, installing a valve is not recommended.

What functions of the damper have we derived?

- With its help, traction is adjusted.

- It protects the chimney from temperature changes.

Tips for choosing a gate valve

It must be remembered that the correct selection of an element such as a slide damper is reflected in the future not only on the draft indicator, but also on the safety of the heating system, of which the chimney is a part. Installation of the damper is carried out on any model of fireplaces and stoves, except for the most modern ones, which have a deflector.

We recommend: Carbon infrared heaters - operating principle, how to choose, areas of application, best models, prices and reviews, where to buy

The main recommendations for choosing slide valves for smoke exhaust communications are as follows:

- If the heating device operates by processing gas, it is better to purchase a rotary valve model. This is due to the fact that such models exclude the possibility of completely blocking the smoke exhaust channel. Thus, the heating system will be safer. The chimney, which removes combustion products from the gas stove, must be closed by at least 40 percent during operation;

- There are heating systems that operate intermittently (periodic). A closed damper installed in such a heating structure, as a rule, allows steam to pass during supply, and an open damper contributes to the formation of a large amount of soot on the pipe, which is located below the plate;

- It is strictly not recommended to use rotating elements for installation in sauna chimneys.

A rotating device is the most suitable option for a gas-consuming system

Note! The chimney damper is a shaped part of the chimney service, so if you purchase everything necessary for laying a chimney, it will be included with the pipes. Such shutters can be purchased at any specialized store or ordered using an online store on the Internet.

Experts recommend carefully measuring the cross-section of the smoke exhaust duct before purchasing a gate product. Perhaps this is the main thing that needs to be done before purchasing a gate.

Features of installation of gate valves

To install the throttle valve, it is necessary to make markings on the pipe in order to drill holes according to the welded valve structure.

To do this, you need to measure the pipe using a measuring tape and make marks for future holes. After making sure that the marks are symmetrical, use a drill to drill holes for the future rotary handle.

The throttle valve is installed as follows:

- A steel damper circle with a welded tube is inserted into the chimney pipe.

- A metal rod is threaded through the drilled holes in the pipe through a small tube, the end of which is secured with a bolt and nut.

- The end of the rod is bent using pliers for a rotary handle.

Important! It is advisable to install a wooden element at the end of the rod, which will serve not only as decoration, but also as protection from touching hot metal, since the damper will become very hot during operation.

Next, you can install the resulting structure in the chimney pipe. To do this, the first piece of pipe is put on the furnace pipe of the stove heating, onto which a structure with a gate valve is installed on top. The next piece of metal pipe is put on the gate. All connections are treated with liquid silicone sealant.

Installation of a retractable damper in a brick chimney occurs during the masonry process. To do this, after 6-8 rows of bricks, a layer of cement masonry mortar is applied, on which a wire frame is installed with the open side facing the performer. You need to insert a latch into the frame and bring it into the closed state.

The frame is covered with mortar on top and bricks continue to be laid according to the standard pattern.

Attention! The slide damper is allowed to be installed in the first section of the chimney, at a height of up to 1 m above the firebox. This will ensure ease of adjustment of the damper and good aerodynamic properties of the chimney.

Installation method

Installation of gate valves is carried out using four methods:

- Welded - the end parts of pipes and fittings are soldered using welding equipment. The result is a reliable, sealed, but non-separable unit.

- Flanged - if the end parts of the valve are equipped with flanges - round or square plates with holes, flange adapters are also installed at the ends of the pipes. To connect pipeline elements, the flanges are aligned and bolted together to form a detachable assembly.

- Threaded - the pipes are threaded, the connection is made using union nuts. The method is rarely used, since the threaded unit becomes loose due to vibration of the working environment and needs periodic tightening.

- Embedded - the body is laid horizontally between sections of a vertical pipe or shafts, the assembly is cemented. Used only when installing smoke shafts of heating units.

According to the installation method, there are two types of valves:

- coupling - has a full-fledged body with branch pipes, can be connected using flanged, welded and threaded methods;

- wafer - the body does not have branch pipes, in some cases the body consists only of a frame with saddles; such a valve is installed in a section of the pipeline or grooves in the chimney shaft and is connected using a welded, flanged or embedded method.

DIY making

The simplicity of the design of the damper plate for the chimney allows you to make it yourself to ensure further regulation of the draft in it.

Option 1. Manufacturing a rotary gate from stainless steel

We offer detailed instructions for manufacturing the damper already with a finished stove heating, when the design is completed, but the damper mechanism was not provided.

To make and install a gate valve with your own hands, you will need the following materials:

- grinder, cutting and grinding abrasive wheel;

- drill;

- tap;

- oil for lubricating the tap when cutting threads;

- hammer;

- vice;

- pliers;

- welding;

- core;

- electrodes for stainless steel;

- compass;

- roulette;

- permanent marker.

The materials you should immediately prepare are:

- stainless steel sheet 1.5 -2 mm thick.

- stainless steel tube with an internal diameter of 6 mm;

- 2 bolts 8mm,

- nail (or metal rod).

When all the tools and materials are prepared, you can begin to carry out the work.

- Measure the inside diameter of the pipe and mark it on the stainless steel sheet using a compass.

step 1 - Now, using a grinder, cut out a circle according to the markings made.

Step 2 - We try on the cut-out damper and, if necessary, modify it with a grinding wheel until it clearly fits into the pipe.

Trying on the damper - Take the prepared stainless steel tube and apply it to the finished circle. Use a marker to measure the size of the flap. We make it smaller than the internal diameter by 3 mm on each side.

Step 4 - We cut the pipe with a grinder and a cutting wheel.

- We drill an internal hole in the 6.8 mm tube for threading. When drilling, it is necessary to periodically lubricate the inner surface of the tube with machine oil.

Drilling out the tube - We cut an 8mm thread on both sides of the tube with a tap, not forgetting to lubricate the tap in the process. To remove the cutting chips, it is necessary to make a half turn back every half turn of the tap along the thread.

Step 5 - Now you need to make three holes in the damper. Immediately use a marker to make marks.

- Clamp the tube and the valve in a clamp and weld the tube to the valve through these holes (welded rivets). We start welding from the central hole, then release any one clamp and weld it into the free hole.

Step 6 - We mark the future holes on the smoker. To ensure that the axis of the holes clearly coincides, wrap the pipe with a tape measure and measure the center horizontally and vertically. Let's drill.

Making the markings - We assemble the damper into a tube.

Step 7 - Making a template for the damper clamp.

Step 8 - We transfer the markings to the metal sheet. You can use a compass.

Step 9 - Mark the middle for the fastener holes, cut and drill according to the markings.

- We weld it to the pipe.

We weld the clamp

Option 2. Manufacturing a horizontal sliding gate from stainless steel

For this option, you need to purchase a ready-made factory stainless steel gate valve. The design represents a frame within which the mechanism moves.

- Lay out 2 rows of the stove or fireplace according to the ordering pattern used.

horizontal sliding gate - On the row where the valve will be installed, we cut grooves in the brick. These are small grooves into which the metal element will fit. It is best to use an angle grinder with a wheel for this work. But if you don’t have such a professional tool, then you can get by with a file.

- The damper is installed.

- It is necessary to cut a recess in the side brick for the movement of the damper handle, because it will need to be cleaned of soot during operation.

We block the gate with a row of bricks - The next row of bricks is laid and all the resulting gaps are well sealed.

We recommend: Safety valve in the heating system - purpose, design, installation

As you can see, making a gate does not require much time or much experience. At the same time, this is a very important detail that will significantly increase the efficiency of the boiler or fireplace.

Pipe installation

A gate valve can also be installed on a pipe. To do this, select a section of it where there is no insulation, otherwise it simply jams due to expansion as the element heats up. Experts recommend placing it about 1 meter short of the firebox.

The following procedure is suggested:

- Fastening the first part to the pipe with coating of the joints with a sealant characterized by heat-resistant properties.

- Installation of the gate on this segment or on the tee.

- Placement of the second trim for the pipe, which will connect the structure with the insulated sections of the chimney.

Due to the tight fit of all elements of this design, no additional fastenings are required. The installation technique is suitable for rotary and retractable gates. Sometimes a rotation limiter is additionally provided.

Installing a gate valve on a pipe

How to install?

How to properly install a valve on a stove and how to install a valve on a chimney? It's simple, let's consider 2 cases.

Installing the damper in the furnace

When installing the damper in the furnace, you need to take into account that this is done during brick laying. It is placed at the beginning of the pipe, about a meter from the surface of the furnace itself. The frame fits tightly into the chimney structure, and the damper is installed after.

Installing a valve in a furnace can be done in three steps:

- Reach the 6th row of brick laying.

- Apply the solution in the desired location and carefully install the frame there. Sometimes you need to cut grooves in the brick for convenience and easier retraction.

- Align the frame so that it lines up with the bricks. Then you can continue laying bricks.

All cracks that may form when installing the plug must be sealed with mortar. Otherwise, there will be loss of thrust and combustion.

Video instruction:

Pipe installation

The damper is also installed at a height of 1 meter from the firebox. It is important that this is the uninsulated part of the pipe. Then there will be no temperature difference when the valve operates.

Installation on the pipe is also simple. First, the first part of the pipe is attached. The joints are lubricated with sealant (temperature-resistant). A gate is tightly placed on top of the structure (the first nozzle). The second part of the pipe is attached to the gate on top. This entire structure is connected to an insulated chimney.

Thus, there is no need to further secure the structure.

It is worth saying that homemade gates can be attached to the pipe a little differently. This already depends on the design. An example of installation of a homemade rotary gate, we reviewed the manufacturing instructions above:

- We make a mark on the chimney pipe.

- Let's try on our preparation.

- We insert the gate into the pipe and screw it into the structure with a thread.

Installing a damper on a chimney

Today, there are two main ways to install a damper on a chimney:

- Installation in a fireplace insert. This installation option implies the location of the gate product in close proximity to the heating equipment. As a rule, in this case the distance from the damper to the heating apparatus is 1 meter. This arrangement is very convenient for regulating the valve.

- Connection with other elements of the heating system. In this case, there is no need to use additional locking elements, so this option is quite common. This type of installation can also be called “pipe to pipe”.

Helpful information! In addition, it is worth noting that the gate product can also be installed in the ventilation system. A gate valve for ventilation is necessary to prevent the fan motor from overheating. The fan motor may overheat during shutdown.

The above options for using valves for chimneys and ventilation systems are used everywhere. It is worth noting that today you can find a huge variety of stoves and fireplaces, which differ from each other from a constructive point of view. This variety of heating devices also influenced the range of gate valves. Therefore, the choice of a damper for a chimney depends entirely on the characteristics of the heating device and the chimney design in a particular case.

Rotary damper for chimney

The rotary chimney damper is a metal damper on an axis. The axis is mounted inside the pipe itself. This device has a removable flap, but with prolonged use it may become unusable. But since such a unit is easily repaired, it does not present much difficulty. This type of design does not require constant monitoring. Its main advantage is simplicity.

rotary damper for chimney

A chimney gate valve is needed for all heating devices operating on solid fuel. For gas boilers, such a part is needed only to protect the chimney from precipitation. Therefore, a rotary mechanism would be more practical for such boilers. When gas burns, the temperature is lower, so this mechanism will be convenient.

Advantages and disadvantages

Like any engineering solution, a gate has a number of advantages and disadvantages.

Pros:

- Possibility of traction control;

- Fuel economy;

- Dampers help retain heat.

Minuses:

- The devices make it difficult to clean chimneys;

- If installed incorrectly, the gate may jam and negatively affect the movement of gases;

- To make the correct adjustment, you must have some knowledge in the field of smoke exhaust systems.

Visual demonstration of the efficiency of a gate valve (video)

Closed gate:

Open gate:

In most cases, the gate is made of stainless steel with a thickness of no more than 1 mm. This part can withstand temperatures up to 9000C, is resistant to corrosion and has a low coefficient of thermal expansion.

In order to ensure maximum ease of operation of the chimney and good soot removal, the surface of the damper must be polished.

The joints are joined using the rolling method.

A standard damper covers up to 85% of the chimney, which is the optimal indicator for the effective removal of combustion products.

Frequent errors and problems during installation

- Installation of a valve in an insulated area. Under the influence of thermal expansion, the damper may jam;

- Installation of a cast iron part in a metal chimney (cast iron weighs a lot);

- Using too thin steel or stainless steel with a low nickel content for the manufacture of valves. Such a product quickly deforms under the influence of hot gases and can burn out;

- Installation of a gate with a non-smooth surface;

- Installation of a valve without a hole for carbon monoxide release;

- Installation of handles that do not allow monitoring the position of the valve (applies to rotary elements).

Purpose of the design

The main purpose of the valve is to control draft by partially blocking the channel.

In addition, using a damper increases fire safety and increases equipment productivity.

And when all the fuel burns out, the valve can be closed - this will reduce heat loss through the chimney. It is worth noting that it is forbidden to completely block the smoke channel: according to safety standards, there should always be a small opening.

This element is used for any heating device - a traditional stove, fireplace, modern boiler, for home and bathhouses. Installation of a damper is not required if a draft control deflector is used.

Features of gate maintenance

The gate, made of stainless steel, is usually polished to perfect smoothness. Soot settles on it poorly, but still settles. Therefore, it must be cleaned periodically.

The horizontal valve can be cleaned simply by pulling it out to the maximum and applying a special solution. Rotary - cleaned through the chimney with a special plastic brush. You should also ensure that the damper moves freely along the guides. It is allowed to periodically lubricate them with an anti-corrosion compound.