Home / Gas boilers

Back

Published: 03/04/2020

Reading time: 7 min

0

2976

The Danko brand is known in the CIS countries for its gas boilers. The first Danko boiler was produced in the Ukrainian city of Rivne in 2002.

Today the company sells heating products on markets in Russia, Belarus and Moldova, significantly expanding the brand line.

- 1 About the manufacturer 1.1 Official website where you can see all models and factory instructions

- 6.1 The wick goes out

Gas water heaters Atem Zhytomyr - technical properties of floor models

What attracts most domestic consumers when purchasing heating equipment is that the price is not expensive. Most owners of privatized houses will be able to afford devices from common foreign brands due to their high cost. But everyone wants to buy themselves a simple and at the same time reliable boiler at the best prices. Such equipment can be found under the Atem brand, under which they are made and supplied to the market. The more common and common name for the heater is gas boiler Zhitomir .

A gas boiler

floor Zhitomir 3 KS-G-025 SN

Peculiarities

The Conord brand represents gas boilers only of the floor-standing type, so each model has a fairly large size and a casing protected by special enamel.

The characteristics of the Conord gas boiler for heating can be given according to the following descriptions:

- The use of steel 3 millimeters thick for the manufacture of the boiler.

- The efficiency of the device is about 90%.

- The need to connect to the power supply network.

- Reasonable price.

- Positive consumer reviews.

The Conord gas boiler is available in several modifications. For example, with or without hot water preparation. The units can also have SIT automatics or thermo-hydraulic automatics. For the second type of boiler, a power supply is required; a thermostat is responsible for supplying and turning off fuel. When certain temperature values are reached, the gas supply to the main burner is stopped, which allows maintaining the required temperature. It doesn’t hurt to know how a gas heating boiler works in order to appreciate the advantages of this equipment.

The Conord gas heating boiler can operate in any conditions, including cold winter. Correct calculation of power allows you to maintain the set temperature regime. A high-quality burner installation increases boiler productivity by creating an optimal gas-air mixture and thermal insulation. This makes it possible to direct a large amount of thermal energy to heat the working environment.

The safety of the Conord gas boiler is ensured by several levels of protection:

- Smoke sensor. This device turns off the gas supply to the burner in the absence of draft. In addition, the sensor prevents the burner from switching off during short-term reverse draft from a strong gust of wind (about

About the manufacturer and its products

The Atem brand and its Zhytomyr gas water heaters have been known and available to customers for more than 27 years. Undoubtedly, from the beginning of production to the present time, the products have changed a lot. The company's manufacturers are constantly improving units to satisfy all the needs and desires of consumers. This is precisely why Atem is considered a leader in the field of heating equipment in the market of our country.

High quality and durability are key indicators related to boilers of this brand.

Atem products have been repeatedly awarded with various awards. Let’s say, “European quality level”, “Golden Mark”. The units are marked with the “Highest Standard” quality mark.

Gas water heaters Atem Zhytomyr are intended for houses equipped with chimneys. The assortment range is the widest, and this provides a possible buyer with a chance to choose a good model.

Boiler specifications

Looking at the owners' reviews of gas water heaters Zhitomir

, it becomes clear why this manufacturer’s equipment stands out so much, why it is so in demand and important.

The equipment is distinguished by a large number of characteristic positive properties when compared with similar competitors. Yes, like any other devices, boilers of this brand also have disadvantages, but in comparison with the large number of advantages, any inaccuracies are insignificant.

Let us note the main positive qualities that Atem gas water heaters have:

- A heat exchanger made of steel, which makes it possible to transfer to water the maximum heat energy that is generated when fuel is burned.

- Full compliance with all Western standards.

- Good and reliable burner design. Thanks to it, the heating unit is considered highly efficient and emits a minimum of substances that are harmful to health during gas combustion.

- Using good automation from a foreign manufacturer. This makes it possible to achieve better technical parameters.

- Simple and convenient control and operation.

- Beautiful design.

- Small design dimensions.

The device has a variety of settings that allow you to adjust the required temperature level. There are installed sensors that monitor the constant operation of the heating structure.

Technical parameters of Atem gas water heaters

Atem company produces:

- gas boilers for floor Zhytomyr ;

- wall devices (parapet).

Units installed on the floor are also divided into single-circuit and double-circuit. Devices with 2 circuits heat water for two or three consumers at low costs. See the technical properties of all Zhytomyr floor-mounted gas water heaters all together.

The productivity of the hot water circuit for floor-standing installations with 2 lines is from 175 to 1400 l/h with a temperature difference of the heated liquid of 35 °C. The device can be equipped with a circulation pump, which is mounted as a function. Parameters of a number of models of double-circuit Zhytomyr parapet type in the table.

Parapet 2-circuit units provide warm water flow from 160 to 345 l/h with a liquid temperature difference of 35 °C.

From the tables we conclude and make sure that the wall-mounted and floor-standing boilers of this manufacturer are adapted to the conditions of low gas pressure in pipelines, and this is their big advantage. A significant disadvantage is the maximum coolant pressure in the heat exchanger, which is possibly very low. For boilers installed on the floor, this is up to 2 kgf/m2, and for suspended boilers, up to 0.7 kgf/m2. Then how can foreign analogues operate at a system pressure of up to 3 kgf/m? Thanks to this, you can make sure that Atem gas equipment is more suitable for gravity systems and small houses with one or two floors.

Professionals do not recommend purchasing wall devices for two-story cottage buildings, since the pressure simply will not be enough for the system to work well.

When, in addition to heating, you also want to receive warm water, it is better to choose models with 2 circuits.

Technical parameters of Atem gas boilers

Atem company produces:

- floor-standing gas boilers Zhytomyr;

- wall-mounted devices (parapet).

Units installed on the floor are also divided into single-circuit and double-circuit. Devices with two circuits can heat water for two or three consumers at low costs. See the technical characteristics of all Zhytomyr floor-mounted gas boilers in total.

| Parameter | Power range | Efficiency | Minimum gas pressure for operation | Maximum coolant temperature | The amount of coolant in the boiler | Maximum operating coolant pressure | Natural gas consumption |

| Meaning | From 7 to 60 kW | 92 % | 635 Pa | 90°C | From 14 to 70 l | From 1 to 2 kgf/m² | From 0.76 to 6.8 m³/h |

The productivity of the hot water supply circuit of floor-standing installations with two lines is from 175 to 1400 l/h with a temperature difference of the heated liquid of 35 °C. The device can be equipped with a circulation pump, which is installed as a function. Parameters of the model range of double-circuit gas boilers Zhytomyr parapet type in the table.

| Parameter | Power range | Efficiency | Minimum gas pressure for operation | Maximum coolant temperature | The amount of coolant in the boiler | Maximum operating coolant pressure | Natural gas consumption |

| Meaning | From 5 to 15 kW | 90 % | 635 Pa | 90°C | From 5 to 17.5 l | 0.7 kgf/m² | From 0.56 to 1.67 m³/h |

Parapet 2-circuit units provide warm water flow from 160 to 345 l/h with a liquid temperature difference of 35 °C.

From the tables we can conclude and make sure that the wall-mounted and floor-standing boilers of this manufacturer are adapted to the conditions of low gas pressure in pipelines, and this is their huge advantage. A significant disadvantage is the maximum pressure of the coolant in the heat exchanger, which is possibly quite low. For boilers mounted on the floor, this is up to 2 kgf/m², and for mounted boilers, up to 0.7 kgf/m². While imported analogues can operate at system pressure up to 3 kgf/m². Therefore, you can make sure that Atem gas equipment is more suitable for gravity systems and small houses with one or two floors.

Experts do not recommend buying wall-mounted devices for two-story cottage buildings, since there simply won’t be enough pressure for high-quality operation of the system.

When, in addition to heating, you also want to receive warm water, it is better to prefer models with two circuits.

Design features

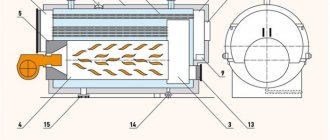

You can take a look at the general structure of the Zhytomyr unit.

Installation of a gas boiler Atem Zhytomyr

The design features of the heat generator provide independence from electrical energy for absolutely all models of the company. The burner is atmospheric and single-stage, with a simple system, brand POLIDORO, bought in Italy, very reliable and durable.

The automation for Zhytomyr gas water heaters is also reliable; it is also manufactured in Italy. The EUROSIT valve is considered automated, does not depend on energy, is more common among manufacturers of heat-generating equipment; production leaders in domestic and foreign countries install it in their devices.

To transfer heat energy in the heating system of the boiler, a fire-tube heat exchanger made of steel is used. This means that high-temperature smoke gases pass through several pipes immersed in a water jacket. They transfer their heat to the liquid and come out at a temperature of 110-150 °C. The pipes have a cross-section with right angles, and this creates a larger exchange surface area and makes the boiler work more effectively. In models with 2 circuits, there are copper coils around the heat exchanger pipes to heat water for domestic needs.

Movement of smoke gases

To slow down the movement of smoke gases in flame tubes, in pipe coils of mounted and floor-mounted units, turbulators are used. Their backup function is to collect soot deposits remaining on the planes of these parts, which are placed perpendicular to the gas flows, and soot deposits almost do not stop on the walls of the pipes.

In the future, soot can be easily removed from the turbulators, just as when dismantling a heating device, they are removed from the flame tubes. A similar characteristic provides a chance for the surfaces of the flame tubes inside to remain clean and transfer heat energy well to the water jacket. Otherwise, the soot layer that settles on the walls can greatly reduce their thermal conductivity, and the temperature of the outlet gases will become higher, and the heat will go outside.

Gas water heaters Atem Zhytomyr will work well with chimneys with low draft. For this purpose, the equipment has a direct damper, which opens the way for smoke gases to escape without affecting the heat exchanger.

It works like this:

- Before ignition, the damper is opened. There is insufficient draft in the chimney.

- The valve adjustment wheel and the piezo ignition button are pressed in stages, the ignition wick lights up.

- The wheel is turned a couple of times, gas is supplied to the burner and it lights up.

- High temperature gases (up to 200 °C) begin to flow directly into the chimney. Due to the temperature difference in the chimney, the draft increases and the boiler enters operating mode.

- After approximately 6 minutes, the damper is closed and the liquid begins to heat up, but the high traction force remains.

A mounted gas Zhytomyr boiler without a chimney is almost similar to the design of floor-standing equipment. The difference is in the design of the chimney; in suspended units it is coaxial. This is a double-walled pipe through which gaseous, liquid and solid substances move, and street air moves towards them between the walls of the inner and outer pipes.

The burner takes oxygen for its operation not from the room, but from the street, and the combustion chamber is of a closed type. In similar foreign units, a ventilation device is built in for air circulation; in Atem boilers, the overall process is independent of energy and operates with natural draft.

Owner's review of the Zhytomyr heating boiler

Kinds

The company produces only energy-independent floor-standing gas boilers.

They differ only in power level and set of functions:

- single-circuit. Provide heating of the coolant for the heating circuit;

- double-circuit. They perform two functions simultaneously - they heat the coolant and prepare hot water for domestic needs.

In addition, the company produces two types of unit designs:

- convection The coolant is heated in the usual way, in the burner flame. The primary heat exchanger is a group of horizontally arranged steel pipes. On dual-circuit models there is a secondary heat exchanger, which is a coil made of a copper tube. It is located directly above the primary node tubes;

- fire tube This type of design is a set of vertical pipes containing coolant. the secondary heat exchanger (on dual-circuit models) has the shape of a copper coil encircling the vertical pipes of the primary unit. Inside the spiral there are thrust stabilizer petals, which reflect hot gases downwards and equalize the temperature throughout the combustion chamber cavity.

NOTE!

Convection-type boilers are designed for residential or public premises with an area of up to 250 m2 (power up to 25 kW), and fire tube installations have an increased power level (up to 50 kW) and are capable of serving an area of up to 500 m2.

Model Atem Zhytomyr 3

Undoubtedly, the company’s assortment includes many models with different parameters. However, the sales driver is considered to be gas boiler Zhytomyr

3, so we need to analyze it in more detail.

The model stands out not only for its good price, but also for its excellent technical parameters.

The power of the unit is 10 kW. It can heat an area of more than 100 m2, and this is enough for a house outside the city. As for gas use, it must be stated decisively that the equipment is economical.

Efficiency - 92%. Owner reviews of the boiler

on

gas Zhitomir 3 are usually good. Almost all customers note the small size, convenient operation and reasonable price.

How to light a gas boiler Zhitomir

The boiler has a regulator with divisions, which must be set to zero. Then open the gas supply on the pipe in front of the boiler and press the regulator like a button and light the wick with a match. After the wick is lit, you need to hold it for 10 seconds and release it smoothly. Then set the regulator to the required compartment (about 2).

If you are not sure of your actions, call the gas service. They will tell you in detail and explain how to turn on the gas boiler Zhitomir.

How to light a gas boiler Zhytomyr

There is a regulator with divisions on the boiler, which must be set to zero. Then open the gas supply on the pipe in front of the boiler and press the regulator like a button and light the wick with a match. After the wick is lit, you need to hold it for 10 seconds and slowly release it. Then set the regulator to the desired compartment (approximately 2).

If you are unsure of your own actions, call the gas service. They will tell you in detail and explain how to turn on a gas boiler in Zhytomyr.

How to light a boiler

Identification of boiler control elements.

The algorithm differs slightly depending on the automation. However, in more than 90% of cases, the choice falls on models with a power of up to 20 kW, on which EuroSit 630 is always installed; using its example, we will look at how to light a boiler:

- Open the gas supply tap on the gas pipeline inlet, turn the mechanical rotator counterclockwise until it stops (to the “⭐” value).

- Press and hold the start button in the center of the controller for 60 seconds, then, without releasing the start button, press the piezo ignition button next to the controller. The start button must continue to be held for another 30 seconds. If the igniter (wick) burns, great, otherwise, to turn on the boiler, you need to repeat the procedure.

- Turn the control knob to the position corresponding to the desired temperature.

A detailed ignition algorithm is always described in the operating instructions. The official website contains detailed, photo-supported instructions for each automation model.

Breakdowns

Let's consider the possible breakdowns of gas water heaters in Zhytomyr, which may appear during use, and options for solving them.

All breakdowns of gas communications and gas boiler valves must be repaired only by authorized professionals.

Disruption of water movement

If the movement of water along a closed circuit is difficult or there is no water in the heating system at all, the reason may be hidden in:

- insufficient amount of fluid in the system;

- presence of air in the heating system;

- water leakage from the heating system;

- significant scale deposits.

This damage can be removed by taking the following steps:

- Refill the heating system with water.

- Release the air by filling the heating system with coolant from below.

- Identify and clean up fluid leaks.

- Clean and flush the system.

Reduced heating efficiency and increased gas consumption

If such a problem occurs, then the reason is most likely the following:

- the heating system is installed incorrectly;

- a lot of scale was deposited.

To get the system working, you need to:

- Correctly install the heating system.

- Clean and flush the boiler.

Condensation forms

If drops of water appear and flow onto the key burner, then most likely the reason is the low temperature of the coolant. To remove this nuisance, you need to warm up the boiler.

The burner goes out

Gas boiler Zhytomyr

does not ignite, and this means the acceptable reasons are:

- not overheating the thermocouple;

- low gas pressure in the system;

- damage to the safety automatics or gas valve;

- loosening of the thermocouple.

This breakdown can only be resolved by calling a gas service professional.

Cotton when igniting

If a pop is heard when the boiler is ignited, then most likely this indicates a poor fire connection between the ignition and key burners. Gas pressure is too low.

In this case, only a master can help.

Burner extinction

If the boiler is on gas Zhytomyr

If both the main and pilot burners go out, then the reason is poor draft. How to fix this problem? Insulate the chimney and remove air suction.

These are the main reasons why breakdowns may occur with a domestic unit.

Now gas water heaters Atem Zhytomyr

are top sellers in their own position. Good technical parameters, excellent quality and budget price make the brand’s products extremely popular. Having decided to purchase a Zhytomyr device, the consumer remains satisfied with the purchase. Due to the fact that such equipment makes it possible to organize reliable and stable heating of the house.

Design Features

You can see the general structure of the Zhytomyr unit.

Construction of a gas boiler Atem Zhytomyr

The design features of the water heating boiler ensure independence from electricity for all models of the company. The burner is atmospheric and single-stage, with a simple design, brand POLIDORO, purchased in Italy, very reliable and durable.

The automation for Zhytomyr gas boilers is also reliable; it is also produced in Italy. The EUROSIT valve is automatic, does not depend on energy, is in great demand among boiler equipment manufacturers, it is installed in their own devices by production leaders in domestic and foreign countries.

To transfer heat energy in the heating system of the boiler, a fire-tube heat exchanger made of steel is used. This means that high temperature smoke gases pass through several pipes immersed in a water jacket. They transfer their own heat to the liquid and come out at a temperature of 110-150 °C. The pipes have a rectangular cross-section, and this makes the exchange surface area larger and makes the boiler operate more efficiently. In dual-loop models, there are copper coils around the heat exchanger tubes to heat domestic water.

Flue gas movement

To slow down the movement of flue gases in smoke pipes, turbulators are used in heat exchangers of mounted and floor-mounted units. Their backup function is to collect soot deposits remaining on the planes of these parts, which are located perpendicular to the gas flows, and soot deposits almost do not linger on the walls of the pipes.

In the future, soot can be easily removed from the turbulators, since when dismantling the heating device they are removed from the smoke pipes. This feature allows the surfaces of the smoke pipes to remain clean from the inside and effectively transfer heat energy to the water jacket. Otherwise, the soot layer that settles on the walls can greatly reduce their thermal conductivity, and the temperature of the outlet gases will increase, and the heat will go outside.

It is best to calculate the power of a gas boiler using

calculator

.

Atem Zhytomyr gas boilers will work properly with low draft chimneys. For this purpose, the equipment has a direct damper, which opens the way for smoke gases to escape without affecting the heat exchanger.

It works like this:

- Before ignition, the damper is opened. There is insufficient draft in the chimney.

- The valve adjustment wheel and the piezo ignition button are gradually pressed, the igniter lights up.

- The wheel is turned a couple of notches, gas is supplied to the burner and it ignites.

- High temperature gases (up to 200 °C) begin to flow directly into the chimney. Due to the temperature difference in the chimney, the draft increases and the boiler enters operating mode.

- After about 6 minutes, the damper is closed and the liquid begins to heat up, but the high traction force remains.

A mounted gas Zhytomyr boiler without a chimney is almost identical to the design of floor-standing equipment. The difference is in the design of the chimney; in mounted units it is coaxial. This is a double-walled pipe through which combustion products circulate, and air from the street moves towards them between the walls of the outer and inner pipes.

The burner takes oxygen for its own operation not from the room, but from the street, despite the combustion chamber being a closed type. In imported similar units, a ventilation device is built in for air circulation; in Atem boilers, the entire process is independent of energy and operates with natural draft.

Owner's review of the Zhytomyr heating boiler

How to start a gas water heater for the first time

When arranging a heating structure, many homeowners prefer installing double-circuits. These heating units, when installing the newest models, are distinguished by their reliability, they are economical and allow you to provide hot water in the house, but you need to know how to start a gas water heater correctly the first time.

In order for the device to work for a long time and without repairs, it is necessary to properly organize the first start-up of the gas boiler, during which the system is filled with water and the air that has entered them is removed from the pump and heating radiators. To facilitate this process, specialized devices - air vents - are used for heating devices. They should be unscrewed until water comes out of them. To prevent air from remaining in the pump, first remove the front panel of the unit and make the necessary adjustments. Air pockets are quickly removed, and the equipment is put into operation on its own.

How to start a gas water heater: preparation

There are simple instructions explaining how to start a gas water heater , which is shown in the photo. The initial start-up is performed when the installation and wiring of all components of the heating equipment is completed, and the accuracy of the work has been verified by the relevant authorities.

The location of the heating unit must be selected in accordance with safety standards and regulations that do not allow the occurrence of fires. Boiler

must be at a certain distance from the wall surface, which depends on the manufacturer’s advice. By the way, for certain models of gas appliances this requirement is not considered important. You also need to make sure that there are no flammable materials or objects nearby.

Plus, it is not allowed to place boilers near windows, because their operation is disrupted. The even placement of the device body is of great importance - even slight distortions are not allowed. After installation is completed, they begin to connect the equipment to a source of cold water: remove the plugs from the pipes, and place a filter with a tap with a round hole at the entrance. Such a device protects the heating structure from a variety of contaminants that cause problems. Valves with a spherical shut-off element must be built into all pipe sections used for piping.

Solving the problem of how to start a gas

water heater, great attention should be paid to the pipe connections from the gas main. These installation works are not carried out with one’s own hands, but rather involve professionals from the relevant services who are involved in connecting, sealing and, if necessary, installing a gas meter.

Before turning on the gas water heater , a separate power line should be installed specifically for the heating unit. The equipment must be equipped with an electrical cable and plug, and a socket must be installed next to the device, separating it from the rest. After which the boiler is connected to the chimney pipe, in which the draft and its performance are checked. She should go outside. The installation work to install a chimney depends on the type of heating device.

Having completed preparations for startup, the boiler is disconnected from the electrical supply to fill it and the heating system with cold water. Then they check that there are no leaks, turn on the thermostat to the maximum value so that the operating mode toggle switch lights up in automatic mode.

How to light a Conord gas boiler

Conord boilers are produced in Rostov-on-Don. The company has existed for 50 years. In recent years, the production base has been modernized. All boilers that the plant produces are floor-standing and have fairly large dimensions. The outer casing is covered with protective enamel.

Gas boiler "Conord"

Let's talk about the advantages right away: the boiler is made of 3 mm thick steel and has a fairly high efficiency of 90%. The popularity of this equipment is ensured by its two undeniable advantages: low price and energy independence.

Conord is produced in several modifications: with or without hot water preparation. Each of the modifications can also be equipped with thermo-hydraulic or SIT automatics. When installing thermo-hydraulic automation, the boiler is non-volatile. In this case, the fuel supply/shutdown is controlled by a thermostat: as soon as the temperature near it reaches the set parameter, the gas supply to the main burner is cut off. This way the selected temperature regime is maintained.

Heating boilers made in Russia "Conord"

The boilers are designed for moderate and cold winter conditions; with the correct calculation of the required power, they can easily maintain the required temperature. High boiler productivity is achieved by installing a high-quality burner, creating an optimal gas-air mixture and thermal insulation of the boiler, which allows more heat to be directed to heating the coolant.

Gas equipment must always be reliable and safe. Conord boilers have several degrees of protection:

- Smoke exhaust sensor, which is triggered in the absence of draft, turning off the gas supply to the burner. It also prevents the burner from turning off when a short-term backdraft occurs during strong winds.

- Monitoring the presence of flame on the main burner. If there is no flame, the gas supply is shut off.

- Control of coolant temperature in the heating circuit. When the threshold value is reached, heating of the coolant stops.

They are also adapted to work at low gas pressure - they operate stably at 0.6 kPa (nominal 1.3 kPa).

Gas boilers "Conord" KSts-GS or KSts-GV are marked, which can be deciphered as follows: K - boiler, C - steel, c - with a cylindrical firebox. Next can go either “G” or “GV” - the first is gas, GV is gas with hot water supply. The following symbols are numbers that indicate the maximum power of the boiler.

When calculating the required power of heating equipment per 10 m2, it is customary to take 1 kW of energy. This is subject to the average height of the ceilings (up to 2.5 meters) and average heat loss.

The letters that follow the numbers indicate the type of automation used. The letter “S” stands for Sit automatics, the letter “H” for Honeywell thermo-hydraulic automatics. The plant also produces gas boilers with cast iron heat exchangers. Then the specification looks like this: KCH-G or KCH-GV

Specifications

One of the main characteristics that attracts buyers is the long warranty period: 3 years, and the service life is 15 years. There are also gas models with cast iron heat exchangers. This is for those who love high reliability. The service life of these units is stated to be 25 years. The main technical characteristics of steel gas boilers are given in the table.

Technical characteristics of gas Conords (click to enlarge)

The durability of the equipment is ensured by a cylindrical firebox, which better withstands high pressure, which makes it possible to use them both in systems with and without circulation pumps. Another “trick” of the Conords is the absence of a middle weld in the firebox, since it is made from a thick-walled (3 mm) seamless pipe. Since the seams in the firebox are the weakest point, their minimum number allows us to guarantee such a service life.

Heat exchangers are made of cold-rolled metal, which better withstands thermal deformations, which inevitably occur during heating/cooling. The coolant in the system with Conords is tap water. The use of antifreeze is prohibited.

Installation of Conord gas boilers

In order for the factory’s warranty to be valid, installation, configuration and commissioning of the boiler must be carried out by specialists from factory-certified service centers. There must also be a corresponding entry in the registration certificate. The connection of the gas main to the boiler must be carried out by gas service workers and again with an entry in the technical passport. Warranty claims will not be accepted in the absence of annual preventive inspection marks.

Heating boilers "Conord" have a low price

Installation highlights:

- If the boiler is installed on a combustible floor, it is necessary to make a fireproof substrate, which should be 50 cm larger than the overall dimensions of the boiler on each side. The fireproof base can be a metal sheet laid on asbestos or mineral wool cardboard.

- For normal water circulation in the system (without using a pump), it is necessary that the lower pipe be located below the heating radiators.

- The pipes in the system can be anything. When using welding for connections, it is advisable to leave a few threaded connections for easy repair if necessary.

- When installing the system, the following requirements must be observed:

- risers must be vertical, the permissible deviation is 3 mm per 3 m of pipe;

- horizontal sections are laid with a slope for air removal - at least 10 mm per meter of pipe;

- bends to heating devices must also have a slope of at least 10 mm per meter of pipe;

- It is imperative to install shut-off valves at the coil outlet.

- Requirements for chimneys:

- The finished chimney to which the boiler is connected must be located inside the building in a load-bearing wall.

- When a smoke exhaust pipe passes through an unheated room, it must be protected with heat-insulating materials.

- The diameter of the chimney must be larger than the outlet pipe. Failure to comply with this recommendation leads to unstable operation (switches off due to insufficient traction).

- The chimney must be vertical without ledges.

- The parameters, design and height must comply with regulatory documents and also be agreed with the fire department.

- Gas boilers must be installed according to a project agreed upon with all special organizations.

- the problem is caused by contamination of the burner (clean the air and gas supply nozzles with a brush and vacuum cleaner);

- insufficient amount of air for the pilot burner to operate (when it first goes out) - remedy - clean the air supply nozzles and improve the ventilation of the room;

- oxidation of thermostat contacts (clean the contacts or “move” if you lack the skills);

- the traction sensor is faulty;

- The flame sensor is faulty.

Reviews and practical recommendations for operation and troubleshooting

For the most part, Conord are characterized as reliable and inexpensive boilers. There is a lack of service functions (and where can they get them with thermo-hydraulic automation). However, there is a common problem: it often goes out for unknown reasons. Based on the advice, the following conclusions can be drawn:

There are several more options, but they can be eliminated (like the last two reasons) only by service or repair workers.

There is also a complaint about the low temperature of the coolant in the system. In this case, you need to move the thermostat switch to the maximum position (or close to it). The operating instructions also contain recommendations for increasing the gas supply to the burner. This will also raise the temperature in the system. The increase in gas supply is shown schematically in the figure.

How to increase the gas supply to the burner in a Conord gas boiler

There is a peculiarity of using a Conord boiler with hot water supply in the summer. To turn off the heating circuit, turn off the water supply tap. When only the igniter (pilot burner) is operating, the water heats up to about C in an hour. If there is no further water consumption (shower, etc.), then there is enough water for hours for small household needs. But after heating the boiler, if you do not plan to actively consume hot water, you need to turn it off. Otherwise, after hours of operation of only the pilot burner, the water in the boiler will boil without consumption, and the boiler will rupture: there was such a case - a recently purchased boiler ruptured.

Solid fuel boiler "Don"

The universal boiler "Don" operates on any solid fuel

The non-volatile universal boiler “Don” can operate on any type of solid fuel. If necessary, a gas burner can be installed. It can work up to 8 hours on one load of coal.

The firebox is made of structural steel, which is highly resistant to corrosion. The firebox has decent volumes: firewood up to 60 cm long (depending on the model) can be placed in it; logs up to 60 cm in diameter can be used. The warranty service life of the Don boiler is 12 months.

The overall dimensions of the new Dons remain the same, so they are installed exactly in the place of the old ones and do not require reworking the system. The transition to gaseous fuel occurs by installing the burner in a special hole.

Technical parameters of universal heating boilers "Don" are given in the table.

Characteristics of the Don boiler (click to enlarge)

The installation of a universal boiler is subject to the same requirements as the installation of a gas boiler, with the exception of points relating to gas service. Read more about universal (combined) boilers here.

The well-known heating boilers under the Conord brand are produced by a domestic enterprise located in Rostov-on-Don. The latest and most advanced technologies, as well as a complete renewal of production facilities, allowed the Rostov plant to produce products that are in no way inferior to the most famous foreign analogues. Quite large floor-standing devices are distinguished by increased productivity and enviable reliability.

Peculiarities

To make sure that this product is of the best quality, you can read the various reviews about these products that users leave about them. Consumers are drawn to the fact that heating devices from Conord have a long service life, a decent degree of reliability and excellent efficiency. All factory products come with an extended warranty; for this reason, if anything breaks in the first 3 years of using the device, the manufacturer will provide free maintenance or high-quality repairs. The full period of such a guarantee is 15 years.

Externally, these units are distinguished by a rather strict design. Models with two circuits can be used in hot water systems during the warm season of the year and will not be dependent on heating. Gas products from Conord are launched using piezo ignition, and the technical characteristics reflect their excellent functionality.

All devices from Conord are divided into:

- Models where there is no system for supplying the consumer with heated water. They have built-in Italian automation and are extremely in demand.

- Heating devices that can only give warmth to your home. Their automatic elements use the principle of thermohydraulics.

- Boilers that not only provide home heating, but also heat water for domestic needs. They have built-in automation from Italy from SIT.

- Models that are capable of heating rooms and calmly warming liquid for various purposes. Thermohydraulic automation makes these tasks more simplified.

Advantages and disadvantages

The positive features of gas appliances from Conord can be determined according to the reviews of those owners who actively use them:

- large model range;

- models have 3 types of automation;

- efficiency;

- high efficiency;

- in the event of a boiler breakdown, you can find spare parts quite quickly;

- good thermal insulation;

- guarantee of flawless operation for 3 years;

- uninterrupted operation for almost 15 years;

- steel heat exchangers help withstand thermal deformations;

- the use of water from the water supply system as a coolant;

- the ability to connect to a system with various types of circulation of the working environment;

- almost complete absence of wall-mounted appliances;

- energy independence of devices;

- use in certain series of automation parts made in Italy and Poland;

- simplified process of using the device.

Boilers from this manufacturer are created in accordance with the characteristics of the domestic climate and are designed to generate the required amount of heat to warm the home even in the most severe frosts.

The reliability of these popular devices is guaranteed by the increased level of durability of heating devices, and their independence from electricity will allow them to function without any failures or delays, especially in conditions where there is no electricity.

The low level of noise impact during operation, compact size and stylish design will allow you to place the device in the kitchen or any other room without harming the design of this room.

An efficiency of 90% makes Conord units the most popular in terms of savings. Thermal insulation materials greatly reduce heat loss.

A gas unit with 2 circuits from Conord can heat the room as quickly as possible, and also provide home owners with heated water for personal needs.

The safe operation of the products is guaranteed by the arrangement of various protection components of the automation box, which will help turn off the product when the traction is lost. In addition, the boiler will be turned off in the event of any breakdown or any other type of failure. You will be able to automatically adjust the heating temperature of the device, and if the fuel pressure level is too low, the device will provide rapid forced air injection to maintain the functionality of the device.

Disadvantages of Conord products:

- not the highest build quality of some models;

- the steel thickness will be no more than 3 mm;

- ban on the use of antifreeze.

The presence of special module burners will provide a significant reduction in fuel consumption. These innovations will help you achieve increased thermal efficiency while reducing fuel consumption, which will allow you to save on fuel.

Types and characteristics

Conord floor-standing devices are available with different powers - from 8 to 30 kW. They come with one circuit: these are models KSts-G-8 and KSts-G, KSts-G and KSts-G, KSts-G and KSts-G, as well as KSts-G; and with two circuits: KSts-GV and KSts-GV, KSts-GV and KSts-GV, KSts-GV and KSts-GV

Each letter in this case will have its own meaning:

- “K” is the name of the device – “Boiler”.

- “C” is the type of material from which the boiler is made. In this particular case it is steel.

- “C” – the firebox is released in the form of a cylinder.

- “G” - without other letters nearby will mean that in front of you is a gas unit.

- The letters “DHW” will show you that in a particular case there is a product with a DHW function in front of you.

- The numbers in this name indicate the level of the maximum power indicator of the device. When selecting these parameters, you need to take 1 kW to heat a room of 10 m2 with a wall height of no more than 2.5 m.

Thus, the KSts-GV device is a steel boiler with a cylinder firebox, having a DHW function and a maximum power of 12 kW. Products with one circuit are selected only for heating a home with an area of 30 to m2. Double-circuit devices from Conord can be used for heating and for producing heated water.

In the line of this popular brand there are almost no options for models for walls; for this reason, for their home heating system, ordinary people buy floor-standing boilers, which sometimes have a number of additional features. Floor products are available in 4 popular series. The plant produces all units from high quality steel. To improve the durability of the boiler, a special powder layer is applied to its body, which will protect the device from exposure to fairly high temperatures and severe loads.

Buyers who are interested in this unit should know that instructions for its use are always included in the kit, and you can choose the right device from several series.

KSC-G-S

In this series you can easily find an excellent device with one circuit, which will also be equipped with a fairly convenient regulator for fuel supply. Imported automation, which is necessary to control the entire operation of the product, guarantees its complete safety. Devices from this series can be adapted to heat buildings with areas from 80 m2 to m2, but you must choose the right boiler according to its power.

The operating pressure level of units from the KSts-G-S modification can be from 0.2 to 2 bar, the lowest temperature when heating the coolant is 60 degrees, and the highest is 90 degrees.

KSC-G-N

Multifunctional products under the designation KSts-G-N have a special heat exchanger in the form of a cylinder, which is made of good steel. This solution helped them achieve the highest possible performance and guarantee the possibility of high-quality heating of the coolant that circulates in the circuit. This modification mainly includes models with one circuit; they can be easily selected for quickly heating homes with a large area (m2).

KSts-G-N products can be used in quite difficult conditions - they can work in systems that have pressure up to bar. To optimize the entire heating process, the products have excellent thermal and hydraulic automation.

KSts-GV-S

The Conord device with two circuits can be found in the KSts-GV-S series. Models have a circuit in order to provide domestic hot water supply. The products operate under the careful control of automation from Italy from SIT and are capable of heating buildings with an area of up to m2.

By purchasing this device, the average person will be able to solve 2 problems at once and will complement their home with a device with which they can heat all rooms and provide the required volume of heated water for various needs. These products are considered quite universal - they can be used in different systems.

KSts-GV-N

Among all types of products that are collected under the designation KSts-GV-N, you can choose a good double-circuit Conord unit, whose main characteristics will be represented by a special type of smoke collector and the integration of a thermo-hydraulic type of automation. KSts-GV-N products are distinguished by a special accident protection system. These units are considered the safest and, most importantly, guaranteed to be reliable. They are complemented by special detectors that will instantly stop the transfer of fuel at the slightest threat of an accident. This product is capable of making its operation stable on its own in the presence of not very large backdraft. The power of devices in this series will be from 12 to 30 kW.

The Conord boiler from the AOGV series is a popular energy-independent unit. Gas unit "Conord" AKGV kW modification-3, has a hot water supply circuit. The AKGV boiler has two circuits, complemented by Italian automation from SIT. The use of a special fuel supply regulator “EuroSIT” allows you to stabilize the required temperature and operation of the product even at the lowest level of fuel pressure. Temperature adjustment parameters – from 40 to 90 degrees.

The thermal insulation of the device guarantees low heat loss, which ultimately allows it to achieve 90% efficiency.

Installing a coaxial chimney in a boiler will practically solve any problems that may be associated with the efficiency of removing combustion products from the home. Usually the autonomous heating system is qualitatively improved. Pay attention to a number of aspects that may well help you make a choice in favor of a coaxial pipe:

- The efficiency of the device increases due to heating of incoming oxygen;

- there is a significant reduction in gas consumption, as a result you will be able to save on buying it or paying rent bills;

- installation of the chimney can be done in the wall, and not, as usual, in the ceiling;

- Oxygen combustion occurs outside the room.

User manual

In order not to lose the warranty for the maintenance of your unit in any case, you do not need to carry out work on installing the boiler and repairing it yourself. Connecting the product, its proper configuration, and the first start-up must be carried out by service specialists. They will make a separate entry about the work performed in the passport of the unit you purchased. It is necessary to carry out preventative maintenance of the entire boiler once a year - this is also noted in the technical data sheet of the device. Failure to maintain such records may void your warranty.

The Conord burner may sometimes not ignite. This may happen because:

- There is a lot of dirt on the burner. Before turning on the structure, you need to clean the nozzles with a soft brush or just a vacuum cleaner.

- There may not be enough oxygen to start the burner quickly. Again, it is necessary to clean the nozzles that supply air, thoroughly ventilate the room, and try to light the burner again.

- Perhaps the contacts in the thermostat have simply oxidized. This is where the cleanup takes place.

- Automation sensors are broken.

- It is necessary to blow out the igniter or clean it of any existing dust or dirt.

If your coolant cools down very quickly, you just need to switch the thermostat to maximum settings or increase the supply of fuel to the burner, if only the device instructions allow this kind of action.

In the summer, you will need to turn off the heating circuit altogether. You just need to turn off the tap at the coolant inlet. If the burner works alone, the water will heat up to 60 degrees in 1 hour. If the heated liquid is not all removed at once, it will retain heat for about another 2 hours.

Domestic has already earned an excellent reputation in the domestic heating equipment market thanks to the production of high-quality equipment. Among users, Conord units, reviews of which have mostly positive features, are always in fairly high demand.

When the device gets seriously hot, and there is no need for a large flow of water, it is simply turned off so that the water in the device does not boil.

To learn how Conord gas boilers are produced, see the following video.

The use of gas boilers in dachas and private homes is an economical way to heat a home. Gas has lower consumption and cost than electricity, and is much more convenient to deliver than solid fuels. The most common at the moment are floor-standing models, such as the Conord (only this type is produced). Wall-mounted ones, for example, “Danko” (this manufacturer produces both types of structures), are also firmly in use.

For your information! The main problem when operating gas boilers is proper starting.

Features of operation

Depending on the manufacturer and model, the device has a certain type of automation, which controls the entire combustion process, as well as its characteristics and, accordingly, operational features and certain rules when trying to ignite the boiler.

"Conord"

The main characteristics observed in the entire model range:

- The manufacturer produces boilers exclusively for floor-standing use, so any model from this company has a powerful casing of a fairly large size. It is protected by a layer of enamel, which prevents damage to the metal from moisture;

- since the manufacturer is domestic, the cost of its products is slightly lower than that of other brands;

- the efficiency of all boilers is on average 90%;

- the body and main structural components are made of steel sheets, the thickness of which is about 3 mm;

- Automation systems that provide control over gas combustion and operational safety require the boiler to be connected to a power supply.

The model range is quite wide, each model in it has various additional design elements. For example, there is an option for sale with warm water supply. It is equipped with automatic thermo-hydraulic type. For its operation, a constant stable connection to the network is required. The fuel supply is regulated by a thermostat: when the temperature sensor readings are required, gas access to the main burner is blocked.

For your information! High-quality automation ensures minimal deviations of the room temperature from the set one.

The productivity of the heating system is increased with a powerful burner when installed correctly. This is the only way to obtain a balanced mixture of gas and air. Good thermal insulation of the boiler, especially the chamber in which combustion occurs, also improves the quality of work. Low pressure will not interfere with the operation of this brand of unit. Thanks to all this, Conord allows you to warm up even in the most severe frosts.

Boilers of this brand also have a good multi-level security system:

- smoke exhaust sensor. It turns off the gas if there is no traction. It also does not allow the burner to be interrupted during strong gusts of wind, during which air moves in the opposite direction (“reverse draft”);

- temperature sensors. Shut off the gas when the temperature approaches the set limit;

- flame sensor. Interrupts the gas supply if there is no fire on the burner.

To know what other design and operation features there are, you need to be able to decipher the markings of a given brand. For example, KSts-GV means that:

- this is a boiler (letter K);

- made of steel ©;

- cylindrical combustion chamber (letter C);

- the fuel for it is gas (this can be identified by the next letter G);

- “HW” means the presence of hot water supply;

- The numbers at the end indicate the maximum power output.

Important! The required heating power is calculated based on the amount of area. So, 1 kW of power is enough to maintain the desired temperature in a room with an area of 10 m², while the height should not be more than 2.5 m.

"Danko"

This foreign manufacturer has already gained popularity in European countries and is gradually moving to Russia. A relatively low price in combination with quality, good efficiency and aesthetics create good advertising for it. Another advantage is the production of wall-mounted and even floor-standing models that have modest dimensions. This makes Danko an indispensable assistant in small rooms (bathrooms, miniature kitchens). It will not steal precious space and will fit into almost any interior.

For Russian users there are a number of special advantages of this manufacturer over others:

- despite the fact that the units are not produced in the Russian Federation, they are perfectly suited for use with Russian pipes and batteries (even old cast iron radiators do not need to be replaced);

- the boiler will not have any problems when working with Russian gas;

- is not afraid of the harsh climate of Russia, it can be launched even in severe frosts;

- the boiler operates silently, which makes it indispensable in residential buildings with poor sound insulation;

- "Danko" can be used in systems where water circulation is not forced. That is, this boiler does not require a pump, which makes the heating system autonomous in relation to the electrical grid.

Danko heating systems have only one drawback in all models that need to be hung on the wall - horizontal chimneys are installed. They are quite vulnerable to strong wind gusts. Also, Danko wall-mounted modifications require more attention and care (especially frequent and thorough cleaning) with less power.

For your information! Due to the higher noise level, floor-mounted ones have to be installed in special rooms or corridors. But they are not so whimsical.

Basic inclusion rules

Correct activation of the device must first of all comply with safety regulations. They are the same for both Danko and Conord:

- children cannot be trusted to turn on the boiler;

- It is prohibited to ignite devices whose automation does not work or does not work correctly;

- if you suspect a leak, do not try to ignite the unit or check the leak location with fire;

- You cannot light the burner without draft in the chimney;

- it is forbidden to turn on the heating without water inside the system;

- When igniting and subsequent operation of the boiler, it is prohibited to keep flammable objects nearby;

- The water temperature in the system during operation should not be higher than 90°C.

How to turn on a gas boiler

The main differences in switching methods depend not on the design of the boilers themselves, but on the type of automation that is installed in them.

For your information! That is, even different models from different manufacturers can turn on in the same way if they have the same automation system.

Danko boiler: how to turn it on and off correctly

Basically, the instructions on how to turn on the Danko gas boiler boil down to the following algorithm:

- Check that the boiler is turned off (the thermostat knob should indicate ignition).

- Next you need to open the tap in front of the boiler.

- The ignition button must be pressed and held in this position for a while.

- With your other hand you need to press the ignition button several times (until the gas in the burner ignites).

- After ignition, the ignition button must be held for about 10 seconds.

- After this, you need to make sure that the burner is still burning.

- Make adjustments by turning the thermostat knob.

Important! If the burner suddenly goes out, then you need to repeat attempts to ignite the boiler after 3 minutes. or more.

Switching off is done by turning the thermostat knob and closing the tap in front of the boiler.

Turning on the Conord boiler

You can ignite the gas in the burner of this boiler using a semi-automatic method. How to do it:

- The regulator should be in the extreme position.

- Then you need to push the wheel down for a period of 5 to 6 seconds. At this time, gas flow into the chamber begins.

- By pressing the ignition button, a piezoelectric element is activated, which ignites the mixture.

- After the fire appears, you need to hold the wheel in the down position for a little longer (about 10 seconds).

- Next you need to start setting the desired temperature.

Care tips and advice

Proper maintenance of the boiler, performed regularly, will help keep it in working condition for a long time and avoid various accidents and accidents. Otherwise, the unit may break even in the first year of operation. Performing several operations will prevent this from happening:

- even during normal operation of the boiler, you need to contact one of the organizations carrying out work in this area, so that a technician inspects the device for gas and water leaks, the condition of the sensors and chimney, and, if necessary, carries out repair work;

- You should always monitor the water pressure inside or at the outlet of the system. If it drops below 0.8 bar, then water needs to be added;

- The addition of water to the system is usually carried out directly through the boiler, where there is a special tap. In this case, the pressure of the added water must be greater than the pressure of water from the boiler. The supplemented water should only be cold (up to 35°C).

For your information! To spend winter evenings warm and comfortable, you need to properly care for your boiler and also know how to light it.

Depending on the model and manufacturer, this process will be slightly different due to differences in design. This can be clarified in the instructions supplied with the device.

Rules for filling the system with water before turning on the gas water heater

Before lighting a gas water heater

, and turn on the heating system, first of all it is filled with cold coolant, which, after heating, will circulate through the pipes and heating devices. When performing the first launch, everything is carefully checked so that subsequent work is trouble-free and the equipment does not require repairs.

In the body of the unit there is a specialized tap, located near the pipe section, to supply coolant into the system. During the filling process, the system pressure is monitored due to the presence of sensors and instruments for determining the pressure value. Modern boilers already have them, and there is no need to buy them additionally. When the device is filled with water, the mark on the meter rises. When it reaches 1.5-2 atmospheres, the water supply is shut off and filling is completed.

These pressure parameters can be changed because they depend on the manufacturer's requirements for the operating pressure in the heating system. But filling with cold water does not end there entirely, because replenishment will be needed after the structure is freed from air pockets.

Malfunctions

Let's consider possible malfunctions of Zhitomir gas boilers that may appear during use, and options for solving them.

All problems with gas communications and the gas boiler valve must be repaired only by authorized specialists.

Disruption of water movement

If the circulation of water is difficult or there is no water at all in the heating system, the reason may lie in:

- insufficient amount of fluid in the system;

- presence of air in the heating system;

- water leakage from the heating system;

- significant scale deposits.

You can resolve this issue by taking the following steps:

- Refill the heating system with water.

- Release the air by filling the heating system with coolant from below.

- Detect and repair fluid leaks.

- Clean and flush the system.

Reduced heating efficiency and increased gas consumption

If such a problem occurs, the reason is most likely the following:

- the heating system is installed incorrectly;

- Too much scale has been deposited.

To get the system working, you need to:

- Correctly install the heating system.

- Clean and flush the boiler.

Condensation forms

If drops of water form and flow onto the main burner, then most likely the reason is the low temperature of the coolant. To eliminate this problem, you need to warm up the boiler.

The burner goes out

The Zhitomir gas boiler does not ignite, which means the possible reasons are:

- weak heating of the thermocouple;

- low gas pressure in the system;

- damage to the safety automatics or gas valve;

- loosening of the thermocouple.

This malfunction can only be resolved by calling a gas service specialist.

Cotton when igniting

If a pop is heard when the boiler is ignited, then most likely this indicates a poor fire connection between the ignition and main burners. Gas pressure is too low.

In this case, only a specialist will help.

Removing air pockets before lighting a gas water heater

Before lighting a gas water heater

, it is necessary to fill the heating structure with liquid cold coolant. But just filling with water is not enough. It will either not work, or the degree of heating of the room will be insufficient. A real first start is impossible without releasing the air accumulated in the system. Often modern gas water heaters have a specialized system that automatically releases air when filled. However, its effectiveness is often insufficient: you will still need to manually reset the air jams. Only after this can you launch.

Remove air pockets before turning on the gas water heater

, it is necessary not only from the heating unit, the circulation pump, but also from all heating radiators. The process must begin with batteries - for this, as mentioned above, they are equipped with air vents. They are opened by placing a container underneath. First of all, a light whistle will be heard, which means that air is gradually leaving the system. After removing the plugs, water begins to flow. Then the taps are closed. A similar operation should be done with each of the heating devices.

How to turn on a gas boiler

The main differences in switching methods depend not on the design of the boilers themselves, but on the type of automation that is installed in them.

For your information! That is, even different models from different manufacturers can turn on in the same way if they have the same automation system.

Danko boiler: how to turn it on and off correctly

Basically, the instructions on how to turn on the Danko gas boiler boil down to the following algorithm:

- Check that the boiler is turned off (the thermostat knob should indicate ignition).

- Next you need to open the tap in front of the boiler.

- The ignition button must be pressed and held in this position for a while.

- With your other hand you need to press the ignition button several times (until the gas in the burner ignites).

- After ignition, the ignition button must be held for about 10 seconds.

- After this, you need to make sure that the burner is still burning.

- Make adjustments by turning the thermostat knob.

Important! If the burner suddenly goes out, then you need to repeat attempts to ignite the boiler after 3 minutes. or more.

Switching off is done by turning the thermostat knob and closing the tap in front of the boiler.

Turning on the Conord boiler

You can ignite the gas in the burner of this boiler using a semi-automatic method. How to do it:

- The regulator should be in the extreme position.

- Then you need to push the wheel down for a period of 5 to 6 seconds. At this time, gas flow into the chamber begins.

- By pressing the ignition button, a piezoelectric element is activated, which ignites the mixture.

- After the fire appears, you need to hold the wheel in the down position for a little longer (about 10 seconds).

- Next you need to start setting the desired temperature.

Valuable advice

To start the boiler , power must be supplied and the heating regulator must be set to the desired operating position. The presence of a weak hum indicates that the circulation pump has started working. Using a screwdriver, you should lightly unscrew the cover of the detected part. However, this must be done before the water starts flowing. If the liquid begins to break through, screw the cap into place. These actions are done a couple of times and after which the air pockets will be completely removed from the system. The gurgling sounds will also disappear and the pump will run quietly.

Repair and operation of boilers Zhitomir

Nowadays boilers have start limiters; they are set to the off position at the factory. It’s better to call a specialist, it’s a headache. Django, Take a voltmeter and measure the voltage on the thermocouple - about 30 mV.

If you ring the traction sensor, it is most likely that the contact is lost.

Andrey, The boiler’s passport does not say anything about limiters. Thanks for the tips. I'll work with the tester and look for a specialist, although I bridged the traction and thermostat sensors with a jumper, it didn't help.

Yes, the boiler is new. Installed last year.

Specifics

The ATEM brand has invested all its efforts in the development and production of a good device for individual heating. For more than 27 years, the company has been providing heat to its own consumers in the form of gas water heaters “ Zhitomir ”. Since the inception of the first boiler, a very large rebranding has been carried out, the device has received changes from the internal base of spare parts to the external design. Nowadays, the Zhitomir boiler

"is a neat, small-sized block with switching instructions that even a child can handle. The main quality characteristic of boilers of this brand is the reliability and quality of the device. The technical properties of products have also changed with the emergence of recent technologies. Not only these components, but also other facts made it possible for the ATEM brand to acquire the “European Quality Level” award.

But the company did not stop there, the Zhitomir received the “Golden Mark” and “Highest Standard” awards, proving to everyone that they occupy first place in the world market.

Characteristics

Nowadays, products represented by Zhitomir are recognized as the most modern and popular. To understand why this brand itself has gained consumer recognition, we should consider a number of models in more detail. Each individual equipment has a great advantage in comparison with similar devices from other manufacturers. There are disadvantages in Zhitomir boilers, as in any product, but the presence of advantages outweighs the importance, showing that the equipment has many more good qualities.

Gas water heaters “Zhitomir” have a number of advantages, thanks to them they are in great demand on the market.

- The heat exchanger of the device is made of steel. Because of this, the water receives the maximum heat that is generated when the gas burns.

- The design of the burner is thought out to very small details. Actually, this characteristic helps to increase the productivity of the device, and the level of release of bad impurities is minimal.

- Imported automation of each boiler makes it possible to achieve the best characteristics.

- Ease of device management. There are no unnecessary buttons or toggle switches.

- The design of the equipment is developed according to the latest fashion. The boiler

does not take up much space, and in appearance it is similar to a small bedside table, which fits into any setting. - During the manufacturing process, each individual model goes through several stages of testing according to Western standards. And after completing all tests, he receives a quality document.

Many settings in the Zhytomyr boiler system make it possible to choose a suitable and convenient state for yourself. Specialized sensors, which are also equipped in the system, monitor the device’s safety and trouble-free operation. Taking into account all the positive qualities described above, we can safely say that Zhytomyr

» are perfect for heating privatized houses, and will cope well with their own work in the apartment and in other rooms. It should be noted that not only the bright design and ease of use attract consumers, but also the price issue.

Cost of the boiler " Zhitomir"

"meets the condition "price - quality", and this quality will not hurt your pocket.

Specifications

Gas boilers Zhitomir are produced in Zhitomir (Ukraine).

They are produced in two versions:

- Floor-standing - installed on the floor or special stands;

- Wall-mounted - placed on the wall using special hangers and brackets.

Both types of boilers, according to their purpose and design, can be:

- single-circuit, intended only for heating premises;

- double-circuit, working for heating and hot water supply to the house.

The table shows the main characteristics of single-circuit floor-standing boilers “Zhitomir”

.

| Indicators | Numerical values |

| Thermal power for heating system, kW | 7…80 |

| Heated area of the building, sq. m | 70…800 |

| Maximum coolant temperature, °C | 90 |

| Efficiency of the boiler heat exchange device | 0,92 |

| Minimum gas pressure value, Pa | 635 |

| Boiler internal volume, l | 14…70 |

| Maximum permissible coolant pressure in the heating system, bar | no more than 2 |

| Average hourly consumption of natural gas, cubic m/h | 0,76…8,72 |

| Only for double-circuit boilers | |

| Hot water capacity, l/h | 175…1400 |

| Maximum water heating interval, °C | 35 |

| Water heating circuit efficiency | 0,87 |

| Possible additional option | circulation pump |

The principle of operation of the floor-standing gas unit Zhitomir

Wall-mounted boilers have a range of indicators presented in the table

.

| Indicators | Numerical values |

| Thermal power for heating system, kW | 5…15 |

| Heated area of the building, sq. m | 50…150 |

| Maximum coolant temperature, °C | 90 |

| Efficiency of the boiler heat exchange device | 0,90 |

| Minimum gas pressure value, Pa | 635 |

| Boiler internal volume, l | 5…17,5 |

| Maximum permissible coolant pressure in the heating system, bar | no more than 0.7 |

| Average hourly consumption of natural gas, cubic m/h | 0,56…1,67 |

| Only for double-circuit boilers | |

| Hot water capacity, l/h | 160…345 |

| Maximum water heating interval, °C | 35 |

| Water heating circuit efficiency | 0,86 |

| Possible additional option | circulation pump |

The information presented indicates that Zhitomir boilers are designed for operation with gas supply at low pressure. This sets these devices apart from the rest. There is also a drawback. The coolant pressure in the heating system is limited to 2 bar for floor-standing boilers, and 0.7 bar for wall-mounted boilers.

Similar imported heat generators allow operation under pressure up to 3 bar. This allows them to be used for heating needs of three or more storey buildings.

Varieties

Nowadays, several types are used Zhitomir For their part, floor products also have divisions into single-circuit and double-circuit.

If a gas water heater

needed only for heating purposes, you need to pay attention to single-circuit models.

They are undemanding, convenient and economical. Equipping a single-stage boiler " Zhitomir " first of all involves foreign components.

Thanks to them, the device can be turned on and off if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to select from dual-circuit options. Due to price demand, double-circuit units are a little more expensive, but they also provide double pleasure to the consumer in their work.

According to their own characteristics, floor-standing boilers mostly have the following similarities:

- the highest temperature limit is +90 degrees;

- Efficiency is 92%;

- gas pressure – 635 Pa.

However, when selecting exactly the model you like, you need to consider its specific characteristics and capabilities.

The same zoning as for floor-mounted boilers is also found in wall-mounted boiler models. They can also be single-circuit or double-circuit. The efficiency of all devices is similar. The same applies to gas pressure.

But it is still necessary to consider their characteristics in more detail:

- the power of chimneyless boilers must be at least 5 kW and less than 20 kW;

- the thermal fluid in the device is no more than 17.5 liters;

- depending on the model that was selected, the network gas consumption is considered; standard – 0.56–1.67 cubic meters per hour;

- economy due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but the Zhitomir -3 KS-G-020 SN model is still in incredible demand. This device differs from its counterparts not only in terms of affordability, but also has clear technical data. The design of the device is designed in a minimalist style; the outside of the boiler looks like a cabinet. It must be placed exclusively on the floor. On the front of the model there is a small flap, behind which the button for turning on and adjusting the device settings is hidden. In this part there is a control window, thanks to which you have to monitor the boiler productivity indicators.

The key package includes a housing, which also includes parts of the heat exchanger. On the outside it is covered with thermal insulation material and a casing made of steel. There are two burners shown: one is the main burner, and the second is the pilot burner. The kit includes a gas duct and an automated gas valve; it is responsible for safety during operation.

If the temperature becomes more than +95 degrees, the shutdown meter breaks the circuit to the valve, and the valve itself automatically closes the gas supply.

Care tips and advice

Proper maintenance of the boiler, performed regularly, will help keep it in working condition for a long time and avoid various accidents and accidents. Otherwise, the unit may break even in the first year of operation. Performing several operations will prevent this from happening:

- even during normal operation of the boiler, you need to contact one of the organizations carrying out work in this area, so that a technician inspects the device for gas and water leaks, the condition of the sensors and chimney, and, if necessary, carries out repair work;

- You should always monitor the water pressure inside or at the outlet of the system. If it drops below 0.8 bar, then water needs to be added;

- The addition of water to the system is usually carried out directly through the boiler, where there is a special tap. In this case, the pressure of the added water must be greater than the pressure of water from the boiler. The supplemented water should only be cold (up to 35°C).

For your information! To spend winter evenings warm and comfortable, you need to properly care for your boiler and also know how to light it.

Depending on the model and manufacturer, this process will be slightly different due to differences in design. This can be clarified in the instructions supplied with the device.

The production of Conord gas heating boilers is carried out by a Russian plant located in the city of Rostov-on-Don. Improvement of technology and complete renewal of production allows the plant to produce products that are in no way inferior to foreign analogues. Large floor-standing boilers are characterized by high performance and reliability.

Operating instructions

at the beginning of using the Zhitomir equipment, you need to make a high-quality installation of the product, check the pipes, especially if the boiler is a double-circuit one. Next, the first launch is performed. And then the boiler

part of normal operating procedures. According to the typical scheme, you need to turn on the device, light the wick, then adjust the heat supply. After these steps, you can change the settings to decrease the heating or, conversely, increase it.

At the end of the cold season, the boiler must be turned off for the warm period , because there is no need for it, which will make it possible to eliminate additional waste of the device’s potential. In most cases, after a warm period during the connection period, it is not possible to light the boiler

, the ignition fuse goes out. This may be due to weakened draft, weak gas pressure, or breakdown of the valve responsible for the gas supply.