What air pressure should be in the expansion tank of the heating system?

Indicator of the empty capacity of the air chamber at room temperature. It should be equal to the static value in a tank filled with water. In this position, the membrane is in equilibrium, and the gas pressure is compensated by the liquid pressure. For every 10 meters of pressure, about 1 atm is required. Despite this, for normal operation of the entire system it is enough to create the indicator specified in the device passport.

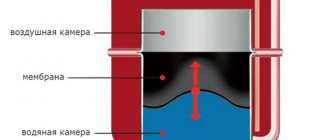

Photo 1. Diagram of the expansion tank for closed-type heating systems. Arrows indicate parts of the product.

, 0.9 atm is enough for favorable operation This is due to the pressure that the membrane creates during operation. Its average is 1.2 atm . Both values fluctuate within a small range with a maximum deviation of 0.1.

If the heating system is not made according to classical schemes, separate calculations are carried out for it: the volume of the coolant, the tank, the efficiency factor and the initial charging pressure are determined. To do this, you should invite a specialist who will take into account other minor factors.

How to check the indicators

The easiest way to take a measurement is to attach a pressure gauge . The problem arises during the preparation phase as most tanks do not have space for mounting. At the same time, the device must have a nipple to which a compressor with a sensor can be easily connected.

Reference. It is easy to convert the dimension of the values: 1 Bar = 1 atm = 0.1 MPa.

How to adjust the hot water pressure in the system

Water pressure is a fairly easy to adjust parameter. For this you will need:

- Make a calculation. Having completed it, 0.2 atm is subtracted from the obtained value.

- Before starting installation, bleed (or pump) air from the system to the required level.

- Connect the container to the pipeline and fill it with liquid. The process is done slowly so as not to miss the moment of establishing normal pressure.

- Connect the pump and pump in liquid until operating pressure is achieved.

- The first switching on of the device occurs after maximum water heating . In this case, the volume of liquid will increase to a value that takes into account the specific increment.

To make an adjustment with a car pressure gauge, you need:

- Turn off the heater and wait 7-10 minutes until the system stops.

- Tighten the shut-off elements and drain the working water. If the membrane is built into the boiler, close the supply and return.

- Connect the pump to the nipple.

- Pump up one and a half atmospheres , drain the remaining liquid, then air.

- Close all valves and create the required pressure.

- Remove the pump , open the valve, pour water.

Calculation of expansion tank volume

It is not difficult to ensure stable operation of the heating system; the main thing is to correctly select the volume of the compensation tank. The volume of the expansion tank should be calculated taking into account the most intensive operating mode of the gas boiler. When heating is first started, the air temperature is not yet very low, so the equipment will operate at an average load. With the arrival of frost, the water warms up more and its quantity increases, requiring more additional space.

It is recommended to select a tank with a capacity of at least 10-12% of the total amount of liquid in the heating system. Otherwise, the tank may not be able to cope with the load.

You can independently calculate the exact capacity of the expansion tank. To do this, first determine the amount of coolant in the entire heating system.

Methods for calculating the volume of water in the heating system:

- Completely drain the coolant from the pipes into buckets or other containers so that the displacement can be calculated.

- Pour water into the pipes through the water meter.

- The volumes are summed up: the capacity of the boiler, the amount of liquid in the radiators and pipes.

- Calculation based on boiler power - the power of the installed boiler is multiplied by 15. That is, for a 25 kW boiler you will need 375 liters of water (25 * 15).

After the amount of coolant has been calculated (example: 25 kW * 15 = 375 liters of water), the volume of the expansion tank is calculated.

There are many methods, but not all of them are accurate and the amount of water that fits into the heating system can be much greater. Therefore, the volume of the expansion tank is always selected with a small margin

The calculation methods are quite complex. For one-story houses, use the following formula:

Expansion tank volume = (V*E)/D,

Where

- D – tank efficiency indicator;

- E – liquid expansion coefficient (for water – 0.0359);

- V is the amount of water in the system.

The tank efficiency indicator is obtained using the formula:

D = (Pmax—Ps)/(Pmax +1),

Where

- Ps=0.5 bar is an indicator of the charging pressure of the expansion tank;

- Pmax – maximum pressure of the heating system, on average 2.5 bar.

- D = (2.5-0.5)/(2.5 +1)=0.57.

For a system with a boiler power of 25 kW, an expansion tank with a volume of: (375*0.0359)/0.57=23.61 l will be required.

And although a double-circuit gas boiler already has a built-in 6-8 liter tank, looking at the calculation results, we understand that stable operation of the heating system will not be possible without installing an additional expansion tank.

Setting indicators in a new membrane-type expansion tank

The device is divided into two parts, separated by a membrane. It exerts pressure on one of the halves , this is taken into account when setting up.

Most devices have factory default values, which are not always suitable for use in certain conditions.

To change the indicators, there is a nipple to which the plumber connects a compressor or hand pump.

Attention! Many pressure gauges show excess. To determine the actual pressure, add 1 atm.

The initial indicator is made equal to that obtained in the cold system by adding 0.2 atm. The sum gives the value of the static head divided by 10 . For example, in a house 8 m high:

P = 8/10 + 0.2 atm.

The values are achieved by filling the container with air through the spool.

Incorrect calculations can lead to one of two problems:

- Tank overflow. Sometimes the air cavity exhibits a value twice the static pressure. Turning on the pump will lead to a change in the number, but not more than 1 atm. If the difference is larger, there will be a disadvantage, due to which the compensator will begin to push the coolant out of the tank. This could lead to a serious accident.

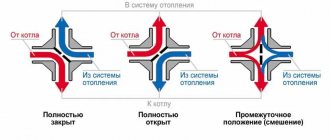

Photo 2. Pressure standards in the expansion tank: when it is empty, filled with water and when the filling of the device reaches the limit.

- Receiving an insufficient indicator . In a filled system, the working fluid will push through the membrane and fill the entire volume. Each time the heater is turned on or the pressure increases, the fuse may trip. The expander will become useless in such a situation.

Important! The initial setup must be done correctly to avoid problems. But even after the work of a good specialist, fuses may begin to trip. This is usually due to insufficient volume of the expansion tank.

To solve this you will need to purchase a new device. It must contain at least 10% of the volume of the entire harness.

Why does blood pressure drop?

The indicator should be constant, but in some cases there are problems with deviation. The value decreases:

- When a leak occurs. They rarely occur in water-filled systems. Other liquids contribute to the formation and expansion of small cracks that cause the problem.

- In case of malfunctions with the boiler. If there is no leak, but the pressure drops, you should call a specialist. He will help identify the problem and recommend a solution.

Reasons why pressure drops in a double-circuit gas boiler

Faults are difficult to detect unless you use professional equipment. Common reasons are:

- Lack of power.

- Coolant leak.

- Malfunction of the expansion tank.

- Incorrect calculation of the system , respectively, installation of inappropriate equipment.

A decrease in pressure leads to a stop in operation. This is due to a drop in the level: of liquid in the device, which cannot flow into it, or of gas, which leads to automatic shutdown. To prevent such situations, periodic maintenance is carried out, including diagnostics and repair of damaged components.

Power outage

If the boiler is powered by electricity , it can operate without it for some time. But a long absence will lead to a stop in operation, which will cause a drop in pressure in the system. The solution to the problem is to install backup power . It's expensive, but effective. Or buy a more capacious battery for the boiler.

Leak in the heating system

During operation of the circuit, the pipeline gradually becomes unusable: scale and rust accumulate. This problem can be solved by cleaning the pipes.

But leakage can also occur, for example, when a crack forms. Due to the loss of coolant, pressure decreases.

The malfunction can be eliminated in two ways: individual points are covered or the pipeline is replaced.

Air outlet from the expansion tank

If problems occur, gas may escape from the device. This will lead to a decrease in its pressure and an increase in the same indicator of water. To fix the problem you need to find and seal the leak , then make up for the losses. The reasons are also problems with the make-up tap. In such a case, you will have to replace the entire device.

If there are no leaks - common reasons

Other faults include air pockets that need to be removed. They cause noise and vibration of the harness. The latter weakens the system, which aggravates the situation by expanding leaks and weakening connections. And the formation of corrosion , and cold spots appear in the pipes.

Attention! Gas plugs also form when the circuit is not filled correctly with water, due to blockages , or malfunctions of the valves.

There may not be a drop in pressure, but the pressure gauge shows a low reading.

Maintenance

Regular monitoring of the condition of the equipment will help avoid problems during the heating season. It is recommended to carry out fault detection work twice a year: before and after the end of winter. To do this, you should invite a specialist who will carefully check the system.

How to properly pump the expansion tank in a boiler.

Today I want to talk about what a closed expansion tank is, how it works, what it is needed for, how to choose the right expansion tank, what air pressure needs to be maintained in it and how to inflate it correctly. If you are interested, then listen further.

The design of a closed expansion tank is very simple - it is a container, most often steel, divided inside by an elastic diaphragm. On one side of the diaphragm there is water in working condition, on the other there is air. Instead of a diaphragm, something like a rubber bulb or “balloon” placed inside a steel container can be used. A connecting fitting with a thread with a diameter of 3/8, ½, ¾ or 1 inch and others is welded into the part that is filled with water. In the part where the air is located, there is a built-in fitting with a regular car nipple for filling with air. The shape of the tank can be different - cylindrical in the form of a small barrel, it can be rectangular or round. It depends on where you need to install this expansion tank. There are tanks with legs for installation on the floor, and for hanging on a wall or inside a boiler or other equipment.

Now let's figure out why an expansion tank is needed and where they are installed. They are installed in heating and water supply systems .

In a heating system, an expansion tank is needed to compensate for the thermal expansion of water or other coolant poured into the system. As we all know, liquid is an incompressible medium that has the property of changing its volume depending on temperature. To put it simply, the same amount of liquid at different temperatures occupies different volumes. Most modern heating systems are closed, that is, they have no connection with the atmosphere, and have a certain volume that does not change. If an expansion tank is not installed in the system, or it is selected incorrectly, then when the heating is heated, the liquid will have nowhere to expand and the pressure will rise to a critical value, after which the coolant will be discharged through the emergency relief valve in the system. After turning off the boiler and cooling, the pressure, on the contrary, will drop to zero, the pressure sensor will work and to put the boiler into operation, you will have to replenish the system with water again.

Often, when installing a boiler, people do not think about whether the volume of the built-in expansion tank is sufficient for the normal operation of the heating system, and then they have to deal with the negative consequences of such carelessness. So how to choose the right expansion tank? If you make a calculation, you need to know such parameters as the minimum and maximum heating temperatures and the maximum pressure values in the heating system, the expansion coefficient of the filled coolant. The formula can be found in open sources. But there is one simple rule - the larger the volume of the expansion tank, the less the pressure will change when the temperature changes. That is, “the more,” “the better,” J within reasonable limits, of course. You need to focus on the following figure - the volume of the expansion tank must be at least 10% of the volume of coolant in the system. That is, if 100 liters of water are poured into the heating system, the minimum volume of the expansion tank for normal operation should be 10 liters. Calculating the volume is not difficult. The technical characteristics of pipes usually indicate the capacity of 1 meter of pipe. If such information is not available, you can calculate the cross-section of the pipe using the formula and multiply by the length of the pipes. This was all taught at school in geometry and physics lessons. The volume of one radiator section can also be found in technical data. characteristics in the documentation.

If the system is filled with coolant and not water, then the volume of the tank must be increased by 1.5 - 2 times. This is due to the fact that the expansion coefficient of non-freezing liquids when heated is much greater than that of ordinary water.

The next question is what air pressure needs to be pumped into the expansion tank. There is no universal answer for all situations. The air pressure that needs to be created in the expansion tank depends on the operating pressure in the heating system. The operating pressure in the heating system depends on specific conditions and is a separate topic. So, you need to understand that the result of correct actions should be the following: when the heating system has cooled down and the pressure in it is normal, there should be a small amount of water in the expansion tank. You can take approximately 1/5 of the volume of the expansion tank as a criterion (precision to grams is not needed here). In order to achieve this, you need to pump air into the tank at a pressure 1/5 less than the operating pressure of the heating system.

For example, the working pressure in the heating system is 1.5 atmospheres. This means we pump 1.5 – (1.5x1/5) = 1.2 atmospheres into the expansion tank. If the operating pressure is 1 atm, then the pressure in the tank is 0.8 atm. etc.

Expansion tank for heating systems

Heat supply is the main life support system of a privatized house and its constant operation is especially important. One of the indicators that needs to be monitored is blood pressure. If it is too low, the boiler will not work; if it is too high, excessively rapid wear of the equipment occurs. To stabilize the pressure in the system, an expansion tank for heating is needed. The device is simple, but without it the heat supply will not work for a long time.

Why do you need an expansion tank for heating?

During operation of the heating system, the coolant often changes its own temperature - it sometimes heats up, sometimes it cools down. Of course, it is clear that the volume of liquid changes. It either becomes larger or smaller. The remaining coolant is forced out into the expansion tank. So the purpose of this device is to compensate for changes in the volume of the coolant.

Working principle of heating expansion tank

Types and device

There are two traditional heating systems - open and closed. In a closed system, circulation of the coolant is provided by a circular pump. It does not apply additional pressure, it simply pushes water at a given speed through the pipes. In such a heating system there is a closed expansion tank for heating. It is called closed because it is an impenetrable container, which is divided into 2 halves by elastic membrane fabric. In one part there is air, in the other the excess heat carrier is displaced. Due to the presence of membrane fabric, the tank is also called membrane.

An open heating system does not take into account the presence of a circulation pump. In this case, the expansion tank for heating is simply each container - even a bucket - to which heating pipes are connected. It doesn't even require a lid, although it may have one.

In a simplified version, this is a container welded from metal, which is placed in the attic. This option has a serious drawback. Since the tank is not airtight, the coolant evaporates and you have to monitor its quantity - add it all the time. This can be done manually - from a bucket. This is not very convenient - there is a risk of forgetting to replenish water reserves. This threatens to cause the system to become airy, which can lead to a malfunction.

More convenient automatic water level control. True, then, in addition to the heating pipes, you will also have to carry a water supply to the attic floor and somewhere to route the overflow hose (pipe) in case the tank overflows. But there is no need to constantly check the amount of coolant.

Volumetric calculation

There is the most common method for determining the volume of an expansion tank for heating: 10% of the volume of coolant in the system is calculated. You had to count it when developing the project. If there is no such data, you can determine the volume experimentally - drain the coolant, and then fill in a new one, measuring it at the same time (put it through a meter). The second way is to count. Determine the volume of pipes in the system, add the volume of heating devices. This will be the volume of the heating system. Here we find 10% of this figure.

The shape can be very different

The second way to determine the volume of an expansion tank for heating is to calculate it using the formula. Here you will also need the system volume (marked with the letter C), but other data will also be needed:

- maximum pressure Pmax at which the system will operate (in most cases, the maximum pressure of the boiler is taken);

- the first pressure Pmin - from which the system starts working (this is the pressure in the expansion tank, noted in the passport);

- indicator of increase in coolant E (for water 0.04 or 0.05, for antifreeze it is noted on the label, but in most cases within the range of 0.1-0.13);

Having all these values, we calculate the exact volume of the expansion tank for the heating system using the formula:

Formula for calculating the volume of an expansion tank for heating

The calculations are not very difficult, but is it necessary to bother with them? If the system is open, the answer is obvious - no. The cost of the container does not depend so much on the volume; in addition, it can be done with your own hands.

Expansion tanks for closed type heating are worth counting. Their cost depends greatly on volume. But, in this case, it is better to take it with a reserve, since a small volume leads to rapid wear of the system or even to its failure.

If the boiler has an expansion tank, but its capacity is not enough for your system, install a second one. In total, they should give the required volume (the installation is no different).

What will the small volume of the expansion tank lead to?

When heated, the coolant becomes wider, its remains end up in the expansion tank for heating. If all the excess does not fit, it is released through the emergency pressure relief valve. In other words, the coolant goes down the drain.

Working principle in graphic representation

Then, when the temperature becomes lower, the volume of the coolant decreases. But since there is already less of it in the system than there was, the system pressure drops. If the volume minus is barely noticeable, such a decrease may not be critical, but if it is very small, the boiler may not work. This equipment has a lower pressure limit at which it is operational. When the lower limit is reached, the equipment is locked. If you are at home at the moment, you can improve the situation by adding a heat carrier. If you are not there, the system may unfreeze. By the way, working at the limit also does not lead to anything good - the equipment quickly breaks down. Therefore, it is better to play it safe and take a slightly larger volume.

Tank pressure

In certain boilers (in most cases gas boilers), the passport indicates what pressure should be set on the expander. If there is no such record, for proper operation of the system, the pressure in the tank must be 0.2-0.3 atm less than the working one.

The heating system of a low privatized house in most cases does not stop working at 1.5-1.8 atm. Naturally, there should be 1.2-1.6 atm in the tank. The pressure is measured using a traditional device for determining the pressure value, which is connected to a nipple located on top of the container. The nipple is hidden under a plastic cover; unscrew it and gain access to the spool. You can still relieve any remaining pressure through it. The working principle is similar to that of a car spool - you bend the plate with something thin, bleeding the air to important levels.

Where is the inflation nipple located?

You can also expand the pressure in the expansion tank. To do this, you will need a car pump with a device for determining the pressure value. Connect it to the nipple and pump it up to the important readings.

All the procedures described above are carried out with the tank disconnected from the system. If it is already installed, there is no need to remove it. You can check the pressure in the expansion tank of the heating system on site. Just need to be careful! It is necessary to check and correct the pressure in the expansion tank for heating when the system is not working and the coolant has been drained from the boiler. For the accuracy of measurements and tank settings, it is important that the pressure on the boiler is zero. That’s why we drain the water carefully. After this, we connect the pump with a device to determine the pressure value and adjust the parameters.

Where to install on the system

The expansion tank in a closed system is placed after the boiler before the pump, in other words, in such a way that it creates a flow in the opposite direction. This way the system doesn't stop working better. So the specific installation location depends on where you have the circulation pump.

Installation diagram of expansion tank for heating

It is connected to the system via a tee. You cut a tee into the pipe, direct the perpendicular outlet upward, and wrap the tank around it. If the wall does not allow you to install the container, you will need to make an elbow, but the tank is turned upward. Now we can assume that the expansion tank is installed.

Installation example with tap

But for the convenience of checking, it is best to install 1 more tee after the tank, and install a shut-off valve on the free outlet of which. This allows you to check the accumulator without draining the entire system - it cuts off the reservoir. Turn off the tap and bleed water from the boiler. Check the pressure on the disconnected branch (in the boiler). It must be zero. Afterwards, you can carry out all other setup work.

Why is this design needed?

Before talking about the functions and settings of the expansion tank, it is necessary to understand the types and operating principles of this equipment. Why is such a design needed in a heating system? The main task of the device is to compensate for thermal expansion in the network. After all, during heating and cooling, the coolant changes its density and volume.

Note! If this device is not installed in the utility network, as the water heats up, it will increase in volume and affect the walls of pipes and radiators. With a strong increase in water pressure, the system can simply break. Installing an expander allows you to save not only the pipeline, but also the boiler. After all, its work is initially calculated for a certain water pressure in the system.

Expansion devices may vary in volume. When choosing a model that is suitable in terms of technical parameters for a specific network, it is necessary to take into account that the volume of this element must be at least 10% of the volume of coolant circulating in the system. To perform this calculation, the volume in the radiators, pipes and boiler is summed up. The easiest way to determine the volume is while pumping the system. It should be remembered that a volume of 10% is the minimum, but it is better to take a model with a small margin.

It is worth mentioning separately about expansion tanks for wall-mounted gas boilers. Most modern wall-mount models have a built-in device mounted on the rear or side wall and equipped with a nipple. Pressure is pumped up using the nipple.

Installation of expansion element

Boiler equipment is designed to operate at a certain water pressure. This means that there must also be a certain pressure in the expansion tank for it to work properly. It is supported by air or nitrogen, which fills the housing. Air is pumped into the container at the factory. During installation, care must be taken to ensure that no air is released. Otherwise, the device will not be able to function.

The pressure is monitored using a pressure gauge. The running arrow of the device indicates that air has escaped from the expander. In general, this situation is not a serious problem, since air can be pumped through the nipple. The average water pressure in the tank is 1.5 atm. However, they may not be suitable for your particular system. In this case, the pressure must be adjusted independently.

Normal values are 0.2 atm. less than in the system. It is strictly forbidden to exceed the pressure in the expansion tank compared to this indicator in the network. In such situations, the increased coolant volume will not be able to enter the tank. The tank is connected to the pipeline through the connecting size.

It is important not only to connect the expansion tank correctly, but also to choose the right location for its installation. Despite the fact that modern models can be installed anywhere, experts advise installing this element of the system on the return line between the boiler and the pump.

To ensure the maintainability of the structure, a ball valve is installed on the pipe through which the expander tank is connected. In the event of equipment failure, shut-off valves will allow it to be removed without pumping coolant out of the system. The tap must be open while the system is operating. Otherwise, the pressure in it will increase sharply, and it will leak at its weakest point.

In open systems with natural coolant circulation, tanks of other types are installed. Such a tank is an open container, usually welded from sheet steel. It must be installed at the highest point of the utility network.

The principle of operation of such an element is very simple. As the volume increases, the liquid is forced out of the pipes, rising through them along with the air. When cooled, the coolant returns to the pipeline under the influence of gravitational forces and natural air pressure.

What should be the pressure in the heating expansion tank?

When carrying out work on designing heating systems and selecting practical components of the heating circuit, it is important to approve the parameters of the equipment being installed. The stable and trouble-free operation of the heating circuit is influenced by the pressure in the closed-type expansion heat supply tank, the correct adjustment of which makes it possible to compensate for temperature changes. The expander, which verifies the volume of the coolant and ensures the integrity of the lines and equipment, should be selected correctly and professionally installed.

How does the pressure in the expansion tank stabilize the operation of the heating system?

When thinking about creating an effective heating system, not everyone has an idea what the pressure is in the expansion tank of a gas water heater and how the expansion tank does not stop working.

The principle of operation of the compensation tank is very simple:

- An increase in the temperature of the coolant causes an increase in volume.

- At the same time, the fluid pressure in the closed circuit increases.

- The expansion tank receives excess liquid.

- The pressure in pipes and heating equipment quickly stabilizes.

- The water in the boiler expansion tank is cooled in stages and returned through the pipes.

The device is a necessary element to maintain a constant temperature in a privatized house, apartment or production facility. The tank performs the following functions:

- compensates for the relief increase in fluid. As the temperature increases, the volume of liquid filling the closed circuit increases - the expansion tank absorbs the excess;

- smoothes out surges caused by the cyclic operation of the feed pump. The device reduces the effect of water hammer on equipment and lines and ensures stable operation.

The container for the operation of the expansion chamber acts as a shock absorber for the heating circuit and makes it possible to:

- ensure long-term use of heating equipment;

- compensate for the effects of temperature changes;

- ensure non-hazardous operation of components and ensure their greater reliability.

Due to the ability to pump air into the working capacity of the expander, stable and stable operation of the heat supply is maintained. The device is a necessary element of the heating circuit.

Damper tanks are a mandatory element of various heating circuits:

- open. The circulation of the coolant is truly carried out without the use of specialized pumps. The design of the expander allows, if necessary, to add evaporating water into an open container manually or using a supply line. The constant process of evaporation requires constant restoration of the liquid;

- closed. Sealed heating circuits are equipped with closed tanks, which are an impenetrable container with an elastic membrane fabric located in the middle. Part is occupied by the air. The other part is filled with a heat carrier, which, as the volume increases, acts on the membrane tissue, reducing the capacity of the chamber with air.

Previously, common open tanks used in systems with natural circulation were distinguished by their design simplicity, low cost and ease of manufacture. The reservoir was a steel tank, equipped with a lid, as well as fittings for connecting to heating pipes and a drain line.

Today, open-type devices are not often used, which is associated with some disadvantages. Weak spots:

- direct contact of water with air, which causes accelerated destruction of the housing as a result of rusting processes;

- the need for the installation process only in the highest part of the circuit, which is quite often located in an unheated room;

- the need for systematic renewal and control of the volume of heat carrier that constantly evaporates during operation;

- reduced efficiency of the work process of the damper unit, which requires good thermal insulation.

Sealed structures used in closed heating systems are superior in performance to open tanks. Specifications:

- very high corrosion resistance;

- there is no need for strict level control;

- stable operation without constant addition of water;

- impossibility of contact of the coolant with the air;

- easy DIY installation.

Let us dwell in much more detail on closed-type expansion tanks, which have proven themselves to be good in heat supply systems with forced liquid supply. They perfectly compensate for pressure differences that appear as the volume of liquid increases.

The following types of tanks are used:

- membraneless. The design of the device is characterized by the absence of elastic membrane fabric. To operate the tank, you need to attach a cylinder or equipment that pumps air;

- membrane The main design specificity is considered to be the presence of a rubber shock absorber that separates the coolant from the air, as well as the possibility of replacing the elastic element.

Membrane-free devices were popular before the development of the production of reliable rubber membrane fabrics, distinguished by durability and a very high strength margin. Membraneless devices differ:

- the absence of a rubber gasket that prevents contact of antifreeze or water with the gaseous environment;

- stability of operation only with systematic control of the air supply and ensuring its continuous pressure.

Membrane units are quickly replacing membrane-free devices, which cannot compete in terms of performance. Elastic membrane tissue dividing liquid and gas is released by shape and made:

- in the form of a hemisphere. The disc-shaped component is permanently fixed and under load takes the radius shape of a sphere;

- in the form of a balloon. A pear-shaped membrane fabric attached to the flange, when loaded, tries to replicate the shape of the vessel. It can be easily removed if necessary.

Components of poppet tanks:

- a vertical body made of two tightly fastened parts;

- a rubber plate permanently placed between the housing elements;

- lower connection pipe, which is designed for connection with heating pipes;

- an upper nipple that makes it possible to fill the part at the top of the tank with air.

As the volume increases, the coolant fills the container and acts on the air through the disc-shaped membrane fabric. As the heating temperature decreases, the volume of liquid that is squeezed out by air naturally decreases. The adjustment is made by pumping air through the nipple or opening it.

Tanks with pear-shaped membrane fabric include the following elements:

- container with flange fastening for fixing rubber membrane fabric;

- a spherical chamber for a coolant fixed on the flange;

- connection pipe, making it possible to connect the damper component to the lines;

- valve that checks the air supply.

Water fills the rubber container, it will protect the body from rust. This has a beneficial effect on its durability.

The main differences between this type of tank:

- lack of contact of the coolant with the metal of the case;

- possibility of dismantling the rubber chamber;

- small sizes;

- operation without recharge;

- operation under very high load;

- small amount of heat loss;

- impenetrability.

To ensure continuous operation, you should monitor the readings of the device to determine the pressure value and sometimes pump in air.

How to choose an expazmomat

Choosing an expansion tank is a responsible task, the solution of which must be approached with a high degree of responsibility. When selecting a compensator, the main thing is not to forget to take into account the following points:

- constructive implementation;

- body material;

- product size;

- operational period.

In special stores, qualified consultants will be able to help you purchase the right expander and tell you what pressure in the expansion tank of the heating system needs to be maintained.

How does the pressure in the expansion tank of the heating system affect the volume - calculation method

The main characteristic of the unit is the capacity of the tank. The amount of work is directly proportional to pressure and must exceed the amount of heat carrier displaced by temperature expansion.

The capacity of the tank depends on the type of liquid used as the coolant. To determine the capacity of the shock absorber, take into account the following data:

- the volume of the tank is equal to the amount of water in the heating system multiplied by 1.15;

- the use of antifreeze requires a very high reservoir volume, calculated taking into account a coefficient of 1.2.

The total volume of coolant circulating in the circuit is determined by adding the capacity of the constituent components:

Having calculated the volume of the coolant, you need to multiply the resulting value by the indicator suitable for the specific liquid. Thus, for a heating system with a total volume of 100 liters, a compensating tank with a working capacity of 15 liters is required for water and 20 liters when using antifreeze.

For very high loads created by excess volume of coolant, an increased volume of tank work is required.

Installation and adjustment of the expansion tank in the heating system

When installing and connecting the expansion tank, follow the manufacturer's advice and keep in mind the following factors:

- when using an open system, the installation of the container is done at the maximum elevation;

- in a closed circuit, the reservoir is connected after the circulation pump.

The sequence of actions for installing a tank for a closed circuit:

- Check the comfortable location of the installation process on the supply line.

- It is necessary to check the operating pressure in the tank.

- Carry out installation, taking into account the increase in mass when filled with liquid.

- Connect the damper device to the heating pipes.

During installation, it is worth considering the following subtleties:

- distance from the boiler plant;

- ease of access for maintenance;

- container fastening strength.

Check the capacity like this:

- Start the heating system with the cylinder valve closed.

- Supply coolant into the working chamber of the tank at 1 atm.

- Check the pressure drop, which should be 0.1–0.2 atm.

This indicates the absence of problems and stable functioning of the system. Proper placement and adjustment of the tank promotes good operation and makes it easier to carry out service activities.

How to adjust the pressure in the expansion heating tank - service specifics

When servicing the device, it is necessary to ensure that the pressure in the tank is 0.2 atm less than the total load in the circuit.

Perform adjustment operations using the following method:

- Disconnect the device from the system.

- Drain the water from it.

- Connect the pressure measuring device to the nipple.

- It is necessary to check the readings of the device to determine the pressure value.

- If necessary, inflate the container using an air blower.

During the maintenance process it is also necessary to check:

- presence of damage to the body;

- integrity of elastic membrane tissue.

By monitoring the degree of air filling of the working compartment with a device for determining the pressure value, you can find out what pressure is in the expansion tank of the boiler. This will make it possible to ensure the effective functioning of the device and increase its service life. If the adjustment is incorrect, the service life is significantly reduced. The work is not difficult to do on your own, following the advice.

Why does pressure drop?

The pressure in the expansion tank must be constant, but situations where it drops during system operation are not uncommon.

There are several reasons why blood pressure may decrease:

- Coolant leaks. Most often, this problem occurs in systems where antifreeze, rather than water, is used as a coolant. Such liquids can penetrate into the smallest cracks, causing leaks. In this case, it is necessary to repair the leak and fill the tank with air.

- Pressure drop in the boiler. If there is a significant decrease in indicators, you need to contact a specialist. If the pressure decreases slightly and equalizes after starting the system, it can be operated, since such failures do not cause harm.

Pressure setting

The water pressure in the expansion element of the heating system is an adjustable parameter. The setup is quite simple, and you can do all the steps yourself.

To configure the necessary parameters you need the following:

- Make a calculation and determine the required indicators - by 0.2 atm. less than in the system.

- Set these indicators before installing the tank into the system by releasing air or pumping it through the nipple.

- Connect the container to the pipeline and fill the system with water. This should be done slowly, monitoring the pressure in the pipes and tank. The coolant should be pumped until the pressure indicators are equal.

- After this, you need to connect the pumping equipment and continue pumping the coolant. Water must be pumped until the operating pressure calculated before installing the network is reached in the tank. This will ensure that a reserve volume of water enters the housing.

- The first switching on of the system should be carried out in the maximum temperature mode. Under this condition, the volume of coolant increases by the specific increment. This ensures that an amount of water equal to its capacity enters the tank. The pressure in the tank rises to maximum levels.

What should be the pressure in the expansion tank?

This publication discusses a serious topic regarding pressure in the heating expansion tank. You will be shown a couple of pressure calculation options. The following will also be described: the design of the product, the meaning of its operation and possible problems that arise during operation. Eventually you will become familiar with the rules for setting up a sealed membrane tank.

To stabilize the jumps in the needle of the device for determining the pressure value, specialized compensating tanks are installed in the circuit. The pressure in the expansion heat supply tank forces the operating fluid back into the pipe. They can be of two options. Design differences allow their use in systems of various types:

- with access of the heat carrier to the air;

In open-type circuits, the circulation of fluid for operation occurs due to gravity. What pressure is in the expansion tank of an open-type heating system is not of primary importance; its volume is more important. These systems are therefore designed to have an expansion tank at its highest point. This is a vessel of some dimensions made of plastic or metal. It is not airtight and the heat carrier in it comes into contact with air. An open-type tank may not have a lid, but it’s still better when it has one. Thanks to it, garbage or insects, if there are such in everyday life, will not get into it;

- without access of fluid for work to air;

The pressure in the closed-type expansion heat supply tank is greater than that of the usual one. In closed circuits, water is pumped by an electric pump, which is considered to be the cause of pressure. Without a pump, circulation is not possible. Schemes of such systems require the installation of a sealed expansion tank. It can be installed at very different points on the contour, except for segments:

- after the electric pump;

- after the heater.

Its location in space is also of great importance. Air bubbles are pushed upward by the heat carrier. They must not get into the tank. Since this will affect what pressure will be in the expansion tank of the sealed heating system.

People often start talking online about what the pressure should be in the expansion tank of the heating system. To find out the latter, the average person will have to sift through a large amount of information, since the answers of the participants often contradict. Let's try to sort everything out and start with the design.

Design and working principle

The pressure in a sealed, closed-type heating expansion tank is created due to its design. It consists of two chambers, which are separated by a rubber membrane fabric. In one of the chambers there is a thermal fluid, it is combined with a common circuit, and in the other, sealed, there is air. Its quantity varies depending on the parameters of the heating system. To do this, a nipple is supposed to be in the air compartment, to which an ordinary machine pump will fit. There is no connection between air and the heat carrier. In order for the coolant from the circuit to enter the expansion tank for closed-type heating and back, the pressure must be correctly adjusted. This is an important requirement to compensate for the increase in fluid when heated. Increasing in volume, it acts with greater force on the walls of the pipes. Slowly, excess coolant is forced into the reservoir. As soon as the temperature of the fluid for operation decreases and it becomes smaller in volume, the air in the gas chamber will force it back into the circuit.

Calculation of pressure in two options

Before purchasing a tank, you need to calculate its volume. In reality, decisions are made in the following sequence:

- design. At this step, a decision is made about which rooms will be heated and which will not, diagrams are drawn and the volume of the system in liters is calculated;

- boiler selection. Based on the volume of the system and the area of the heated premises, a heater is selected. For 15 liters of coolant, one kilowatt of heater power is required;

- designation of sufficient volume of the expansion tank.

Now let's look at several different ways to calculate the pressure in the expansion tank of a sealed heating system.

For this we need the following quantities:

- system volume (OS);

- tank volume (VT);

- the maximum permissible value of the instrument scale for determining the pressure value for this system (DM);

- increase in water – 5%.

By the time it is necessary to make calculations, it is already known how many liters the system holds. The required tank volume is calculated by dividing the capacity of the circuit in liters by ten. Although this is an approximate calculation, it is very working.

The volume of the tank in a closed system may be more than required, but it will not be less. An error leads to the replacement or installation of an additional one.

You can also calculate the air pressure in the expansion tank of the heating system in one way:

It’s great that we live in a world of fierce competition. To ensure that the customer is satisfied with the purchase and does not have any issues with operation, boiler manufacturers indicate the required pressure of the heating expansion tank in the product passport. If for some reason this cannot be found out, then you can calculate this value, knowing what the readings of the device must be to determine the pressure value in the operating mode of the system.

The latter can with one hundred percent probability be found in the technical documentation or on the boiler. Then 0.2-0.3 atmospheres should be subtracted from the working pressure. Why is this necessary? If the pressure in the tank is greater than the working pressure in the system, then the coolant will not be squeezed into the tank. He simply will not be able to do this, since a considerable force is still acting on him from the side of the tank. And if there is not enough air in the tank, then there will be difficulties with the return of the coolant to the system.

Changes in the system and setup

If everything is selected correctly, then there will be no differences in the system. Therefore, when faced with this problem, it is worth looking for the cause:

- incorrectly selected volume;

- breakthrough of membrane tissue;

- nipple breakage;

- bad installation.

All repair work is done only after the tank has been removed from the circuit. The adjustment can be made if there is no liquid in the tank. Because of this, it needs to be removed from there. To do this you need to pump it up. When there is no liquid left, the air must be vented. Then, using a pump with a device for determining the pressure, pump air into the tank to the proper level. If there is no pump with a device for determining the pressure value, you can use a manual device to determine the pressure value. Since it is not possible to check the pressure in the expansion heating tank without it, you will still have to purchase one. After making sure that the settings are correct, you can put the tank back on the circuit.

All red tanks are intended for heating. Besides them there are also blue ones. These are hydraulic accumulators for cold water; they work on a different principle than expansion ones.

If the setting is made incorrectly, then the following problems will occur in the heat supply:

- increase in pressure in the heating system and expansion tank;

- emergency releases of coolant and, based on this, the need for constant replenishment;

- regression of the instrument readings for determining the pressure value to a critically low level at which the boiler cannot turn on.

There are many models on sale that do not have the ability to regulate the amount of gas in the air chamber of the tank. Of course, it’s better not to buy one, but their budget price often plays an important role. According to the network's clients, there are situations where there are simply no options to choose from, only inexpensive ones without a nipple, take it if you want it.