The use of wood stoves for space heating is most often used to heat small spaces. The technology itself is based on the use of traditional cast iron or steel stoves with low efficiency. In addition to high fuel consumption, such stoves also require the constant presence of a person, because if you do not constantly add firewood, it will simply go out. Long-burning stoves are another matter, but alas, today they still have an unreasonably high price, so there is only one option left - to make such a potbelly stove yourself.

What is the difference between a long-burning stove and a wood-burning stove?

Fundamentally, the difference between a long-burning stove and a conventional potbelly stove is how the combustion process occurs. A conventional cast iron or steel stove with a grate and a straight chimney is characterized by rapid combustion of fuel. In fact, the name “potbelly stove” itself comes from the exorbitant appetites of the stove. The combustion process in the firebox occurs on a grate, with a large air flow, which, on the one hand, makes it possible to increase draft, and on the other hand, when burning wood, I burn with a large amount of soot and smoke. This state of affairs cannot indicate fuel economy; they simply have to be constantly added to maintain the temperature.

In a long-burning furnace, the process occurs differently. Depending on the design of the firebox and additional equipment, combustion can take the form of slow combustion (smoldering) or pyrolysis - combustion of gases emitted by the fuel.

When smoldering, it is possible to make the combustion process controlled by reducing or increasing the air flow into the firebox. The result is slow combustion of fuel and the combustion process increases in time. It is difficult to judge how economical such heating is, but it is a fact that the combustion time increases significantly.

During pyrolysis, solid fuel decomposes into simple substances under the influence of high temperature. As a result, it turns out that it is not wood that is burned in the firebox, but the gas emitted by the wood. Such long-burning stoves are much more economical and their installation quickly pays for itself.

But, in fairness, it is worth mentioning intermediate designs that combine the advantages of controlled smoldering furnaces and pyrolysis furnaces. These hybrids are basically the most commonly used DIY projects.

How to make a long-burning stove with your own hands

It will be difficult to weld a gas generator installation yourself, without specialized equipment. However, a small long-burning stove can be made even from scrap materials. To heat non-residential areas, a metal structure of the “bubafonya” type, named after the developer, is often made. The heater is based on a 50 liter steel propane cylinder. Additionally, small pieces of sheet metal and pipe sections will be required.

Attention!

The “bubafonya” type design can be used as a solid fuel boiler. To do this, make a water jacket in which the coolant will be heated.

Calculation of basic parameters

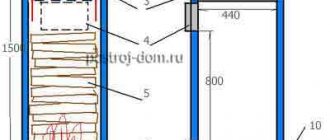

In the absence of any drawings and diagrams for manufacturing, you must make all the necessary calculations yourself. The main parameters of the furnace are diameter and height. They directly affect the amount of fuel loaded and the duration of combustion. As a rule, the diameter ranges from 30 to 90 cm. It is not advisable to make a channel that is too small: the power of such a design will not be enough for heating. A large diameter will lead to uneven fuel burnout.

The height of the channel should be 3-5 times greater than the diameter, but not less than 1 m. However, you should not make the structure too high, as it will be inconvenient to load it with firewood. It can also negatively affect traction. The thickness of the heater walls must be at least 5 mm. Thinner steel will burn out quickly and will not maintain the temperature in the combustion zone well.

In addition to the body of the device, it is necessary to prepare a steel pressure disk, a chimney and an air duct. The first serves as a partition separating the fuel from the afterburner. It should be 10-20 mm smaller than the inner diameter of the furnace. Plates are welded to the disk, which form the flow of air entering the combustion. The chimney and air duct are made of steel pipe with a diameter of 100 and 80 mm, respectively.

Making a “bubafonya” stove from a gas cylinder

After preparing all the parts, assembly begins. Sequence of work:

- Cut off the upper elliptical part of the cylinder using a grinder. In the future, it will become the oven lid.

- A steel strip is welded to the cut to center and seal the lid.

- Assemble the pressure piston. Cut a disk from a thick-walled metal sheet with a diameter slightly smaller than the body. A hole equal to the air duct pipe is made in the center of the workpiece and welded. Four sections of a channel or corner are attached to the back side of the circle in a cross pattern. They form unique channels through which air will flow into the combustion chamber.

- A hole is formed in the cover into which the piston air duct is inserted. The latter should move without jamming.

- A hole for the chimney is cut out on the side of the cylindrical shell. It should be as close to the top edge of the oven as possible. The pipe is welded to the body.

- Handles made of a steel circle, reinforcement or angle are attached to the lid and the oven itself.

After completing the assembly, it is advisable to clean the welds and visible cut areas with a grinding machine. To prevent the outer surface of the stove from rusting, it can be painted with heat-resistant paint, having previously been degreased and primed.

Making a brick oven

Compared to a homemade steel structure, a brick one looks better. However, its construction is a labor-intensive process that requires certain skills and time. First of all, you will need to build a foundation that can support the weight of the masonry. Then, in accordance with the order (schematic arrangement), bricks are laid out. The latter are placed on a clay solution. In addition to building materials, you will need combustion and cleaning doors, smoke dampers and other furnace fittings.

By assembling a simple long-burning stove, you can get not only a source of heat, but also save money, as well as gain relevant experience. A video of the process will help you make a more complex structure, in which experienced craftsmen willingly share all the intricacies of the assembly technology.

What types of fuel can be used

When it comes to the heating system for a temporary premises, such as a workshop or garage, two aspects are usually taken into account - economic feasibility and safety. In terms of economic feasibility, the most affordable type of fuel today is wood. Liquid fuel, such as diesel fuel or used engine oil, is used for heating mainly utility rooms; in residential areas, the use of this fuel is limited because it has a specific odor. Coal is usually not used for long-burning furnaces of handicraft production; it is intended for heating boilers and stationary brick furnaces.

Thus, the most acceptable type of fuel is firewood or pallets - fuel from wood processing waste. And here lies the whole secret of long-burning furnaces. The fact is that to get maximum effect you need to use only dry firewood. In ordinary, freshly cut firewood, the wood contains a large amount of moisture; during combustion, it turns out that two processes occur in parallel - burning of wood fibers and drying, releasing a large amount of water vapor. The result is a large amount of unburned fuel and combustion at a low temperature. These processes do not allow obtaining the maximum amount of heat.

It's a different matter with dry firewood. The moisture content in them is minimal, which means that when the temperature rises to 300 degrees, the process of decomposition of wood into simple substances begins. This allows you to significantly increase heat transfer, as a result of which the firewood burns completely with minimal formation of soot and ash.

Designing a long-burning potbelly stove

The starting point in the process of designing a long-burning potbelly stove is the need to ensure a comfortable temperature in the room with minimal expenditure of time and effort. The next stage is the search for the optimal design option. To heat a residential house, you can use a Burelyan or rocket stove circuit. But for a greenhouse, garage or industrial premises where there are no high requirements for cleanliness, you can use bubafonya - a stove with vertical fuel loading.

In practical terms, the following is taken into account:

- Location of heating devices;

- Purpose of the premises;

- Dimensions of the heated room;

- Availability of necessary materials and tools;

- Availability of skills to work with tools.

Each of these points is important in its own way and it is simply irrational to discard it during design. The installation location must ensure complete safety of the premises, both in terms of fire safety and safety during use. In addition, it is important to place the stove in such a way that it does not interfere, the chimneys do not take up much space, and the heat from it is evenly distributed over the entire area of the room.

To efficiently heat a room, you need to choose the right dimensions of the structure itself. In a garage or workshop, it is enough to construct a stove of standard sizes, but for a greenhouse you will need a stove from a 200 liter barrel.

The idea of building a long-burning stove with your own hands is often put off until later due to the lack of necessary materials or tools. But on the other hand, if there is no metal sheet 5 mm thick, this does not mean that the idea should be abandoned completely, because there are many successful stove designs created from old cylinders, channels, angles or thick-walled pipes.

Types of devices

The traditional Russian stove does not fit into the design of modern buildings, it takes up too much space, and its heating capabilities leave much to be desired. Nowadays, it is not advisable to install a bulky stove, because you can build a more compact and efficient device if you find suitable drawings. Assembling a miracle oven with your own hands is not as difficult as it might seem at first glance. Such a device can make a room warm and cozy even on the coldest days. Miracle wood-burning stoves come in the following types:

- potbelly stoves;

- devices under testing;

- buleryans or bullers.

If the owner of the house knows how to work with his hands, then with the help of schematic descriptions and video master classes he will be able to create the device he likes. This will help him acquire a heating system without constructing a pipeline and installing radiators.

You can see an example of a wood-burning miracle stove in this video:

Metal potbelly stove

Such installations are usually used in small rooms, for example, in garages, sheds, greenhouses and country houses with a small area. They are great for creating a warm microclimate and are an ordinary barrel with thick metal walls. Before its manufacture, a drawing is developed, according to which the unit is subsequently assembled.

The design of the Buleryan stove assumes self-assembly

The body must have a volume of at least 100 liters; its internal space is divided into two parts by placing a metal partition 5-10 millimeters thick there. A hole is made in it to be able to clean the device from combustion products. The first compartment plays the role of a combustion chamber, and the second is designed to collect ash.

An iron box is placed in the ash pan, in which all the garbage will accumulate. A hole for the combustion chamber is cut out in the front wall; its size is usually 40x40 centimeters. The ash pan also needs an opening, but it is smaller than the first by about 10-15 centimeters. It must be equipped with a valve and a door.

The barrel itself is closed with a lid through which a chimney pipe is inserted into the stove. All parts of the furnace are connected together using a welding machine. The finished structure is placed on legs or a brick stand so that when it is hot it does not damage or set fire to the floor. It is worth noting that such a device has disadvantages:

- cools down quickly;

- you need to regularly add firewood to it;

- low efficiency.

However, the potbelly stove has a low cost and is very easy to assemble. Typically, craftsmen spend no more than 3 hours on making a structure. It is capable of heating small rooms, which is why such devices are often placed in bathhouses.

Buleryan or buller

A powerful air heater suitable for heating various areas is a buleryan (otherwise known as a buller). The price of such a stove is several times higher than that of a potbelly stove; in addition, not every owner can cope with its assembly. The device has a more complex design, and its manufacture requires detailed drawings, as well as the ability to perform plumbing and welding work.

The complex structure of a wood-burning stove requires detailed drawings

A distinctive feature of such stoves is the ability to regulate the burning time of wood. One load of fuel can provide an average room with heat for 10-12 hours. In addition, the heat comes not only from the device itself, but also from the pipes. They must be included in the design of such a furnace.

It is not necessary to use iron to make a buller. The structure can be made of brick. A large body will increase the power of the stove, and the chimney is easily made from cement pipes.

However, such a device has a serious drawback - uneven heating of the air. The temperature of the floor is much lower than that of the ceiling. This disadvantage can be compensated for by connecting water heating pipes to the device. In this case, the stove will not only warm up the entire room completely, but will also provide the household with hot water.

It is worth noting that while the buleryan is operating, the room warms up not only due to the heat generated by the body, but also from the hot air coming out of the stove. The process looks like this:

- The firewood gradually burns out.

- The heated air flow passes into a special chamber.

- There it gives off some of the heat to the walls and then goes outside.

The advantage of such an installation is its ability to burn the gases released by the fuel during combustion. This significantly increases efficiency and the amount of heat generated. It is for these purposes that the stove is divided into two compartments: in the first, wood burns, and in the second, gas. This happens using a special arrangement of nozzles. This feature allows you to save fuel and also eliminates the formation of ash and soot, which makes cleaning the stove more convenient and quick.

Thanks to the special design, the amount of fuel is reduced and heat transfer is increased

It is important to place the chimney closer to the floor. To better understand the design and mechanism of operation of the buleryan, it is recommended to watch several videos on this topic. Information is never superfluous, and the master will be able to obtain more accurate and visual information that will help him create a detailed and accurate drawing of his own device.

Stoves under development

It is better not to use such devices for heating residential buildings, since burning oil smells unpleasant and also releases carcinogenic substances into the air that are hazardous to health. Car enthusiasts should pay attention to such devices, because they can be placed in garages. They have a rather simple and primitive design, so these stoves are easy to make yourself.

Exhaust devices warm up the air quickly, but have a number of disadvantages: they require constant monitoring, systematic addition of firewood, and are characterized by low productivity.

Bubafonya - the most popular long-burning potbelly stove design

The practicality of the Bubafonya stove is proven by its popularity. The fact that this is one of the most popular long-burning stoves is evidenced by the fact that it is used in almost all small greenhouse farms.

The great advantage of this stove is its practicality and ease of use - it is practically omnivorous; dry firewood, sawdust, pellets and briquettes made from straw or sunflower can be burned in the firebox. This stove also shows one of the highest results in terms of fuel combustion duration.

The basic concept of this heating device is that the fuel combustion process combines the process of burning conventional fuel with a controlled supply of oxygen and the process of pyrolysis. The design of the furnace is a metal body with an open top. For the body, a 200 liter thick-walled metal barrel is most often used. It contains a central rod, made of a thick-walled pipe, with a rigidly welded metal disk slightly smaller than the internal diameter of the barrel. The height of the pipe is 10-15 cm higher than the barrel. Ribs are welded on the bottom side of the disk so that there is a small space between the disk and the bottom of the barrel - this is necessary for oxygen access to the firebox. The third element of the design is a structure similar to a guide with a disk. The difference is that the diameter of the pipe is larger than the guide, and the disk itself has holes throughout its entire area. It is put on the internal guide and gradually moves down as the fuel burns. The lid is made of thick metal so that the hole allows the press to lower evenly as the fuel burns. The chimney is sealed in the upper part of the body at a distance of 5-7 cm from the top.

How bubafoni works

Before use, the central guide is inserted into the housing. The entire volume of the body is filled with fuel - firewood, briquettes, flights. The firewood is stacked vertically very tightly. The height of the bookmark should be 5-7 cm below the top cut of the barrel. After this, the upper press is installed on the guide and the cover is put on. Ignition is carried out from above. After the fuel combustion process begins, a process of gradual temperature rise occurs - oxygen enters through the pipes into the combustion chamber. When the temperature rises to 300 degrees, the process of gas formation begins. The gases rise upward and the flame moves into the space between the lid and the upper press. Thus, the process of combustion of gases begins. To regulate the burning speed, an adjustable damper is installed on the pipe of the upper press. When using such a stove, one load of firewood is enough for 48-72 hours of burning.

Operating a Wood Stove

To keep your oven safe, you need to take care of the following:

- nail a sheet of steel 30 cm long and 2 mm thick onto the floor from the side of the combustion chamber, which would extend 15 cm beyond the brick structure;

- use a chimney (if it is not brick) made of acid-resistant material that can disperse smoke well.

Firing the stove will not create problems if you follow the rule when operating it - put into the chamber only the firewood that is stored in a covered woodpile, which protects the fuel from moisture.

Operating a wood stove is a real craft. To make it enjoyable and beneficial, you should listen to some tips:

- the firewood is placed in the firebox more densely, with the gaps that were left in the woodpile;

- It makes more sense to put thick firewood on top and thin wood below;

- a gap of 1/5 of its height is supposed to be left under the arch of the firebox;

- After loading the first batch of firewood, the firebox door must not be opened for an hour.

Video: how to properly light a stove

Upon completion of the work, it will become clear that the construction of a wood-burning stove is not as burdensome as it seems at first. Although it takes a lot of effort and hours to complete this task, the result will not make you regret what you did.

Improved potbelly stove

Like bubafoni, this project has many fans, and do-it-yourself assembly videos can be found in large quantities on the Internet. Unlike other potbelly stoves, its advantage is that, with its compact size, the duration of fuel combustion is 4-5 times longer than that of a simple potbelly stove.

The whole secret lies in the design of the firebox. More precisely, in the absence of a grate in the firebox and the presence of an adjustable damper. The duration of the combustion process is regulated by the supply of air to the combustion chamber.

To independently manufacture such a metal furnace, you must have not only accurate calculations, but also skills in working with a welding machine. The fact is that the moving parts of the housing must be very precisely adjusted to each other, otherwise there will be no controlled air access; it will simply penetrate into the firebox through loosely fitting doors and a gate valve.

The principle of operation of this version of a long-burning potbelly stove is as follows: after the combustion process begins, the gate valve is installed in the desired position so that a slow smoldering mode is maintained in the firebox. Due to the fact that the design does not have a grate or ash pan, air enters through a gate valve.

How to light a wood stove

To effectively use a wood-burning stove, you must fire it using the laws of physics and common sense. It is inappropriate to use the word “correctly” here, because it is the rules for safety reasons that require firing at maximum draft.

Effect of traction

In fact, it is precisely the regulation of draft that allows you to achieve the maximum positive effect from the firebox. By reducing thrust, you can reduce the intensity of fuel combustion. In this case, the stove array will receive the same amount of heat over a certain period of time as at maximum draft, but the wood will burn a little longer.

Covering the vent to reduce the intensity of combustion, as many believe, is inappropriate - the combustion will slow down, but only because there is not enough oxygen for the process. But it is its presence in the firebox that increases the temperature of the flame. Accordingly, when the ash door is closed, the firewood will simply smolder, releasing a minimum of heat. In addition, with such a firebox, soot settles on the walls of the chimney due to the fact that the flue gases have a low temperature, insufficient for the self-cleaning process of the pipe.

The negative impact of a loosely closed firebox door or the presence of gaps between it and the masonry on the quality of firewood combustion is a controversial issue. In a well-built stove, air will be drawn into the combustion chamber through the door, thereby increasing the temperature of the flame, but this will not in any way reduce the quality of the firebox. Another thing is fire safety. You need to heat with the door tightly closed.

What fuel to use

Firewood must be stored in a woodshed so that it is always dry.

To fire the stove, you must use well-dried firewood from deciduous wood - alder, aspen, birch. Damp wood will burn poorly, producing a large amount of steam, which prevents smoke from escaping from the stove. Birch firewood produces a large amount of heat when burned, but damp logs contribute to the release of tar, which, settling on the walls of the chimney, worsens the performance of the stove.

To constantly use the stove for heating, you need to take care of creating a supply of dry firewood in advance, before the start of the cold season. In order not to be left without dry firewood in the winter, it is better to prepare it in the spring. Recently, a relatively new type of fuel has appeared on sale - wood waste - shavings and sawdust, formed into fuel briquettes. The calorific value of such fuel is greater, it is always ready for use, but its price is higher than that of firewood.

Fire order

To light the stove, you first need a small amount of fuel - place firewood or briquettes in the center of the grate. If the stove has not been fired for a long time, it will not be possible to immediately generate draft in the chimney. A large load of fuel will generate a lot of smoke, which will come out of the firebox and enter the room through the door of the firebox and vent. To prevent this from happening, you must first burn a small amount of fuel in the firebox, for example, a rolled-up newspaper.

When the draft appears, you can light the wood with the valve fully open. Until the flame engulfs the entire stack of firewood, it is not recommended to open the firebox door, stir the firewood, or close the valve. After the entire fire has flared up, you can gradually close the valve, limiting the draft. This must be done carefully so that smoke does not go into the room, which can happen if there is not enough draft. The flame should not consume the wood with a bang, humming in the chimney, but burn steadily and calmly. Then the maximum amount of heat will remain in the oven and will not fly outside.

To add fuel to the stove, you first need to close the ash door and then open the fire door. This will prevent smoke from escaping into the room. If a large amount of fuel is added, you can open the valve slightly, but the best result will be if you add firewood in small quantities, but often. After the firebox door is closed, the ash pan must be opened.

As the fuel burns, you need to close the valve. You can close it completely only when there is not a single smoldering coal left in the firebox. Otherwise, carbon monoxide will enter the room and may cause poisoning to those present. After finishing the fire, it is necessary to thoroughly ventilate the room using ventilation to remove any remaining smoke that may have come from the stove while the fuel was burning. It is not recommended to open the stove until the next fire.

Oven care

In order for the wood-burning stove to always operate efficiently and smoothly, you must follow simple operating rules:

- promptly remove ash from the ash pan and ash pan for better air supply to the firebox;

- control the performance of valves, doors, grates, since the presence of draft and the tightness of the furnace closure depend on this, as well as the creation of conditions for efficient combustion of fuel;

- clean chimneys, as channels clogged with soot impair draft.

Brush for mechanical cleaning of the chimney

The ash is simply removed using a stove scoop. The serviceability of stove casting is checked by inspection, but with chimney channels everything is much more complicated. It is possible to discover that they are clogged with soot only when the draft has already decreased so much that it will be difficult to light the stove. Then mechanical cleaning of the canals using special tools will be required. To prevent this, you just need to follow three simple rules:

- do not heat the stove with raw firewood or cuttings of softwood lumber, and do not burn household waste in the stove;

- always keep the vent open while burning;

- Do not finish firing the stove until the chimney has warmed up.

As a preventative measure to prevent the formation of soot in the chimney, it is advisable to burn several aspen logs or some potato peelings at the end of the firebox. Aspen will provide a high temperature at which the soot simply burns out, and the starch contained in the potatoes, together with the steam, will soften the deposits, which will subsequently simply fly out through the pipe in large flakes.

Table salt gives a good result for protecting the chimney from soot deposits - just throw a handful of it directly onto the burning wood. This method will not help to clear the soot layer, but it will certainly prevent the formation of new layers.

Rocket stove with a cylinder for combustion of exhaust gases

The conventional lightweight rocket stove is quite easy to recognize from photographs due to its unusual design. Three round or square pipes welded at one point and having a common internal space are perhaps the simplest design for a camp fireplace.

But, like an ordinary cast iron stove, the rocket has a very large appetite. On the other hand, the rocket furnace simply has enormous heat transfer from the fuel; it is not for nothing that this design is recognized as the most efficient compared to other projects.

It is this property of rocket-like emission of flame that is used in the design of long-burning potbelly stoves with a cylinder. The fact is that the flame coming out of the firebox is used ineffectively. The video of the operation of such a furnace shows that the flame comes out with great pressure. But along with the flame, a large amount of unburned gases also comes out. The idea of using this potential is to install a large cylinder after the rocket furnace, with the entrance window located on one side and the exit window on the other.

The flame with unburned combustion products, entering the cylinder, continues to burn until complete splitting. Thus, further combustion of flammable gases occurs in the cylinder itself, and smoke and other combustion products are removed through the outlet window.

Pros and cons of homemade long-burning potbelly stoves

Now that the basic designs of furnaces with an extended fuel combustion period are known, it is necessary to analyze the positive qualities and disadvantages of these devices.

The positive aspects include:

- Significant fuel savings;

- High heat transfer;

- Ability to work in “offline” mode for a long time;

- Possibility of use for most types of different fuels.

Alas, these designs also have disadvantages that cannot be called insignificant:

- The need for a hermetically sealed connection of all parts of the housing during assembly;

- High requirements for keeping chimneys clean;

- Despite the fact that the stoves are designed for a long period of operation, they must be looked after periodically;

- To use such devices, certain skills and abilities are required;

- To assemble such a stove yourself, you need to have fairly high skills in metalworking;

- To use, you need well-dried firewood.

Step-by-step instructions for assembling a potbelly stove with your own hands

The first stage is the preparation of the drawing and necessary materials. As for the drawing, it should reveal the design features and subtleties of all elements in as much detail as possible.

For experienced craftsmen, this stage can be skipped, but for those who are just starting the journey of constructing potbelly stoves, it is recommended to assemble a model from cardboard. Modeling, in this case, will cost much less than miscalculations immediately embodied in metal.

The next step is the selection of tools and materials. Here it is recommended to use ready-made components and housings produced industrially as much as possible. This way you can not only reduce the cost of work, but also find new, more effective technical solutions. Another piece of advice regarding this stage is proper organization of the workplace. When working with sheet metal, it is recommended to assemble a jig from wood so that the structures to be welded can be easily installed in the desired position.

During assembly, you need to remember that all connections must be as precise and strong as possible, especially for the body and supports of the potbelly stove. And of course, after assembly, it is necessary to make a test firebox to check the functionality of the assembled structure.