Why do you need a pressure switch?

The most dangerous situation when operating a gas boiler is its overheating in the event of a sharp decrease in water flow or a change in gas pressure. To supply a control signal to the control and regulatory circuit of the system, a temperature sensor is installed in all its structures, with the help of which the most effective protection of the unit is ensured. It can perform different functions.

- Like a time relay that will turn off the device if the temperature in the combustion chamber exceeds.

- As a device that monitors minimum and maximum pressure values.

- As a means of responding to the onset of moisture condensation in combustion products or in the gas itself.

The first option was historically used (and is still used) in instantaneous gas water heaters. The adjustment method is simple and quite reliable, but has a significant drawback - significant inertia. For water heating columns, this is not critical, since the temperature rise is to some extent restrained by the low temperatures of the water coming from the water supply, and then the relay is activated.

The third method of diagnosing operating conditions is used relatively rarely, since it mainly affects the quality of evacuation of flue gases through the chimney, and cannot be installed directly in the combustion chamber. But it is often installed in the secondary operating circuit, as an additional diagnostic unit. The most reliable and versatile device is a pressure sensor.

How the device works

The operating principle of the gas boiler pressure switch is as follows. The sensor is equipped with a pair of contacts that are connected to two control circuits. In operating mode, one pair of contacts is closed; in standby mode, the other is closed.

Electrical resistance depends on gas pressure, and as pressure increases, resistance decreases. Since an increase in pressure characterizes either a violation of draft or overheating of the coolant, this parameter determines the possibility of normal operation of the boiler and, therefore, the need for its immediate shutdown. In the work of this type of indicator, two stages are clearly distinguished.

- Ignition of gas. The heating system microprocessor supplies operating voltage to the air supply fan to the combustion zone. At the same time, the flame control function is turned on and the boiler goes into operating mode.

- After the fan starts, the temperature drops, which triggers another pair of control contacts. If for some reason this does not happen, then when you try to re-ignite, only the fan will turn on, and the flame control function will not be activated. Thus, the boiler will not turn on. The launch will only take place when the air pressure is within the required limits.

Checking the product operation

How to check the pressure switch of a gas boiler?

This is not difficult to do at home - just reduce the flow of water entering the operating unit. For this purpose, the water supply valve is gradually closed (it is impossible to perform such a check with ball valves!), and the actual pressure value will be displayed on the control panel. The user manual determines the factory settings of the sensor. Typically the lower critical pressure value is 0.5 bar. Consequently, as the water pressure decreases, the temperature of the flue gases will begin to increase. Overheating of the working contacts will cause them to immediately open with a break in the control signal, as a result of which the gas supply will stop. By comparing the response value of the pressure sensor with the values specified in the instructions, we can draw a conclusion about the performance of the product.

An equally important parameter for double-circuit boilers is the upper level. If it is exceeded, the pressure switch sends a command to turn off the automatic feeding of the unit, since otherwise untimely shutdown of the pump threatens to overfill the expansion tank. The upper level is controlled in the same way - by the maximum possible increase in water flow - and is also compared with the values of the initial settings.

Comparative analysis of sensors from different manufacturers

Each brand produces boilers of its own design, so there is no need to talk about the presence of a universal device for measurements.

When purchasing a pressure switch, you should pay attention to its operational capabilities and technical characteristics. Sensors are distinguished by excess, insufficient and differentiated pressure. Accordingly, the blocking parameters will be:

- maximum value;

- minimum value;

- their range.

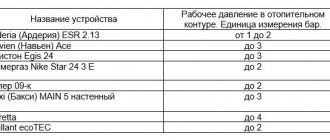

By comparing the purpose of pressure switches for different types of aggregators, you can choose the appropriate sensor. They are unlocked either manually - with a button on the panel or (for fully automated boilers) - by an electronic digital control system. Regardless of the design, the pressure switch must respond to changes in pressure of both air and flue gases. The main technical characteristics are summarized in the table below.

| Controlled Environment | Air, flue gases, natural gas, liquefied gas (the latter is optional) |

| Maximum operating pressure of the medium, bar | Up to 500 |

| Lowest value, bar | Not less than 0.5 |

| Material | Silumin, heat-resistant plastic |

| Temperature operating range, °C | –15…+ 80 |

| Contact current load, A | 0,05…5 |

Replacement and repair

The considered type of sensor operates in difficult conditions, so its warranty period is limited. To choose and buy the right pressure switch for a gas boiler, you need to know:

- exact brand of gas boiler;

- reliability of the manufacturer of the pressure switch;

- availability of a certificate of conformity of the trading enterprise that sells these units.

It should be noted that products are produced in two series: type GW - for monitoring flue gases and LGW - for monitoring air and gas flow. Pressostats of the second type are more useful.

The price of a gas boiler pressure switch is determined by its manufacturer (Chinese-made sensors are cheaper). Approximate prices are as follows:

- GW type products - 650-750 rubles;

- LGW type options - 1750-2300 rub.

Up

Repairing a gas boiler pressure switch on site, the price of which will depend on the specialization of the repair company, is performed quite rarely - many designs of such sensors require very fine adjustments, and this is not always possible. It is more expedient and smarter to purchase a new pressure switch suitable for a given brand of gas boiler, and then install it. Due to the ease of subsequent checking of the mounted sensor and if the necessary instruments are available, this can be done with your own hands.

Source

Pressure switch for a gas boiler: device, review of popular faults and their repair

The pressure switch in the design of a gas boiler is a device that is not familiar to every owner of gas equipment. The mechanism, which is essentially a differential pressure switch, is activated under the influence of the draft force of the smoke flow generated by the fan system. But how does a pressure switch for a gas boiler work, why is it needed and what malfunctions are it susceptible to?

Pressure switches for gas boilers: purpose and principle of operation

Modern gas boilers are complex units that are used to heat residential premises by heating water. They operate using explosive gas, so the design of such equipment requires the presence of special elements that control the operation of all mechanisms. Such control devices are called pressure switches for gas boilers.

What it is?

Pressostat, monostat, smoke sensor, differential smoke pressure switch, pneumatic relay - all these are different names for the same device. An important part controls the activity of the boiler fan, as well as the process of removing smoke, protects the heating apparatus from overheating during a sharp drop in gas pressure or when the amount of water supplied is reduced. In addition, the smoke sensor allows the burner to function or, conversely, causes it to turn off.

Visually, the pressure switch is a small flat plastic box , inside of which there is a sensitive membrane and a three-pin microswitch connected to it. It is these parts that control the operation of a complex heating apparatus.

How does it work?

A differential relay has a pair of contacts connected to each other by two control circuits. During normal (standard) operation of the heating device, one block of contacts is closed, and during standby - the second.

The operation of the device can be described in more detail as follows.

- The first mode is operation at normal pressure. At this time, the thermostatic membrane of the controller does not change its position, and one pair of contacts closes. The boiler operates in normal mode due to the passage of current through the described circuit.

- The second mode is activated when any of the system’s mechanisms fails: the relay moves inside and the diaphragm bends. The first block of contacts of the smoke sensor is disconnected, and the second, on the contrary, is closed. The heating equipment stops working.

The pressure switch is triggered by the slightest change in temperature in the combustion chamber, registers the appearance of condensate, and monitors all pressure indicators in the boiler.

Functional check

Finding out whether everything is in order with a pressure switch at home and learning how the device operates is quite simple. To do this, you need to slowly turn the water supply tap in order to reduce the volume of liquid entering the operating apparatus. At the same time, the value of the currently received pressure will appear on the control panel.

The minimum pressure indicator (critical number) is considered to be 0.5 bar. That is, if the water pressure decreases, the temperature of the flue gases will increase and the contacts will overheat. As a result, the gas supply to the boiler will stop and the device will stop working. The values given in the instructions for the device indicate in which mode the heating device is operated.

Another significant parameter for gas boilers is the upper (maximum permissible) pressure indicator. If the permissible value is exceeded, the relay sends a command to turn off the automatic power supply of the dual-circuit device. Otherwise (for example, the monostat has failed), the expansion tank may overfill and burst.

Thus, by monitoring the readings of the pressure switch and comparing them with the tabular data in the explanatory book for a gas boiler, you can understand whether the heating unit is working correctly or not.

Symptoms of a problem

Evidence that the pressure switch for a gas boiler has become unusable are the following factors.

- The fan in the monostat turns on silently. The absence of a beep indicates that the device has malfunctioned and requires immediate repair or complete replacement. Important! When the fan starts, you should definitely hear a clicking sound.

- The boiler does not turn on, and when you try to turn it on, the device gives an error signal (most often the red indicator lights up).

If the pressure switch does not work for any reason, it is better to suspend further operation of the gas boiler in order to avoid serious problems.

Causes of failure

In conditions of constant operation of a double-circuit boiler, breakdowns or inaccurate information from the smoke sensor are possible.

The following negative aspects can lead to similar consequences.

- Oxidation of contacts. When the fan is turned on, a sound signal from the switch is heard, but due to oxidation processes on its current-conducting elements, the circuit cannot be closed.

- Membrane wear. The operation of the pressure switch can deteriorate significantly if the technical properties of its moving element (membrane) deteriorate.

- Debris plug, damage to the condensate collector tube. If the tube has cracks, ruptures, or is clogged or filled with water, the smoke sensor may begin to give an error in the readings.

- Reduced fan performance. Deterioration in fan performance entails deterioration in the performance of the pressure switch itself.

Repair

If the pressure switch stops working, you can determine the faulty unit in this way:

- disconnect the heating boiler from the power supply;

- open the decorative part of the unit body (its front panel);

- conduct a visual inspection of all mechanisms of the heating device;

- If no visible damage is found, reset the error and restart the boiler by connecting it to the power supply.

The boiler turned on without any problems - this is a sign that the damage is located in the pressure switch.

To diagnose and repair it, you should check the condition of some parts.

- Condensate collector tube. This device should be inspected to rule out or confirm thermal wear. It is also necessary to check whether there are any foreign agents inside the tube. Since this part of the condensate collector is located in a place of high temperatures, due to the constant thermal influence, the material of its design gradually loses its original physical properties, and through holes may also appear.

In addition, the passage of the tube channels can be hampered by dirt or liquid formed on the inner walls due to sudden temperature changes. If defects have been identified, the damaged tube should be replaced or an attempt should be made to repair or clean the worn-out product. For example, clogged areas can be carefully cleaned with wire, and deep cracks on the surface can be covered with thermal paste or electrical tape.

- Internal differential relay chamber. When liquid gets inside the housing, an oxidation process begins to occur on the microswitch contacts (they begin to become rusty). Consequently, if condensate is present in the monostat for a long time, the pressure switch of the gas boiler may begin to work intermittently, so it is better to move it to another place, away from the place where condensation may appear.

- Electrical contacts. You can check these elements with a multimeter. If the tester makes a piercing sound, this means that the current-carrying parts of the relay are not oxidized and the relay is working properly. If the display of the measuring device shows one, it means the sensor is broken. Many models of pressure switches have a solid body, so it is quite difficult to inspect their internal contents. To separate the parts of the box, you need to carefully clean off the solder. Then open the housing and clean the conductive elements. Inspect the diaphragm for the presence or absence of damage. If there are none, assemble the device or replace the diaphragm and then return the body to its original position.

- Fan power. When the power of the smoke exhauster deteriorates as a result of a decrease in voltage in the electrical network, severe contamination of the turbine blades, or the service life of the bearings has long expired, the relay membrane will not be adequately adjacent to the switch. And, despite the fact that the relay has screws for manual adjustment, you should not change anything, since the initial settings can be lost and it will not be possible to set them to the required position. Thus, you need to carefully inspect all the listed elements; perhaps a breakdown occurred in the smoke exhauster of the gas boiler.

Malfunctions of the Beretta gas boiler - solutions

Among the many offers of climate control equipment, products under the Beretta brand stand out. These are gas heaters, made according to generally accepted designs, using different types of combustion chambers.

According to the instructions of Beretta gas boilers, it becomes clear that the equipment is specially adapted for work in the territories of the post-Soviet space, taking into account various non-standard parameters of gas supply and water pressure of the supply network.

Here is a link where you can choose ceramic tiles for your bathroom and kitchen.

Origin of the brand

Although the instructions for the Beretta wall-mounted gas boiler, like other equipment, position the devices as a separate brand, in fact the boilers are the product of a very well-known manufacturer of climate control equipment on the world market.

Riello is a very experienced company with a proven reputation. Its activities began in 1922 with the production of diesel burners, and today Riello's annual turnover is about 600 million euros.

The company's factories are located mostly in Italy. There are also factories in Turkey, Canada, and Poland. Riello is the owner of seven brands, including Beretta. All of the company’s products meet the ISO 9001 quality standard. If you read the instructions for the Beretta double-circuit gas boiler, it becomes clear that the equipment uses a very advanced burner.

The Riello company is a recognized leader in this segment. A separate research center is working on the study of combustion processes, and the production volume of burners for the needs of various consumers is about 400 thousand per year.

Features of heating systems of this brand

If we look at the range of units intended for domestic use, we can see how comprehensively Beretta approaches the organization of heating. Among the wall-mounted devices on the market, the following series of equipment are presented:

- BOILER;

- CITY;

- EXCLUSIVE;

- CIAO.

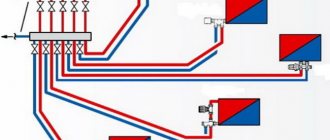

The most interesting units for users are the City series. These are wall mounted devices. The line includes equipment with a wide range of power - from 24 to 50 kW, which is well suited for heating an apartment or house. The operating instructions for Beretta City gas boilers do not put forward any restrictions on piping, so the devices can be used as part of any circuits, including multi-circuit decoupling using hydraulic arrows. City series devices have an impressive list of advantages.

- The two heating circuits are equipped with separate heat exchangers.

- A condensing circuit can be added to the boiler design, as a result, the efficiency rises to 108%.

- To ensure use in strong wind conditions, it is possible to supply air to the blower assembly simply from a room or boiler room.

- Boilers are capable of transmitting diagnostic signals to external devices. This makes City models an ideal solution for organizing centralized monitoring, for example, in an apartment building.

- Three speed circulation pump.

- Thanks to precise control, the modulation burner consumes fuel economically and provides excellent boiler efficiency.

- Self-diagnosis functions, frost protection, internal three-way valve blocking, self-ignition and weather-compensated control (external sensor included).

- When a boiler is connected, the boiler's electronic system is able to independently control an external three-way valve.

- Boilers can operate on both natural and liquefied gas.

It is especially worth noting that all Beretta boilers can be classified as mid-price. They are affordable, however, very effective and allow you to organize a convenient heating system. Key features of other lines of gas boilers.

- BOILER boilers are designed for domestic use, thermal power 28 kW, closed combustion chamber. A special feature is the built-in 60-liter boiler, which allows for maximum hot water output with smooth, economical operation of the boiler.

- The EXCLUSIVE series provides users with maximum choice. This will be an ideal solution when modifying existing heating structures. EXCLUSIVE boilers have a power from 24 to 35 kW, open and closed combustion chambers, two circuits and one.

- CIAO boilers offer the best price-performance ratio and are aimed at the low price segment. The series includes models designed for regions with extremely low average annual air temperatures.

It is worth noting that Beretta boilers sometimes cause problems for users. Although, to the manufacturer’s credit, the number of problems that the device cannot overcome on its own is minimal.

Trouble at work

Most cases of malfunctions of a Beretta gas boiler of a specific model are given in the operating instructions. Among them:

- absence of flame and blocking of operation by sensor signal;

- failure of the system board;

- blockage due to strong excess pressure in the chimney (strong wind);

- malfunctions of sensors that the electronic system determines independently;

- lack of water supply pressure.

As can be seen from the list, the user's actions are logical. Either contact the service center or check the parameters of the support systems. However, there are some malfunctions of Beretta gas double-circuit boilers that are invisible and the source is not localized.

One of the most common problems and malfunctions is that the Beretta gas boiler does not turn on. The signals on the electronic panel are completely contradictory. Sometimes a situation arises when the boiler starts and turns off. Based on the experience of service centers, the problem is solved using the following methods.

- Checking the chimney, or more precisely, the external air intake system. The simplest option is to switch the boiler to the mode of air intake from the room (if it is provided in a specific model).

- The cause may be extremely low voltage in the power supply network. A strong excess of the maximum voltage has a similar effect. Using a stabilizer may help.

- Often the chimney heating sensor is affected by condensation formed during the passage of exhaust gases. In this case, you need to either change the location of the chimney or isolate its area located close to the sensor.

- There are enough cases of the lack of draft sensor triggering if the chimney outlet is covered with frost. It is formed when starting work - as a result, the boiler stops, although literally 5 minutes ago it went through the ignition phase perfectly and began heating.

According to reviews, failure of the control board relay is very rare. If it is not possible to eliminate the emergency stop problem using simple methods, then the reason is most likely in the hot water supply system sensor. It is bimetallic, becomes covered with scale over time and does not work or causes unexpected changes in readings, which leads to the appearance of a signal from the electronic circuit to stop the boiler.

Beretta boilers are a very convenient solution when there is a desire to modify an existing heating system or build a new one, spending a minimum of money. They are reliable, technologically advanced, and thanks to the modulated burner, they are very economical. Up These devices can operate in a wide range of gas and water pressure parameters. Naturally, like any complex technology, there are problems. However, the number of non-standard situations is minimal. Beretta boilers simply work long and reliably, requiring minimal attention.

We recommend:

decorative plaster bark beetle photo

kotelstroi.com

Diagnostics and repair of boiler pressure switch

A pressure switch, also known as a smoke pressure switch, differential relay, smoke sensor, is a sensitive device designed to turn off the boiler in case of poor removal of spent fuel. It controls the operation of the fan and, if there is insufficient flow of contaminated air in the chimney, sends a signal to the control board to turn off the gas burners. Such sensors are equipped with gas water heaters with a forced smoke removal system.

Principle of operation.

The pressure switch of a gas boiler consists of a housing with pipes, a microswitch with 2 positions, a movable membrane with a pin, which divides the internal space of the housing into 2 chambers.

When the smoke exhauster is not working, contacts 1, 2 are in the closed position (contact 2 is not connected to the control board). When the fan starts, a vacuum arises in chamber 2, which is transmitted from the rotation of the turbine through the Venturi tube, the tube with the condensate collector and pipe 2, due to which the membrane with the pin is attracted and closes contacts 1, 3 (contacts 1, 2 are open). This signal indicating the normal operation of the smoke exhauster is sent to the control board (contacts 1, 3 are connected to the control module), which ensures the operation of the boiler according to a given algorithm.

Signs of malfunction.

If the smoke sensor breaks down, the following symptoms of a malfunction occur: 1. In the differential relay, when the fan is turned on, there is no click of the microswitch. 2. The boiler does not work and gives approximately the following error: “The air relay is turned off, the fan is working.”

Causes of failure.

The following reasons can lead to breakdown or malfunction of the relay: 1. Oxidation of the contacts. When the fan starts operating, a click of the microswitch is heard, but due to the oxidized film on its conductive parts, the circuit does not close. 2. Wear of membrane material. Deterioration of the technical properties of the moving part of the smoke sensor contributes to the disruption of its operation. 3. Clogging, damage or formation of a water seal in the tube with the condensate collector. When cracks or ruptures form on this element, as well as when the tube is clogged or filled with water, the sensor responds inadequately to changes. 4. Reduced fan performance. The attractive forces that arise during the vacuum in the turbine chamber are not sufficient to move the membrane to the microswitch.

Pressostat breakdowns and repair tips

Before considering how you can independently fix a pressure switch installed on a gas boiler, we will deal with typical malfunctions affecting this structural element.

Identifying Major Faults

As the practice of operating household gas boilers shows, defects in the differential relay are usually indicated by:

- absence of a characteristic “click” when starting the exhaust system fan;

- inability to put gas equipment into operation;

- output of an error signal through an indicator or on the display;

Any of the noted errors may be associated with defects in the pressure switch elements , as well as with such a fairly ordinary moment as the appearance of an oxide film on the contacts of the pressure switch microswitch.

In order to be able to perform high-quality cleaning of the contact petals of the microswitch, this element of the system must be dismantled. However, oxidation of the contact inside cannot be ruled out, which requires a complete replacement of the part.

Also, a fairly common reason for the failure of gas equipment is physical wear of the differential relay membrane . This part of the device is traditionally made on the basis of silicone rubber.

With long-term use, rubber partially loses its elastic properties (dries out). As a result, incorrect operation of the mode microswitch is noted.

Among other things, physical wear of the flue gas exhaust fan can cause an emergency operation of the pressure switch. Similar conditions cannot be excluded due to clogging of the condensate collection system , damage to system pipelines , etc.

We also recommend that you read the instructions for checking the functionality of the draft sensor and three-way valve in a gas boiler.

How to repair a pressure switch on a gas boiler?

If the reasons for the malfunction of the pressure switch of a domestic gas boiler are specifically identified, then most often the optimal way out is to completely replace it.

This approach is explained by the fact that most differential relays of gas boilers have a “cast” design. Accordingly, repairing this type of device will simply be more expensive than buying a new one.

It is easy to buy a new pressure switch for a gas household boiler of one model or another in the appropriate stores. The commercial market offers devices for almost any model

However, if you have the desire, skills and opportunities, trying is not torture. You will first have to dismantle the device by turning off the power supply to the gas boiler and turning off the linear gas supply valve.

Then you can begin to remove the pressure switch, for which you will:

- open the boiler body;

- remove the air intake cover;

- disconnect the silicone tube from the fan fitting;

- unscrew the fasteners and remove the pressure switch;

- disconnect a pair of faston contacts from the device;

- disconnect the silicone tube from the device fitting.

The first step is to check all the silicone tubes included with the system for contamination. If there is contamination inside the tubes, it is necessary to rinse and blow out the internal area.

It is also recommended to wash and blow out the internal area of the differential relay using special technical fluids that are neutral to silicone.

It is easy to check the functionality of the microswitch of the differential relay of a gas boiler. To do this, in the resistance measurement mode, the contact groups are “ringed” for conductivity

Then the microswitch, namely the contact group of this element, is subject to verification. The conductivity of the contacts is checked using a measuring device - a tester. If there is a conductivity failure on any of the contact groups, the microswitch should be repaired or replaced with a new one.

When checking the pressure switch microswitch of a gas boiler, it may be necessary to simulate a vacuum pressure. To do this, just connect, oh, a small piece of silicone tube to the pressure switch pipe of the gas boiler. The second (“positive” pipe) is simply closed, and air is sucked through the connected tube through the mouth with little effort.

In the process of performing such manipulations, connect a measuring tester to the contact groups of the microswitch and look for the presence or absence of current passing through the contacts.

This testing technique, of course, is exclusively of a “domestic” nature. Professionally, these same actions are performed using service equipment.

In addition to a breakdown of the pressure switch, the user of a gas boiler may encounter a number of other breakdowns. We provided an overview of popular faults and recommendations for their repair in the following article.