Pros of the device

Filtering hoods can afford slightly less power than models with exhaust air removal. Naturally, this is reflected in the cost, and in favor of the buyer. At the same time, the equipment experiences minimal loads, which means it can operate trouble-free for much longer.

Another plus in favor of an autonomous hood is that it does not create reverse draft, which is sometimes the problem with vent models. In the absence of a special valve, ventilation equipment with a chimney vented outside allows air to flow back into the kitchen. This is especially felt in winter, when the hood suddenly turns into an air conditioner. This is not possible with recirculating models.

The autonomy of the hood leaves freedom for maneuver when installing the hob. It can be placed where it will be more convenient to work, rather than looking for a place closer to the ventilation duct. And the appearance of the filter hood is more neat and compact. And the absence of a ventilation pipe allows you to quickly and easily install the equipment without spoiling the interior of the kitchen.

Operating principles of recirculation ventilation

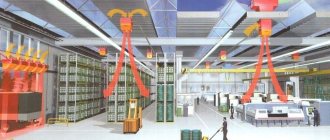

The general scheme of operation of a supply and ventilation system with recirculation is as follows: street air is supplied into the room through the supply air, which after some time is drawn into the exhaust system. Some of it is irretrievably thrown out into the street, and some goes into the mixing chamber. There, the air is mixed with the fresh influx, cooling or heating it (depending on the type and settings of the system), then it enters the heater or air conditioner, from which it again enters the room through the ventilation pipes. The main purpose of recirculation is to reduce the load on air treatment systems (heaters, air conditioners, etc.).

To ensure that the air in the room remains fresh and breathable, when using recirculation in the ventilation system, the following conditions must be met:

- The volume of clean air coming from outside must be at least 10% of the capacity of the air handling unit;

- The air entering the room must contain a maximum of 30% of harmful substances from their maximum permissible concentration.

About heat and recycling

One more point - when should you not turn on this system right away? All right in extreme heat. Here’s the scheme: for example, if your car is parked in the heat under the direct rays of the sun for several hours, its interior will warm up VERY well. It can be up to + 60, +70 degrees Celsius.

If you turn on recirculation right away, the air will circulate in the cabin, which is hot. And it will take longer for the air conditioner to cool it down.

You just need to cool down the car interior, open the windows for a while and move. The oncoming flow will blow + 60 out of the car and drive + 35 onto the street. Then we close the windows, turn on the air conditioning and recirculation.

Now let's watch the video version of the article

This is where I end my article. The feature is really worthwhile. It is especially useful on weak cars (small displacement engines), where the compressor is not so efficient and may be a little lacking in extreme heat. This is where recirculation comes to the rescue; the air is cooled better (it goes in a circle). This is where I end, I think you liked my materials. Sincerely yours, AUTOBLOGGER.

Similar news

- ECO mode | What is this? | New Kia Rio

- Car fresheners

- The engine does not warm up

What standards exist for ventilation systems?

Recommended air exchange parameters depend on various conditions and are prescribed in the relevant regulations, which must be taken into account during design. In general, for domestic premises, when rooms for different purposes are concentrated on one floor, the following amount of air should change in an hour:

- office – 60 cubic meters;

- common living rooms or halls – 40 cubic meters;

- corridors – 10 cubes;

- bathrooms and showers – 70 cubic meters;

- smoking rooms - over 100 cubic meters.

In living rooms, air mass exchange is calculated per person. It should be more than 30 cubic meters per hour. If the calculation is made based on living space, then the standard is 3 cubic meters per 1 meter.

For non-residential premises, the average standard is 20 cubic meters per meter of area. If the area is large, then ventilation systems include a multi-component system of paired fans.

What formulas are used in calculations

The main parameter that needs to be calculated in any system is how much air should be changed within an hour.

For residential apartments, the value is determined according to the living area: V=2xSxH, where S is the area of the living room, 2 is the coefficient of air mass exchange rate per 1 hour, H is the height of the room.

For work premises, the calculation is made based on the number of personnel: V=Nx35, where N is the number of people simultaneously present in the room.

When calculating the power of a ventilation station, the formula is used: P=ΔT * V * Сv/1000, where V is the volume of air mass consumed per hour, Сv is the heat capacity of the air mass, ΔT is the temperature difference of the air mass at the ends of the pipeline. The accepted value of heat capacity is 0.336 W * h/m³ * °C.

Another important indicator is the cross-sectional area of the duct, measured in square centimeters. There are 2 types of sections: square and round. By calculating the cross-sectional area, it is possible to determine the width and height of a rectangular pipe or the diameter of a round one.

Video description

More about ventilation calculations in the video:

Ssection = V * 2.8/w, where Ssection is the cross-sectional area, V is the volume of air mass (m³/hour), w is the speed of air flow inside the highway (m/sec) (average from 2 to 3), 2, 8 – dimensional matching coefficient.

For installation, it is necessary to calculate how many diffusers (intake and outlet openings) and their parameters are required. The dimensions of the nozzles are calculated based on the cross-sectional area of the main pipeline, multiplied by 1.5 or 2. To calculate the number of diffusers, use the formula: N=V/(2820 * W * d2), where V is the volume of air mass consumed per hour, W is speed of movement of the air mass, D – diameter of the round diffuser.

For rectangular diffusers, the formula is transformed as follows: N=π * V/(2820 * W * 4 * A * B), π is the number pi, A and B are the section parameters.

In any case, calculations of ventilation systems should be carried out by professionals - if something is forgotten or not taken into account, then the cost of the mistake is the need to redo the calculations and work.

A full calculation of supply ventilation is done using specific software Source ventisam.ru

In bathroom

The best option for improving the capacity of exhaust vents in bathrooms is a household fan. It is not difficult to verify its necessity - just hold a strip of newspaper paper to the ventilation grille. If it sticks to it, it means that the intensity of gas exchange can be considered sufficient. When the strip of paper does not stick or deviates only slightly, you should consider purchasing a household fan.

Unlike other rooms, sanitary rooms are an area of increased risk of mold formation. High-quality ventilation of a bathroom, toilet or combined bathroom is the basis for the comfort and environmental safety of the room. A humid environment plus stagnant air are ideal conditions for the development of pathogenic bacteria

Therefore, it is very important to ensure good ventilation of such areas

Sometimes even purchasing a household fan does not help achieve the required level of ventilation in sanitary premises. The reason for this may be tight doors. The air is not removed from the room due to the fact that there is nowhere for new air to come from. The fan removes the gas, creating an area of low pressure. And the resulting pressure difference is equalized by the air that enters the ventilation duct from other apartments. This situation can be corrected by opening holes in the doors or creating a leaky doorway that does not prevent air from the apartment from entering the bathroom.

Choosing the optimal household fan for the bathroom is easy to do, based on the following recommendations:

- The productivity of the device must be at least 90 m3/h.

- The fan must be moisture resistant.

- A system with a device on/off timer is better than a device that only works when the light bulb is on.

- A household fan with a check valve is noticeably more reliable than exhaust devices without it.

Using these tips, you can choose a quality appliance for use in kitchens, bathrooms, bathrooms, or other areas with high humidity.

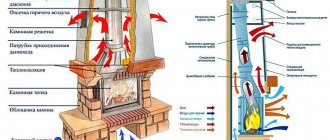

Principle of recirculation with ventilation

A recirculating supply and exhaust system is a technically complex installation and requires organized coordination and control.

Elements included in the complex:

- two electric fans on which air flow and flow depend;

- a recirculating energy exchanger heats the outdoor atmosphere, mixes the supply and exhaust flow;

- filters clean jets from the external air duct and process internal flows before feeding them into the heat exchanger;

- an electric heater warms the outside air if there is not enough heat from the internal flow;

- air duct valves are placed at the inlet and before the outlet, they regulate the strength of the jets or close the channel when the equipment is turned off.

Principle of operation

If for certain reasons you cannot install an air duct in your room, you should not look for ways to install it in other areas of the kitchen. It is enough to purchase a hood with recirculation properties, as it will perfectly cope with its main task even in a small isolated space.

The peculiarities of this type of hood are that it processes the air directly inside the exhaust duct.

The recirculation mode in the hood allows the air to be quickly cleaned and returned to the room. Contaminated air enters the hood and passes through one or more filters.

This hood quickly clears the air of contaminants and has sufficient power to clean rooms where a lot of cooking is done frequently.

The quality of air recirculation in the hood largely depends on how many filters are installed in it. Modern hoods use two types of filters. The first - fat - is attached to the outside of the hood: as a rule, it is made of metal and serves to retain fat deposits on the surface. It is enough to clean such filters periodically using detergents.

The second type of filter - carbon - serves directly to clean the air penetrating deep into the air. Filters of this type cannot be cleaned, so they will have to be renewed approximately every 3 months of operation of the hood. On average, one high-quality filter of this type will cost about 200 rubles.

Attention! Despite their high operating efficiency, hoods with recirculation mode also have disadvantages. The main one is the impossibility of completely getting rid of unpleasant odors in the room. Difficulties during operation may also arise with the replacement of filter systems

It will not be difficult to install them yourself, but it is not always possible to predict the need for replacement in time

Difficulties during operation may also arise with the replacement of filter systems. It will not be difficult to install them yourself, but it is not always possible to predict the need for replacement in time.

To ensure that customers do not forget about changing filters, manufacturers equip modern hood models with special sensors that notify them when they are dirty.

As you may have noticed, the main advantages of using a recirculating hood are that you do not need a ventilation shaft. In addition, when equipping an island kitchen, it can be difficult to determine the optimal location of hoods with air venting.

To ensure that this equipment serves you as long as possible, do not forget about timely cleaning and careful care. Since there will be humidity in the room when operating hoods with recirculation, there is a possibility of mold forming in the room. Regular ventilation of the kitchen will solve this problem.

A powerful recirculating hood without an air vent will cost very little, but will cope with the task of cleaning the air in your kitchen. Therefore, experts consider this technology option to be one of the most successful among all economy class hoods.

SNiP

Air recirculation is not allowed:

- from premises in which the maximum external air flow rate is determined by the mass of emitted harmful substances of the 1st and 2nd hazard classes

- from premises in the air of which there are pathogenic bacteria and fungi in concentrations exceeding those established by the State Sanitary and Epidemiological Supervision of Russia, or pronounced unpleasant odors

- from rooms in which there are harmful substances that sublimate upon contact with the heated surfaces of air heaters, if air purification is not provided in front of the air heater

- from premises of categories A and B (except for air and air-thermal curtains at external gates and doors)

- from laboratory premises for research and production purposes, in which work can be carried out with harmful or flammable gases, vapors and aerosols

- from 5-meter zones around equipment located in rooms of categories B1-B4, D and D, if explosive mixtures of flammable gases, vapors, aerosols with air can form in these areas

- from local suction systems for harmful substances and explosive mixtures with air

- from vestibule locks

Air recirculation is allowed from local suction systems for dust-air mixtures (except for explosive dust-air mixtures) after they have been cleaned of dust.

Air recirculation is limited:

- within the same apartment, hotel room or single-family home

- outside the same room in public buildings

- outside one or more rooms in which equally harmful substances of hazard classes 1-4 are released, except for the rooms listed in the section above “Air recirculation is not allowed.”

Peculiarities

A kitchen hood with a ventilation outlet allows you to renew the air in the room in full and prevent fat and soot from settling on horizontal and vertical surfaces.

The difference between this device and an autonomous hood operating on the principle of recirculation is that it removes air masses to the street. Thus, the space is cleared of odors from cooking food more quickly, and there is no need to periodically replace filters.

For large kitchen areas, manufacturers offer large-sized devices equipped with not one, but two motors. Such devices are designed specifically for use in catering establishments.

As you can see in the photo of the ventilation hood, it consists of a control panel, a deep cleaning filter, an air duct and a housing.

The essence and purpose of recycling

The recirculation system works on the principle of air purification through a carbon filter.

The exhaust air is already heated to a certain temperature, and its mixing with the flow coming from outside allows the heater power to be reduced. The mass is passed through a carbon filter before being reused for cleaning. Energy efficiency increases, up to 80% of internal air is allowed to be used.

Purpose of the hood in recirculation mode:

- formation and maintenance of a comfortable climate for humans and animals within the building, as well as plants and material objects (valuable artificial works, technological equipment);

- saving material resources to ensure the functioning of organized ventilation.

In a well-functioning recirculation system, engineering devices operate sequentially, cooling or heating the flows. The operating modes are different, for example, the system operates in the presence of people or the night schedule is selected. The cleaning and conditioning procedure is established separately for weekends and working hours, and is set for a certain period.

Features and principle of operation

How do such devices work? They are usually installed above the kitchen stove or panel. The rising air with particles of dirt and grease is drawn in by the device, cleaned using special filters and blown back out. These devices are in no way inferior to equipment with an air vent.

In addition, they have a number of advantages:

- Easy installation and operation;

- They serve for a long time;

- No chimney or vent required;

- They have high efficiency and productivity.

Often ventilation devices fail prematurely and fail to cope with their task due to heavy load. In addition, over time, the air outlet channels become clogged, which leads to a decrease in the efficiency and performance of the device.

Operating principle of a recirculation hood

In multi-storey buildings, problems quite often arise with the ventilation system: there is insufficient draft or ventilation is not carried out at all due to clogged internal channels. This is where a hood that works without a connection to ventilation, or simply a circulation type, comes to the rescue.

The fan rotates in a horizontal plane above the hob, drawing streams of contaminated air from cooking into the system socket. On its way, this flow meets special filters that deposit fat particles on the mesh surface. Then the odors are removed, after which the air flow returns to the room. After finishing cooking dinner, turn off the system and open a window for ventilation to restore normal atmosphere.

In modern city apartments, hermetic double-glazed windows are installed, which eliminate noise from the street, but the flow of air into the room must be constant.

Recirculation hood operation

Positive and negative points

Although filter hoods have a low capacity, they have many advantages. These include:

- ease of installation and operation;

- unlimited choice of placement of the stove, because a ventilation shaft is not needed for this;

- easy care.

These exhaust devices also have disadvantages. This is a small efficiency - up to 70%, the need for frequent replacement of disposable filters - 3-4 times in 24 months. The hood does not affect the humidity level in the room in any way. The electric drive of the device when turned on creates a certain noise.

Small, compact hoods are becoming increasingly popular because they save space. This design can be installed anywhere

Hoods of the latest releases, as a rule, can operate both in air mass removal mode and as recirculation mode. Such a device must have a connection to the ventilation shaft. Since a stand-alone hood does not provide fresh air, it is necessary to ventilate the room after turning it off.

How to install a hood in a wall cabinet?

Built-in hoods are installed in recirculation mode in a hanging kitchen cabinet (above the stove). Each manufacturer provides holes on the top of the case for attaching the device to the bottom shelf of the cabinet. The fasteners themselves are usually included in the kit. The cabinet is bought without a bottom. The bottom shelf in it is hung inward in such a way that the attached hood is completely hidden. Only the bottom surface remains outside - a reusable grease filter and, if available, a retractable panel.

Another question arises if you use the hood in recirculation mode. How to build it into a cabinet without blocking the outlet? Make a hole in the top or side wall of the cabinet and use a round corrugation and a pair of adapters to connect the hood outlet to it.

What is recirculation mode in the hood. Hood operating modes

There are two types of kitchen hoods - flow-through and circulation - which are designed, respectively, to operate in air exhaust and recirculation modes.

- Using the hood in recirculation mode does not require additional installation, which makes its installation somewhat easier, but this significantly reduces the performance of the hood.

However, it is necessary to pay special attention to the safety requirements when installing kitchen hoods in rooms with installed gas flow-through heaters (columns) and gas capacitive heaters (boilers) with an open combustion chamber. The simultaneous operation of a flow-through kitchen hood and the specified gas equipment will almost certainly lead to the formation of backdraft in the chimney and may lead to poisoning of residents with natural gas combustion products (in particular, carbon monoxide CO). These safety requirements (sometimes in a very sophisticatedly veiled form) are indicated in each kitchen hood manufacturer's passport - you just need to read it carefully. If you doubt the safety of connecting and operating your kitchen hood, it would be much better to turn to professionals.

In the garage

The garage is often mistakenly considered a non-residential area that does not require a separate ventilation system. Even if the room is rarely used, it is necessary to create mechanical air exchange in it. The owner’s comfortable stay in the garage, which is considered a non-residential premises, is not the main reason why the room needs high-quality air exhaust.

Good forced air exchange in the garage allows you to solve a number of problems familiar to many owners of such real estate:

- Prevent the development of mold and mildew on the walls.

- Ensure high-quality removal of exhaust gases and harmful volatile mixtures.

- Remove excess moisture brought inside with the car.

- Keep the walls, inspection pit, tools, etc. as dry as possible.

- Protect your car from corrosion caused by condensation.

High-quality forced ventilation of the garage allows you to maintain the functionality of everything stored in it. And savings on ventilation can lead to increased costs for car repairs, buying new tools or replacing other damaged items that were stored here.

Installation Rules

The installation requirements for the hood are the same for all types of models. Since the device is an electrical device that collects grease and moisture, a breakdown of current may occur through the housing of the equipment. To protect yourself during installation, you must properly ground the hood.

Typically, modern houses are equipped with a grounding loop and there should be no problems in this regard: you can insert the plug into the socket and the device is ready for use. If such a circuit does not exist, it is necessary to make it. Under no circumstances should you connect the grounding wire to pipes or radiators, as not only family members, but also neighbors may be injured if they receive an electric discharge through the risers.

Before purchasing a hood, you need to measure the cooking surface of the kitchen stove - length and width. For the device, these dimensions should be larger or, in extreme cases, the same. A hood with a smaller area will not cope with high-quality removal of polluted air.

Another rule that you need to remember when installing a hood is maintaining the distance from the surface of the stove to the appliance. The height above electric and induction stoves should be 65-75 cm, above gas stoves - at least 80 cm. If these parameters are not taken into account, inconvenience in working at the stove or fire hazards may arise due to overheating of the device.

The device must be fastened to the wall firmly and reliably, otherwise the device may break and injure one of the family members. Therefore, when covering the walls with plasterboard during repairs, you need to strengthen the place and place wooden blocks in the intended area for attaching the hood.

Prices for models from different manufacturers

The cost of this type of hood will depend on the material, design, additional features, reliability of the filter systems, as well as the manufacturer’s brand. We invite you to familiarize yourself with the most budget options.

A Hansa flat recirculation hood will cost you approximately 3 thousand rubles. A Liberty Base hood with similar properties will cost about 4.7 thousand. The Pyramida technique is popular today: recirculating hoods from this manufacturer are valued at 5 thousand rubles or more.

You can purchase even better options for hoods from the manufacturer Ventolux - such models will cost from 8.5 thousand rubles. The minimum cost of a Gorenje hood with recirculation mode is about 7.5 thousand rubles.

More well-known models with high functionality and modern design will cost you much more. For example, an Electrolux inclined recirculating hood will cost approximately 40 thousand, and Bosch equipment will cost an average of 55 thousand rubles.

Tip: For maximum air purification efficiency in the kitchen, purchase a recirculating hood with air exhaust. Such models are the most expensive.

What to look for when choosing

Before choosing a specific hood without a pipe, it makes sense to remember or better write down your criteria and capabilities:

- Intensity of cooking. In the case where fried dishes and long-simmering borscht are often cooked on the stove, then the resource of the installation must meet the requirements. But if dinners are prepared once or twice a week, and the dishes are gentle, for a healthy lifestyle, then the apparatus with a hood can easily cope with such a load. Therefore, this aspect directly affects the frequency of filter replacement.

- Interior. Recirculation hoods should be selected to match the overall styling of the furniture. An elegant “sparkling” hood will look unnatural in a kitchen where the furniture is chosen, for example, in the Baroque style.

- Device type. If the headset provides space for installing a hood, of course, it is better to select a built-in device. If the stove is in the middle of the kitchen, then you need to leave your choice among hanging models.

Device characteristics

After determining your overall needs, you should pay attention to the device parameters.

Dimensions

For the hood to work effectively, the dimensions of the installation should be slightly larger than the dimensions of the stove. Recirculation units are manufactured in different shapes and sizes. Types of ductless hoods are flat, volumetric, dome and inclined. Accordingly, the latest models will require more space. Flat hoods are convenient to install in wall cabinets, but it is necessary to observe the features of purified air output.

Power

This parameter is an essential indicator, since it determines whether the device will be able to create proper air exchange. According to SNiP requirements, the frequency of air exchange in 1 hour should be 12 times or more. For example, for a kitchen with volume:

4 × 3 × 2.8 = 33.6 m³ (length, width, height);

the required extraction capacity should be:

33.6 × 12 = 403 m³/h.

To this value you need to add 30% for the reserve.

Speed adjustment

Kitchen hoods without connection to ventilation must be equipped with at least three speeds to create convenient operation with any intensity of fumes. The recirculation rate affects how often the air in the kitchen is replaced. The higher the speed, the better. However, it must be taken into account that the quality of the filter elements can also affect its air exchange.

Backlight

This is a convenient feature that allows for more careful control over the preparation of complex dishes. Modern products are distinguished by the type of lamps and their placement. Typically these are fluorescent, LED, halogen and incandescent lamps. The latest lamps are a budget option and they are usually installed in all economy class hoods. Such lighting gives a soft, warm radiation associated with comfort.

Filters

To increase the performance of a kitchen hood without an air duct, it is important to use filter elements correctly. The types of recirculating hoods depend on the quality of the material and the filter design itself.

Types of filters for kitchen hoods

The filtration system can be divided into single-stage and two-stage filters, as well as level 1 and 2 purification complexes.

- Single-stage recirculating hoods are equipped with one filter element. This is an acrylic disposable filter, which requires regular replacement, or a reusable filter element, in which only the inner liner needs to be changed.

- The most effective in recirculation mode is air purification with two filters. As a rule, conventional hoods without air exhaust are two-stage. The contaminated air mass is not only cleaned of grease and fumes, but also specific odors are removed from it.

- First stage filter elements maintain their functionality through regular cleaning. They are usually made from acrylic or metal.

- Second-level filters - carbon - are not washed, but they are the ones that are able to clean the air the most.

A number of products use disposable inserts made of nonwoven materials. For this purpose, non-woven fabric or padding polyester is used. This option will require additional costs for their purchase, but you will not have to spend effort on washing acrylic or metal filters.

Additional functions

Manufacturers of many models offer complementary operations:

- the touch screen on the panel will show all the necessary information about the power of the recirculation unit and the processes taking place in it;

- the indicator light will promptly signal that the filters are dirty and thereby remind the owner to replace or clean these elements;

- sensors configured for different modes make it possible to fully automate the exhaust installation;

- the function of regularly turning on the appliance keeps a constantly fresh air mass in the kitchen;

And also an adjusted timer can set the operation of the exhaust device at a given time.