When constructing monolithic houses and foundations in the recent past, formwork made of plywood, wooden boards and panels were widely used. This design is collapsible and it is not always possible to reuse the removed formwork.

Modern technologies do not stand still. And increasingly, when creating a monolith, builders use polystyrene foam formwork. Its main feature is that after the concrete solution hardens, this form is not removed, but creates an additional thermal insulation layer over the entire surface. All the nuances of constructing permanent formwork from expanded polystyrene will be discussed in this article.

Advantages of permanent formwork

Of course, polystyrene foam formwork has a number of undeniable advantages.

- The main advantage is that this form is a “2 in 1” option. That is, the process of constructing walls or foundations and installing a heat-insulating layer are combined. When building walls, you at the same time insulate them.

- This technology can significantly reduce the time spent on building a facility.

- Expanded polystyrene formwork makes it easy to create structures of various configurations, as well as lay communications inside them.

Expanded polystyrene formwork is in high esteem among professional builders due to its excellent performance qualities and speed of construction. However, in addition to the advantages, there are also a number of disadvantages.

Features of formwork for polystyrene foam foundations

The technology is used for the following purposes:

- for insulation of warehouses and various industrial premises with heating;

- for insulation of various swimming pools;

- for insulation of warm basements;

- for housing construction.

What is expanded polystyrene?

This is a gas-filled material.

The following materials are used to make polystyrene foam:

- styrene copolymers;

- polystyrene derivatives.

Consider the composition of polystyrene foam:

- gas 98%;

- polystyrene 2%.

Modern polystyrene foam is made using the non-press method. This manufacturing method allows you to increase water absorption up to 350%.

The elements of the box-shaped structure are blocks. These blocks are formed by PSB-S slabs.

Let's consider the characteristic features:

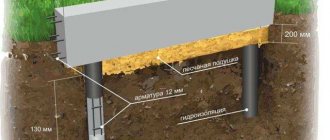

- Special jumpers provide the distance between the walls. In this case, the distance between the walls must correspond to the thickness of the concrete. This parameter can vary from 15 to 40 cm. The purpose of the polystyrene foam formwork is taken into account.

- Corner elements are used to design a turn.

- The blocks are available in 2 sizes (100 cm and 200 cm).

Advantages

Expanded polystyrene formwork has both advantages and disadvantages. Let's look at the benefits first:

- Durability. Expanded polystyrene is made only from high quality materials. Therefore, these products are durable.

- A wide variety of blocks are available. For each type of foundation it is necessary to use certain blocks. Most often, such blocks are used for pouring pile and strip foundations.

- To install polystyrene foam formwork, you do not need special lifting equipment. All work can be done manually. And also standard tools are required for installation.

- Installation of polystyrene foam formwork can be carried out by low-skilled workers. That is, builders do not need to have special skills and knowledge. You can use the services of private developers who have little experience. This will significantly reduce costs.

- Pouring concrete in sub-zero temperatures can be disastrous. The form-building structure maintains the required temperature regime. Therefore, concrete retains its strength characteristics. Perm can be done in the winter season. When concrete hardens, heat is released. This heat will be enough to maintain the required temperature.

- The form-building structure does not absorb moisture. Therefore, concrete retains its properties.

- Made from materials that are not subject to rotting.

- The blocks are mounted passages, which are used for various communications.

- Can be used at any time of the year.

- Excellent heat-shielding properties. In the cross section of the foundation, the temperature difference is significantly reduced. This helps increase durability. The effect of temperature is also significantly reduced.

- Simplicity and high speed of installation. Even unqualified builders can build a foundation in a short time.

- High quality construction. The form-building structure has excellent characteristics.

Flaws

Now let's look at the disadvantages:

- Expanded polystyrene is susceptible to ultraviolet rays. Therefore, the products are needed outside. To do this, you can use semi-rigid or rigid ready-made sheet material. It will provide excellent protection from rays.

- The strength of the foundation may be reduced due to polystyrene foam lintels. Therefore, so-called amplification is required. For this purpose, special transverse reinforcement is used.

- It is necessary to use separate waterproofing.

- Concrete must be laid evenly. Therefore, this process takes a long time.

- High price.

- Poor thermal insulation at the bottom of the foundation.

- The walls need to be lined.

Minuses

- Among the disadvantages of structures of this type, the following can be highlighted: Fixed polystyrene foam formwork belongs to the segment of expensive materials.

- It is recommended to carry out the construction of such structures in the warm season.

- Expanded polystyrene is a fragile material. And for its safety, special conditions during storage and transportation are required.

- If the construction technology is violated, the amount of material waste can become quite large. And this will further increase the cost of the structure.

- During the combustion of polystyrene foam, substances are produced that can cause human poisoning (even death). The use of modern additives by manufacturers makes it difficult for the material to ignite, but complete safety is still not ensured.

- In the production of expanded polystyrene, aggressive chemicals are used. When you use such insulation on the outside of a building, they do not harm human health. But in the case of permanent formwork, polystyrene foam is also located inside. And this means a deterioration in the indoor microclimate.

Installation instructions for polystyrene foam formwork

The construction of monolithic structures with permanent forms does not require high qualifications. Even novice builders can handle this work, and for a small project only two people will be enough. Before you begin, you need to prepare the required number of polystyrene foam blocks and agree on timely delivery of concrete.

The installation process is divided into several stages.

Formwork assembly

To install the first row of blocks, you will need to prepare a waterproofed base. Vertical reinforcement bars connecting the wall being built and the foundation are mounted in advance, and the blocks are placed on top of them.

Subsequent rows are erected with an offset of half a block, so that the seams are bandaged and the structure becomes more rigid.

Reinforcement tying

In addition to vertical reinforcement, designed to secure the base and wall, to ensure the strength of the monolith, it is necessary to create horizontal connections. In each row, horizontal rods are laid overlapping. They are connected to each other with steel wire, which is also used to connect them to vertical rods. Rigid reinforcing mesh prevents heavy concrete from pushing light blocks out.

Pouring concrete

Before starting work on pouring the mortar into the formwork, all communications should be laid. After concrete gains strength, it will be impossible to install wiring and plumbing pipes inside the walls. To pour monolithic walls into polystyrene foam forms, concrete with fine fillers is used.

Fixed foam formwork

The option of permanent formwork made of penoplex is quite popular today. These are slabs made of polystyrene foam measuring 0.6x1m. They have an excellent margin of safety and are an excellent insulation material.

Penoplex tiles are not equipped with their own fasteners. This creates some difficulties when constructing permanent formwork. Most often, the problem of connecting elements is solved with the help of metal jumpers, the edges of which are threaded. As an alternative, you can use special clamps used when assembling polystyrene foam structures.

If we compare the costs of foam formwork and the costs of forms made of plywood panels on telescopic racks, then the first option as a whole will certainly be more advantageous.

Foam formwork

Foam formwork is assembled from blocks of expanded polystyrene foam, fastened together with locks on them. To connect foam blocks, do not use glue or other fastening agents. The blocks are stacked on top of each other in a checkerboard pattern.

There are variations of foam elements such as cast and prefabricated blocks. The first is also known as a fuser. They are characterized by a fairly high density and have good thermal insulation characteristics. The blocks consist of two plates connected to each other by jumpers.

The average weight of one such block is 1 kg. Standard dimensions are 100x25x25 cm. With such dimensions, the thickness of the foam plates at the edges is 5 cm. The thickness of the concrete layer when using such formwork will be 15 cm.

Manufacturers also offer options for blocks of other sizes.

Even those without construction experience can construct permanent formwork from foam plastic.

Such structures are poured in layers. That is, they fill the inside of the foam part with concrete and then wait for it to harden. When it is necessary to give the structure additional strength, reinforcing elements are added, which are installed inside the formwork.

The first row is laid out on a surface equipped with waterproofing.

The main advantages of foundation formwork

So, what are the advantages of this technology over the classics? Let's try to list:

- Minimum labor costs. The formwork for the foundation can be assembled by 2 people in literally 1 day.

- The SVT universal screed is a convenient and practical fastening element: the reinforcement cage is securely attached directly to it, and due to the extensions, the width of the foundation can be easily adjusted.

- The ability to set exact dimensions and minimize concrete loss.

- Implementation of geometrically complex projects.

- No dismantling work (an exception may be the internal part of the formwork, which is suitable for insulating the floor, walls, blind area or roof, but this is at your request).

- The finished structure has no cold bridges and retains heat perfectly.

- There is no need to insulate the base: it is already there.

- The load-bearing base and thermal insulation are installed in one technological cycle.

Do-it-yourself permanent polystyrene foam formwork

The installation process of permanent polystyrene foam formwork consists of the following steps:

- Installation of blocks.

- Knitting reinforcement.

- Pouring with concrete mixture.

So, the algorithm is as follows:

- The first row of formwork is installed on the waterproofed surface. The elements are fastened together with metal reinforcement ties.

- Elements must be installed very precisely, in accordance with the project. In places where the partitions of the building will be located, bends must be left.

- After installing the bottom row, they begin to lay the second one. The plates are installed in a checkerboard pattern. Vertical joints in adjacent rows should not coincide.

- Next, proceed to the installation of the reinforcing belt. Reinforcing bars of horizontal rows are laid inside polystyrene foam blocks in special holes. They need to be laid with an overlap. The connection between each other and with the vertical elements is made using knitting wire.

- At the next stage, planned communications are laid inside the blocks.

- Filling is carried out with cement mortar without crushed stone content. Filling is carried out in stages. You cannot fill more than 100 cm of the structure with solution at a time. Typically, the formwork is filled to a height of three to four blocks.

- To avoid the formation of voids inside the hardened concrete mass, a special tool is used during the pouring process - a vibrator. In the absence of professional equipment, the solution can be pierced with a bayonet.

Extruded polystyrene foam Penoplex is successfully used for foundations, as well as the construction of walls. Such designs have a completed appearance. The walls do not require additional leveling. Thanks to this, in the process of further finishing you can easily do without a large amount of plaster.

Concept and design of permanent formwork

In general, what is formwork? This is an enclosing structure that is designed to pour a sand-concrete mixture and give the foundation or walls a certain geometry. Neither private nor industrial construction can do without it. After the concrete has cured, it is usually removed, but not in our case. The enclosing elements remain and continue to be used as part of the building.

In a unique modern technology, Penoplex slabs are used as formwork. It is also called extruded polystyrene foam (EPS). I have already talked about it more than once, but if you are interested, you can read it here. In this case, EPS slabs “kill two birds with one stone”: they are a fencing element and an excellent insulator for the foundation, as well as the entire base.

Of course, other materials can be used instead of penoplex. For example, plywood, CSP (cement-bonded particle boards), glass magnesite sheets and even welded metal structures. But we will not consider them, but will touch on the most “advanced option” for private construction.

By the way, such permanent formwork made of polystyrene foam is widely used in construction in many Western countries. This is due to the high energy efficiency of buildings and quick installation. The technology allows you to combine the creation of formwork and thermal insulation of the foundation into one process in the shortest possible time.