Insulating a bathhouse with sawdust: how to make a steam room even more effective?

To increase the efficiency and benefits of the bathhouse, it must be properly insulated.

After all, high heat loss leads to the appearance of cold bridges, which not only reduces the overall temperature, but also causes the circulation of cold air, which can lead to a cold.

To insulate baths, various types of materials are used, including wood cutting waste (sawdust).

In this article we will cover:

- what is the difference between the thermal and steam conditions of a bathhouse and a house;

- how to insulate walls, floors and ceilings using sawdust;

- How does insulation with sawdust differ from insulation with other materials ?

How to choose sawdust for thermal and sound insulation of the ceiling

Sawdust is divided by fraction:

- small;

- average;

- big.

Experts recommend giving preference to the second type, because fine-grained materials are difficult to work with, and coarse-grained ones cannot provide high-quality heat insulation.

When purchasing wood shavings formed from round logs at a natural moisture level, make sure they are thoroughly dried. If they are not sufficiently dried, you need to lay them out on a horizontal surface and leave them for a week under a canopy. In humid weather, the drying period is increased. It is also recommended to place thick burlap under the sawdust.

It is better to choose coniferous wood as sawdust for insulating the ceiling in a private house, because... They have a high level of resin, which helps prevent insects. The bath should be insulated with larch shavings. Such material, when mixed with ash, reduces the risk of rotting processes.

Important: after purchasing sawdust, you must wait at least six months. This will reduce sugar, which causes rot.

Indicators of high-quality sawdust are the absence of moisture and mold. It is necessary to ensure that foreign impurities and debris do not get into the chips. If this happens, the material is sieved, and large particles are selected by hand.

Insulation with clay and sawdust - the main thing is to do it right

With a huge selection of modern insulation materials, it would seem stupid to use old-fashioned methods of thermal insulation. However, insulation using clay with sawdust is an effective and cheap method of insulation, which is not inferior to modern expensive insulation materials, and some are even superior.

An additional advantage of such insulation is that it is easy to prepare at home - no special knowledge or materials are needed.

So, you will need: clay, which you can buy

, but I used ordinary clay from the garden, taking it from a depth of about two shovels, you can do the same with sawdust (perhaps it would be more correct to say - wood chips) - if you have sawdust left over from construction work, then use them, if not - You can buy them in the store, they cost pennies.

I insulated the garage ceiling, it’s wooden, made of boards

. I covered the boards with waterproof fabric, although regular plastic sheeting will do. I stapled it to the boards. All.

Next, prepare the mixture. In a wide bowl or on a sheet of tin, mix clay and sawdust, removing lumps, debris and stones.

Mix in a 1:1 ratio

, after the sawdust and clay are thoroughly mixed, add water and mix until it becomes thick sour cream.

Pour the finished mixture onto the prepared ceiling, or the surface that needs to be insulated. Apply the mixture to the walls with a spatula.

The layer thickness is 10-20 cm, this is quite enough for effective thermal insulation. In summer, the clay takes about 2-3 weeks to dry, depending on the weather.

As for walls, it is quite problematic to apply the liquid mixture on vertical surfaces, so here it is worth using another option.

We are preparing formwork for making clay insulation slabs. Recommended slab thickness – 10 cm

. We line the formwork from the inside with film, pour in the mixture, which is prepared in the same way as when insulating the ceiling. We pour it in and dry it under a canopy so that the slabs are not exposed to sunlight. After two weeks, we remove the slabs from the formwork and dry them for another three weeks, also under a canopy with good air flow.

Next, the slabs are attached to the walls using wooden sheathing.

This is how you can easily and cheaply insulate outbuildings, a garage or even a cottage.

They wrote to me that mice will chew the clay. The solution is simple - add 3-5% fluff lime to the mixture, and there will be no problems with rodents.

Source

Basalt mineral wool

The most common and unlimited use insulating material, which is based on repeatedly intertwined inorganic fibers.

Basalt mineral wool has the same heat-saving characteristics as polystyrene foam, but is completely devoid of its main disadvantages.

Safe to use both indoors and outdoors. Neutral to high temperatures, does not burn. Withstands temperatures up to +700C. Environmentally friendly, absolutely harmless to human health.

The term of impeccable service is up to 40 years. There are no conditions for the appearance of fungi or mold in basalt wool.

It is produced by manufacturers in rolls and basalt slabs, which makes them easy to install to insulate a room. There is also a specially designed type of such cotton wool for baths - foil-coated on one side.

Conclusion: insulating the ceiling in a bathhouse with basalt mineral wool is the most optimal solution.

How to insulate a ceiling with sawdust: features

Sawdust is quite often used as a high-quality insulation material, but before carrying out high-quality comprehensive insulation, it is imperative to prepare the attic floor. If a private house has a wooden floor, then additional flooring needs to be made between the beams. Before insulating the ceiling with sawdust, you need to decide on the choice of the required material. There are several types of sawdust that vary in size.

In particular, we can highlight the following material:

- Fine-grained;

- Mid-fraction;

- Large faction.

Before insulating the ceiling, decide what type of sawdust you will use.

It is best to select a medium-fraction material, because small sawdust is quite difficult to use and creates a lot of dust, and very large sawdust cannot provide high-quality thermal insulation. It is best to give preference to sawdust obtained by cutting coniferous wood, because it contains a lot of resins, which will prevent the formation of an insect colony.

Types and nuances of vapor barrier

Regardless of the type of bathhouse chosen - a sauna or a wood-burning Russian bathhouse - the room will be constantly exposed to high humidity and temperature. Installing waterproofing in the ceiling area will help maintain a healthy microclimate in the room and will also minimize the likelihood of moisture condensation. If polystyrene foam or polystyrene foam is used as insulation, you can skip this step, since such materials are moisture resistant.

Types of vapor barrier

The simplest and most obvious option is to use film. Budget materials can be either rough or smooth; more expensive ones include reinforcement.

- Membrane material. Its woven surface retains moisture and eliminates the formation of condensation.

- Foil is one of the best options for use in a bathhouse. The material not only provides a vapor barrier, but is also an excellent thermal insulator.

- Izospan is a combined material with high vapor barrier properties. Enjoys increased popularity.

How to properly install a vapor barrier?

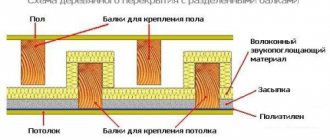

First of all, you need to decide on the choice of the base material, and then proceed with the installation of the vapor barrier layer of the bath ceiling. A correctly installed ceiling of a steam room looks like a layer cake, with the following layers:

- The top finishing layer is often linden lining.

- The lathing, which serves as a support for the finishing, also serves as an additional ventilation duct.

- Vapor barrier laid over the entire area of the ceiling and extending onto the surface of the walls.

- The ceiling itself and the logs are made of wood.

- Vapor barrier film.

- Insulating material of the selected type - clay with sawdust, mineral wool, polystyrene foam, expanded clay, etc. The minimum layer is 10 centimeters.

- If the attic is needed for storing household items. equipment, installing flooring.

- In the case when the attic space is not used, it is enough to simply cover the insulating material with film. This is necessary in order to protect the insulator from possible heat loss, as well as accidental ingress of moisture and condensation.

How to insulate a ceiling with prepared sawdust

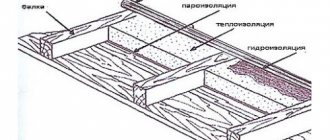

Before applying a solution mixed according to a particular recipe, a number of preparatory work should be performed. The most important of them is vapor barrier. The following options are popular:

- Modern semi-permeable membrane films. They are laid on the boards of the rough ceiling, the canvases are fastened together with double-sided tape.

- Glassine or roofing felt. It is laid overlapping, secured with tape or glued with mastic.

- Clay-sand screed. Prepare a thick solution of clay and sand in a ratio of one to four, apply it in a thin layer on the boards, then level it. After the screed has dried, an insulating solution can be applied to it.

General insulation scheme

High-quality vapor barrier will help to avoid waterlogging and wetting of the insulating layer.

Ceiling insulation with clay and sawdust

The sequence of actions when applying a clay-based solution is as follows:

- Perform a vapor barrier using one of the methods listed above.

- Prepare the solution in accordance with recipe No. 2. Particular attention should be paid to the absence of lumps before adding sawdust. If you cannot grind and stir them, you will have to strain the solution.

- Cover the surface of the ceiling with an even layer of the prepared solution. Layer thickness 10-15 cm.

- Let it dry. The drying time depends on the temperature and humidity. It is better to apply the solution in early summer, before a period of hot and dry weather.

- If the building is located in a region with a cold climate, a second layer of insulating solution is applied.

- After drying, cover the insulation with a layer of waterproofing. Attach film or roofing felt to the beams.

Applied clay mixture

The dried mixture is a strong, porous mass. You can even walk on it.

Insulating the ceiling with a cement-based mixture

Such solutions, which are called sawdust concrete, have a high density and are well suited for durable floors that can support their weight. The procedure is as follows:

Advantages and disadvantages of ceiling insulation with clay

Clay as a heat insulator for floors has become popular due to the following qualities:

- Low cost. The raw material has no competitors among analogues used for these purposes. You can always get it with minimal effort. In rural areas, the rock is often dug up and brought in independently.

- Clay is a fireproof material; it does not burn and does not contribute to the spread of fire. It can be safely laid near chimneys.

- Rodents and insects do not live in the thickness of the coating.

- The ceiling solution is prepared from a base and light fillers, which significantly reduces the load on the walls.

- There are no harmful impurities in its composition, so the ceiling is environmentally friendly.

- It’s easy to master insulation technology; you can do everything yourself.

- Clay and lumber interact well with each other. The wood remains in its original form for many years, and the insulating layer does not lose its qualities for a long time.

- If necessary, the already dried mixture removed for some reason can be reused, for which it is enough to wet it. This way, waste can be avoided after construction.

- After adding water, the rock becomes plastic and is able to fill any voids, which allows it to be applied to complex surfaces.

- Once the moisture evaporates, it becomes hard, so it is not necessary to install walk-on decking on the attic floor.

However, the material has practically been replaced by modern heat insulators. There are several reasons for this:

- This method of insulation is far from the most effective. In most cases, clay is used as an addition to the main heat insulator.

- To prepare the solution, it is necessary to carefully maintain the proportions, otherwise the insulating layer will crumble or simply not perform its functions.

- The finished batches are quite heavy, so the floors must be designed for heavy loads.

Organic raw materials

Insulating the bathhouse with natural materials will provide a high level of vapor barrier.

The following types of raw materials are distinguished:

- flax tow;

- cellulose;

- felt;

- wood sawdust.

When the question arises of what is the best way to insulate the ceiling in a bathhouse from above, it is worth remembering that some samples of animal or plant origin cannot tolerate high temperatures. They can only be used in the waiting room or rest room.

Method of insulating a bathhouse ceiling with sawdust

Among other techniques, the leader is the procedure for improving the roof of a room using compressed wood shavings. It gained such popularity among the people because of its accessibility and ease of installation.

Photo from the website Tomsk.fis.ru

Considering the fact that thermal insulation should not only prevent hot air from passing out, but also promote the accumulation of steam, it is necessary to lay two layers of blocks. To better distribute the wood processing product between the upper beams, a binder is used, so the bathhouse ceiling is insulated with clay with sawdust or with cement.

Photo from the website Maxfloor.ru

The procedure occurs in several stages:

- We spread polyethylene on the ceiling boards. It is advisable to choose a thick oilcloth without mechanical damage. The size of the sheet should be 30-40 cm larger than the roof area on each edge.

- Then, after making sure there are no holes and sealing the seams so that they do not allow moisture to pass through, we distribute the composition of clay and wood shavings over the surface. The maximum layer height should be no more than 20 cm.

- Next you need to wait until the mixture dries completely. The process will take a month. During the first week, it is necessary to spray the surface with water to prevent cracks from appearing.

After the clay has hardened, you should once again update the layer of sawdust, and then cover the resulting pie with roofing material.

When working with a more viscous substance, such as cement, all uncovered wooden structures, especially in the pipe area, must be sheathed with asbestos.

Photo from Balkon.guru website

Waterproofing works

Ceiling waterproofing

The clay mixture is placed on the flooring wet. Therefore, it is necessary to somehow protect the base from moisture. Usually a simple film is used for this. It is laid on top of the ceiling and attached to it with staples or some other way. The same film will protect the insulation from fumes from the room, for example, if clay is used in a bathhouse.

It is not recommended to use various impregnations and chemicals. Moreover, varnish or paint. Especially in a bathhouse or in a room with a stove. When heated, chemicals begin to emit harmful fumes, and varnish and paint can melt, “cry” and also evaporate toxic substances.

Tags: bathhouse, clay, ceiling, straw, insulation

« Previous entry

Insulation of a bathhouse ceiling with sawdust

Quite common methods include insulating the bathhouse ceiling with sawdust. This material is especially recommended for use where the bathhouse will be used by elderly people and children. It is the safest.

However, you should know that using sawdust exclusively can also be fraught - uncovered scattering of sawdust:

- fire hazard (any spark can cause a fire);

- too dirty (a draft can scatter sawdust throughout the bathhouse).

It is best to use sawdust mixed with clay or cement. The advantages of clay are described above, and sawdust combined with cement provides a reliable and strong screed on the ceiling.

Common options include a layer of sawdust covered with a layer of earth on top. This guarantees protection from possible fire, and the layering guarantees high insulating properties.

Insulation of a bathhouse ceiling with clay and sawdust

It is important to remember that the “pie” of ceiling insulation requires compliance with the established regulations:

- preparing the ceiling for filling with clay and sawdust (preparing a flat ceiling or creating formwork);

- it is advisable to divide the ceiling into sections (this will facilitate the insulation process in the future);

- mandatory use of waterproofing (you can limit yourself to covering the ceiling cracks with clay, but it is best to use rolled waterproofing materials);

- laying a mixture of clay and sawdust;

- It is possible to add an additional layer of sand after the clay has completely dried.

The most difficult part of this process: creating the mixture itself.

It is important to maintain the required proportions of the substance and choose the right consistency, as well as choose the right clay and sawdust. With clay, everything is quite simple: any clay will do, red is considered the most common. But the sawdust must be dry; fresh will not work. The ideal choice would be oak sawdust, but they are rare, so you can go with coniferous wood. The clay must be soaked with water (a metal barrel usually requires 4-5 buckets of clay). Constant stirring will not be very effective: it is best to fill the clay with water and leave it for a couple of days. After which it needs to be stirred and the remaining water drained. As soon as the consistency of the solution has become homogeneous, sawdust is added at the rate of 2/3 buckets per 1 bucket of clay.

The ready-made mixture can be used to lay the ceiling. The required layer is 8-15 cm, a thicker one is needed in areas with cold winters. But in any case, the clay insulating layer should not exceed 30 cm (and even less with an additional layer of sand). Clay is a fairly heavy material, and an excess layer can negatively affect the foundation and the structure as a whole.

The process of insulating a ceiling structure with sawdust

Ceiling insulation using sawdust is possible only in the upper part of the structure. In order to complete this work, you need to stock up on wooden boards with which you need to flash the beams. The thickness of the purchased material should be no more than 3 cm. See the article on the topic of interfloor ceilings on wooden beams.

In order to firmly fix the boards to the beams, it is worth using screws and nails

When attaching the material, it is important to remember that the weight of the insulating mixture is quite large, so the result of the work must be of high quality

Ceiling insulation with sawdust

The fasteners must be driven into the tree at an angle, with each one being in the opposite direction from the previous one. The length of screws must be at least 50 mm, and nails - at least 100 mm.

Next, all wooden surfaces must be treated with special antiseptic agents. Their action is to protect the material from mold and fungi. If this point is not followed, you can see the consequences that will subsequently affect the surface of the ceiling itself.

Next, the vapor barrier film is laid. Roofing felt is often used for these purposes. After this, a mixture of wood insulation material with cement and lime is laid out, which should ultimately have a smooth and compacted appearance. Insulation with sawdust should be carried out to the floor level. Experts recommend sprinkling sawdust with some ash, as it can prevent the material from rotting.

Next, you should stop all work for a couple of weeks to allow the moisture to evaporate from the insulation. After this, the surface is again covered with a layer of vapor barrier. You can use a stapler to attach this film.

To finish the ceiling of a room such as a bathhouse, where sawdust is also used as insulation, it is necessary to take more serious waterproofing measures, since there is excess moisture there.

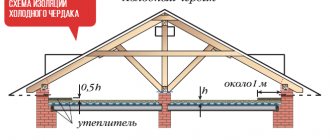

Principles of thermal insulation

High-quality insulation of the ceiling in a bathhouse depends on the roof structure itself, which can be divided into two types: buildings with an attic ceiling and those without an attic. Thus, a feature of the attic ceiling is the fact that the heat-insulating material is installed in it during the construction process, and the air flow will be obstructed by a fairly thick ceiling covering.

Note! Despite the power of the ceiling with attic space, it is also necessary to insulate it, as in a bathhouse building without an attic, in which the air passing through the ceiling encounters fewer obstacles.

Device specifics

Regardless of the design of the ceiling, before insulating it, it is imperative to lay a vapor barrier layer. For example, for a building without an attic, aluminum foil is suitable.

Vapor barrier using aluminum foil

In bathhouses with an attic, the same vapor barrier materials are used, but in most cases, the ceiling boards are coated with a 2 cm layer of clay.

Often materials such as 0.4 mm polyethylene film or a special vapor barrier membrane are used.

A vapor barrier layer is required to prevent moisture vapor from settling in the insulation. Otherwise, water accumulated in the thermal insulation layer can increase the weight of the ceiling structure and reduce the service life of the thermal insulation layer.

Three functions of insulation

The thermal insulation layer prevents all kinds of heat leaks.

There are three types of leaks:

- Transit of heated air through cracks in the ceiling surface;

- Transfer of heat from heated objects to cold ones;

- Overcoming obstacles by heat flows.

Therefore, the construction of a barrier to retain valuable heat is simply necessary; the insulation will easily cope with the tasks assigned to it and will successfully perform all the necessary functions.

It is important to remember that with poor thermal insulation, the possibility of condensation settling increases, which will lead to high fuel consumption and warm-up time.

What kind of ceilings can there be in a bathhouse?

The bath ceiling must meet the following rules:

- reliability and strength;

- retain heat;

- long service life;

- with minimal resin content;

- moisture protection of insulation.

- Grazing. It is laid directly on the frame, so the thickness of the ceiling boards is at least 40 mm. It is used when the distance between walls is no more than 2.5 meters.

- Hemmed. Tongue boards or lining are used, which are nailed to the beams. It is important to use stainless nails or screws.

- Layered and hemmed. It is considered the most reliable, as it combines the first two.

- Panel. The ceiling is covered with panels consisting of two bars, a finishing board, insulating material, insulation, waterproofing and rough boards. The most labor-intensive, but requiring less material.

Wall insulation

Throughout the evolution of our housing, the inevitable use of clay has always been visible. Currently, there are also several options for its use for wall insulation. These include:

- the use of adobe, in the form of dried building blocks consisting of clay with filler;

- during frame construction, when a cavity is made in advance, subsequently filled with clay with a binding material;

- due to the application of clay with filler to the inner surface of the wall.

When using it in its natural state, it is imperative to use a binding element in the form of fine straw or sawdust, which helps maintain the integrity of the structure when completely dry.

Principles of thermal insulation of bath ceilings

Based on the design features of the roof, bathhouses made of logs or timber can be divided into two types: buildings with and without attic space. In the path of warm air flowing out of bathhouses with attics, there will be a much more powerful ceiling, into the layer cake of which thermal insulation material is usually laid during the construction process.

The under-roof space itself, filled with an air mass, also inhibits the leakage of thermal energy, and the insulation of the roof structure also slightly moderates the agility of the “escaping” heat.

However, this does not mean that insulation of the ceiling in a bathhouse with an attic or attic is not necessary. Increasing the thermal insulation characteristics in it is no less necessary than in a building without an attic, where the heat leaking out encounters few and too weak barriers in its path.

Specifics of the vapor barrier device

In both cases, regardless of the roof structure, a vapor barrier is laid on the bathhouse ceiling before laying the heat-insulating layer. To equip a building without an attic space, you can use aluminum foil, compacted cardboard, generously impregnated with drying oil, or wax paper as a vapor barrier layer.

In bathhouses with an attic, the same materials are used, but most often the ceiling boards on the roof side are coated with a two-centimeter layer of clay.

Of the options offered by the industry, the following are used:

- standard polyethylene film (as for greenhouses 0.4 mm with variations) - a type of vapor barrier that is not very popular due to the greenhouse effect;

Note. The use of polyethylene film as insulation requires leaving a gap necessary for condensation to evaporate.

- a special vapor barrier film made of polyethylene with fibers to retain condensation;

- membrane type vapor barrier material.

Vapor barrier is necessary to prevent the transit of wet vapors and their settling in the insulation. After all, water accumulated in the thermal insulation material will shorten its service life, increase the weight of the multilayer ceiling system and, if we return to the physics course, reduce its insulating qualities.

Three functions of bath ceiling insulation

The hotter the room temperature is required, the more difficult it is to build a barrier to retain heat. To solve this difficult problem, those who want to know how to insulate the ceiling of a bathhouse should familiarize themselves with the three main leak patterns:

- movement of heated air through the cracks in the ceiling;

- gradual transition of heat from heated objects to cold ones;

- intersection of homogeneous barriers by thermal waves.

Laying thermal insulation material in a multi-layer roofing system prevents all types of thermal leaks. Properly done insulation will adequately perform all the work assigned to it. Due to poor thermal insulation, condensation will settle on the ceiling, it will take much longer to warm up the room, and more fuel resources will be spent.

Selection of materials for insulation

Before deciding how to insulate the ceiling in a bathhouse, you need to consider all options for suitable thermal insulation materials.

- “Classic” mineral wool is used most often. In its chaotic interweaving of fibers melted from basalt there are billions of air-filled voids, each of which works responsibly to retain heat. Disadvantage: loss of insulating properties when wet.

Note. When using mineral wool to insulate the ceiling in bath buildings, it is recommended to lay a waterproofing layer on top of the insulation if the roof is not sufficiently protected from atmospheric water leaks. A thermal insulation gap must be created between the waterproofing layer and the insulation.

- Super-light polypropylene foam - penotherm - is also often installed on the ceiling of a bathhouse. The foil-laminated material was developed specifically for arranging bath buildings and saunas. In addition to its intended function of insulation, its foil side reflects the flow of thermal energy. Working on the mirror principle, penotherm allows you to reduce the heating time of the steam room by 2-3 times.

- Expanded clay is suitable for large-sized bath structures. The layer sufficient to insulate the ceiling should be 30 cm. Although the material is relatively lightweight, it will inevitably increase the weight of the building. Its porous granules, like mineral wool, are susceptible to moisture. Waterproofing is also necessary.

- "People's" heat insulator. The first element is a 2 cm layer of crumpled clay. Instead, a mix of black soil and peat, wood shavings filled with cement mortar, a mixture of clay, sand or sawdust are suitable. A “carpet” of dry sawdust or leaves (preferably oak) is laid on top of the laid layer, and the insulation is completed by laying a layer of dry earth 15 cm thick.

- Growing aerated concrete, for pouring which a simple formwork is arranged. The video will clearly depict how this insulation of the bathhouse ceiling is carried out: the video demonstrates the simple technology in detail.

It is difficult to recommend the thickness of the insulation layer offhand, without knowing the actual size of heat loss and the technical parameters of the structure. The figures are approximate throughout, variations are allowed. Much depends on the climate zone, because the ceiling insulation in a bathhouse is not only a barrier to heat, but also protection from external temperature factors. If the ceiling freezes from the outside, moisture will certainly condense on the ceiling. In such cases, the thermal insulation layer is simply increased.