The vast majority of apartments, especially those built during the Soviet period, were equipped with wooden floors. But for rooms with high operational load or high humidity - such as corridors, kitchens, bathrooms, showers - tiled floors are more suitable. Ceramic tiles (tiles) are superior to wood in durability and practicality. It is much easier to keep it perfectly clean. But will the tiles fit on a wooden floor if you don’t want to disassemble it? Or is it not possible to do this?

What are the problems with laying tiles on wood?

The installation of tiled floors requires a perfectly flat, stationary base. Wood is sensitive to changes in the microclimate of the room: it swells with excessive humidity, dries out and shrinks when used at high temperatures. This type of base is not suitable for tiles: they will crack or begin to “walk”. When using small tiles, cracks will appear along the seams between the floor elements.

In turn, wood is also uncomfortable under the ceramic layer. Wooden parts deprived of natural ventilation will deteriorate much faster under the influence of dampness and microorganisms.

But modern materials and appropriate technologies make it possible to create an intermediate layer that allows you to lay tiles on a wooden floor.

How to Lay Tile on Wood Floors in the Kitchen and Bathroom

Let's consider how to lay tiles on a wooden floor in the kitchen, bathroom, and hallway.

The standard design of a wooden house involves laying ventilated floors along joists that are rigidly connected to the walls of the building and supporting the flooring made of boards or tile wood materials.

Such a base is not suitable for laying tiles due to the risks of beams bending, wood deformation under the influence of moisture or shrinkage processes, and in some cases due to insufficient evenness of the coating.

The problem is solved by:

• Laying dry screeds made of durable sheet materials, without bonding to the walls. This solution is allowed only in rooms with normal humidity and if you are confident in the stability and strength of the flooring; in wet areas of the kitchen and bathroom, it is best to use DSP • Pouring reinforced concrete or semi-dry screed with the addition of reinforcing fiber over the rough flooring and a double layer of waterproofing materials. This method is considered the most reliable and the only correct one when working in wet areas if it is necessary to install a heated floor system under the tiles.

Regardless of the chosen method, before arranging the base, the condition of the logs is checked and antiseptic treatment is carried out (if necessary, with their complete or partial replacement).

If the beams deflect more than 2 mm, which occurs when their cross-section is insufficient or their spacing exceeds 60-80 cm, additional supports are laid under the rough flooring. Their functions are performed by columns made of brick, rubble concrete or reinforced concrete, strong bars attached in a special way to load-bearing beams or iron pipes.

If possible, such supports are shifted to the base of the foundation and protected from destruction and ground moisture. It is to them that it is recommended to attach logs to hold the rough flooring of the future screed, connected without nails and not rigidly tied to the walls of the house.

With the right approach, these works are combined with insulation of floors on the ground - spreading expanded clay or laying an insulated layer of expanded polystyrene or hydrophobized stone wool.

Revision of old coating

Before choosing a method for preparing the base for laying tiles, you need to conduct a thorough inspection of it. The sequence of future work will largely depend on the condition of the old floors.

Under no circumstances should it be installed on newly constructed wood floors. They need to be given at least two to three years to shrink. So in new buildings you cannot lay tiles on wood. You must either wait or completely dismantle the floors and construct a fundamentally different base, for example, a concrete screed.

It should be noted that the tile covering is laid for a very long time. Therefore, you need to be absolutely sure that the elements of the old coating will last no less. There is no point in fussing with the tiles if they will soon have to be opened due to rotten elements of the base.

USEFUL INFORMATION: How to make 3D floors with your own hands (video): step-by-step instructions

Professionals insist on a complete overhaul of old floors to find and replace all defective elements.

Be sure to check the condition of the joists and the distance between them. It should not exceed 50 cm, otherwise the base may not withstand the weight of tiles, glue and other materials.

Strong boards that do not have visible defects can be used, but first they must be freed from the old coating: paint or varnish. This can be done in different ways:

- Mechanical - clean the coating using an abrasive tool: sandpaper, grinder, grinder with a special attachment.

- Thermal – heat the paint with a hair dryer. It will swell and be easily removed with a spatula. Some craftsmen manage to use a regular blowtorch for these purposes, but we must remember about the possibility of fire.

- Chemical - remove varnish or paint using various reagents. But wood, once saturated with them, will emit unpleasant odors for a long time, so this method is used very rarely.

Preparing the base

So, you should carefully disassemble the wooden floors and assess the condition of the joists. Replace defective ones, add additional joists if necessary, securely fasten them and level them.

All elements of the wooden floor structure must be treated with an antiseptic. After it dries, you can update or replace the insulation. This could be a layer of expanded clay, mineral wool slabs or another type of thermal insulation. When laying, the recommendations for using the selected material must be followed.

It is necessary to leave a space of 5 cm between the subfloor boards and the insulation to create natural ventilation.

When installing the flooring back, you should not pack the boards tightly, but leave a gap of a few millimeters between them so that the wood can breathe. A 10 cm gap is left between the floor and the walls. Then it can be sealed with polyurethane foam.

The progress of further work depends on the chosen method of preparing the base. The main ones are the device of a lightweight screed, the use of plywood or polyurethane adhesives.

USEFUL INFORMATION: Glue for butt gluing linoleum

Laying tiles on a wooden floor

Ceramic tiles are an excellent material for flooring, especially in rooms with high humidity or where there is a high likelihood of liquids or other substances getting onto the floor. Typical examples are bathroom, toilet, hallway, kitchen. They do not refuse to use tiles in residential premises if the floor is equipped with a heating system.

Laying tiles on a wooden floor

But what about the owners of private housing, in which all the floors are originally wooden? A similar question may arise for owners of apartments in old buildings, where the plank covering is mounted on joists. Is it possible to lay tiles on a wooden floor?

You can immediately reassure those who are worried - this is a completely doable operation that does not require complete dismantling of the coating to the ground or concrete base and subsequent pouring of a thick concrete screed. True, you will have to work hard, since the success of such a modification of the coating will mainly depend on the quality and strength of the wooden base.

The most important thing is a thorough revision of the old coating

Taking on the task of laying tiles if there is even the slightest suspicion that the wooden base is unstable is the height of recklessness. This is explained simply:

- Wood is a fairly flexible material, tending to return to its original configuration after deformation. But what is “forgivable” for a wooden floor (slight deflection, springing, etc.) is absolutely unacceptable for ceramics. Each individual tile is very rigid and cannot be bent. If the floor “plays”, it may simply crack.

- Another case is if, for example, the ceramic tiles are small-format. Cement-containing tile adhesive also does not like dynamic bending loads. It will definitely develop small cracks, begin to delaminate, and the tile, even maintaining its integrity, will simply move away from the base.

We should not forget that the load on the coating will increase significantly - in addition to everything else, the ceramic tiles themselves, mortars, and other possible structural elements of the multi-layer “pie” of the floor being created have considerable weight. Thus, the wooden base must have guaranteed static stability. This is exactly what needs to be achieved at the first stage of work.

It is clear that the first step is always a thorough visual inspection, applying efforts to the most problematic areas of the wooden floor in order to identify its possible vibrations and sources of squeaks. If there are any, then no questions should arise at all - the coating must be thoroughly rebuilt and repaired, and not only in places of instability, since strengthening the floor in one place does not guarantee that it will not appear in another. It is necessary to understand the cause and eliminate it at the root.

Sometimes after dismantling the floor a “scary” picture appears

Moreover, experienced craftsmen always advise, in all cases of laying tiles on a wooden base, to carry out a complete search of it. If you are planning a ceramic coating, then you need to think that it is for the long term, and not for a year or two. Where is the guarantee that a defect hidden by a wooden floor or a process of wood decomposition that has begun, which does not appear in any way today, will not be discovered literally in a month or even a year, when the tiled covering has already been completely laid? To carry out repairs, you will have to remove all the tiles, dismantle the wooden base - and all due to the fact that the proper principles were not shown during the preparation. Isn’t it better to be completely, 100% confident in the reliability and stability of the wooden floor before you start laying tiles?

The main thing is to get to the joists and floor beams

Don’t let this prospect be particularly scary - compared to completely dismantling a wooden floor and pouring a new concrete slab to replace it, this procedure is much simpler and requires significantly less labor and financial investment.

Typical wood flooring with subfloor

So, the usual layout of a wooden floor is a plank covering mounted on logs. The logs themselves can be installed on a concrete base. Another option is that they are a double timber covering system, with a rough and finished floor and a space between them, which can be filled with thermal insulation material. For any type of floor inspection, you will have to remove the boardwalk completely to expose the joists for inspection, repair and alignment.

- If the condition of any of the joists causes even the slightest concern - there are cracks or areas with signs of wood decomposition, it must be unconditionally replaced.

- If the distance between adjacent joists exceeds 500 mm, it will be necessary to install additional beams, otherwise even the thickest floorboard may bend in this place.

- The logs must be leveled horizontally. If they are securely embedded, and it is not possible to change the height of the supports, this can be achieved by adjusting it with a plane, or, conversely, by increasing it with a wooden plank.

- Of course, if there is a subfloor, it should also be given some repairs - replace worn out or cracked boards, eliminate possible distortions, creaks, etc. When it is ready, both it and the logs are covered with a layer of dense waterproofing film.

- If you already have the opportunity to get to the joists and subfloor, you should take the opportunity and treat all the parts with antiseptic and water-repellent compounds. You should not attribute your reluctance to carry out this procedure to the fact that similar treatment was carried out earlier, during the initial installation of the floor - the compositions are inexpensive, the process itself will not take much time, but the durability of the structure will certainly increase.

A prerequisite is antiseptic treatment of all parts of the wooden floor

- Literally every board of the removed flooring is checked for integrity, the presence of weak areas, cracks, hammered and bent unnecessary nails, etc. All boards with significant flaws should be disposed of and replaced with fresh ones.

- An important action that should not be forgotten is cleaning the finished floor boards from old paint layers if subsequent laying of tiles is planned directly on them. Creating a reliable base for tiles involves working with a cleaned wood structure.

This cleaning can be done in several ways:

- So, paint or varnish can be removed in advance by scraping or using abrasive materials - grinding and polishing machines, sandpaper or special attachments on a grinder or electric drill.

- Sometimes a chemical cleaning method is used - washing off the paint with solvents. However, this is not the best option, because organic solvents are actively absorbed into the wood, disrupting its natural qualities and leaving an unpleasant, pungent odor for a long time.

- The thermal method is widely used - using a hair dryer or even a blowtorch. Under the influence of high temperatures, the paintwork either burns out or melts to such a state that it can be easily removed with a regular scraper (spatula).

- Before proceeding with the reinstallation of the floorboards, it is possible to consider additional insulation of the floor. Between the logs you can fill expanded clay, lay mineral wool mats or expanded polystyrene slabs. Additional thermal insulation will never hurt anyone.

- The reverse laying of the boards onto the joists is not carried out “solidly”, but leaving a gap of 3-5 mm between them is necessary so that the wooden floor under the tiles has the opportunity to “breathe” and to compensate for possible linear vibrations of the material. Another option is to drill through holes in the boards in a random order. Be sure to leave a gap at the walls around the entire perimeter of the room, about 10 mm. Any remaining gaps can be lightly covered with adhesive tape or foam.

- After the final installation of the floorboards on the joists using self-tapping screws, a thorough quality control of the coating is carried out again. If no shortcomings are identified, you can proceed to preparing the base for laying ceramic tiles.

Several ways to prepare the base for laying tiles

So, we have a repaired, solid plank base. What should I do next to fully adapt it to laying ceramic tiles?

The tiles are supposed to be laid directly on top of the boards

- First, you need to create a thin but stable and reliable waterproofing layer. To do this, the wooden floor is thickly treated with hot drying oil, but this method is quite outdated and also very unsafe, so it is better to use a latex impregnating composition. It is applied thickly with a wide brush to the floorboards, which immediately after this, without waiting for the composition to dry, are covered with a fine-mesh fiberglass painting mesh.

Fiberglass painting mesh

- When the latex composition is completely dry, the mesh should be secured to the floor surface with galvanized self-tapping screws with wide heads for reliability.

- The result is a durable waterproofing coating, which, in addition, has certain reinforcing properties.

- Now it’s tedious to achieve good adhesion of the tile adhesive to the resulting base. You can do it this way. A solution is prepared consisting of 2 parts coarse sand, 2 parts silicate glue (often called “liquid glass”), and one part water. After thorough mixing, the resulting composition is evenly applied in a thin layer to the entire surface of the floor.

After complete drying, you will get a rough monolithic surface, completely ready for laying ceramic tiles.

Video: example of laying tiles directly on plank flooring

It is planned to pour a thin screed

- If you read the opinions of many experienced craftsmen, some of them are categorically against laying tiles directly on a plank base. Their suggestion is to pour a small light screed on top of it.

- The initial process - impregnation of the floorboards with a waterproofing compound - does not change.

- Next, a damper tape should be glued around the perimeter to prevent deformation and destruction of the screed near the walls.

- A beacon system is installed, based on the screed thickness of about 30 mm. Between the beacons you can additionally lay a thin metal or fiberglass mesh.

- For screed, you can use a standard basic cement-sand mortar with fine seeded sand (1: 3), but it is better to use special dry construction mixtures that contain fiber microreinforcement and plasticizers. This screed matures faster and is more durable for such conditions. In addition, nothing prevents the use of the technology of pouring a self-leveling composition.

Light screed device on top of a plank floor covering

- After the screed has hardened and fully matured, it is treated with a primer, after which it can be considered ready for laying ceramic tiles.

The floorboards will be covered with plywood (chipboard, OSB)

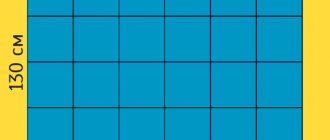

If there is no desire to stir up dirt by filling the screed, the room does not belong to the category of high humidity, but is characterized by a fairly intense dynamic load, then the plank base can be covered with plywood sheets 10 mm thick. The thickness may be greater, but we should not forget that this is an extra load on the joists and floorboards. By the way, here you can save on the floorboard - it is enough to lay it at intervals of even up to 150 -200 mm.

If the floor is covered with plywood, the floorboards can be spaced wider

The work is carried out in the following sequence:

- The plank base, after antiseptic impregnation, is covered with waterproofing material. In the described case, this role can be played by waxed, paraffinized or bitumen-impregnated construction paper or even ordinary polyethylene film with a thickness of at least 200 microns.

- The plywood sheets are laid out staggered so that there is always a compensation gap of 5 to 10 mm between them. A similar gap is left around the perimeter of the room along the walls.

Approximate layout of plywood sheets

- The plywood is attached to the board base with self-tapping screws, in increments of no more than 150 - 200 mm, both along the perimeter of the sheet and along its plane. The screw caps must be completely recessed into the thickness of the material.

Sometimes, for greater strength, additional gluing of plywood is practiced.

- After laying the plywood over the entire area of the room, the expansion gaps between the sheets and along the walls are sealed with sealant or polyurethane foam. After drying, excess material is cut off to floor level.

The floor is completely covered. Pay attention to the compensation gaps between the sheets

- The next step is to create a waterproofing reinforcing layer and prepare the surface for laying tiles. Here everything is exactly the same as described above for the plank floor: latex impregnation → painting mesh → treatment with a silicate-sand composition.

After this, you can proceed directly to laying the tiles.

Once prepared, tiles can be laid on plywood

The wooden floor is covered with gypsum fiber sheets (GVL)

This method is somewhat similar to that described above (with plywood), but it also has its own characteristic features:

- As a rule, gypsum fiber boards are equipped with a locking part for mating adjacent sheets. In these places they are connected with a special adhesive and self-tapping screws. The use of self-tapping screws along the entire perimeter of the gypsum plasterboard and in its center is not required.

It is convenient if the GVL is equipped with a locking part

- If the strength of the wooden base of the floor allows, and the operational features of the room require special reliability of the coating, gypsum fiber boards can be laid in two layers. In this case, the second one should be oriented perpendicular to the first. Coincidence of joints is not allowed.

Approximate diagram of the resulting “pie” with two layers of gypsum fiber board

- The GVL surface, after being treated with a primer, does not require any additional manipulations - it is ready for laying ceramic tiles.

The process of laying tiles on a surface prepared on a wooden floor is, in principle, no different from conventional technology, which is discussed in detail in other articles on our website. The only thing you should pay attention to is the brand of tile adhesive. It is best to choose a composition “for complex surfaces”, and some adhesive mixtures in the instructions for use directly indicate the possibility of using them for laying tiles on a wooden base. This installation of tiles will be more reliable.

Board base

- The boards are impregnated with a latex-based waterproofing solution. Without waiting for it to dry, lay a painting reinforcing mesh on the floor. In the future, it is additionally fixed with self-tapping screws.

- A layer of solution consisting of sand (2 parts), liquid glass (2 parts) and water is applied to the floor surface. All components must be thoroughly mixed.

The tiles are fixed with two-component polyurethane adhesive. It retains its plasticity after hardening, so it will not only ensure reliable fastening of the tiles, but also compensate for slight vibrations of parts of the subfloor.

Lightweight screed

The point of this method is to create a solid and level base that is not connected to walls or wooden floors. This floating structure will ensure the integrity of the tile covering. The optimal thickness of the screed is 30 mm: a smaller thickness will not provide sufficient strength to the base, a larger thickness will significantly increase the weight of the floor.

- A layer of waterproofing is created. This can be rolled material: glassine, bitumen paper or even thick polyethylene. Waterproofing mastics or heated drying oil are often used. In this case, reinforcement with fiberglass mesh is used.

- Damper tape is glued along the perimeter of the room between the floor and the wall.

- A thin metal mesh is attached to the waterproofing layer with self-tapping screws.

- A screed with a height of 30 mm is poured.

You can use a regular solution of cement and sand, but it is better to use self-leveling mixtures: they dry much faster and are more convenient to work with.

- After hardening, the screed is primed, and then the tiles are laid in the same way as on a regular concrete base.

Wooden floor. Preparatory stage

Before laying ceramic and tiles on a wooden floor, you will need to carry out various preparatory work. Floors should be checked for cracks and unevenness. Remember that installing on a low-quality surface simply does not make any sense. Therefore, first we will consider the various situations that may arise.

If the old boards on the floor are rotten, they need to be replaced

Chipboard, plywood or OSB board will help to level a wooden floor

If the old coating creaks and bends

The algorithm of actions in this case should be as follows:

- Old floors must be completely removed.

- It is necessary to dismantle the lower floor using a nail puller.

- Beams are installed on the substrates and set in a horizontal position using a building level.

- The beams and lower floor are treated with a special impregnation.

- After the impregnation has dried, expanded clay is poured between the beams.

- Now you will need to very carefully secure the board to the subfloor across the beams in those places where it comes into contact with them.

- You will need to lay parchment paper on the subfloors and strengthen the substrate on it, which should be made of gypsum fiber board.

- The resulting structure is primed, after which tiles or ceramic tiles can be laid on such a floor.

- The old covering is dismantled, and a layer of waterproofing is laid between the ceiling and the wall at the joints.

- A horizontal line is installed along the perimeter of the kitchen, after which the surface level is marked along it. You also need to set up beacons.

- The screed is filled with concrete.

- Expanded clay is poured between the beacons. The wooden floor is filled with mortar and left in this state for one day.

- After this, the floors are cleaned of excess expanded clay, primed and refilled with the mixture. It is left in this position for 3 days.

- The screed is primed. Next, you need to lay a special self-leveling mixture. Now ceramic or some other tiles can be laid.

Related article: Guide to building a frame house structure with your own hands

Wooden floors require careful preparation before laying tiles

If the covering is in good condition, chipboards are laid on the lower floor

In this case, the actions should look like this:

- All joints between the chipboard and the wall are waterproofed using polyurethane foam.

- The chipboard is processed twice with heated drying oil. Since drying oil is flammable, you need to be very careful when working with it.

- Taking a wide brush, you need to treat the chipboard with a thick layer of latex.

- The painting mesh is laid out on the surface and left in this state until it dries.

- After this, the mesh is secured to the chipboard using self-tapping screws.

- The surface must be treated with a solution containing coarse sand, water and liquid glass.

- After the composition has dried, tiles can be laid on the surface.

Plywood base

To create an even and durable base for the tiles, sheets of plywood with a thickness of at least 10 cm are used. It is better to cut them into 4 parts. Installation is carried out following the following recommendations:

- After impregnating the base with an antiseptic and laying the waterproofing layer, the plywood is fastened in a checkerboard pattern.

- A compensating gap of 5 mm is left between the individual elements. In the future, it can be sealed using sealant or foam.

USEFUL INFORMATION: Kitchen renovation: where to start, main stages

Plywood is also subject to thermal expansion, which is why a compensating gap is needed between the individual sheets. A 10 mm wide gap is also left around the entire perimeter of the room.

- The plywood is fastened to the base using wood screws, recessing the caps deep into the material, in increments of 15–20 cm.

- The resulting surface is processed with a grinding machine along, across and diagonally. Then it is primed.

- A waterproofing layer is formed from latex impregnation, paint mesh and liquid glass solution.

- The tiles are attached with polyurethane glue.

Plywood can be replaced with slabs of moisture-resistant plasterboard or gypsum fiber. The technology will not be much different, but it is worth using components designed specifically for these materials.

Laying tiles

Tiles are laid on wooden floors in the same way as on a concrete base:

- Laying begins from the middle of the room or from the far corner opposite the entrance.

- For lightweight screeds or gypsum boards, it is recommended to use cement adhesive mortars; for plywood or boards, use two-component polyurethane adhesive.

- The glue should be prepared in small quantities and in strict accordance with the manufacturer's recommendations.

- The correct installation of each tile is immediately checked by the building level.

It is better to use mixtures containing silicone as grout. This will increase protection against moisture on the wooden base.

Excess glue or grout is removed from the surface of the tile immediately with a wet cloth. Don't let them dry out.

Bonuses for using tiles

Tile covering has many advantages.

The main ones are:

- Fire resistance. If something happens, the tile will never burn. In addition, it does not emit any toxic substances.

- Easy to clean. Mold and mildew almost never grow on tiles. Their appearance is easily eliminated. Plus, the tiles are very easy to clean.

- Strength. If the tiles are laid correctly, it can be tens of times stronger than cement.

- Coating hardness. Under various severe loads and mechanical damage, the tiles do not deform.

- Resistance to other factors. Ultraviolet rays, moisture and many chemicals do not affect the tiles in any way. Tiles are also excellent dielectrics.

Related article: Artificial flowers in the interior of the house

The main advantage of ceramic tiles is their fire resistance

Floor coverings such as ceramic tiles are very easy to maintain.

The tile covering is ideal for creating a “warm floor” system underneath.

Required tools and materials

To install tiles on wooden floors, you will need:

- building level,

- saw,

- pencil,

- glue,

- cutter,

- rubber hammer,

- putty knife,

- gloves,

- rags.