Today, a large number of insulating building materials are known. Every day, the market for thermal insulation materials is expanding, and manufacturers are striving to improve their quality indicators.

Among the various types of insulation, it is worth highlighting reflective thermal insulation - foil penofol, produced in rolls. Let's find out what this material consists of and what characteristics it has.

Material structure

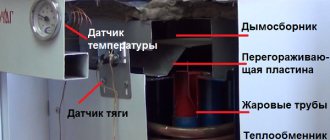

Foil penofol - refers to a type of reflective insulation. Such material was created solely for the purpose of protecting various structures from factors such as draft, cold, wind, moisture and vapor. It went through several stages of improvement, as a result of which it combined such qualities as: sound, heat, steam and waterproofing.

Consists of several main layers:

- The first layer is polyethylene, foam consistency with closed pores. The pores are filled 90% with air, so the material prevents heat transfer. The first layer can vary in material thickness, density and structure.

- The second layer is aluminum foil , which reflects heat. Foil - penofol can be covered on one or both sides, which is reflected in the technical characteristics of the product, as well as its features. It is worth noting that the connection of foil with polyethylene is carried out by heat welding.

Available in thicknesses from 2 to 40 mm. The thickness of the foil varies: from 12 to 30 microns. The operating principle of foil penofol is based on the functioning of a thermos. Thanks to the air cushion, which is covered with a reflective element in the form of aluminum foil, it is possible to retain heat for a long time. The use of such heat-insulating material in the construction of a house makes it possible not only to significantly save on heating, but also to slow down the process of warming up the house in the summer.

What is the difference between penofol and isolon?

Often users have to face the problem of choosing insulation for a balcony. It takes quite a long time to search for materials for each of the options.

Comparison of insulation for balconies and loggias

A balcony, according to Wikipedia, is “an unheated room in the form of a fenced area protruding from the plane of the façade of a building.” It's nice and cool in the summer, but in the winter? There comes a time when there is a desire for the balcony to please even during the long winter months of our harsh winter.

A modern balcony, if you apply a little imagination, desire, materials and material investments, is an additional room that can be used at any time of the year. This is also a room for receiving friends, where you can drink a cup of tea or a glass of wine and chat.

This is a study room with a small bookcase and computer accessories, and a relaxation room. where you can read, knit, daydream, or a playroom for children. This means that in order to use the balcony in winter, you need to insulate it.

Penofol and the like Teplofol, Energofol (foil insulator based on foamed polyethylene)

This insulation consists of several layers of polyethylene foam, having unequal density, thickness and different porous structure. The insulation also has a layer of foil for a reflective insulation effect.

Penofol has a thickness of only a few millimeters, which is on average 10 times thinner than conventional mineral wool insulation. It reflects about 97% of thermal energy and is very light and thin. Penofol is used for internal and external thermal insulation, vapor barrier, sound insulation, waterproofing, has a long service life, is not particularly difficult to install and is relatively inexpensive.

Izolon, Penolon (foil insulator based on foamed polyethylene)

This material has the structure of foamed cross-linked (physically and chemically) polyethylene and is used for thermal insulation, sound insulation, vapor barrier, and moisture insulation. Penolon (izolon) is an ideal option for insulating balconies and loggias. It does not compact after a long time, does not create dust and does not emit substances harmful to the body.

Externally, Penolon is an elastic, mostly white, sometimes with a yellowish or grayish tint. The canvas is produced in rolls and sheets. The surface of Penolon has a slight roughness. It is used for both internal and external thermal insulation, sound insulation, waterproofing, vapor barrier, is not subject to wear, and is easy to use. The price is affordable.

This thermal insulation insulation is made using steam foaming of polystyrene. Polystyrene foam has very low weight and low thermal conductivity, is resistant to dampness, is easy to cut with a sharp knife, has low compressibility, and is easy to use during installation. Due to its low cost, it is in priority demand for insulating balconies.

- PVC membrane waterproofing

- Plastic windows – variety of choices

- How to kill weeds with vinegar?

- Competent choice of contractor for installation of PVC windows

- High-tech balcony - high-tech style

- Window lock BSL

Advantages and disadvantages

Penofol, like any other building material, has its advantages and disadvantages. Thanks to these important factors, it is possible to choose the best option for insulating the house.

Benefits include:

- Possibility of using the material in various types of construction and repair work. The material can be considered universal;

- Low coefficient of vapor permeability, which makes it possible to exclude the additional use of vapor barrier materials;

- High level of sound insulation. Penofol perfectly protects houses and other construction buildings from noise;

- Ease of installation work. It is easy to cut and attaches to any type of surface;

- Subtlety. Penofol thickness: 4 mm allows you to replace polystyrene foam thickness: 3 cm;

- Environmentally friendly. The material is an absolutely safe and environmentally friendly product. The materials from which penofol is produced are used for food storage;

- Fire safety. The material does not support combustion, since it is based on foil;

- This type of insulation is not susceptible to negative effects from various rodents, as is typical for polystyrene foam;

- The material is easy and convenient to transport.

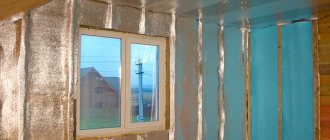

Installation of material

Penofol insulation 10 mm, 5 mm, etc., of course, must also be attached to the sheathing in compliance with all required technologies. Such material is fixed on the walls on the timber exclusively end-to-end. When installing penofol foam, there are no overlaps between the strips. This material is secured to the sheathing beams with brackets using a construction stapler. The joints between the strips are covered with masking tape. Of course, foil material of this type should be used for penofol.

When installing penofol on walls, you can cut it using ordinary sharp scissors. This thin material is very easy to cut.

Main technical characteristics

Having learned about the advantages and disadvantages, it is worth finding out what basic technical parameters this material has:

- It is used at the following temperature limits: from -60 to +100 degrees;

- Thermal reflection coefficient reaches: 97%;

- The value of the thermal conductivity coefficient ranges from 0.037 to 0.052 W/m*C;

- Vapor permeability parameters do not exceed: 0.001 mg/m*h*Pa;

- Specific heat capacity - 1.95 J/kg*C;

- Sound wave absorption: no less than 32 dB;

- The specific gravity of 4 mm penofol is 44-74 kg/m3.

Penofol insulation: characteristics, application

Foam-based foil.

For comprehensive insulation of residential and non-residential buildings, the following synthetic materials are used: expanded polystyrene, penoplex, polystyrene foam, and other polymer products, including penofol. The technical characteristics of the latter are quite good.

Unlike its counterparts, which accumulate heat and then return it to the room, it reflects thermal radiation. As a result, the level of thermal permeability of the building is reduced several times. Another advantage of this insulation is fire safety.

You can insulate walls with penofol from the inside and outside. Neither weather conditions nor a possible aggressive environment will harm it.

What is penofol?

Penofol is a foamed, foil-coated polyethylene with a closed-cell structure. Today you can buy the following types of this material:

- A – foil is applied only on one side, which reduces the cost of purchase;

- B – foil is applied on both sides. This increases the resistance of the material to physical stress;

- C – foiling occurs only on one side, while the other is covered with a durable adhesive. This simplifies the use of insulation in hard-to-reach places;

- ALP – foil on one side. A polyethylene film is applied over the aluminum layer. Used in agriculture;

- R – the upper, reflective layer has a relief structure;

- NET – characterized by increased vapor barrier, and therefore is used when laying heating main pipes and water utilities;

- AIR – indispensable for thermal insulation of ventilation wiring.

Where can I use penofol? Its technical characteristics make it possible to reduce the thermal conductivity of walls and ceilings of residential and non-residential buildings and industrial facilities. Penofol can act as a vapor barrier layer, and therefore it is relevant for saunas and baths, heating and water supply pipes, and ventilation wiring. Also read: “Do-it-yourself floor insulation in a bathhouse.”

The thickness of the pillow may vary.

Penofol has the following characteristics:

- ultra-low thermal conductivity, which ranges from 0.037 W/m°C to 0.052 W/m°C;

- surface reflectivity of thermal radiation from 95% to 97%;

- low water absorption 0.35-0.7% per 1 cubic meter;

- low vapor permeability 0.001 mg/m h Pa;

- high level of sound insulation - over 32 dB;

- compressive and bending strength – 44-74 kg/m. cube

It is very convenient to insulate walls with penofol from the inside and outside of the building, since it does not create additional loads on the ceiling. Material weight 44-74 kg/m. cube (weight depends on the type of thermal insulation). Floor insulation with penofol is also relevant. After all, the material is not afraid of temperature changes (the operating temperature range is from -60°C to +100°C).

How to make long-burning stoves with your own hands: diagram, necessary materials and tools, useful tips.

About where a long-burning furnace can be useful during mining is written here.

Penofol and floor

Is it possible to insulate the floor with penofol in a wooden house, as well as the walls, roof and ceiling of the building? After all, as you know, a wooden house has good air exchange with the environment, and the low level of vapor permeability of penofol can disrupt it.

As practice shows, the above material does not affect the technical and operational characteristics of a wooden building. The main condition is the organization of a ventilation gap. Also read: “Do-it-yourself floor insulation on a balcony: what materials to choose?”

It is necessary to leave a ventilated gap.

Thermal insulation of the floor in a wooden house. Floor insulation with penofol in a wooden house is carried out along logs. In this case, material types A and B can be used. The installation method depends on the type of thermal insulation chosen. We have already written about the comprehensive insulation of a wooden house according to modern technology.

Method using type A insulation. Work progress:

- surface preparation;

- choice of timber;

- organization of vapor barrier;

- laying the lower tier of logs;

- installation of the main insulation;

- laying penofol;

- second tier of logs;

- floor finishing.

The previous coating is completely removed down to the foundation. The surface is cleaned of debris and dust. To do this, it is advisable to use an industrial vacuum cleaner.

Penofol, as an independent thermal insulation material, cannot protect a building from heat loss. That is why it is used in combination with the main insulation, for example, polystyrene foam, mineral wool.

The height of the beam should be commensurate with the height of the selected main insulation plus 5 cm to create a ventilated gap. In most cases, beams of 100 mm by 100 mm or 100 mm by 150 mm are suitable, where the first value is the height, the second is the width of the product.

If necessary, the height is increased. The length is chosen arbitrarily. Experts recommend choosing the length of the beam in accordance with the size of the room. Otherwise, the logs will have to be extended, which will negatively affect the stability and strength of the structure.

The joints are taped with special tape.

The vapor barrier can be a polyethylene film or a special membrane. In some cases, penofol type B is used. The previously selected beams go on top of it.

They are laid across the width of the room in increments of 35-40 cm. At the same time, a distance of 1-2 cm is made from the walls. This is needed to compensate for the thermal and operational expansion of the logs.

A gap of 1-2 cm is maintained between the last lag and the wall, regardless of the pitch of laying the beams.

The main insulation material is installed by surprise. In this case, there should be no gaps between the joists and the thermal insulation. Penofol is laid on the insulation with the foil layer down. Floor insulation with penofol in a wooden house is not overlapped.

This will have a bad effect on its protective functions. Only an overlap of about 10 cm is made on the walls. The joints between the sheets are glued with adhesive aluminum tape.

Next, a second tier of lags is arranged on top of the foil material, along which the rough floor and finishing go.

A stapler or construction staples are suitable for fixation if the balcony is insulated with penofol.

Thermal insulation of the concrete base. If insulating a wooden floor with penofol is impossible without organizing double logs, then with a concrete or cement base everything is much simpler. The main requirement is a perfectly smooth rough coating.

For residential and administrative buildings, the presence of an additional layer of thermal insulation under the rough floor screed is mandatory. The next condition is the ventilation gap. It should be located above the foil part of the penofol.

Otherwise, condensation will accumulate on the foil, which will negatively affect the protective properties of the thermal insulation pad.

The joists are placed on top of the reflective insulation.

Experts tell you how to insulate a floor with penofol correctly on a concrete base. All work is carried out in several stages:

- rough floor screed;

- installation of penofol;

- installation of a metal frame;

- organization of the second layer of penofol;

- floor finishing.

Penofol is laid on top of the rough concrete floor screed. Here it is advisable to use type C material, since it already has an adhesive composition on one of its sides and is easier to work with.

Penofol is mounted end-to-end on the floor, an overlap of 10 cm is made on the walls. All seams are taped with foil tape. Next, a metal frame is organized on which the second layer of penofol is laid. There is another metal frame on top.

It will act as a support for rough and finishing flooring.

If you are insulating unheated rooms or buildings that are used only in the warm season, one layer of penofol is sufficient.

Buleryan long-burning metal stoves were developed by lumberjacks in Canada.

The complex design of the Stropuva boiler does not allow you to make it yourself. Confirmation here.

Penofol and roof insulation

Penofol is placed with the reflective surface inward.

The main requirement when insulating the attic and ceiling of a house is a good vapor barrier. In the absence of this, moisture that accumulates indoors will penetrate into the insulating material. This phenomenon is explained by the difference in steam pressure inside and outside the building.

Gaseous water, accumulating in the insulation layer, leads to a deterioration in the technical characteristics of the latter. As a result, over time the entire thermal insulation pad has to be replaced. In the worst case, moisture affects the wood floors and beams of the house.

They rot and lose their strength.

When organizing a vapor barrier, a ventilated gap is required. After all, there is always a possibility of moisture penetrating into the upper layers of the thermal insulation pillow of the ceiling. The air gap will allow the accumulated condensation to be removed from the insulation.

When the ceiling is insulated with penofol, there is no need to create a ventilation gap between it and the main layer of heat-protecting material. Penofol has low vapor permeability.

In addition, this product is coated on one side with an adhesive substance, which simplifies the installation process.

Insulating the attic with penofol also has its advantages. If external work is carried out, then penofol can replace the waterproofing barrier, plus additional thermal insulation of the attic is provided.

Inside the attic, penofol is installed below the insulation, protecting the latter from water vapor. The use of penofol also helps to reduce the thickness of the layer of the main thermal insulation material.

For example, a layer of penofol 4 mm and mineral wool 100 mm are equivalent to a layer of mineral wool 200 mm.

Only original material can provide complete protection of the building from heat loss. How to choose the right penofol is described in the video:

Insulation of building envelopes

With external insulation, the reflective surface faces the street.

Insulating external walls with penofol has a number of advantages. This is additional protection of the building from heat loss. This material is a high-quality vapor barrier in the path of gaseous water. Penofol can act as a water barrier. When a house is insulated from the inside with penofol, in addition to heat-reflecting and vapor barrier properties, it performs the function of effective sound insulation.

Nuances of external insulation. Is it possible to use penofol insulation for external use? The use of this material for thermal insulation of the exterior of a building causes disagreement among experts.

Some are categorically against penofol, considering it ineffective in combating precipitation. Some people complain about the appearance of mold on the walls, the outer side of which is covered with penofol.

According to the manufacturer, all of the above problems can arise if the installation is carried out incorrectly and the instructions for using foil thermal insulation are not followed.

Typical mistakes when installing penofol:

- incorrect location of the reflective surface;

- lack of ventilated gap;

- organization of closed ventilated gaps.

Thus, insulation is always laid with a reflective surface towards the heat source. That is why type C material (with an adhesive composition on one of its sides) is not used for external thermal insulation.

In this case, penofol, foiled on both sides, is relevant. It is characterized by low thermal conductivity due to double reflection of thermal healing. This allows you to reduce the thickness of the main insulation.

The ventilation gap should be made between the finishing and the insulation, and not between the penofol and the wall.

The second nuance is the mandatory presence of a ventilated gap. Otherwise, the walls of the house accumulate condensation. This explains the appearance of mold inside the building. The next nuance is choosing the right brand of material.

The wall is insulated from the outside with penofol type R, which implies a relief structure on one of the foil sides.

It is the relief structure that makes thermal insulation resistant to precipitation, thereby extending its service life.

When external roof insulation is carried out with penofol, this material is used both as a vapor barrier and as a water barrier. Penofol is placed between the interior finishing of the attic and the main insulation. There is ventilation between them.

The second layer goes on top of the insulation and under the main roofing material. There must be draft inside the ventilated gaps, that is, the air must enter under the eaves and exit at the ridge of the house.

Only in this way can condensation be prevented, maximum thermal protection of the roof and drying of its rafters possible.

The feasibility of using penofol

Penofol is not only a modern thermal insulation material. It acts as a hydro- and vapor barrier, significantly increasing the life of the building, protecting it from the effects of precipitation. The action of penofol is based on the reflection of thermal radiation, and not on its absorption. This is what distinguishes the above product from other insulation materials.

Is it possible to insulate the ceiling with penofol? How effective is the use of this insulation in the attic? Penofol is versatile and therefore suitable for thermal insulation of any part of the building.

Is it possible to insulate the floor with penofol in a wooden house without disturbing the air exchange of the building? Penofl will not cause harm to the wooden frame if during its installation you take care of the presence of ventilated gaps.

They prevent the formation of condensation, help remove excess moisture vapor from the outside of the building, and also act as additional thermal protection.

Source: https://utepleniedoma.com/uteplenie/banya/uteplenie-penofolom

Kinds

Depending on the intended use of the material, manufacturers produce the following types:

- type A , covered with foil on one side only. It is also called one-sided;

- type B , presented in the form of a double-sided foil coating. Used for autonomous type of insulation;

- type C, self-adhesive penofol, which at its base consists of foil, polyethylene and a layer of moisture-resistant glue. This option is convenient for installation and does not require additional installation tools.

In addition to the three main types, manufacturers also produce the following options:

- type ALP , which is additionally covered with polyethylene film. This film is designed to protect the material from aggressive environments;

- type M and R , presented in the form of one-sided insulation with a relief base;

- type AIR , special materials used to install air vents.

What is foil penofol? Methods of application

Every day new building materials appear on the market or their trade name changes. Because of this, many craftsmen ask questions that different materials, the name or features of which are not completely clear. Such materials include foil penofol. What is this, you have a question.

The materials needed for insulation have gained popularity today. The areas of application have expanded greatly. When you come to a market or store, it’s really difficult to figure out and choose the right material. Therefore, we will help you solve this small problem.

Specifications

The material itself is a new product on the market, but its properties have been used for a long time. Penofol was first used in America to make spacesuits for astronauts. After a while, Russia found another use for penofol (a building material).

The actions of foil penofol that it performs are similar to the effect of a thermos. In winter it is able to retain heat, and in summer it does not allow heat to pass through. Penofol is not able to retain heat or coolness, it simply reflects them.

Penofol has many layers; the material consists of foamed polyethylene, which has many pores that are filled with air. Penofol is covered on both sides with layers of foil. Hermetic pores do not allow heat transfer, and heat reflection occurs with the help of foil.

The thickness of foil penofol ranges from 3 to 15 mm, but there are also types whose thickness is up to 40 mm.

The polyethylene layer is connected with foil using heat treatment. In addition to the fact that foil penofol reflects heat, it is able to function as a soundproofing and vapor barrier.

Technical characteristics of different types of penofol in the tables:

Type "A", "B" and "A-LP" have the same characteristics

Type "C"

Types of penofol

There is more than one type of foil foam, which differ from each other and have different characteristics. The manufacturer draws letter designations on different types, with the help of which you can distinguish penofol.

The following types are available on the market:

- The marking with the letter “A” indicates that there is only one side of the aluminum foil coating. Usually craftsmen combine it with other materials.

- Marking with the letter “B” indicates that both sides have a foil coating. Can be used stand-alone.

- If the material is marked with the letter “B”, it is self-adhesive insulation. Material with a self-adhesive coating in the form of moisture-resistant glue. Can be used without the use of installation tools or tools.

- Type "ALP" . Polyethylene is applied to the aluminum coating. This type of penofol is also called laminated. Often used in agriculture.

- Types "R", "M" . The material has a foil coating on one side and also has a relief structure.

- Super-Net marking . The word comes from the English word "network". This type is used for insulation of utility networks and communications.

- Type "AIR" . This foil penofol is used in a special air-venting structure.

Important! Experts do not recommend buying Penofol 2000. This is a cheaper version of ordinary penofol. It has much worse characteristics.

Advantages and disadvantages

Let's consider the advantages and disadvantages of the material.

The advantages of foil penofol include:

- Small thickness. The layer can be a maximum of 1 cm, which can provide thermal insulation, which in its properties is not inferior to other materials with greater thickness.

- Penofol is a material that has good hydro, noise and moisture insulation properties.

- Foil foam is capable of protecting against beta radiation in an enterprise or other technogenically unfavorable area and provides reliable protection.

- High strength. Penofol is very resistant to mechanical stress.

- Easy to install. To lay foil penofol insulation you need a minimum amount of funds and construction tools.

- Low price.

But the material also has its disadvantages :

- Softness. Foil penofol is not used when finishing with plaster.

- If you are using a non-darkening type of material, then you still need to purchase special glue or double-sided tape.

- Sometimes one foil penofol is enough to provide reliable protection for the room.

Application of foil penofol

The area of use of the material is wide and is becoming wider every day.

Most often used for this purpose:

- For hydro- and thermal insulation work in baths or saunas;

- Roofing works, roof insulation;

- Protection of utilities, boilers;

- Insulation of refrigerators and cold rooms;

- Insulation of floors, ceilings, and walls on balconies.

Insulation of interior walls

Source: https://MoyBalkon.com/uteplenie/penofol

Application

As a heat insulator:

- for houses;

- saunas and baths;

- hangars;

- warehouses;

- refrigeration chambers;

- shops and pavilions;

- air conditioning systems.

As an additional element of the structure:

- for internal and external walls;

- floors and ceilings;

- steam, hydro and heat insulators for roofs and attic floors;

- as a shielding heat reflector for heating radiators;

- insulator for doors and windows.

When to use foil insulation for the ceiling

Insulation with a reflective layer is used for thermal insulation of walls and ceilings in houses and apartments. They are suitable for commercial and residential premises. Most often, penofol and isolon are used for insulating loggias and balconies.

Independent use of polyethylene foam insulation with foil is permissible on the ceiling of a room above which there is a warm attic or attic. Due to their increased moisture resistance, these insulators are used to insulate the ceilings of kitchens, baths, bathrooms, and saunas.

Important! When insulating the ceiling of a living room under an unheated room, reflective thermal insulation is used in complex insulation with other materials.

Installation rules

Depending on the scope of penofol application, the methods of its installation differ. To carry out installation work on laying material on the balcony, you should be guided by the following technology:

- To begin with, you should remember that there should be a distance of 1-2 cm between the structural elements and the penofol. Such a margin is required in order to eliminate the possibility of moisture and ventilation;

- Penofol should be laid with the foil side directly to the heat source;

- The material must be connected using special foil tape;

- Penofol sheets should be connected to each other end-to-end, which allows you to achieve maximum thermal reflection.

Stages of finishing walls with penofol

Penofol, in addition to its heat-insulating properties, helps preserve the space of the room, since its layer is much thinner in thickness than similar insulation materials.

To insulate walls and internal partitions, all three types of insulation are used. To prevent the accumulation of moisture on the foam foil, create a space with air ventilation with a thickness of 2 cm.

Penofol is mounted on the wall surface if it has an adhesive layer. The material with foil on both sides is attached with a ventilated gap on both sides of the layer.

To do this, a frame made of lath is attached, an insulator is placed on it, nailed to the tree with nails, staplers or drilled with screws. To create a second air gap, another slatted frame is made, and plasterboard, sheets of plywood or chipboard are mounted on it.

We advise you to study - Types of polycarbonate: structure, sizes and colors of sheets

The insulation strips are joined end to end; the best option is to cut the seams for a tighter fit. The seams are protected from unfolding and drafts with aluminum tape.

External thermal insulation of walls is carried out with penofol, if further finishing of the facade is planned with hinged ventilated systems made of plastic, siding and other finishing.

We insulate the walls of the house with penofol from the inside

To insulate walls from the inside, it is recommended to use penofol up to 5 mm thick. You should use a material with a one-sided foil element. If 5 mm of insulation is not enough, then it is better to additionally insulate the walls with polystyrene.

The installation principle consists of the following steps:

- First you need to measure the required size of insulation and cut it;

- Using a stapler, you need to attach the material to the wall. For a concrete wall, you can use glue or staples;

- The material should cover the entire surface of the wall;

- The joints of the sheets should be taped with adhesive tape;

- A frame made of slats or plywood is installed on top of the foam foam;

- Then, plasterboard or chipboard is installed.

After the entire room has been covered with plasterboard, you can additionally insulate the house from the outside using polystyrene foam.

Using penofol, you can insulate the walls of the house from the outside, but after installation, you will need to protect it by covering the walls with plastic or corrugated sheeting.

Using this material as insulation for your home, you can significantly reduce your heating costs, since the material copes well with its main purpose - saving heat.

Foil insulation for walls and floors

Foil insulation has relatively recently appeared on the construction market, but is rapidly gaining popularity for various reasons. Next, we will consider the types of this material, the advantages in comparison with traditional insulation and how to use it correctly.

What is rolled foil insulation

This is a combined material for insulating walls, floors and ceilings, consisting of several layers:

- Insulation made from familiar materials.

- A layer of foil.

The material is rolled, therefore it has a relatively small sheet thickness. How does heat retention occur?

- A thin working layer delays the penetration of cold air from outside,

- The foil reflects heated air into the room.

Varieties

Roll insulation materials are classified according to the main material:

- Foamed polyethylene with foil that can be attached on one or both sides.

- Folgoizol is created on the basis of bitumen/rubber, mineral fillers and antiseptic.

- Mineral wool rolls with one-sided foil surface.

- Basalt lamella insulation,

- Expanded polystyrene boards with one aluminum surface.

Each of the presented materials is intended for use in certain conditions.

Application

Penefol (closed cell polyethylene foam) is versatile in use. They insulate walls and floors in residential premises.

Foil insulation for pipes and roofing - foil insulation. It is also used in the construction of industrial facilities.

Rolls of mineral wool with an aluminum layer are used in the same way as conventional insulating mats: for insulating walls, floors and other structures. The difference between foil-coated mineral wool and regular wool is the built-in waterproofing; aluminum does not allow moisture to pass into the fibers, preventing the material from getting wet.

The ideal insulation foil for a bathhouse is based on basalt: it has a low heat transfer coefficient, is not afraid of humidity and large temperature changes. As you know, stone wool is a hard material. To roll it into a roll, the basalt is sawed into lamellas, which are laid on an aluminum base. This insulation is used to insulate various social and industrial facilities.

Foiled polystyrene foam is used for floor insulation.

All materials with a layer of aluminum foil have higher technical performance than their traditional form. The cost of foil insulation is an order of magnitude higher than the cost of conventional material; this is the main disadvantage of the “advanced” sample.

The first and most important question is which side to put the foil insulation on?

The first rule of installation: the reflective side should be directed towards the room. This will ensure natural heat reflection.

The structure of insulation and finishing must be thought out: in the case of walls, there must be an air gap between the insulation and subsequent finishing. When using a mineral wool base, it is necessary to insulate the material from the penetration of water; for this, a membrane is attached to the base, allowing steam to pass out.

How to attach foil insulation to a wall: roll out the insulator over the fixed membrane and fix it with guide rails, the thickness of which should exceed the thickness of the main insulation. The layers are connected with staples along the edges of the slats. Subsequent finishing of panels or lining is carried out along guides, which provide an air gap with their thickness.

Some craftsmen recommend protecting the foil with vapor-proof films to prevent moisture from entering the body of the mineral wool layer through possible holes in the metal.

For wooden and concrete floors, the algorithm of actions remains identical:

- The base is cleaned of old coatings, and debris is carefully swept away.

- Prime the subfloor with a concrete or wood primer.

- After the primer has dried, measure out the required amount of roll insulation and roll it out. It is optimal to use adhesive-based material. The strips are laid with an overlap of 10 cm, the joints are taped with aluminum tape.

- The finishing coating is laid on top.

If the room has an electric or water “warm” floor, the rolls are rolled out with the reflective side up, a reinforcing mesh is laid on top, then heating elements and a cement screed is produced followed by cladding.

Foil insulation for walls and floors

Let's look at the types of foil insulation, its advantages over traditional insulation, and how to use it correctly.

Features of foil insulation, some disadvantages and scope of application. How to properly install penofol with glue. The choice between penofol and basalt wool.

Varieties of penofol types

There are several types of foil penofol. Each of them is designed for a specific type of work.

- Type A - foil is applied to one side of the main surface, used as an additional material when insulating walls outside or inside a room, for insulating pipes.

- Type B - both sides of the base layer are covered with foil; it is used as the main insulating material for insulating partitions and ceilings between floors.

- Type C - one side is covered with foil, on the other there is a self-adhesive compound, on top of it there is a film that protects against gluing inside the roll, used in places that are difficult to get to and in poor conditions.

- Type ALP - penofol using a laminated layer, when polyethylene is glued on top of aluminum, used in agriculture for insulating cowsheds, chicken coops, and greenhouses.

- Type R and M - relief foil on one side.

- Super NET type - for isolating networks.

- Type AIR - for insulation of air ducts.

Penofol-2000 is found on the construction market, which has low technical characteristics and is especially inferior in strength.