Ventilation systems in any home perform an important function. Laying brick ventilation ducts solves one of the problems in ensuring the operation of such a system.

Ventilation ducts are designed to remove exhaust air from the room.

Depending on what the house is made of, the design of exhaust ventilation may be different. Many standard circuits and devices are offered in this direction. If the walls of the structure are brick, then laying ventilation ducts from brick suggests itself.

Device Features

Ventilation ducts are air ducts through which air moves due to the difference between external and internal pressure (natural ventilation), or the movement is set by a fan (forced ventilation).

Exhaust ventilation is made up of ventilation ducts (inside the wall or attached), closed with louver-type grilles, prefabricated air ducts located horizontally, and a shaft to provide exhaust. Stagnant air from the house is directed into the channel, bypassing the grille louvers, rises and accumulates in a horizontal air duct, from where it escapes out through the shaft exit. Inside, the air flow is controlled by a louver valve, and inside the duct and shaft by shut-off valves.

Living room ventilation diagram: 1 - exhaust grille, 2 - transom or window, 3 - ventilation duct.

In buildings with brick walls, ventilation ducts are installed inside the walls or in grooves covered with slabs.

The minimum size of brick ventilation ducts should be half the length of the brick (14x14 cm). The thickness of the channel partition should not be less than half a brick. Ventilation ducts are not formed in external load-bearing brick walls.

In cases where the house does not have internal brick walls, attached air ducts with a minimum size of 10x15 cm are installed. Such air ducts at normal humidity are usually made of gypsum slag and plasterboard boards, and at high humidity from concrete panels up to 40 mm thick. Sometimes air ducts are made of asbestos cement, metal sheets or plastic.

Horizontal air ducts located in attics or other rooms are made of gypsum slag panels up to 50 mm thick with an air gap of 40 mm or from hollow concrete slabs up to 10 cm thick.

Horizontal air ducts are installed on top of the ceiling covering by laying one row of slabs, then covered with a layer of cement more than 5 mm thick. The size of horizontal air ducts is at least 20x20 cm. Horizontal air ducts in rooms with high humidity (bathhouse, sauna) are made with a slope of 0.01 to the exhaust shaft.

Return to contents

Device requirements

The ventilation shaft is represented by a system through which air flows move in one of the existing ways:

- due to the difference in atmospheric pressure readings and a similar parameter in the room;

- due to a working fan device.

The ventilation system consists of ducts, louvres, horizontally located blowers, and shafts.

The principle of operation is this: air flows from the building are drawn into the channels, seep through the blinds, pass into the blower and are discharged out through the shaft. The flow is regulated by a grate and special locks.

In buildings built of brick material, ventilation is mounted in the walls or groove, hidden behind the slabs, and has a minimum size of half a brick (140 by 140 mm).

There is no ventilation passage in the load-bearing wall.

If the building does not have brick partitions, an overhead ventilation duct is installed, the dimensions of which are 100 by 150 mm. To construct such systems, plasterboard material or gypsum slag is used, and in rooms with high humidity, concrete is used. In addition, air ducts are made of plastic, metal and asbestos cement.

There are certain requirements that must be observed when installing a brick ventilation duct in a private house:

- when the shaft is located near the ridge, the exhaust hole is arranged above the upper mark by fifty centimeters;

- if the outlet is located away from the ridge, it is allowed to arrange it at the same level;

- when arranging a kitchen, the shaft is made one meter high;

- the height of the ventilation duct above the roof slab should be one meter. If necessary, this parameter is increased;

- at a lower temperature in the channel, the efficiency of the system decreases. To avoid this, a thermal insulation layer is installed.

Exhaust shaft system

The natural ventilation system shafts are installed on the roof of the house, similar to the chimney of a stove.

They can be an individual channel or have a channel combined with a ventilation one. Shafts with their own channel are made by brickwork with insulation with fiberboard or thickened frame insulation. Shafts of the second type are made of brick filled with heat-insulating and moisture-resistant material (foam plastic, foam glass, expanded clay, etc.) or with insulation from boards 40 mm thick, covered with roofing steel on top of a layer of felt (mineral wool), impregnated with clay mortar and plastered.

Determination of the height of exhaust shafts.

The height of the shaft above the roof must meet the following conditions:

- If it is placed near the ridge of the roof, the mouth of the shaft (exhaust hole) should be located above the ridge by more than 0.5 m. When removed from the ridge at a distance of 1.5-3 m, the mouth may be at the same level as the ridge. If it is up to the ridge more than 3 m, then the hole is located on the side of an angle of 10º to the horizon with the top at the ridge. In rooms where food is prepared, the height of the shaft should be at least 1 m. The height of the mouth above the roof in ordinary houses is taken to be about 1 m, and in the case strong emissions with a pungent odor (flare emissions) of at least 2 m. If there is a risk of very strong air pollution, the mine will have to be raised to a height of at least 3 m.

Return to contents

Requirements for ventilation ducts

One of the main requirements (according to the standard) for ventilation ducts is to provide exhaust at an external temperature of +12ºС and above, and an internal temperature of 20ºС.

Such devices must be installed in rooms without windows (bathrooms, bathrooms, etc.). The cross-section of the channel must be at least 0.016 m², and the wall thickness must be at least 100 mm.

Installation of ventilation ducts.

To reduce resistance to air flow, the cross-section of the channel along its length must be the same.

All brickwork seams must be smoothed. The length of all brick ventilation ducts that have access to one exhaust shaft must be equal. The ventilation duct must be vertical; deviation from the vertical is allowed no more than 30º.

A decrease in temperature in the shaft or prefabricated air ducts reduces the efficiency of ventilation, which necessitates the need to apply thermal insulation to them.

Laying brick ventilation ducts has some specific recommendations. Such channels are made with a brick wall thickness of up to 38 cm in one row, with a thickness of up to 64 cm in two rows.

Dimensions should be selected according to the power of the heat source. So, with a power of up to 3.5 kW, 14x14 cm is recommended, with a power of 3.5-5 kW 14x20 cm, with a power of more than 5 kW 14x27 cm. Brick laying is done vertically, at a distance from the door and the joint of the walls of at least 40 cm.

If a chimney duct is laid nearby, then between the chimney and the ventilation it is necessary to place reliable thermal insulation and increase the thickness of the duct wall.

Return to contents

Ventilation duct parameters

According to technical regulations, ventilation ducts must operate at an outside air temperature of 12 degrees and above 20 degrees indoors. Channels must be located in rooms where there are no windows (for example, bathrooms, toilets, etc.).

The minimum cross-section of the ventilation duct is 0.016 square meters. m, and the wall thickness is 100 mm. At the same time, in order to reduce resistance to air flows, the cross-section of the ventilation duct must be constant throughout its entire length. The seams on the brickwork should be smoothed. The length of all channels leading into a single exhaust shaft must be the same. The ventilation duct should be positioned vertically, although a maximum deviation of 30 degrees is allowed.

At low temperatures in the shaft or adjacent air ducts, the efficiency of the ventilation system is reduced. In this regard, the mine requires thermal insulation.

Insulation of the ventilation shaft

Separate specific recommendations are made for the brickwork of ventilation ducts. They are created in one row if the wall thickness is up to 38 cm, and in two rows if the thickness exceeds 64 cm. The dimensions of the channel depend on the power of the energy source. For example, for 3.5 kW the recommended size is 14x14 cm, and for power in the range of 3.5-5 kW - 14x20 cm. If the power of the heat source is above 5 kW, the recommended channel size is 14x27 cm. Brickwork is carried out vertically, the distance to the doors and wall joints should not be less than 40 cm.

Note! If there is a chimney in the immediate vicinity of the ventilation, thickening and thermal insulation on the walls of the duct will be required.

Necessary tool

Laying brick ventilation ducts with your own hands will require the following tools:

Bricklaying tools.

- trowel, grater, grater, spatula, chisel, hammer, chisel, mallet, level, plumb line, hacksaw, emery cloth, grinder, electric drill, grinder.

Brick ventilation ducts are laid using a template. The template is made of plywood or chipboard and has a square or rectangular cross-section equal to the cross-section of the channel. The length of the template is equal to 8-9 brick thicknesses.

Brick laying begins from the corner of the wall. The first channel is formed after laying 1.5-2 bricks.

The channel is formed using a template, which is installed strictly vertically along a plumb line. Between the channels, a distance equal to the width of the brick is established. The laying is carried out “end-to-end” with cutting of the mortar.

Linking is done between the rows of bricks, that is, the vertical seams in two adjacent rows are shifted by half a brick relative to each other.

Determining the readiness of the mortar for laying bricks.

The solution used is a regular cement-sand mixture in a ratio of 1:(3-4), thoroughly mixed in water. It is recommended to use cement grade M500. You can use the ready-made mixture for laying bricks.

Before laying, the brick is moistened. The mortar is applied to the surface of the masonry and the bottom of the brick. Every 6-7 rows the template moves.

If there is a need for a drain, it is done at a distance of no more than 100 cm. The angle of inclination of the drain channel should be no more than 30º to the wall surface.

The inclination of the outlet is achieved by grinding the brick at the desired angle. It is laid strictly horizontally. The cross-sections of the outlet and the main channel must match.

If there is a chimney next to the ventilation hole, then between them it is necessary to lay a continuous masonry with a width of at least 40 cm. When forming a wall with a chimney and ventilation, sand-lime brick should be used. The seam inside the ventilation device must be carefully smoothed and rubbed.

Upon completion of the wall laying, you should check the cleanliness of the channel; to do this, a ball with a diameter of about 100 mm is lowered into it on a cord for the entire length.

Return to contents

Tubular channel in a brick wall

A ventilation duct in a brick wall can be made from a pipe. Asbestos or plastic pipes with a diameter of 125-150 mm are used, and for forced ventilation 100-125 mm. The pipe is installed inside the brickwork strictly vertically and sealed with cement mortar.

For a thin brick partition (0.5 brick thick), using a pipe is the most acceptable method. In this case, the pipe is not located inside the masonry, but between two sections of the wall. The pipe is connected with mortar and thoroughly plastered.

Exhaust natural ventilation is a very important element of home improvement. When erecting brick walls, it is necessary to immediately provide ventilation ducts that can be placed inside the masonry. Otherwise, you will have to use overhead systems, which will spoil the appearance of the room.

Comments:

Rating: 94

To ensure constant ventilation of all rooms and maintain normal air temperature in the house, it is customary to install a ventilation system. If this important component is ignored during construction, there is a possibility of problems such as increased humidity, decreased fresh air, and even the formation of mold on the surface of the walls.

Design of ventilation ducts and air ducts: a - in brick walls; b - in the grooves of the wall, sealed with slabs; c - suspended air duct near the ceiling; g—added vertical channels; d - layout of channels with built-in cabinets; e - channels made of dry plaster in partitions; 1 - brick walls; 2 - plaster; 3 - gypsum slag slabs; 4 - overlap; 5 — steel suspension; 6 - fastening (50x50x4 mm).

Without the installation of ventilation ducts, any living space turns into a breeding ground for microbes that are harmful to the health of people living in the house. Modern household appliances emit harmful substances during their operation, so rooms with electrical appliances must be ventilated.

Today, most install plastic or aluminum windows with noise and heat insulation. Along with this, the problem of lack of proper ventilation arises, because old-style window frames were made of wood, which everywhere contains micro-slits that allow air to pass through. This ensured natural ventilation of any room with windows.

To solve the ventilation problem, you will need to install ventilation ducts in the living space. Moreover, the best solution would be to take them into account at the construction planning stage.

Today, ventilation shafts are most often made of metal-based material. But any experienced builder will advise making brickwork for the ventilation system.

For this reason, this classic scheme is widely in demand in the field of modern construction. Channels are usually located on the inside of the load-bearing walls of the building. The cross-section of smoke and ventilation ducts should be equal to 1 × 1/2 or 1/2 × 1/2 bricks.

Floor-by-floor section of ventilation ducts.

If the house is being built on a brick base, ventilation must be pre-designed in its walls. In this case, the most suitable building material is a solid brick, but if there are difficulties in purchasing it or there is not enough material, you can replace it with a brick for cladding or with an empty cavity.

It is not recommended to use silicate rocks, as they are not resistant to sudden temperature changes. Such building materials quickly wear out and begin to crack.

Tools, materials and accessories that will be needed to install ventilation ducts:

- solid brick; cement and sand; trowel and container for concrete mortar; building level and plumb lines.

Return to contents

Brickwork involves the use of identical mortar that was used in the construction of load-bearing walls on the inside. Its proportions are calculated as follows: for 1 kg of cement there are 3 kg of sand.

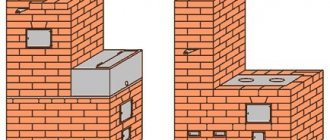

Laying chimneys and ventilation ducts: a) in walls 1.5 bricks thick; b) in walls 2 bricks thick. You should choose good quality sand, since low grades can significantly weaken the structure of the mortar, which will negatively affect the design of the ventilation ducts. When mixing, it is important to monitor the moisture level of the sand.

It is recommended to select high-quality cement M-500, as it has a plastic structure, which is most suitable for laying bricks in the interior of walls. Having mixed dry sand and cement well, you need to add water little by little and continue mixing. It is advisable to mix the solution inside a plastic trough until it reaches a medium degree of liquefaction. This can be easily determined by tilting the trough at a 40° angle. If the solution does not pour out, it means that the required consistency has been achieved.

In case of large volumes of mortar, it is advisable to mix it in a concrete mixer with an electric drive. The structural diagram of a brick-based ventilation system may differ depending on its purpose. The most popular and proven method is considered to be double brickwork with a vertical square stroke. Laying bricks: a – leveling the mortar; b - spreading the mortar on the brick. First of all, you will need to make approximate markings, which are made on the basis of a template. Then you need to build the masonry in 3-4 levels and place the buoys using plumbs (the bricks are located transversely inside the shaft). This is necessary to ensure proper design of channels in the ventilation system. In addition, they will prevent dirt from entering during the work being performed. In addition to the fact that the buoys strengthen the channel, they form a kind of barrier that greatly interferes with the process of cleaning the smoke channels.

Every 6-7 rows, the buoys must be moved, and the brickwork can be built according to the principle of multi-level or single-level connection of joints. The laying technology should be carried out closely, as this makes it possible to prevent the penetration of burning and smoke into living rooms or ventilation ducts located nearby. Return to contents Techniques for cutting and hewing bricks: e – cutting; g – incorrect cutting method; h – cutting with a trowel; and – chopping onto a spoon; k - teska. The main disadvantage of such a shaft is the release of heat, which goes away along with the smoke. But this can be partially prevented by making a deliberate bend inside the channel. It will help contain a certain part of the thermal energy inside the ventilation. To equip such a structure, you will need to build brickwork using the ladder method, fill the openings with concrete mortar and lay a brick on top of it edgewise.

After this, you need to lay 1 more row and thus press the masonry. At the point where the chimney exits onto the roof, you need to leave a space about 15 cm wide. The smoke shaft with the roof must be combined using a special frame based on stainless steel. If the smoke and fumes in the shaft will be cooled, this will inevitably lead to the formation of moisture inside it. The masonry will become covered with moisture, and the ventilation will lose its properties as an exhaust duct.

This can be prevented at the construction project stage. Thus, if the street temperature is 20 ° C most of the year, an interval of 1.5 bricks should be maintained between the masonry of the air duct and the outside of the wall. If the temperature is likely to drop down to -20°C, the interval will be 2 bricks. If the temperature drops to -30°C - 2.5 bricks. Unlike country houses with a vertical shaft, in high-rise buildings ventilation ducts are most often built with a slope that reaches 1 m. This masonry is carried out using hewn bricks, this allows to reduce the level resistance to smoke movement.

Once the brickwork is complete, a metal ball on a chain is lowered into the shaft. When resistance is identified, the point of contamination of the ventilation duct is determined. Ventilation ducts are now widespread, but the relevance of the brick version of the ventilation system has remained. This is facilitated by some of the advantages that brick ventilation ducts have: long service life, ease of maintenance, resistance to high temperatures.

Tubular channel

You can make a tubular ventilation shaft in a brick wall. To do this, use an asbestos or plastic pipe with a diameter of 12.5-15 cm, which is lined with brick. If the channel is needed for forced ventilation, then a tubular structure with a cross-section of 10-12.5 cm is suitable. The element is installed strictly vertically during the masonry of the wall, fixed with cement mortar.

The use of a tubular channel is justified in the case of half-brick brick partition devices. In this case, the pipe will come into contact with the masonry only on two sides. The visible part of the tubular element from the wall side is covered with mortar and subsequently plastered.

Ventilation system

The ventilation system channel is an air duct in which air movement occurs. There are two ways to force air masses to move in the desired direction: natural (the movement is initiated and maintained by the difference in pressure indoors and outdoors) and forced (the work is performed by an electric fan). Any classic ventilation system consists of:

- Ventilation ducts. Louver grilles. Horizontal air ducts. Shafts.

Schematically, the process looks like this: air masses from the room go into the channel, pass through the louvers, penetrate into the horizontal air duct and exit through the shaft outside the room. The speed of air movement can be adjusted by installed louvers and valves.

If the building is built of brick, then ventilation ducts are installed during the construction stage in the internal walls.

They cannot be smaller than half a brick (a square with a side of 14 centimeters). Ventilation ducts are not installed in load-bearing walls. In the case when the building does not have internal brick walls, the air ducts are made of overhead ones from different materials: concrete, metal, plastic and others.

Horizontally located air ducts are made of gypsum slag sheets or concrete slabs with holes. They are installed above the ceiling, covered with a cement screed. The cross-section of this type of duct must be more than twenty centimeters.

Exhaust type ventilation

The outlet of the natural ventilation shaft passes through the roof and looks like a chimney. There are mines that have their own channels, and others are combined with a ventilation one. The first option is implemented in the following ways:

- Insulation of the channel with fiberboard or other rigid material. The channel is protected by waterproof materials with good thermal insulation (expanded clay, polystyrene foam, foam glass and others). Insulation of the channel with a board 4 cm thick, galvanized. Felt with clay and covered with plaster is placed under the tree.

Criteria for good mine execution:

- If the shaft exit is located near the roof ridge, then its hood opening is located 0.5 meters or more above the ridge. If the distance from the ridge to the shaft is two to three meters, then they can be at the same height. When the hood mouth is removed from the ridge by a distance more than three meters, it should be placed according to the following scheme. The height should not be lower than a line drawn from the ridge at an angle of ten degrees to the horizontal. In the kitchen, the height of the shaft should be higher than one meter.

In most cases, a meter-long shaft is sufficient, but if the emissions have a bad odor, then a two-meter shaft is made. If there is a possibility of pollutants getting into the air, the shaft is increased to three meters.

Technical parameters of ventilation ducts

The ventilation system must operate at an outdoor temperature of at least twelve degrees, and a room temperature of at least twenty. The presence of ventilation ducts in rooms without windows (bathrooms, toilets) is mandatory.

The area of the channel opening should not be less than 0.016 square meters, and the channel wall should not be less than 10 centimeters. Resistance to air movement can be reduced by maintaining the cross-sectional area of the channel along its entire length. Brickwork must be made with smoothed seams.

Separate channels that lead into one shaft must be of the same length.

The deviation of the ventilation duct from the vertical is allowed at an angle not exceeding thirty degrees. Cold air in the shaft and adjacent air ducts leads to reduced draft. To prevent this, the mine must be insulated.

Recommended parameters for brickwork of ventilation ducts.

A single-row arrangement of channels is arranged with walls no thicker than 38 centimeters. Double-row placement is done with walls from 64 centimeters. The dimensions of the channel clearance are selected based on the power of the heating system:

- 3.5 kW - 14x14 centimeters. 3.5-5 kW - 14x20 centimeters. more than 5 kW - 14x27 centimeters.

The masonry is carried out vertically so that there is a distance of 0.4 meters to doorways and corners. If there is a chimney near the channel, then the walls of the channel are thickened and insulated.

Brick ventilation duct laying

Ventilation ducts are made using solid bricks.

In rare cases, facing and hollow are used. Existing voids in the material must be eliminated with clay or cement mortar. Sand-lime brick is not suitable for ventilation ducts due to its poor resistance to temperature changes. This causes it to crack and crumble, disabling the entire system.

The ventilation duct is laid using the same mortar as the internal walls. Prepare masonry mortar in the following proportion: one part cement (M500, but another can be used) and three parts sifted sand.

Debris and stones in the sand can make the solution worse. When calculating the amount of water, an adjustment is made for the moisture content of the sand. Add water gradually with good stirring.

There is a simple way to determine whether the solution is ready: it does not pour out when the container is tilted at an angle of 45 degrees.

It is easier to make a large volume of masonry mortar using an electric concrete mixer.

Usually the ventilation duct is laid out in 2 bricks; before starting work, markings are done using a plywood template. After several laid rows, buoys are placed (bricks laid in a plumb direction transverse to the channel). They protect the channel from debris and ensure correct geometry.

However, it is more difficult to clean the ventilation duct with them. The masonry is carried out independently with single-row or multi-row dressing. Laying end-to-end will help prevent smoke from escaping into the living space.

How to lay brick ventilation ducts

- Device Features

- Exhaust shaft system

- Requirements for ventilation ducts

- DIY brick laying process Necessary tools

Ventilation systems in any home perform an important function. Laying brick ventilation ducts solves one of the problems in ensuring the operation of such a system.

Ventilation ducts are designed to remove exhaust air from the room.

Depending on what the house is made of, the design of exhaust ventilation may be different. Many standard circuits and devices are offered in this direction. If the walls of the structure are brick, then laying ventilation ducts from brick suggests itself.

Ways to improve ventilation

Ventilation ducts in brickwork are not ideal; they have their drawbacks. Along with the air, a lot of heat escapes outside the building.

Heat loss can be reduced by bending the channel. The laying is done using a ladder, filling the niches with mortar. Next, the stones are laid edgewise, and a new row of bricks is laid on top.

Condensation will form inside the channel, which will lead to waterlogging of the bricks.

The consequence of this is a deterioration in traction. This can be prevented if you adhere to the requirements of SNiP. There should be the following distance from the chimney opening to the outer surface of the wall:

- one and a half bricks, if the temperature is 0...-20 degrees; two bricks, if the temperature is -20...-30 degrees; two and a half bricks, if the temperature is -30 degrees.

Houses several stories high have an inclined ventilation duct made of hewn brick to reduce resistance to air flow. After completing the work, it is recommended to determine the location of the blockage. This can be done with an iron ball having a diameter of 100 mm. At the height where the ball will experience maximum resistance and will be considered the location of the blockage.

Why is it needed?

Advantages

Building a house from scratch requires studying all the nuances. One of the controversial issues is the need to install a ventilation gap in the brickwork. The device has the following positive aspects:

- Drying. During the period of temperature difference inside and outside the room, condensation is observed on the outside of the main wall. Excessive humidity reduces the thermal insulation capabilities of the insulation and leads to destruction of the brickwork.

- Hiding surface imperfections. A small air gap between the wall and the cladding helps hide its unevenness without intervention.

- Keeping cool air inside the house in the summer. When the facing brick heats up to 90 °C, it begins to transfer heat not to the wall, but to the air cushion. This promotes the release of hot air into the atmosphere, rather than further transmission into the room.

Design flaws

Ventilation in masonry is a controversial issue. The argument that makes us think about the need for this device is heat loss in winter. Indeed, through the holes in the brick cladding, not only excess moisture, but also heat evaporates from the gap. To prevent strong cooling, it is recommended to make the supporting structure thicker. If the building material from which the wall is made does not lose its quality characteristics when wet, then there is no need to leave a gap. A ventilation gap must be made in the following cases:

- the use of insulation, which loses its ability when wet;

- high vapor permeability of the building material from which the inside of the wall is made;

- selection of facing material with high vapor barrier and moisture-condensing abilities.