Who wouldn’t want to reduce heating costs, especially in the face of constantly rising energy costs?

The simplest way to achieve this is to absorb solar heat, which can be consumed without any conversion.

Of course, in winter it comes to our latitudes in very meager quantities, but this should not be neglected. Moreover, to collect it you will need an extremely simple and cheap device that you can easily make yourself.

In this article we will talk about how to make an air solar collector with your own hands for heating a house - device, diagrams, designs.

Design and principle of operation of a solar collector

In its design, the solar collector is the opposite of the radiator of the heating system. If the walls of the radiator are heated by the coolant, then in the collector, on the contrary, the coolant is heated by the walls.

The walls themselves, in turn, heat up due to the absorption of solar heat (they are painted black), due to which this part of the collector is usually called an absorber.

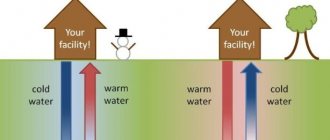

Solar system in an autonomous heating system

The absorber material must have high thermal conductivity, so at home it should be made of copper or aluminum. In factory-made collectors, the absorber is made of special alloys, which are characterized not only by high thermal conductivity, but also by low intensity of infrared radiation.

For obvious reasons, it is advisable to make the contact area of the coolant with the absorber as large as possible, so the latter is usually equipped with ribs or similar structural elements.

Alternative heating is used quite rarely, and many people wonder whether a solar collector is effective in winter. Types and expediency of its use.

Tips for making a solar collector with your own hands are presented here.

It makes sense to make a solar water heater with your own hands, if only because the energy obtained from its operation will be absolutely free. In this topic you will find instructions for making such a unit.

Technology

The canvas should always be installed on the south side. The size of the collector is chosen so that it heats the room well. That is, you need to take into account the dimensions, the diagram allows the difference. It goes without saying that this also depends on the size of the southern wall and the amount of money.

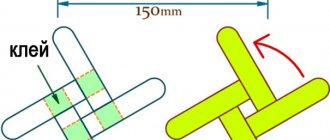

Wooden beam measuring 150 by 50 mm for making the frame of the air collector

First we make the frame of the device. To do this you will need a beam 150 by 50 mm. In principle, the upper part can be made from timber 200 by 50 mm, then you will get a visor. In the middle of the frame it is better to make an additional overlap or even several, depending on the size of the frame. This will increase the strength of the structure. If you plan to use a double-glazed window as a protective coating, then the frame must be reinforced.

The frame should be securely attached to the wall of the house with your own hands and all the cracks between them should be insulated with foam. The housing of the airborne solar collector must be sealed.

Then you need to make holes on the top and bottom of the wall inside the frame for air exchange. If the walls are made of boards or similar materials, this will be easy, but if the wall is brick, it will be more difficult. But still this must be done carefully.

In an air solar collector, the role of an absorber is played by a metal mesh. It can be a mesh, like a mosquito net, only made of metal, but much better results are obtained from an expanded metal or perforated sheet.

Perforated metal sheets for making absorber

Aluminum has high thermal conductivity, so it is best suited. In addition, the larger the area capable of receiving energy, the better the end result. Unfortunately, due to the high price, few people can afford it, so they usually make do with a metal mesh.

The surface must be coated with black paint, this will enhance the selective abilities of the absorber.

It is necessary to install valves on the upper openings through which warm air will enter the room; this is easy to do with your own hands. Otherwise, in cloudy weather, cold air will enter from the collector.

A piece of not too dense polyethylene is suitable as a valve. It is attached only to the top edge and warm air will be able to lift it, but cold air will not get through.

You need to install a fine mesh, preferably nylon, on the lower holes. It will protect the collector from dust getting inside, so it is better to install several layers. Dust must not be allowed to get inside the collector, because it will settle on the protective glass and worsen the efficiency of the device.

The nylon mesh will need to be changed from time to time with your own hands, because it will become clogged with dust and will no longer allow air to pass through. You can also wipe it down occasionally.

Transparent polycarbonate to install the protective layer of the air manifold

Then you need to install a transparent protective layer. This could be tempered glass, different types of polycarbonate, transparent slate, double glazing or something else. The main thing is not to forget that the solar collector box must be sealed and all cracks must be securely sealed. A double-glazed window is best, but it costs much more, but there are different types of more affordable polycarbonate.

Using this scheme, you can do it yourself by heating a chicken coop or any other outbuilding.

SolarVenti system

Separately, we need to remember the SolarVenti system. This is an air collector that works on the principle of ventilation. It is used in rooms where mustiness or mold may form. For example, basements, garages, cottages, construction sheds, boats, terraces, residential buildings and the like.

A distinctive feature of the SolarVenti system is that the fan does not require additional power supply, and the absorber is protected using polycarbonate.

As in conventional collectors, the absorber in SolarVenti collects energy from the sun's rays, but then the built-in photocell comes into action. It converts it into electricity, which turns on the fan. That is, even the operation of the fan occurs thanks to solar energy.

Air collectors using the SolarVenti system

Fresh air enters through many small holes on the back wall without the help of pipes. This ensures the necessary circulation. There is also a filter that prevents dirt from getting inside the SolarVenti. And such a collector uses the heat of the walls to increase the heating performance of the house. Typically some type of polycarbonate is used as a protective layer.

DIY solar air collector for heating: diagram

To avoid heat loss due to contact with street air, the absorber of a homemade collector is placed in a well-insulated wooden case, covered on top with transparent plastic (polycarbonate or plexiglass) or durable tempered glass.

For factory-made collectors, the absorber tubes are placed in evacuated flasks, so that the heat is stored in them, like in a thermos.

Solar collector assembly diagram

Both air and a liquid medium - water or antifreeze - can be used as a coolant. We will consider the air manifold, since it is easier to manufacture.

What can a solar system be made from?

First, you need to understand what operating principle a solar water heater uses. The internal structure of the block contains the following components:

- frame;

- absorber;

- a heat exchanger within which the coolant will circulate;

- reflectors to focus the sun's rays.

The factory solar water heating collector works as follows:

- Heat absorption - the sun's rays pass through the glass located on top of the body or through vacuum tubes. The internal absorbent layer in contact with the heat exchanger is painted with selective paint. When sunlight hits the absorber, a large amount of heat is released, which is collected and used to heat water.

- Heat transfer - the absorber is located in close contact with the heat exchanger. The heat accumulated by the absorber and transferred to the heat exchanger heats the liquid moving through the tubes to the coil inside the heat storage tank. Water circulation in the water heater is carried out by forced or natural means.

- DHW - two principles of heating hot water are used:

- Direct heating - hot water after heating is simply discharged into a thermally insulated container. In a monoblock solar system, ordinary household water is used as a coolant.

- The second option is to provide domestic hot water with a passive water heater based on the principle of indirect heating. The coolant (often antifreeze) is sent under pressure to the solar collector heat exchanger. After heating, the heated liquid is supplied to a storage tank, inside of which a coil (playing the role of a heating element) is built, surrounded by water for the hot water supply system. The coolant heats up the coil, thereby transferring heat to the water in the container. When the tap is opened, heated water from the heat-storing tank flows to the water collection point. The peculiarity of a solar system with indirect heating is its ability to operate throughout the year.

The operating principle used in expensive factory-made solar systems is copied and repeated in do-it-yourself collectors.

The working designs of solar water heaters have a similar structure. They are only made from scrap materials. There are schemes for the production of collectors from:

- polycarbonate;

- vacuum tubes;

- PET bottles;

- beer cans;

- refrigerator radiator;

- copper tubes;

- HDPE and PVC pipes.

Judging by the diagrams, modern “Kulibins” prefer homemade systems with natural circulation, thermosiphon type. The peculiarity of the solution is that the storage tank is located at the top point of the hot water supply system. Water circulates through the system by gravity and is supplied to the consumer.

Polycarbonate manifold

To make a solar system yourself, in particular a homemade solar water heater made of polycarbonate, you will need the following materials:

- two threaded rods;

- propylene corners, the fittings must have an external threaded connection;

- PVC plastic pipes: 2 pcs, length 1.5 m, diameter 32;

- 2 plugs.

The pipes are laid parallel to the housing. Connect to the hot water supply via shut-off valves. A thin cut is made along the pipe into which a sheet of polycarbonate can be inserted. Thanks to the thermosiphon principle, water will independently flow into the grooves (cells) of the sheet, heat up and go into the storage tank located at the top of the entire heating system. To seal and fix the sheets inserted into the pipe, thermally resistant silicone is used.

To increase the thermal efficiency of a cellular polycarbonate collector, the sheet is coated with any selective paint. Heating of water after applying selective coating accelerates approximately twice.

Vacuum tube manifold

In this case, it will not be possible to get by solely with improvised means. To make a solar collector you will have to buy vacuum tubes. They are sold by companies involved in the maintenance of solar systems and directly by manufacturers of solar water heaters.

For independent production, it is better to choose flasks with feather rods and a heat-pipe thermal channel. The tubes are easier to install and change if necessary.

You also need to purchase a concentrator block for a vacuum solar collector. When choosing, pay attention to the performance of the node (determined by the number of handsets that can be simultaneously connected to the device). The frame is made independently by assembling a wooden frame. Savings when manufacturing at home, taking into account the purchase of ready-made vacuum tubes, will be at least 50%.

Solar system made from plastic bottles

To prepare you will need about 30 pcs. PET bottles. When assembling, it is more convenient to use containers of the same size, 1 or 1.5 liters. At the preparatory stage, the labels are removed from the bottles and the surface is thoroughly washed. In addition to plastic containers, you will need the following:

- 12 m of hose for watering plants, diameter 20 mm;

- 8 T-adapters;

- 2 knees;

- roll of Teflon film;

- 2 ball valves.

When making solar collectors from plastic bottles, a hole is made at the bottom of the base equal to the diameter of the neck, into which a rubber hose or PVC pipe is inserted. The collector is assembled in 5 rows of 6 bottles on each line.

On a clear day, within 15 minutes. the water will heat up to a temperature of 45°C. Considering the high performance, it makes sense to connect a solar water heater made from plastic bottles to a storage tank of 200 liters. The latter is well insulated to prevent heat loss.

Aluminum beer can collector

Aluminum has good thermal characteristics. It is not surprising that metal is used to make heating radiators.

Aluminum cans can be used in the manufacture of homemade solar systems. Cans made of tin or any other metal are not suitable for production.

For one solar panel the following components will be needed:

- jars, about 15 pcs. per line, the body accommodates 10-15 rows;

- heat exchanger - a collector made of a rubber hose or plastic pipes is used;

- glue for gluing cans together;

- selective paint.

The surface of the cans is painted dark. The box is covered with thick glass or polycarbonate.

A solar collector made of aluminum cans is often made for air heating. When using water coolant, the thermal efficiency of the device decreases.

Solar system from the refrigerator

Another popular solution that requires minimal time and money. The solar collector is made from the radiator of an old refrigerator. The coil is already painted black. It is enough just to place the grille in a wooden case with insulation and connect it to the hot water supply using soldering.

There is an option for making an air conditioner from a condenser. To do this, several radiators are connected into a single network. If it is possible to purchase cheaply about 8 pcs. capacitors, manufacturing a collector is quite possible.

Copper tube collector

Copper has good thermal properties. In the manufacture of a copper solar collector, the following is used:

- pipes with a diameter of 1 1/4″, used in the installation of heating and hot water supply systems;

- 1/4″ pipes used in air conditioning systems;

- gas-burner;

- solder and flux.

The radiator grille body is assembled from copper pipes with a large diameter. Holes equal to 1/4″ are drilled into the surface. Pipes of the appropriate diameter are inserted into the resulting grooves. The radiator is covered with glass or polycarbonate. Copper is painted with selective paint.

Solar boiler made of HDPE pipes and PVC hoses

In the production of solar systems, almost any available material is used. There are solutions that allow you to make a collector from corrugated hose, a rubber hose used for watering plants.

It is possible to manufacture a solar collector from corrugated stainless pipe. The popularity of the solution is due to the speed and ease of installation. Corrugated stainless steel pipe is laid in rings or snakes. The disadvantage is the relative high cost of stainless corrugated pipe.

Making a solar hot water collector from PEX pipe:

All the pipes described are used with varying efficiency as a core in the manufacture of a homemade solar collector from plastic bottles and aluminum cans.

Determining the installation location and available space

The installation location of the collector must meet the following requirements:

- The device should be located as close as possible to the consumer, that is, the room into which the heated air enters.

- The panel should face as far as possible due south or as close to this direction as possible. In this case, it is highly desirable to position its surface at right angles to the sun’s rays, as a result of which losses due to reflection will be minimal.

- The location where the collector is installed should not be shaded by trees, pipes or buildings.

There are no restrictions regarding the choice of collector area: the larger it is, the higher its productivity will be and, accordingly, the lower the amount of heating bills will be.

Selecting a collector absorber design

It is proposed to make the absorber tubular, that is, consisting of several parallel tubes connected at the inlet and outlet by distribution combs.

In this case, for the manufacture of this part of the collector, you can use a very affordable and convenient material - aluminum cans for carbonated drinks.

They are ideal for this purpose, as they have a number of advantages:

- Aluminum, as already mentioned, has high thermal conductivity.

- The thin wall of the can can be easily cut with a regular knife.

- In the vast majority of cases, beverage cans have a standardized size (with a volume of 0.5 liters - 168x66 mm).

- For ease of storage and transportation, the cans are specially shaped so that they fit well together (the upper edge is narrowed to a diameter of 59 mm, and the bottom is given a concave shape).

- After consuming the contents of the can, they are usually thrown into the trash, so this material is absolutely free for the future owner of the collector.

Sometimes cans are made of steel. It is not difficult to identify such containers, since, unlike aluminum ones, they are attracted to a magnet. They should be discarded.

Before assembling the panel, be sure to wash the cans with detergent, otherwise the air passed through them will have an unpleasant odor.

How the collector works - it's simple

Any of the designs discussed in the article for converting solar energy into thermal energy has two main components - a heat exchanger and a light-collecting battery device. The second serves to capture solar rays, the first - to modify them into heat.

The most progressive collector is a vacuum one. In it, tube batteries are inserted into each other, and an airless space is formed between them. Essentially, we are dealing with a classic thermos. The vacuum manifold, due to its design, provides ideal thermal insulation of the device. The pipes in it, by the way, are cylindrical in shape. Therefore, the sun's rays hit them perpendicularly, which guarantees that the collector receives a large amount of energy.

Progressive vacuum devices

There are simpler devices - tubular and flat. The vacuum manifold surpasses them in all respects. Its only problem is the relatively high complexity of manufacturing. You can assemble such a device at home, but it will require a lot of effort.

The coolant in the solar heating collectors in question is water, which costs little, unlike any modern fuel, and does not emit carbon dioxide into the environment. A device for capturing and converting the rays of the Sun, which you can make yourself, with geometric parameters of 2x2 square meters, is capable of providing you with approximately 100 liters of warm water daily for 7–9 months. Large structures can also be used for heating a home.

If you want to make a collector for year-round use, you will need to install additional heat exchangers on it, two circuits with an antifreeze substance and increase its surface. Such devices will provide you with warmth in both sunny and cloudy weather.

Manufacturing of the collector body and its thermal insulation

The manifold proposed for production will consist of 8 tubes of 8 cans each. Moreover, its body will have dimensions of 1400x670 mm. To make all the elements of the box (case), you will need a sheet of plywood measuring 1525x1525x21 mm. The following parts need to be cut from it:

- Bottom size 1400x670 mm - 1 pc.

- Walls measuring 1400x116 mm - 2 pcs.

- Parts measuring 630x116 mm - 4 pieces (2 are used as walls, the other 2 as guides for cans).

The edges of the parts will most likely have to be processed, for which when marking you should leave an allowance of 3 to 5 mm.

Since the collector will be installed outside, all wooden parts must be treated with an antiseptic or painted.

Creating a collector

When assembling the box, the parts are fastened together using corners and some kind of screws, for example, furniture screws measuring 6.3x50 mm (they are called confirmats). The holes for installing such screws are made with a drill with a diameter of 4 mm.

Each part must be sealed with silicone sealant during assembly to ensure the box is airtight.

From the inside, the bottom and walls are covered with foam plastic 20 mm thick, and then with any foil thermal insulation (foil inward, that is, towards the absorber).

Manufacturing guides for the absorber

In each of the guides, using a crown, you need to drill 8 holes, the diameter of which corresponds to the diameter of the can. In this case, the jar should fit tightly enough into the hole.

The guides are installed on both sides of the box, and the absorber tubes are installed between them.

Thus, the cans in the tube are pressed against each other without any clamps.

Manufacturing of absorbers

We assemble the tubes as follows:

- The wall covering the top of the jar (in which there is a hole) is cut with metal scissors into “petals” that are bent inward. It is convenient to bend the “petals” by placing the can on a plastic pipe of the maximum possible diameter (so that it fits inside the can).

- In the bottom of each can, using a conical drill, you need to make 3 holes with a diameter of 20 mm, so that their centers are at the vertices of an equilateral triangle.

- Now you can collect tubes from the cans - 8 pieces each. in each. The joints of the cans should be sealed with high-temperature chimney sealant, for example, High Heat Mortar brand. This composition should be applied to a previously degreased and moistened surface. The composition is leveled with your fingers, wearing rubber gloves, which should also be moistened with water.

To ensure that the tubes are perfectly straight, when assembling the cans, they should be placed in a template made from two boards and shaped like an equal angle. It is installed at a slight angle to the vertical (you can lean it against the wall).

A weight must be placed on top of the newly assembled tube, located in the template, until the sealant is completely cured.

Airborne solar collector: design diagram

In order to make an air solar collector from materials that are available in any household, you need little.

You will need:

- Wooden boards, bars, plywood;

- Self-tapping screws, nails or other fasteners;

- Iron drink cans;

- Black paint;

- Glass.

First of all, you need to prepare a wooden box of the required dimensions (length x width). The depth of the box should be slightly larger than the diameter of the cans planned for use. The walls of the box can be fastened with self-tapping screws or any suitable fasteners. Then, at the top and bottom of the box, stepping back 10-15 centimeters from the top and bottom walls, you need to install shelves, along the entire length of which you need to drill holes for cans equal to their diameter.

It is necessary to cut holes in the cans by cutting off the neck and bottom, thus obtaining a through pipe, similar to a small air duct. You need to connect the cans by inserting the second into the empty bottom of the first can, the next one into it, and so on for the entire length of the box. Then insert the resulting pipe from the cans into the box through the holes drilled for this purpose. Thus, you need to fill the entire box with cans, not counting the space between the top wall and the top shelf into which the cans are attached, and the space between the bottom shelf and the bottom wall.

The junctions of the upper and lower shelves with the cans must be fastened with self-tapping screws, drilling the shelf together with the wall of the can. Air from the room will enter the space between the upper wall of the box and the upper shelf, for which it is necessary to provide holes, preferably a couple. Passing through the cans and heating up, the air will enter a similar space between the bottom shelf and the wall, from where it will flow back into the room through the holes; a fan will need to be provided here. Thus, a full process of air circulation and heating must occur.

The box itself and the installed cans need to be degreased and painted with matte black paint (you can use the cheapest) to create the impression of a single structure and increase the heating rate.

Assembly of an air solar collector

Having laid the tubes on a horizontal surface in the form of a battery, each of them is lubricated on one side with sealant and installed in the guide. On the other hand, a second guide is installed on the battery, also using sealant. Before the sealant hardens, the guides should be tightened with an elastic band. At this stage, the battery along with the guides on top should be painted with matte black paint.

Bonding aluminum cans for solar collector

Next, the assembled absorber is installed in the box. Before this, grooves for the guides should be cut in the foam. The space available on each side between the wall of the box and the guide will act as a distribution comb. At this point, holes should be cut in the bottom of the panel to connect the collector to the air ducts. The top of this space needs to be covered with plastic clapboard.

A sheet of transparent plastic (plexiglass made of polycarbonate or acrylic) is installed above the absorber, which is placed on the sealant and screwed to the walls with screws and a press washer.

How to make selective coating

A highly efficient collector has a high degree of solar energy absorption. The rays hit a dark surface and then heat it up. The less radiation is repelled from the solar collector absorber, the more heat remains in the solar system.

To ensure sufficient heat accumulation, it is necessary to create a selective coating. There are several production options:

- Homemade selective collector coating - use any black paints that leave a matte surface after drying. There are solutions when an opaque dark oilcloth is used as a collector absorber. Black enamel is applied to the heat exchanger pipes, the surface of cans and bottles, with a matte effect.

- Special absorbent coatings - you can go the other way by purchasing a special selective paint for the collector. Selective paints and varnishes contain polymer plasticizers and additives that provide good adhesion, heat resistance and a high degree of absorption of sunlight.

Solar systems used exclusively for heating water in summer can easily get by by painting the absorber black using regular paint. Homemade solar collectors for heating a house in winter must have a high-quality selective coating. You can't skimp on paint.

Homemade or factory solar system - which is better?

It is unrealistic to make a solar collector at home that can be compared with factory products in terms of technical characteristics and performance. On the other hand, if you simply need to provide enough water for a summer shower, solar energy will be enough to operate a simple homemade water heater.

As for liquid collectors operating in winter, not even all factory solar systems can operate at low temperatures. All-season systems are most often devices with vacuum heat pipes, with increased efficiency, capable of operating at temperatures down to –50°C.

Factory solar collectors are often equipped with a rotating mechanism that automatically adjusts the angle of inclination and direction of the panel to the cardinal points, depending on the location of the Sun.

An effective solar water heater is one that fully meets its intended purpose. To heat water for 2-3 people in the summer, you can get by with an ordinary solar collector, made with your own hands from improvised materials. For heating in winter, despite the initial costs, it is better to install a factory solar system.

Video course on making a panel solar water heater

Recently, alternative energy sources have attracted increasing interest from our compatriots.

The simplest of them in design are solar collectors, due to which their share in non-traditional energy, especially household energy, is extremely large.

This article will introduce the reader to their varieties, and will also help to find the answer to the question: how effective is a solar collector in winter?

Connection

The collector is fixed to the roof using a bracket and connected to two air ducts leading into the room. A fan with a capacity of about 150 cubic meters should be installed on the inlet air duct. m/h.

Factory-made solar panels are very expensive, and they will not pay off soon. Do-it-yourself solar panels are much cheaper to manufacture, and assembling the structure is not so difficult.

Types of solar panels for home heating are presented in this review. And also about the pros and cons of each option.