The lining is the fence that separates the combustion chamber and gas ducts from the environment. The purpose of the lining is to reduce heat loss from gases and prevent air from being sucked into the boiler flues.

According to operating conditions, the temperature of the outer surface should not exceed 50 °C. Only in some places elevated temperatures of up to 70 °C are allowed.

There are three main types of lining construction for steam boilers:

Within each type there are a large number of design solutions.

Heavy lining is used in unshielded or weakly shielded low-power boilers. In the firebox area, the temperature in the boiler lining should drop from 1200-1300 °C to 50-70 °C, so the lining should be thick. For it, fire-resistant fireclay bricks are used (the inner surface is laid out with a thickness of 1 brick) and red brick (the outer part is 2-3 bricks thick). Both bricks conduct heat relatively well, so the thickness of the lining reaches 750-1000 mm. The bricks are tied together in the masonry. To ensure freedom of thermal expansion in the corners, vertical expansion joints are left along the entire height of the lining, which are sealed with asbestos.

Heavy type lining is usually performed independently of the frame of the boiler pipe system. In this case, it rests freely on the boiler foundation. Sometimes the lining is divided into belts according to height. The lower belt is supported on the foundation, and the upper ones are supported by horizontal beams on the boiler frame.

Heavy lining is simple in design, but weighs 1000-1200 kg per

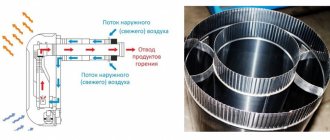

In modern boiler designs, the combustion chamber is heavily shielded, so the temperature of the lining wall facing the firebox is 500-600 °C. This allows for easier installation. The so-called lightweight lining was created (Fig. 17.4).

Rice. 17.4. Supporting the lining on a steel bracket:

1 – steel bracket; 2 – shaped fireclay bricks; 3 – asbestos cord with a diameter of 25 mm; 4 – casing; 5 – expansion joint 12 mm

Lightweight lining is divided in height into a number of belts 1000-1500 mm high. Each belt rests on the frame through intermediate brackets and beams. Thus, the entire lining is supported on the boiler frame. The total thickness of the lining is one brick (250 mm).

Inside the firebox to the pipes there is red brick (1L bricks), outside there is diatomaceous earth brick (Vi bricks), which is a good insulator. The density of the lining is achieved by covering the entire outer surface of the boiler with an iron sheet 2-3 mm thick. There is an air gap of 5-10 mm between the sheathing and the diatomaceous brick. Sometimes lightweight lining is made in the form of slabs (thermal insulating) 100-150 mm thick.

Instead of diatomaceous earth bricks, the following can be used: sovelite, vermiculite, slag wool, etc. The weight of 1 m2 of lightweight lining reaches 400 kg.

Further development of the design led to the creation of pipe lining (Fig. 17.5). The pipe lining consists of several layers of heat-insulating mass. Carbon steel rods with a diameter of 10-12 mm are welded to the pipes at a certain distance from each other, to which corrugated wire and mesh are attached. First, the gaps between the pipes are filled with chromite mass. This forms the first layer 40mm thick. The wavy wire ends up inside the layer. Then a wire mesh (3 mm with a mesh size of 20 mm) is stretched and a second layer of thermal insulation 50 mm thick is applied. This layer is made of lightweight concrete. Next, sovelite slabs are laid and the mesh is reinforced. The thickness of the third layer is 50 mm. On the outside, a gas-tight elastic coating is applied to the mesh. The coating consists of asbestos, clay, tar and mineral oil.

Rice. 17.5. Pipe lining of the combustion chamber walls of a steam generator with natural circulation:

1 – screen pipes; 2 – lowering pipes; 3 and 8 – metal mesh; 4 – shotcrete mass; 5 – pin; 6 – high-temperature insulating mass; 7 – asbestos-cement slabs; 8 - ; 9 – sealing plaster

If there are spikes on the screens, you can do without corrugated wire. One of the pipe lining designs is described. Many different modifications are known.

The pipe lining is not connected to the frame. To create rigidity along the height of the firebox, the pipes are covered in several places with rolled belts.

With pipe lining, it is possible to reduce the wall thickness to 130-180 mm and increase the weight to 120-200 kg/m.”

The cost of pipe lining is 2-2.5 times less compared to lightweight lining. In addition, the boiler casing is missing.

Thermal insulation materials must have low thermal conductivity, light weight, sufficient mechanical strength, and must also be cheap.

The greater the porosity of the material, the lighter it is, the higher its thermal insulation properties, but the less durable it is. The following thermal insulation materials are used.

Asbestos is introduced into the composition of thermal insulation material in order to increase strength and reduce thermal conductivity. As the temperature rises, asbestos loses bound moisture, causing its strength to decrease. At t = 600°, moisture is completely lost and asbestos turns into powder. Made from asbestos

Cord, cardboard and fabric are molded; asbestos-cement boards are used for insulation at temperatures up to 450 °C.

Diatomite is a sedimentary rock (mostly silica). It has a slightly porous structure. They are used in the form of powder (backfill) at temperatures up to 900-1000 °C, but more often at lower temperatures due to low insulating properties.

Asbozurite - prepared from a mixture of dolomite and asbestos with a small additive to bind lime or cement and water. Apply up to a temperature of 450 °C. Used in the form of mastic or slabs.

Newvel - prepared from a mixture of magnesite (85%) with asbestos (15%), used in the form of mastic up to t = 350 °C. When fired, magnesite (MgCO^) releases CCb and a powder remains - magnesia.

Sovelite - consists of a mixture of burnt dolomite (MgCCb • CaCO3) with asbestos. Used in the form of slabs up to a temperature of 500 ° C, it has the same heat-insulating properties as Newvel.

Diatomaceous earth brick - made from diatomaceous earth and sawdust. When fired, sawdust burns out and creates pores.

The porosity of some heat-insulating materials is achieved by swelling of the product due to the release of vapors when heated. Foam glass is made in this way - from a mixture of glass and coal powders. Well amenable to mechanical processing at a temperature of 30 °C, 5 = 0.5 kJ/m • h deg.

Zonolite is a porous material obtained by heating vermiculite (a type of mica). In this case, the volume of mica increases 20 times. Use directly up to a temperature of 1000 °C.

Burnt vermiculite mixed with asbestos and related substances is used to make slabs that can be used up to temperatures of 600 °C.

Mineral wool (glass wool, slag wool) - used up to a temperature of 600 ° C in the form of mats, felt, slabs, etc.

Refractory and thermally insulating concretes contain hydraulically hardening substances (cements) and aggregates (refractory and insulating materials).

Chamotte concrete is most suitable for lining steam boilers. The cements used are: Portland cement (better), aluminous cement (worse) and other grades not lower than 300. Filler - fireclay powder and crushed grain (also fireclay).

For lining boilers, refractory concrete grades 100-300 are used (compressive strength, kg/cm3). The permissible temperature of refractory concrete depends on the composition and is 1100-1300 °C.

Varieties

The main purpose of the protective layer is to reduce the level of heat loss and the risk of burns for workers, and energy costs are also reduced. Particular attention is paid to the materials used to create the lining and the technology of formation. There are several basic schemes, each of which is selected individually and has a high level of efficiency:

- The pipe lining of the boiler consists of lightweight concrete, characterized by thermal insulation characteristics. The outer layer is made using chromite mass and special plates.

- The frame scheme consists of three layers: mineral wool, diatomaceous earth concrete and chamotte concrete.

- Heavy has a limited scope and is only suitable for boiler rooms with a maximum temperature level within 800 degrees. The outer layer is red brick, the inner layer is made of refractory bricks.

Carrying out work on sealing joints of block linings.

- Before carrying out work on sealing the lining joints between the screen blocks, the correct installation of the latter must be checked.

- The edges of the mesh located in the clay concrete layer of adjacent screen blocks (width no more than 300 mm) must be sewn together with annealed wire with a diameter of 1.6-2.0 mm.

- Before concreting the lining joint, the previously laid concrete must be cleared and moistened.

- When concreting joints, for the convenience of applying chamotte concrete, it is allowed to add fireclay to its composition in an amount of up to 5%

- After installing mineral wool mats, mesh stitching must be carried out taking into account the requirements of clause 7.2

- The joints of the pipe lining of the front and side screen blocks in the area of the floor and ceiling must be carried out especially carefully.

- Concrete placed at the joints of the lining must be thoroughly compacted.

Peculiarities

The lining of hot water boilers is a labor-intensive process that requires adherence to technology and competent selection of materials. Stuffing compounds are produced on a corundum, carbundum or chromite base. Liquid glass often acts as a binding base. The amount of mass produced depends on the surface requiring processing and the required thickness.

The composition applied to the surface is covered with a special mesh made of fire-resistant material. The sealing coating is made with magnesite, asbestos or fireclay powder. It is worth noting that coating can be carried out if the mass has not yet hardened.

Thermal insulation of the external elements of the boiler.

- Thermal insulation of ash bins, gas boxes, air heaters, etc. made from heat-insulating mats with a total thickness of 80-100 mm. plastered with asbestos-cement plaster. It is allowed to pack thermal insulation material under the mesh.

- To attach thermal insulation to the insulated surface, pins 120-150 mm long are welded. Ø6mm. according to GOST 2590-88 with a pitch of 450 mm. After installing the thermal insulation and tensioning the mesh, the pins are bent.

- Descent, recirculation, bypass, steam removal pipelines and shot traps are insulated by packing thermal insulating wool under the mesh. Insulation with heat-insulating mats is allowed.

- After leveling the surface, asbestos-cement or other plaster with a thickness of 10-12 mm is applied to the heat-insulating layer.

- The finished plastered insulation must be even and smooth and firmly adhere to the insulated surface.

- Pasting and painting of the insulation is done after it has completely dried.

What you need to know

Basalt fiber, which is highly resistant to temperature, is used to form thermal insulation boards.

In some cases, partial lining of the boiler becomes more rational. Reducing thermal energy losses and ensuring the safety of operating personnel is possible by treating the doors of the structure. In this case, it is necessary to pay attention to the temperature distribution during cooling.

Repair of boiler linings begins with dismantling the piping, while it is advisable to preserve the base of the structure for future use. If there are uneven areas on the screens and pipes, you can apply a layer of thermal insulation. The service life of the structure can be increased due to aluminum coloring compounds used as a finishing coating.

DKVR.ru

The lining and thermal insulation materials of the boiler and boiler equipment require special attention, since in some boiler units these materials are not included in the cost of the boiler unit and related equipment; in the former, this position has a separate line of financing; in the latter, it is included in the installation materials. So it’s worth dwelling on this issue in more detail. Let's begin. Boilers of any group have two types of lining - light and heavy. The first includes the entire range of boilers and works almost anywhere and everywhere, but no one has canceled the front and rear parts of the boiler, as well as the under and concrete lining, and of course no one will exclude from attention the contact of the foundation with the metal part of the light lining of the boiler. Some manufacturers, especially those from the foreign boiler industry, deny this fact, but physics and chemistry tell a completely different story. Here is an example of the difference between a boiler unit in light lining and the boiler block itself:

Boiler DE-16-14GMO in light lining and boiler block DE - 16-14GM

Boilers of this series include front and rear walls made of monolithic slabs. In the boiler units of the next series, these elements are made by laying heavy lining elements.

In particularly difficult areas, heavy lining of boilers is used. This also applies to multi-fuel boilers of the DKVR series.

Thermal insulation and lining materials for boilers of the DKVR series.

| Brand/material | DKVR-2.5 | DKVR-4 | DKVR-6.5 | DKVR-10 | DKVR-20 |

| Brick og. ShB-5 | 3500 UAH 5500GM | 4000 UAH 6000GM | 5000 UAH 6000GM | 10000 UAH 12000GM | 10000 UAH 12000GM |

| Brick class. ShB-5 | 200 pcs. | 250 pcs. | 300 pcs | 350 pcs. | 200 pcs. |

| Brick single | 8500 pcs. | 10000 pcs. | 15000 pcs. | 20000 pcs. | 3500 pcs. |

| Mertel | 1 t. | 1.2 t. | 1.5 t. | 2 t. | 2 t. |

| Large fireclay | 1 t. GM | 1 t. GM | 1 t. GM | 1 t. GM | 1.5 t. GM |

| Asbestos fluff | 300 kg. | 400 kg. | 500 kg. | 1000 kg. | 1500 kg. |

| Asbestos sheets | 50 sheets | 70 sheets | 100 sheets | 100 sheets | 100 sheets |

| Asbestos cord | 4 coils (D 25-30 mm.) | 4 coils (D 25-30 mm.) | 5 coils (D 25-30 mm.) | 6 coils (D 25-30 mm.) | 5 coils (D 25-30 mm.) |

| Fireproof cotton wool MCRR | 80 bales | 100 bales | 150 bales | 200 bales | 200 bales |

| Rabitz | 2 rolls (cell 20*20) | 2 rolls (cell 20*20) | 3 rolls (cell 20*20) | 3 rolls (cell 20*20) | 1 roll (cell 20*20) |

| Metal b=2mm. 2500*1250 | 20 sheets (easy to exchange) | 20 sheets (easy to exchange) | 30 sheets (easy exchange) | 40 sheets (easy exchange) | 50 sheets (easy exchange) |

| Metal b=1mm. 2500*1250 | 2 sheets GM | 2 sheets GM | 2 sheets GM | 2 sheets GM | 2 sheets GM |

| Alumina cement. | 200 kg. | 200 kg. | 200 kg. | 200 kg. | 200 kg. |

| Liquid glass | 50 liters | 50 liters | 70 liters | 100 liters | 100 liters |

| Portland cement | 100 kg. | 100 kg. | 150 kg. | 200 kg. | 200 kg. |

| Clay og. oroshka | 2 t. (heavy exchange) | 2 t. (heavy exchange) | 3 tons (heavy load) | 5 tons (heavy load) | 1 t. |

| Sifted sand | 10 tons (heavy load) | 10 tons (heavy load) | 14 tons (heavy weight) | 20 tons (heavy load) | 3 t. |

Thermal insulation and lining materials for boilers of the KE series.

| Brand/material | KE-2.5 | KE-4 | KE-6.5 | KE-10 | KE-25 |

| Brick og. ShB-5 | 4000 UAH 6000GM | 5000 UAH 7000GM | 6000 UAH 8000GM | 8000 UAH 10000GM | 10000 UAH 12000GM |

| Brick class. ShB-5 | 200 pcs. | 200 pcs. | 200 pcs | 250 pcs. | 350 pcs. |

| Brick single | 1000 pcs. | 10000 pcs. | 15000 pcs. | 20000 pcs. | 3500 pcs. |

| Mertel | 1 t. | 1 t. | 1.5 t. | 2 t. | 2 t. |

| Large fireclay | 1 t. | 1 t. | 1 t. | 1 t. | 1.5 t. |

| Asbestos fluff | 300 kg. | 350 kg. | 400 kg. | 450 kg. | 1000 kg. |

| Asbestos sheets | 40 sheets | 50 sheets | 60 sheets | 80 sheets | 100 sheets |

| Asbestos cord | 4 coils (D 25-30 mm.) | 4 coils (D 25-30 mm.) | 5 coils (D 25-30 mm.) | 6 coils (D 25-30 mm.) | 6 coils (D 25-30 mm.) |

| Fireproof cotton wool MCRR | 100 bales | 100 bales | 120 bales | 150 bales | 200 bales |

| Rabitz | 2 rolls (cell 20*20) | 2 rolls (cell 20*20) | 3 rolls (cell 20*20) | 3 rolls (cell 20*20) | 2 rolls (cell 20*20) |

| Metal b=2mm. 2500*1250 | 20 sheets (easy to exchange) | 20 sheets (easy to exchange) | 30 sheets (easy exchange) | 35 sheets (easy exchange) | 50 sheets (easy exchange) |

| Metal b=1mm. 2500*1250 | 2 sheets GM | 2 sheets GM | 2 sheets GM | 2 sheets GM | 2 sheets GM |

| Alumina cement. | 200 kg. | 200 kg. | 200 kg. | 200 kg. | 300 kg. |

| Liquid glass | 50 liters | 60 liters | 70 liters | 80 liters | 100 liters |

| Portland cement | 100 kg. | 100 kg. | 100 kg. | 150 kg. | 200 kg. |

| Clay og. oroshka | 500 kg. | 500 kg. | 1000 kg. | 1000 kg. | 1500 kg. |

| Sifted sand | 2 t. | 2 t. | 3 t. | 4 t. | 5 t. |

Thermal insulation and lining materials for DE series boilers.

| Brand/material | DE-4 | DE-6.5 | DE-10 | DE-16 | DE-25 |

| Brick og. ShB-5 | 1500 pcs. | 1500 pcs. | 1700 pcs. | 2000 pcs. | 2000 pcs. |

| Brick class. ShB-5 | 150 pcs. | 150 pcs. | 200 pcs | 250 pcs. | 350 pcs. |

| Mertel | 300 kg. | 300 kg. | 350 kg. | 400 kg. | 450 kg. |

| Large fireclay | 500 kg. | 500 kg. | 700 kg. | 1000 kg. | 1000 kg. |

| Asbestos fluff | 250 kg. | 250 kg. | 350 kg. | 500 kg. | 500 kg. |

| Asbestos sheets | 50 sheets | 60 sheets | 80 sheets | 90 sheets | 100 sheets |

| Asbestos cord | 2 coils (D 25-30 mm.) | 3 coils (D 25-30 mm.) | 4 coils (D 25-30 mm.) | 5 coils (D 25-30 mm.) | 6 coils (D 25-30 mm.) |

| Fireproof cotton wool MCRR | 48 bales | 60 bales | 80 bales | 100 bales | 120 bales |

| Rabitz | 1 roll (cell 20*20) | 1 roll (cell 20*20) | 2 rolls (cell 20*20) | 2 rolls (cell 20*20) | 2 rolls (cell 20*20) |

| Metal b=2mm. 2500*1250 | 12 sheets (easy to exchange) | 15 sheets (easy to exchange) | 20 sheets (easy to exchange) | 25 sheets (easy to exchange) | 30 sheets (easy exchange) |

| Alumina cement. | 250 kg. | 250 kg. | 350 kg. | 500 kg. | 500 kg. |

| Liquid glass | 25 liters | 25 liters | 35 liters | 50 liters | 50 liters |

| Clay og. oroshka | 50 kg. | 50 kg. | 70 kg. | 100 kg. | 100 kg. |

Attention: for more detailed technical characteristics and parameters, see here - PRODUCT RANGE.

Boilers “DKVR”

Systems of this series are designed to provide heated water and heat supply. They produce saturated steam and are often used in ventilation systems. The design has distinctive features in the form of vertically placed pipes and two drums. Boilers of this brand have many positive aspects:

- wide power range;

- use of any type of energy carrier, including fuel oil and gas;

- automated operation of the system;

- assembly of the structure can be carried out in the boiler room, without the need to dismantle the walls;

- lining of DKVR boilers is made from any materials suitable for the intended operating mode;

- the reliability of the aerodynamic and hydraulic system ensures a high level of efficiency.

Features of the production of lining works on certain types of boilers.

- On KV-GM-10,20,30-150 boilers, the lining of the front screen is heavy, the front wall is made of fireclay bricks. The thickness of the lining is 260 mm. The under is made of fireclay bricks in two rows. Fireclay bricks are laid on top of a foundation made of ordinary bricks. In this case, in accordance with the requirements of the drawing, the angle of inclination of the hearth and the gap between the screen pipes and the brick must be maintained. The interpipe space of the intermediate screen is filled with fireclay bricks. The front wall of KV-TS boilers is made of fireclay bricks. The embrasures of the throwers and pre-fireboxes are lined according to the drawings of the manufacturer of the TLZM and TCZM fireboxes.

- The design of the lining of gas-tight screens of boilers operating under pressurization differs in that chamotte concrete is not applied to the screen surfaces, but only thermal insulation is installed. Wire pins Ø6-8 mm are welded to the fins of the screens. GOST 2590-88 with a pitch of 350-450 mm.

- Mineral wool mats with a total thickness of 160 mm are pinned onto the pins. or a mesh is installed and sheathing is done with a metal sheet or coating on the mesh.

- In places where there are no fins between the pipes, pipe panels and risers are sheathed with a metal sheet 1.5-2.0 mm thick. to ensure gas tightness, then, in accordance with the requirements of the drawing, pins are welded at the junction of the sheet to the pipes or directly to the pipes.

Boiler lining: technology

A mandatory step before lining is a hydraulic test of boilers. Next, the lining of the boiler surface and external cladding are performed. The materials used for lining must have fire-resistant properties, and it is also necessary to carefully sift fireclay powder, sand and clay before use. Cement, refractory and red clay should not contain foreign inclusions, lumps and small debris.

Before starting work, it is necessary to prepare a refractory mixture, tools and bricks of the same size. Each row of masonry must be checked with a building level to prevent the formation of depressions and bulges. You can check the quality of the corners using a steel square. As it becomes clear, the lining of steam boilers is a rather complex process that requires compliance with all norms and rules, so the work can only be undertaken if you have the knowledge and relevant experience. In most cases, it is better to contact specialists, since even a minor mistake can lead to serious consequences in the future.

Description of the unit

The DKVR-20-13 steam boiler consists of several main structural elements: an upper short drum and a lower, shielded combustion chamber, which was mentioned earlier. Next, it’s worth taking a closer look at this unit and some of its parts.

The DKVR-20-13 device has a feature that the combustion chamber is divided into two parts: the firebox itself, as well as the afterburning chamber. This chamber is separated from the firebox by the rear boiler screen. Hot gases are supplied to the boiling tubes of the device by direct current and across the entire width of the beam. There are no barriers in their way. However, in the case of additional installation of a superheater on the DKVR-20-13 boiler, some of these pipes may not be installed. The superheater itself will consist of a pair of packages. They will be located on different sides of the boiler. After exhaustion, superheated steam from both packages will be discharged into a special collection manifold. The design of the DKVR-20-13 unit uses feed water, which will be supplied to the upper drum. Now about him.

Peculiarities

The insulating layer must be free of cracks and chips. Before laying refractory fireclay bricks, they are sorted; the material must be of the same size without damage. The use of broken or cracked bricks is strictly prohibited, as this significantly reduces the strength of the structure. Rough edges also reduce the tightness of seams.

Solution

The mixture used for masonry is no less important. It should have a uniform structure without inclusions. A solution based on clay and fireclay powder is suitable for laying fireclay bricks. The degree of fat content of the clay determines the amount of powder. It is worth noting that salt and river sand cannot be added to the composition, despite the fact that such ingredients are often found in mortars for laying stoves.

The thickness of the mixture during complex lining should be within 2 mm; with conventional masonry, an increase of up to 3 mm is allowed. The result obtained directly depends on maintaining the proportions of the ingredients and thorough mixing. The consistency should be medium thick. The solution is mixed only with clean water, this guarantees the absence of lime and other impurities. It is recommended to prepare the composition in a separate, pre-cleaned container.

Front screen operation

The operating instructions for the DKVR-20-13 boiler are attached to each unit and contain all the necessary instructions for using the unit, caring for it and carrying out maintenance. However, you should familiarize yourself with the operation of some parts in more detail.

In the front screen, water circulates along the circuit. The lower collector of this screen belongs to the first evaporation stage. It is fed with water from the upper drum through two overflow pipes. During operation of the unit, not all water evaporates. Unevaporated liquid will also flow into this manifold from the upper drum. For this purpose there are four special downpipes. Next, there are lifting pipes in the structure, through which the liquid will move upward from the lower collector. It will heat up, turning into a steam-water mixture, after which it will be fed into the upper collector.

Water heating boiler lining: description

Before starting work, all used elements must be cleaned of solution drops, corrosion and dirt. The connection points of the reinforcement are connected with wire with a diameter of about 2 mm or welded using electric welding. The use of aluminum and copper wire is undesirable.

Bitumen is applied in an even layer to the reinforcement and fixing elements necessary to strengthen the concrete.

Coniferous wood is used to make formwork, with the exception of larch. The sides adjacent to the concrete mortar are carefully processed and planed. It is possible to use paper or clay with high plasticity to seal cracks in the formwork. Double formwork is suitable for lining a vertical surface or one located at an angle of at least 40 degrees. It is recommended to coat the wooden surface with a lubricant to avoid adhesion to the concrete. A solution consisting of water and mineral oil can be used as a lubricant.

Furnaces and boilers in industry today remain indispensable objects, so there is often a need to repair and modernize such structures. In addition, the boiler must be lined and, if necessary, damaged elements must be replaced.

Preparation and application of sealing plaster.

- The surface of the heat-insulating layer of the lining is plastered with sealing magnesium coating. Replacement with asbestos-diatom plaster, ORGRES coating and asbestos-cement plaster is allowed.

- Fluffed asbestos used for preparing sealing plasters must be dry. If there are caked lumps and foreign inclusions, asbestos must be sifted.

- When preparing a solution of magnesium chloride from a crystalline product, the latter is dissolved in warm water to obtain a solution with a specific gravity of 1.2-1.25 g/cm².

- Plastic refractory clay must be dried, ground and sifted.

- Before applying sealing plasters, the mesh must be carefully tensioned and secured, and the mesh itself must be cleaned of debris, dirt, etc.

- The plaster is poured onto the mesh in small portions, and then carefully compacted and leveled. Magnesia plaster should be applied immediately to the entire thickness of the layer. It is advisable to apply asbestos-cement plaster in two or three layers, carefully punching it behind the mesh. When applying plaster, the same layer thickness must be maintained.

- If cracks appear in hardened plaster, its surface is rubbed over with a thin layer of plaster of the same composition.

- After drying the sealing plaster, its surface is pasted over (it is advisable to use calico with an adhesive composition of liquid glass and refractory clay) followed by coating with aluminum paint AL-177.

- Work on applying magnesium plaster is allowed to be carried out at an ambient temperature of not lower than +10ºС, and of asbestos-diatom plaster not lower than +5ºС.

- Wetting of sealing plasters by atmospheric precipitation during their hardening is not allowed.

- Sealing plasters are applied after the lining has completely dried.