As of June 2021, the NST company serially produces and sells 2 high-pressure stations for spraying polyurethane foam and polyurea:

- PENA-VD18 UM-K1-39/380V

- PENA-VD18 UM-K1-39ro/380V

From April 2021, the production of 220V dispensers has been discontinued, because... In terms of characteristics, such devices are inferior to standard 380V equipment. The reasons why 220V HP equipment cannot be identical to 380V HP dispensers are set out in a separate article on the website poliuretan.ru (link below).

If you have a limited budget, or if the equipment is not intended to be used professionally and often, we recommend purchasing one of the low-pressure PENA devices. The range of all NST installations is presented on poliuretan.ru here.

In the following photos you can observe the transformation and development of high-pressure polyurethane foam equipment over the past 4 years. On the left is the PENA-VD-01 dispenser, one of the first, which was assembled at the NST plant in Vladimir in September 2021. On the right is the PENA-VD18 UM-K1-39ro/380V installation, manufactured in December 2021.

PENA-VD is made according to the classic layout: a vertical platform, a control panel in the upper part, a motor and gearbox in the center, pumps and flow-through heaters on the flanks.

The standard delivery package for high-pressure foam spraying equipment includes:

- Pumping station PENA-VD18-UM-K1-39 or PENA-VD18-UM-K1-39ro

- A bundle of pressure hoses (from the installation to the sprayer) 20 m consisting of: high-pressure hoses for supplying components “A” and “B”, a polyamide tube for supplying air to the sprayer and a self-regulating heating cable with a maximum heating temperature of 70 degrees C.

- Intake pipes with filtration system.

The VD PPU pistol is purchased separately. We offer a choice of either a Chinese replica of the American Probler (pictured on the left) or Fusion AP from the USA (pictured on the right).

The components are mixed efficiently due to the fact that they enter the sprayer under high pressure, while the volume of the mixing chamber is very small. As a rule, it is no more than 1.5 mm in diameter. Essentially, mixing occurs at the molecular level. With this mixing, the components are guaranteed to react completely. Spraying is carried out only due to high pressure, without the participation of air.

It is convenient to work with such a gun, because... It is easy to control the spraying process: when you press the trigger, spraying of the material immediately begins. If you release the trigger, the spraying instantly stops, and compressed air enters the mixing chamber, which cleans it. And, because The chamber has the simplest geometry (cylinder) and is very small, so it is cleaned efficiently.

To ensure the operation of the sprayer units, compressed air is required at a pressure of 0.4 to 0.8 MPa with a flow rate of 250...350 l/min (at the compressor inlet). These parameters allow you to make up to 30 stops per minute when spraying polyurethane foam.

The following video shows how the PENA-VD18-UMK1-39ro model 2021, equipped with a Chinese Probler pistol, works.

The video shows the work of the company CompositeGidroStroy from Belgorod, director Dmitry Vladimirovich Patutin. The company professionally deals with thermal insulation with polyurethane foam, as well as waterproofing and anti-corrosion protection with polyurea.

The voice-over of Dmitry Vladimirovich Patutin names the PENA-VD20 installation that he owns. With all due respect to our respected NST client, we are forced to note that in fact this is PENA-VD18-UMK1-39ro/380V.

If you need a service for applying polyurethane foam or PM in the Central and Central Black Earth regions of Russia, we recommend CompositeGidroStroy . They work professionally, the prices are reasonable, the quality is high. Contacts Patutina D.V. in the description under the video and in the credits of the video.

The company is based in Belgorod and Moscow. Therefore, for the Belgorod region and Moscow, the minimum volume for a PPU brigade to travel is 100 m2 (this is a really low threshold, considering that a high-pressure apparatus is used for spraying PPU). For other regions - by agreement. Depends on distance, complexity and area.

The following video from Tepla Technologies LLC (Ekaterinburg) shows how the PENA-VD18UM-K1-39ro/380V model 2021, equipped with an American Fusion AP pistol, works.

We recommend Heat Technologies LLC in the Sverdlovsk region for work on insulation with polyurethane foam, waterproofing and anti-corrosion protection with polyurea. The company has been specializing in polyurethane foam since 2012, and since the fall of 2021 it has been using high-pressure NST equipment. Website of Heat Technologies LLC - https://www.ppu-ural.ru .

EQUIPMENT FOR SPRAYING POLYURETHANE FOAM

Century of Polymers LLC offers installations for spraying polyurethane foam - all this is already ready for work.

CATALOG OF EQUIPMENT AND MATERIALS FOR POLYURETHANE FOAM

In Russia there are several dozen equipment manufacturers, plus imported brands are well represented in our country. Therefore there is a problem of choice. What to buy so as not to regret later?

Century of Polymers LLC has accumulated very rich experience in operating machines for applying polyurethane foam. Among us there are those who stood at the origins of the production of domestic devices.

We also remember such models as: Truzioma, Pena-9M, Ya10-FNG, Pena-98N10, Pena-15E, Pena-R21, etc.

We recommend reading on ruppu.ru about the history of equipment for spraying polyurethane foam in the USSR. From this article you will learn that PPU received its “start in life” thanks to the May plenum of the CPSU Central Committee and that for several years the assembly of the PENA-9 device for the entire country was carried out by one research institute from Vladimir.

We know and understand the equipment well because we have been doing spray polyurethane foam insulation for the last 20 years. We tried about a dozen cars, both domestic and imported.

We provide thermal insulation services with polyurethane foam at customer sites, and are ready to perform work in the Moscow region and Siberia. Therefore, we have something to say and show in terms of PU foam spraying equipment.

For those who want to learn how to spray polyurethane foam on their own, Century of Polymers LLC offers equipment, components, and related consumables (solvents, lubricants, glue, primers, etc.).

We do not manufacture polyurethane foam spraying machines. But we are ready to consult, advise and supply equipment that we operate ourselves. We are ready to bear warranty obligations without worrying about the company’s reputation.

The price will be the same as that of the manufacturer or distributor (if we are talking about imported units). It’s up to you to decide where to get it: directly from the factory or from us. We will tell you about the pros and cons of each model before purchasing, because... We ourselves have worked before or are currently working on such equipment.

After communicating with us, of course, call the manufacturer. Probably, you should choose someone who knows the product better and who will help with operation after purchase.

We know firsthand and not in theory. We are practitioners. We have been operating such installations ourselves for many years. We studied them inside and out. We took them apart and put them back together many times. Therefore, we will help.

And, by the way, we have one more interest, so that everything works fine for you. We also specialize in the supply of polyurethane chemicals and are interested in our customers constantly purchasing high-quality and proven PPU spraying components from us.

Select an installation for spraying polyurethane foam

The operating principle of polyurethane foam spraying equipment is as follows:

- pick up components from barrels;

- heat them to the recommended temperature;

- dose the polyol and isocyanate in the required ratio;

- feed the components under pressure into the pressure hoses;

- inject “A” and “B” into the mixing chamber of the sprayer;

- remove the PPU composition from the sprayer by spraying it onto the enclosing structure.

Without going into details, all installations work according to the above algorithm. But, as you know, The devil is in the detail. Let's talk about these details.

Let's start with how important it is to mix both ingredients completely and well. Then the reaction occurs 100% and the polyurethane foam is obtained with the declared characteristics and will serve for a long time.

If there is an imbalance (as the “sprayers” say) in the weight or volume ratio (regulated by the manufacturer in the specifications) of the components, then there is no need to talk about the quality of the foam.

If component A (polyol, in Russian terminology) is more than it should be, then, for example, hard closed-cell polyurethane foam turns out to be soft, short-lived and may have the smell of unreacted catalysts, the material loses volume, has poor (high) thermal conductivity and increased moisture absorption.

In the case of an excess of component B (isocyanate in Russian terminology), the foam turns out to be denser and more fragile, with a clearly noticeable smell of isocyanate. In terms of thermal conductivity and moisture absorption, foam plastic also does not meet standard values.

To mix and spray polyurethane foam components, low and high pressure equipment is used in conjunction with a set of auxiliary equipment: generators, compressors, compressed air dryers, liquid heaters, barrel pumps, etc.

Low pressure polyurethane foam spraying equipment

The operating pressure of a low-pressure installation for spraying polyurethane foam is 1…1.2 MPa or 9.87…11.84 Atm.

Compressed air is required to mix the components in the sprayer and clean the mixer.

The equipment is not energy-intensive, most popular models are 220V, power consumption is 0.75...0.9 kW. It also requires 3 to 5kW for the compressor. When connecting additional options that optimize the operation of the equipment, energy consumption increases. In particular:

- barrel pumps for pumping components into the installation;

- air dehumidification;

- air heating;

- heating of components, from milk cans or other containers with heaters or thermal belts to flow-through heaters.

If the above add-ons are installed. options, then until the components are mixed in the gun, the chronology of the processes is identical to the high pressure installation (see below).

To be fair, we note that manufacturers and supporters of high-pressure equipment will deny such an identity. They dispute the very fact that low-pressure pumps are capable of constantly, smoothly and evenly supplying liquid to the sprayer, strictly maintaining the ratio.

In our opinion, they are capable if a pair of pumps was initially tested at the stand and correctly selected at the factory, if the pumps are in working order and not worn out. It is important that the assembly is carried out at the factory, and not in the makeshift conditions of a garage cooperative. It is important that the equipment is accepted by the quality control department, even if it is not as demanding as military acceptance.

It matters what raw materials are used and at what temperature. The length of the hoses and the lifting height of the components matter. However, our experience says that, yes, there are limitations, but if you know them, then there are no problems with supplying components to the sprayer on a low-pressure installation.

The operating pressure of the components in the sprayer is approximately 2 times less than the pressure in the supply hoses, i.e., on average, about 0.5...0.7 MPa. This is approximately 20 times less than in the mixing chamber of high-pressure units.

The components in the chamber are broken down and mixed by a stream of compressed air entering the sprayer from the compressor. Then, using the same air, the mixed components are delivered from the mixing chamber through the nozzle and spray nozzle of the gun to the insulated surface. There the final polymerization (foaming) occurs and the transformation of the two liquids into the final product, i.e. in PPU.

Also, the presence of compressed air at the outlet of the sprayer leads to the formation of a PU foam suspension. In other words, some of the material does not appear on the surface. As a result, work on a low pressure installation is more “dirty” than on a high pressure one. For low-pressure equipment, irrecoverable losses (ricochet, drift, undershoot) should be 5%.

All low-pressure foam spraying units are manufactured in Russia. In the West, only high-pressure equipment is used. The price range for the minimum (basic) set is from 120,000 rubles. up to 250,000 rub.

Here we take into account only actually working, mass-produced models in factories. If we take into account “garage self-propelled guns”, then the starting price will be about 35...40 thousand rubles.

In skillful hands, if the components are correctly selected, if heating of raw materials, drying and heating of air is ensured, and the supply of compressed air is adjusted, then in a low-pressure installation, the quality of PPU foam is difficult to distinguish from polystyrene foam produced at high pressure. At the same time, of course, the process of spraying at low pressure is much more complicated, longer and more labor-intensive.

Manufacturers of high pressure installations

| Name | The lineup | Price range* |

| "Graco" ("Grako"), USA | Reactor Series | from 12,600 USD |

| "Garraf Maquinaria, SA" ("Gama"), Spain | Easy Spray Series, Evolution Series | from 11,400 EURO |

| Tec Mac, Italy | Isoltec Series | from 7,500 EURO |

| Wilhelm Wagner GmbH & Co WiWa, Germany | Duomix Series | from 12,000 EURO |

| Ningbo Dino-Power Machinery Co, LTD, China | DP Series | from 7,000 USD |

| Energo LLC, Russia | PROton Evolution Series | from 255,000 rub. |

*cost of basic installations without options at the time of writing.

High pressure installations for spraying polyurethane foam

The operating pressure of the high-pressure installation for spraying polyurethane foam is 10…12 MPa or 98.69…118.43 Atm.

The equipment is energy-intensive, requiring 10...35 kW to operate the installation itself, the heating system and the compressor.

Compressed air is not used to mix the components. Airless spraying of polyurethane foam. Compressed air is required to operate barrel pumps (if provided by the manufacturer for this model of PPU equipment) and to clean the mixing chamber of the sprayer.

Drum pumps (not plant pumps) take components from containers (usually 200L drums) and deliver liquids to the heating block. Liquids heated to the required temperature are supplied to the pumps of the installation, and the excess is returned through the recirculation system back to the barrels. The dosage of components on HP equipment is only 1 to 1.

The pumps increase the pressure of the liquids in the hoses to the parameters specified in the settings and subsequently maintain it throughout the entire spraying process. The polyol and isocyanate are fed into the atomizer under high pressure.

Pipelines are usually combined into a common hose with a heating system. This heated sleeve is heavy and rigid. Therefore, the last 3 meters, just before the sprayer, are removed from the hose to provide the operator with greater mobility, mobility and convenience.

For some models of high-pressure equipment, pipelines can be extended up to 93 m and applied from bottom to top over most of the length of the hose (attention, large mass!). In this case, there will be no problems with supply to the sprayer, nor problems with mixing in the mixer.

High-quality mixing is ensured due to the fact that liquids injected into the mixing chamber are transformed into a finely dispersed phase, almost into a fog. And then there is a mixing of, in fact, not two liquids, but two “foggy” flows on opposite courses.

High pressure guarantees mixing quality, accordingly:

- smooth and even layer on the surface;

- low thermal conductivity coefficient;

- minimal losses due to overconsolidation and rebound, i.e. if the declared density [free foam, factory, theoretical] of the foam is 30 kg/m3, then the actual density will be 35 kg/m3;

- ease of operation for the operator, who can stop repeatedly and at any time and then continue spraying PU foam.

The equipment requires competent and careful maintenance. The minimum cost of imported, “simple” equipment (only the main set) is about 700,000 rubles.

Such equipment requires: barrel pumps, recirculation system, compressor, generator, stabilizer, air dryer. Heated components and hoses are already included.

We can say that troubles with high-pressure foam spraying equipment begin when repairs are required, because branded [expensive] spare parts are required. In addition to repairs, routine maintenance also takes place, when only “original” components should be used.

Moreover, replacement is required many times more often than desired, and there are also many nodes where replacement is necessary. You should be prepared for this, because... You have to pay for the pleasure of working on high-pressure foam spraying equipment.

Operating principle of high pressure units

Devices for spraying high-pressure polyurethane foam are installations in which raw materials are mixed in the chamber of a spray gun at a pressure of over 100 atmospheres. The components are mixed due to mutual diffusion of flows under pressure. Compressed air is used to clean the nozzle of the spray gun. The pressure is created by driven plunger pumps, or less commonly by gear pumps. The intensity of supply of the mixture to the spraying device is adjustable. Raw materials are supplied directly from containers provided by the manufacturer (216 l barrels) or through built-in consumable containers. Installations with pressures above 160 atmospheres are used to produce polyurea and polyurethane coatings.

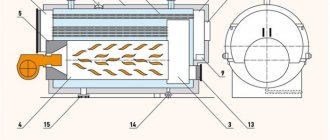

Schematic diagram of a high pressure installation for spraying polyurethane foam

The main components are two pumps, a drive, a spray gun with a mixing chamber, a control unit, a set of hoses and a compressor (purchased separately).

Additionally:

- high-precision dosing pumps. The use of piston pumps that supply components due to vacuum achieves high dosing accuracy compared to gear pumps;

- reliable and efficient drive. There are installations with three types of drive – electric drive, hydraulic drive and pneumatic drive.

- high pressure hoses with heated braiding and temperature sensors to maintain component temperature and viscosity;

- clear and reliable electronic control unit based on the controller;

- a correctly selected compressor with an air preparation unit.

You will find a comparison of the advantages and disadvantages of low and high pressure installations in the article “Equipment for spraying high and low pressure polyurethane foam - what is the difference?”

Installations for spraying polyurethane foam and polyurea

Speaking about high-pressure installations, it should be noted that some of them allow you to apply not only polyurethane foam for thermal insulation, but also polyurea for waterproofing.

Polyurea is excellent for treating concrete and metal surfaces, forming a durable, wear-resistant coating that is UV resistant. It is used not only for roofing and foundations, but also for floor coverings, as a finishing layer. You can walk on the polyurea coating, transport loads, etc., the material is really durable.

Century of Polymers LLC also offers liquid rubber for waterproofing. This is a completely different material that has nothing in common with polyurea.

It is impossible to say for sure which is better, polyurea or liquid rubber. This way of asking the question is incorrect. They differ in properties, characteristics, and installation technology, but both serve to form a seamless waterproof fabric. For some tasks it is correct to use liquid rubber, and for others - polyurea.

In a special article on our website we will analyze in detail the differences, pros and cons, and compare liquid rubber and polyurea. For now, just be aware that some (not all!) high pressure units spray polyurethane foam and polyurea.

Installation for spraying polyurethane foam and polyurea - choose what you need

This section of the catalog presents a number of models of such equipment. They differ in their technical characteristics and design. Of particular importance is the method of obtaining the mixture:

- Airless, using high pressure. It is pumped by special pumps that provide more than 100 atmospheres. The components are mixed in a gun, spraying due to pressure. Most foreign installations for spraying polyurethane foam .

- Air, low pressure. Compressed air is used here to mix materials in a special chamber. Due to it, the resulting polymer is also applied to the surface to be coated. This method is used in the PROton mini device, produced by the Energo Group of Companies.

- Combined, combines the two previous methods of obtaining a mixture. Preliminary formation of an aerosol of each material occurs under the influence of high pressure. The resulting suspensions are combined in a chamber, mixed with compressed air and sprayed in the form of an aerosol torch. The PROton Air device functions in a similar way.

There are several technological solutions - you can choose and buy the one that is most suitable for you.